Factory Shop Manual For Komatsu Wheel Excavator. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 848

Number: UEBM001901 (issued 2003)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Komatsu Wheel Excavator

PW200-7K

SN K40001 And Up

PW220-7K

SN K40001 And Up

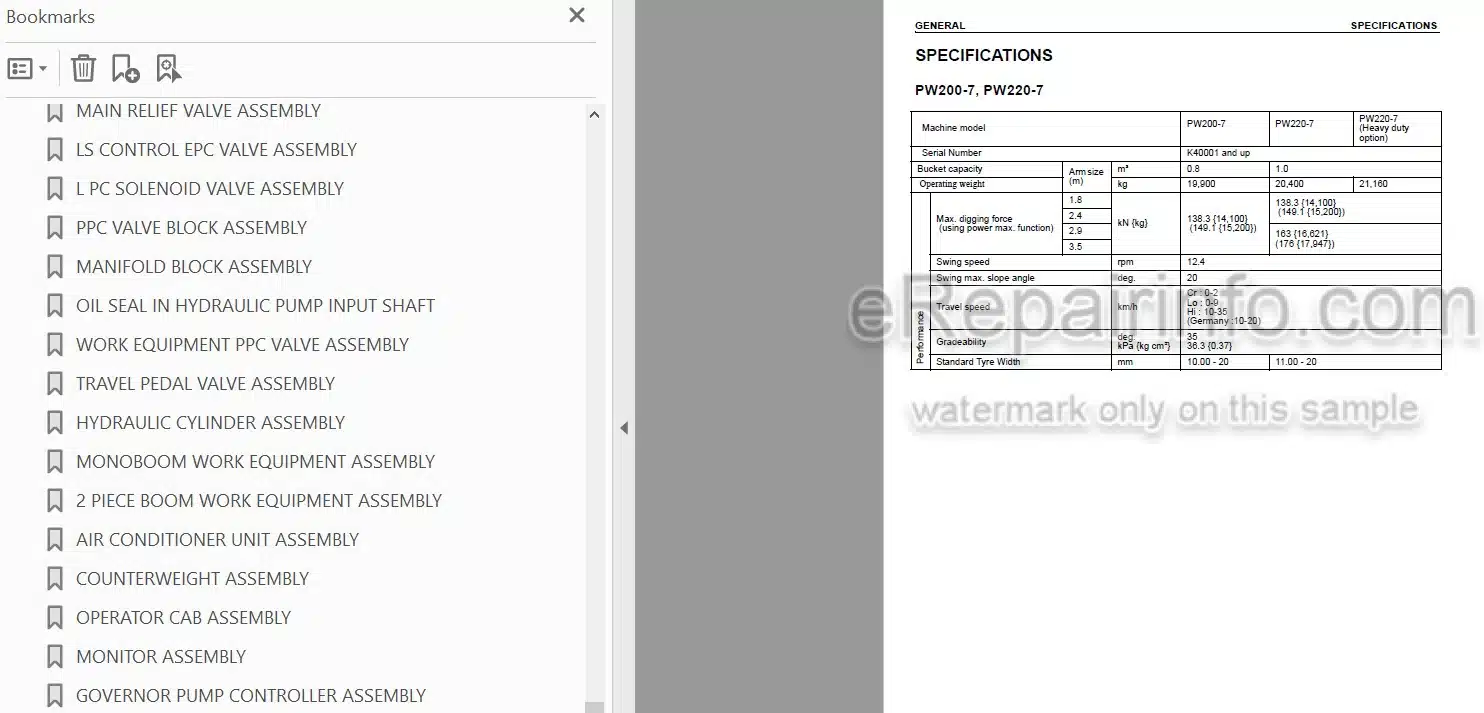

Contents

FOREWORD

-GENERAL

Dimensions

Working Ranges

Specification Dimension Drawings

Dimensions

Specifications

Weight Table

Fuel, Coolant And Lubricants

-STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

Engine Related Parts

Radiator – Oil Cooler – Charge Air Cooler

Powertrain

Swing Circle

Swing Machinery & Motor

Swing Motor

Undercarriage

Transmission

Travel Motor

Clutch Control Circuit

Axle

Suspension Lock Cylinder

Braking System

Brake/Steer Pump

Priority Valve

Power Brake Valve

Accumulator For Brake System

Steering Train

Steering Column

Orbitrol Valve

Hydraulic Equipment Layout Drawings

Hydraulic Circuit Diagram

Hydraulic Tank

Hydraulic Pump

Pilot Pressure Control (PPC) System

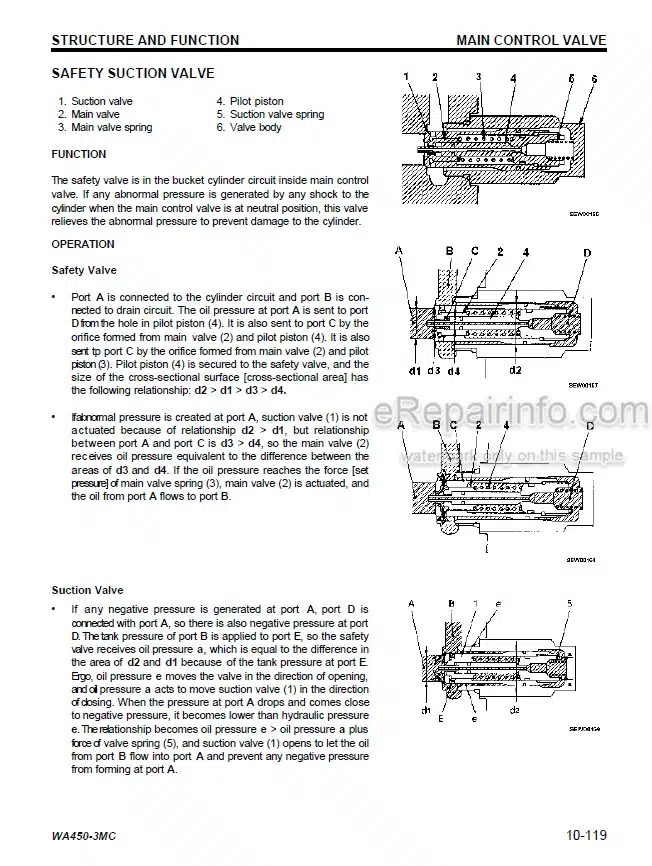

Control Valve

CLSS

Centre Swivel Joint

Travel PPC Pedal

Work Equipment – Swing PPC Valve

Service PPC Valve

Solenoid Valve

Travel-Boom-Stabilizer Solenoid Valve

Boom Safety Valve

Hydraulic Cylinder

Outrigger Cylinder

Dozer Cylinder

Work Equipment

Air Conditioner

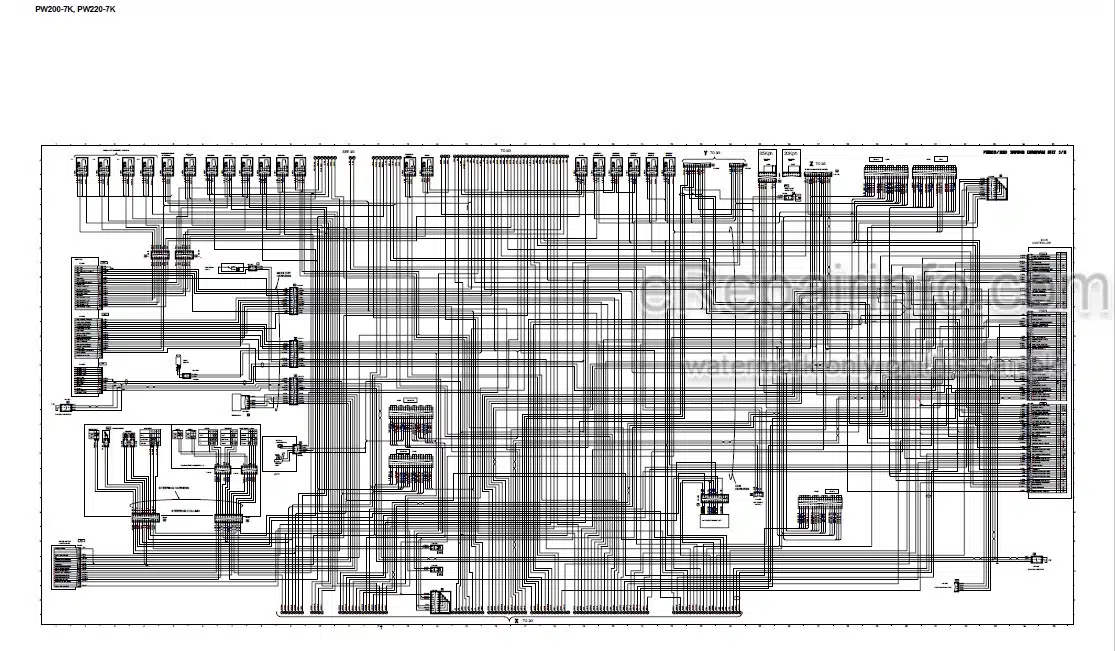

Electrical Wiring Diagram

Engine Control System

Electronic Control System

Machine Monitor System

Overload Warning Device

Sensor

1St Attachment Circuit Hydraulic Performance (Main Valve Bypassed)

1St Attachment Circuit Hydraulic Performance (Via Main Valve)

Travel System

Steering System

Service Brake And Suspension System

-TESTING AND ADJUSTING

Inspection And Adjustment Of Engine Rpm

Measurement Of Exhaust Gas Color

Adjustment Of Valve Clearance

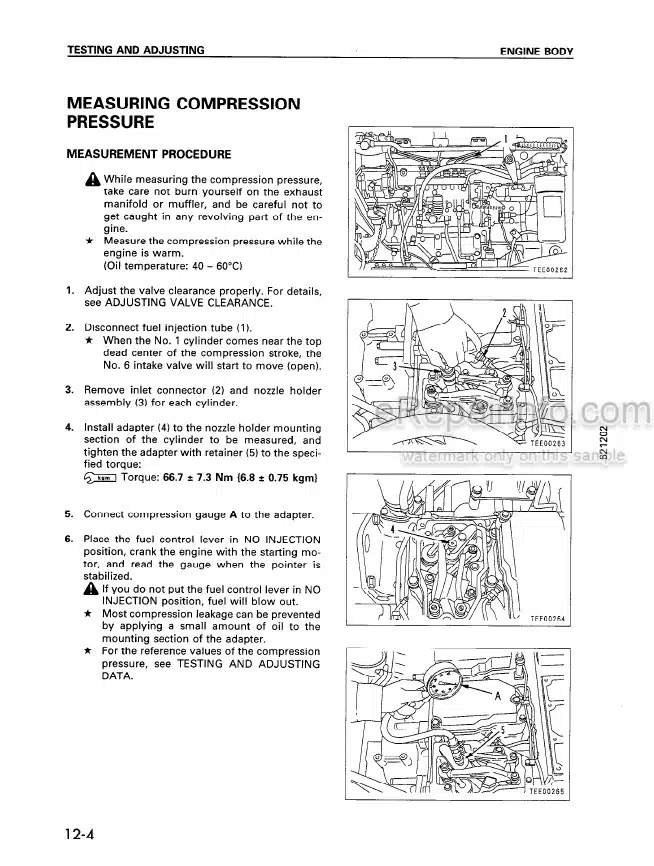

3Measurement Of Compression Pressure

Measurement Of Blow-By Pressure

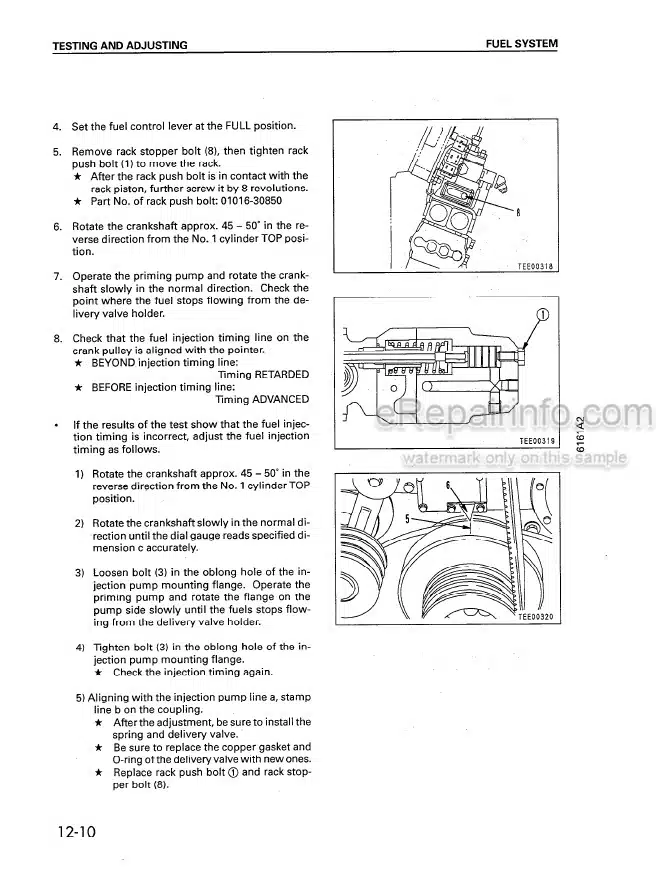

Inspection And Adjustment Of Fuel Injection Timing

Measurement Of Engine Oil Pressure

Emergency Setting If Failure Occurs In Engine Control System

Measurement Of Clearance In Swing Circle Bearings

Inspection And Adjustment Of Hydraulic Oil Pressure In Hydraulic Circuit For Work Equipment, Swing

Inspection And Adjustment Of Control Circuit Oil Pressure

Inspection And Adjustment Of Pump PC (Valve Inlet) Control Oil Pressure(Pw200/220)

Inspection And Adjustment Of Pump LS Valve Control Oil Pressure(Pw200/220)

Measurement Of Solenoid Valve Output Pressure

Measurement Of PPC Valve Output Pressure

Adjustment Of Work Equipment And Swing PPC Valve

Testing Travel Motor Relief Pressure

Adjusting Travel Motor Relief Pressure

Testing Propshaft Speed

Testing Transmission Clutch Control Circuit

Inspection Of Locations Of Hydraulic Drift Of Work Equipment

Measurement Of Oil Leakage Amount

Air Bleeding Of Various Parts

Inspection Procedures For Diode

Special Function Of Monitor Panel

Preparations For Troubleshooting Electrical System

Troubleshooting

Troubleshooting When Service Code “Electrical System” And Failure Code “Mechanical System” Are Indicated

Troubleshooting Of Hydraulic And Mechanical System (H-Mode)

Troubleshooting Of Electrical System

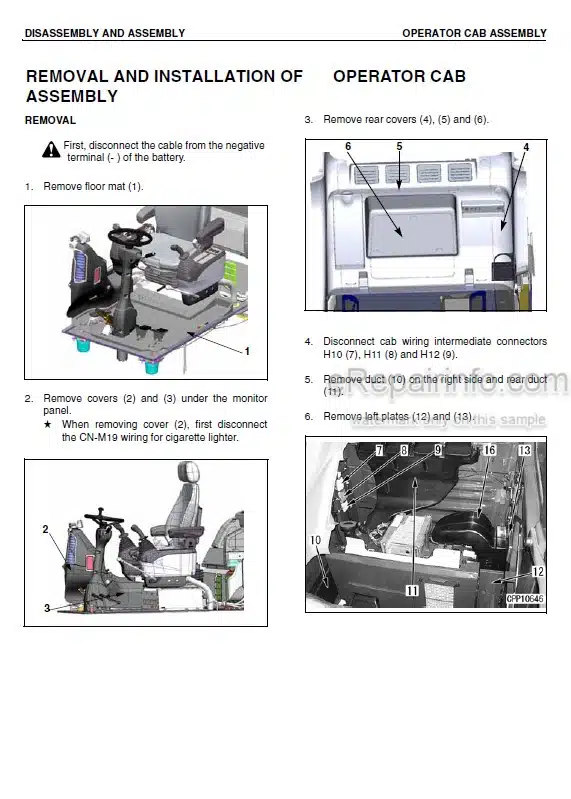

-DISASSEMBLY AND ASSEMBLY

Special Tools

Precautions When Performing Operation

Governor Motor Assembly

Starting Motor Assembly

Fuel Injection Pump Assembly

Engine Front Seal

Engine Rear Seal

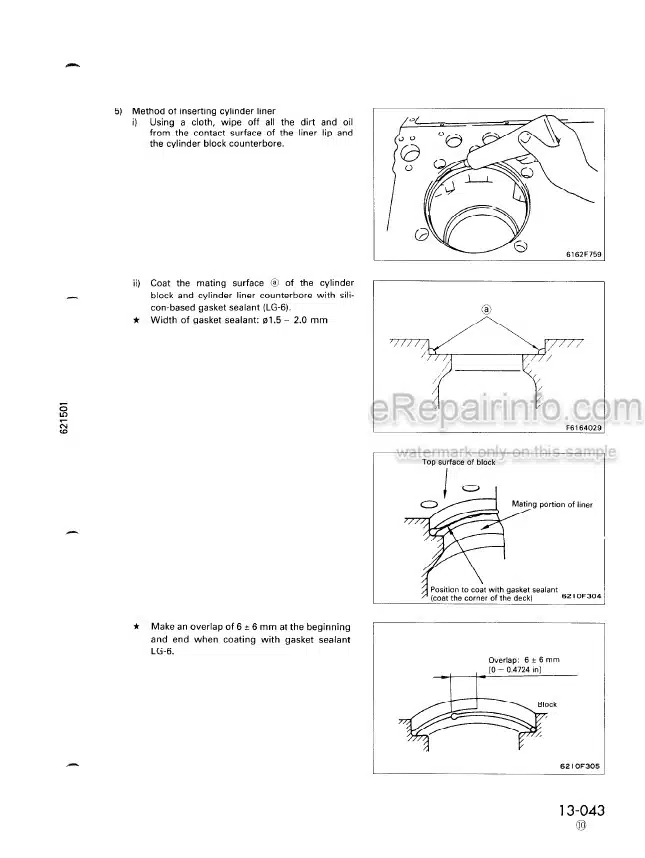

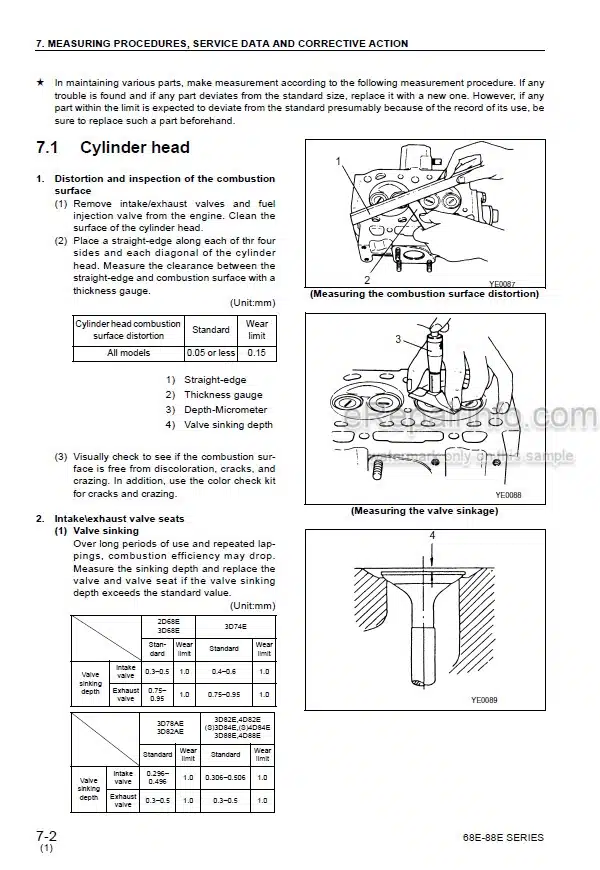

Cylinder Head Assembly

Combination Cooler

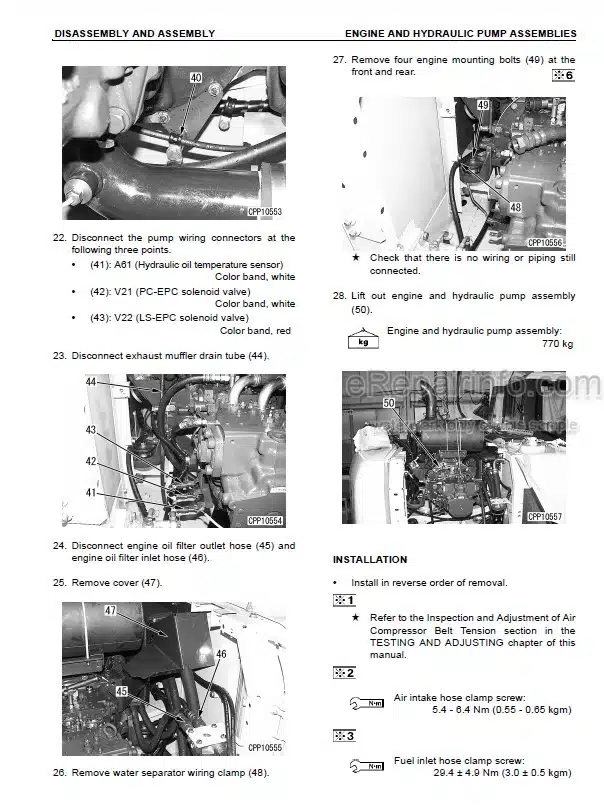

Engine And Hydraulic Pump Assemblies

Transmission And Travel Motor Assembly

Transmission Assembly

Travel Motor Assembly

Swing Motor And Swing Machinery Assembly

Front Axle Assembly

Rear Axle Assembly

Propshaft Assembly

Wheel Assembly

Suspension Lock Cylinder Assembly

Suspension Lock Assembly

Outrigger Assembly

Dozer Blade Assembly

Swing Circle

Assembly

Revolving Frame Assembly

Centre Swivel Joint Assembly

Hydraulic Tank Assembly

Fuel Tank Assembly

Control Valve Assembly

LS Select Valve Assembly

LS Shuttle Valve Assembly

Pressure Compensation Valve Assembly

Main Relief Valve Assembly

LS Control EPC Valve Assembly

LPC Solenoid Valve Assembly

PPC Valve Block Assembly

Manifold Block Assembly

Oil Seal In Hydraulic Pump Input Shaft

Work Equipment PPC Valve Assembly

Travel Pedal Valve Assembly

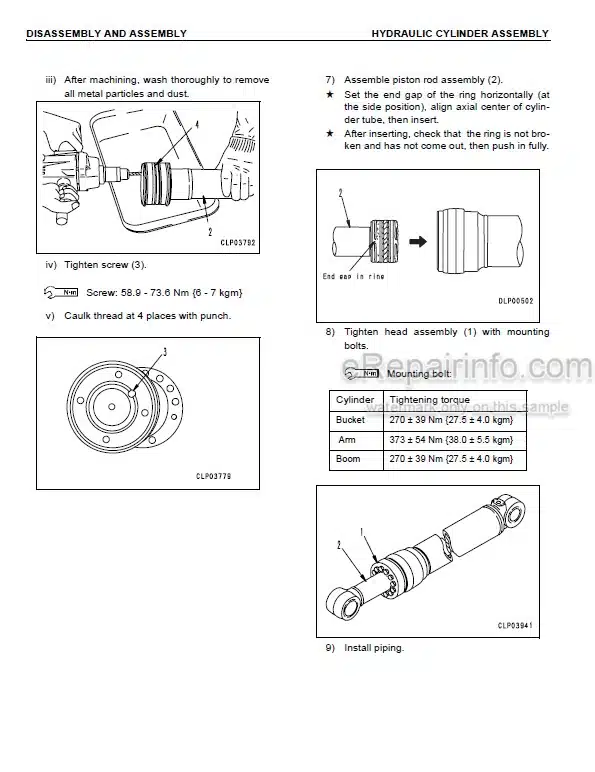

Hydraulic Cylinder Assembly

Monoboom Work Equipment Assembly

2 Piece Boom Work Equipment Assembly

Air Conditioner Unit Assembly

Counterweight Assembly

Operator Cab Assembly

Monitor Assembly

Governor Pump Controller Assembly

-OTHERS

Hydraulic Circuit Diagram

Electrical Circuit Diagram

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet