Factory Technical Manual For John Deere Loader. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 247

Issued: august 1997

Hydraulic Diagrams: Yes

Model

John Deere Cameco Loader

SP1800B

Contents

-SAFETY

Safety And You

Operation Safety

Service Safety

Safety In Your Service Area

Safety When Cleaning Or Storing

Safety Nevers

Recognizing Safety Information

Understanding Signal Words

Follow Safety Instructions

Protect Bystanders

Use Hand Holds And Steps

Prevent Machine Runaway

Avoid Exhaust Fumes

Keep Riders Off Machine

Handle Fuel Safely-Avoid Fires

Safely Service Accumulators

Safely Service Cooling System

Prepare For Emergencies

Wear Protective Clothing

Use Safety Lights And Devices

Use Cylinder Safety Stops

Practice Safe Maintenance

Avoid High Pressure Fluids

Use Caution On Hillsides

Stopping And Parking

Service Tires Safely

Fire Prevention

-SPECIFICATIONS

Engine And Drivetrain

Hydraulic Pumps

Hydrostatic Transmission

General Hydraulics

Pressure Settings

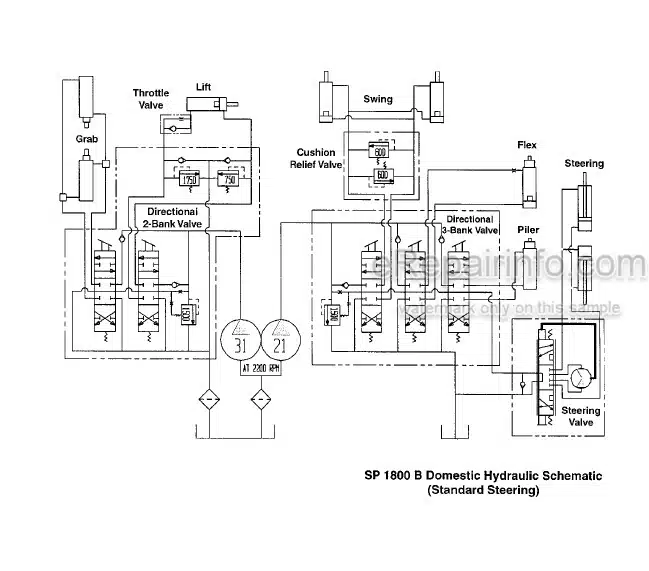

Hydraulic Schematic (Grab & Lift)

Hydraulic Schematic (Steer, Swing, Flex)

-CAPACITIES

Engine

Radiator

Transmission

Rear Steering Axle

Front Rigid Axle

Brake Fluid

Hydraulic Tank

Diesel Fuel

Torques (Dry)

Tire Inflation Pressure

Pump Drive

-TORQUE SPECIFICATIONS

SAE Bolt And Nuts

SI (Metric) Bolts And Nuts

Conversion Tables

-GENERAL INFORMATION

Introduction

Diagnostic Section

Troubleshooting Tools

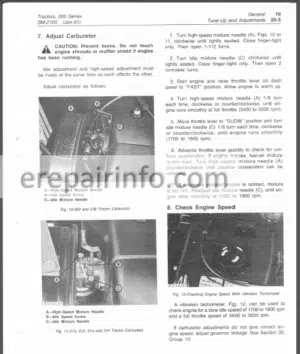

Troubleshooting

Visually Inspect Hydraulic System

Hydraulic System Testing Precautions

Visually Inspect Electrical System

Electrical System Testing Precautions

Service Supplies

Service Tools

Hydraulic Symbols

Miscellaneous Symbols

Methods Of Operation

Electrical Symbols

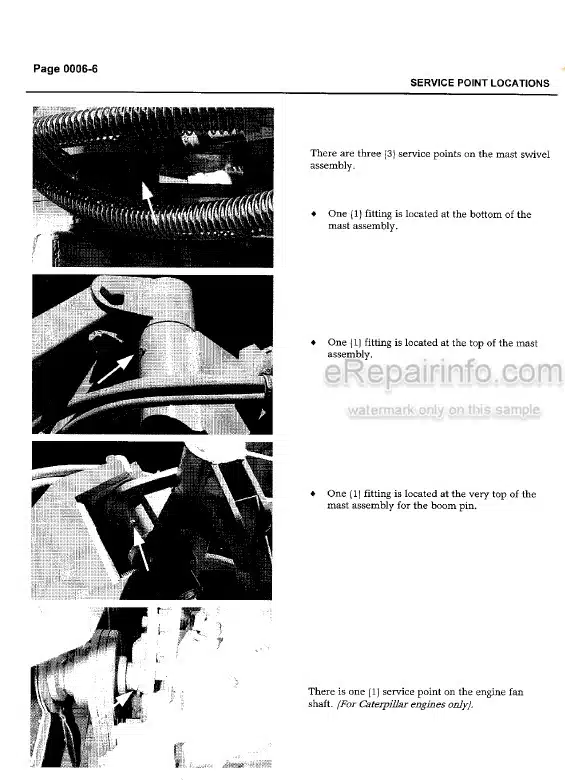

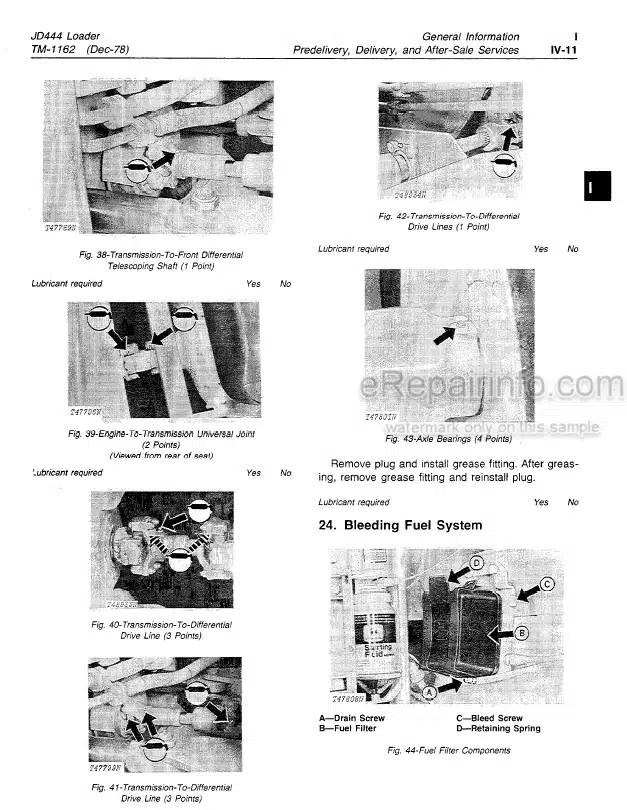

-SERVICE POINTS

Initial Start Up

First 50 Hours Of Operation

Every 10 Hours Of Operation (Daily)

Every 70 Hours Of Operation

140 Hours – 2 Weeks Of Operation

250 Hours – Monthly Operation

500 Hours – 2 Months Of Operation

1000 Hours – 4 Months Of Operation

As Necessary

-HYDROSTATIC SYSTEM

The System Circuit

Theory Of Operation

Initial Start Up Procedure

Fluid And Filter Maintenance

Troubleshooting

Hydrostatic Pump

Minor Repair

Major Repair

Neutral Start/Run Solenoid Valve

Front Axle Motor-Fixed

-MAIN HYDRAULIC SYSTEM

Contamination Control

Hydraulic Oil

Troubleshooting

Diagnosis Of Hyd. System Malfunctions

Diagnosis Of Hyd. Components

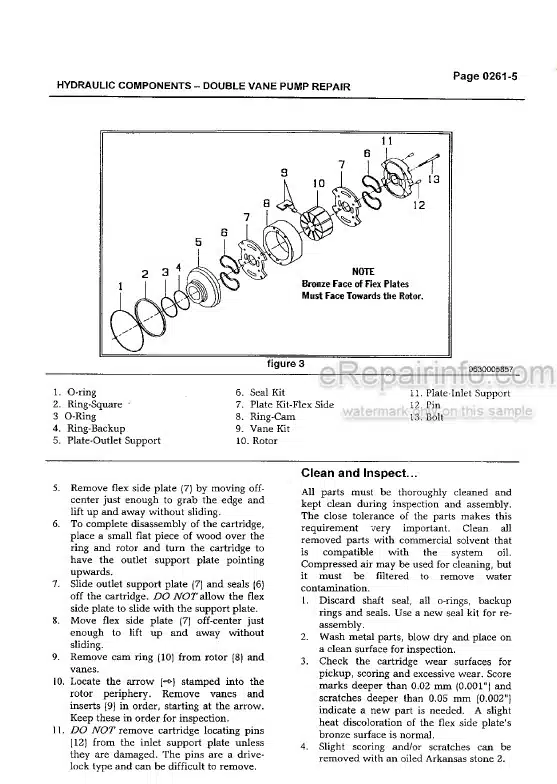

Double Vane Pump

Directional Control Valve

Hydraulic Cylinder Repair

Relief Valve

-STEERING SYSTEM

Priority Valve

Steering Valve

-TRANSMISSION

Drawing

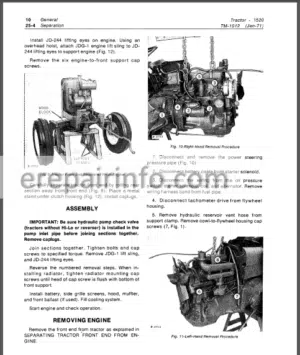

Disassembly

Shifter Assy

Output Shaft

Third Stage Shaft Removal

Remove Input Shaft

Second Stage Shaft

Clean and Inspect

Assembly

Output Shaft

Install Second Stage Shaft

Install Input Shaft

Third Stage Shaft

Shifter Assy Installation

Install Transmission on Loader

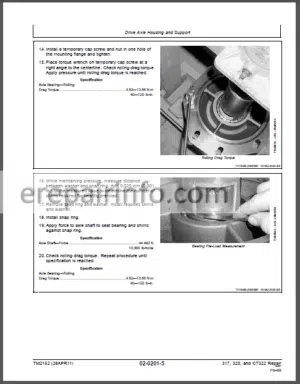

-AXLE REPAIR

Front Rigid Axle

Rear Steering Axle

-ELECTRICAL SYSTEM

Visually Inspect Electrical System

Safety Precautions

Specifications

Theory Of Operation

Cleaning Battery Post

Jumping The Battery

Charging The Battery

Precautions For Alternator

Inspection

Common Circuits

Operational Checks

Electrical Malfunctions

Oil Pressure Sender

Oil Pressure Switch

Engine Coolant Temp Gauge Sender

Engine Coolant Temp Switch

Hydraulic Oil Temperature Sender

Fuel Sending Unit

Hydraulic Filter Pressure Switch

Air Filter Restriction Switch

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet