Factory Workshop Manual For Liebherr Diesel Engine. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Quantity of Manuals: 2

Pages: 176; 664

Number: TM2224 (march 2002); TM1831 (september 1995)

Searchable: Yes

Model

Liebherr Diesel Engine

D9306

D9308

D9406

D9408

Contents

-TECHNICAL DATA

Engine Data

Fuel Injection System

Cylinder Assembly

Crank And Camshaft Drive

Lubrication System

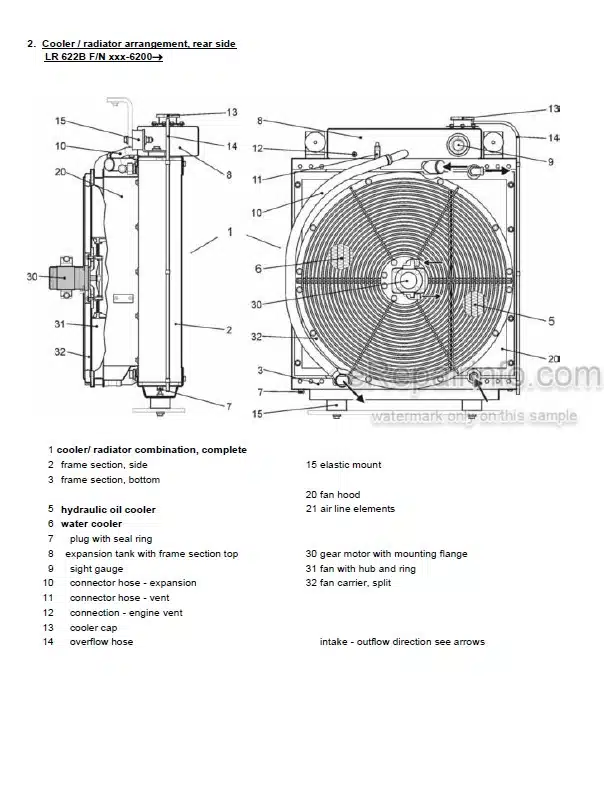

Cooling System

Torques

Cylinder Identification, Engine Number, Crankcase Number, Connecting Rod Number, Engine Identification Plate And Engine Identification

-INSPECTIONS, CHECKS AND ADJUSTMENTS

Inspection

Dry Air Cleaner

Service Fluids

Sealing And Locking Compounds, Greases

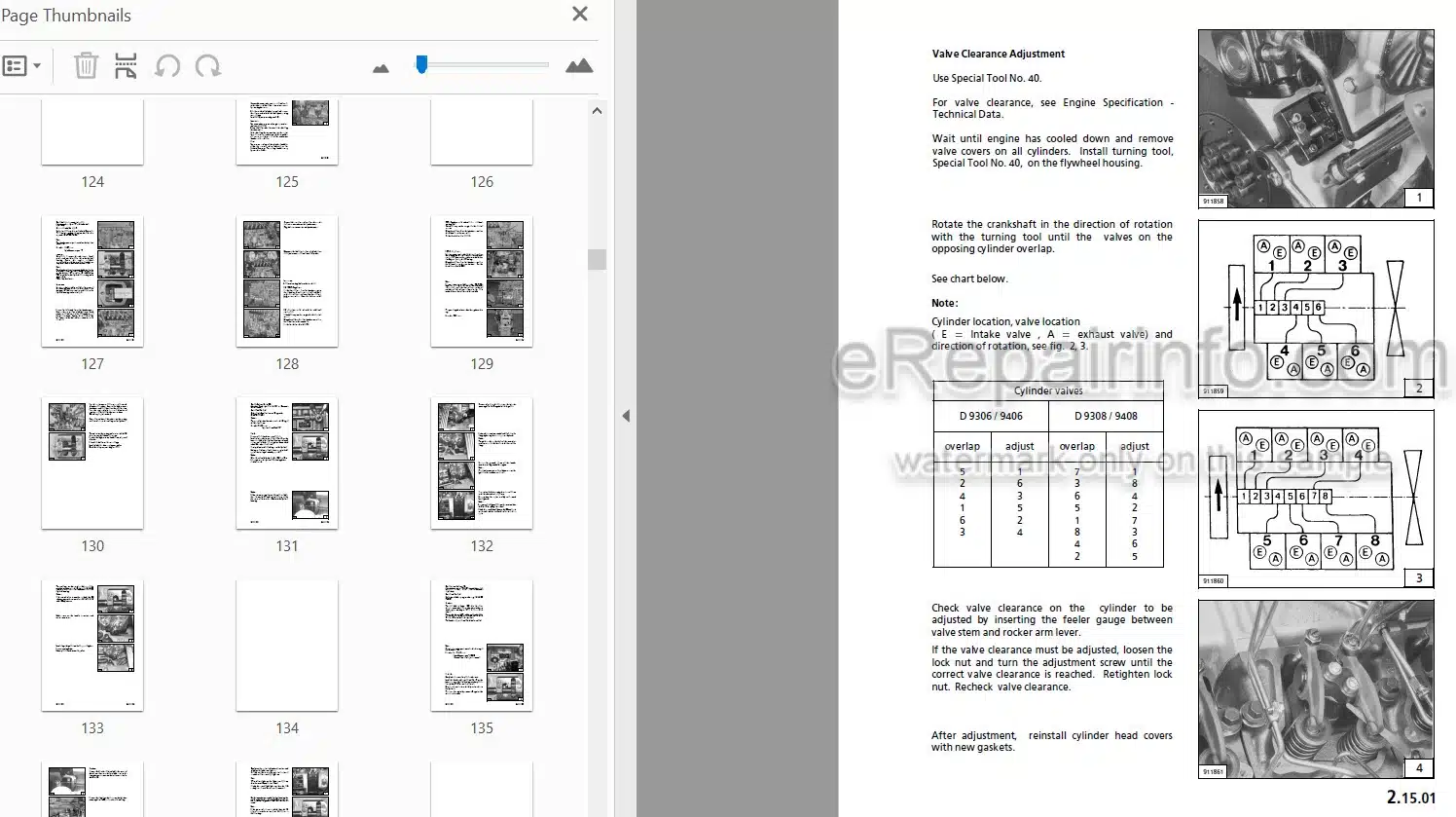

Valve Clearance Adjustment

Engine Compression Check

Timing Check And Adjustment

Fuel Injector Check And Adjustment Injector Nozzle Removal And Installation

Preheater Assembly Check, Removal And Installation

Piston Clearance Check

Alternator V-Belt, Check, Adjustment / Replacement

Fan Drive V-Belt Check, Adjustment / Replacement Fan Drive Lubrication

Fan Drive V-Belt Check, Adjustment / Replacement

V-Belt Tension For Air Conditioning, Compressor And Generator Replace

Thermostat Removal, Installation And Testing

Oil Pressure Relief Valve, Adjustment Removal And Installation

Oil Separator, Check, Removal And Installation

Troubleshooting

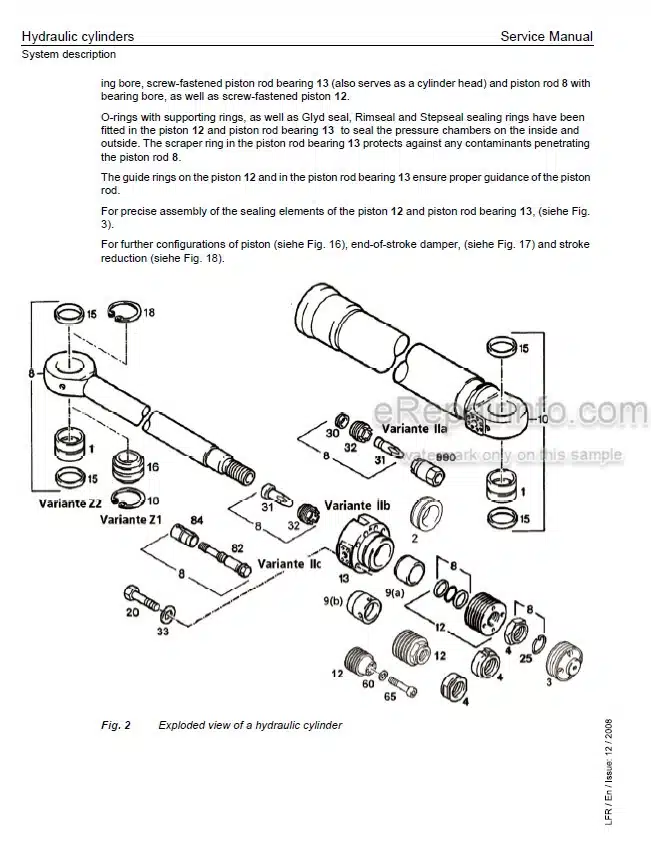

-CYLINDER ASSEMBLY

Cylinder Head Removal And Installation

Cylinder Head Disassembly And Assembly

Valves, Valve Seat Valve Guide And Valve Spring Inspection

Rocker Lever Support Rocker Level, Push Rod And Tappet Inspection

Cylinder Head Repair (Valve Seats, Valve Guides)

Piston Removal And Installation, Inspection

Cylinder Liner Removal And Installation, Inspection

Connecting Rod Inspection

-CRANKCASE, CRANKSHAFT, CAMSHAFT INSPECTION AND BEARING REPLACEMENT

Crankcase, Main Bearing And Thrust Bearing Inspection

Crankshaft Inspection And Grinding

Camshaft And Camshaft Bearing Inspection

Camshaft Bearing Replacement

-COMPONENTS – FRONT SECTION

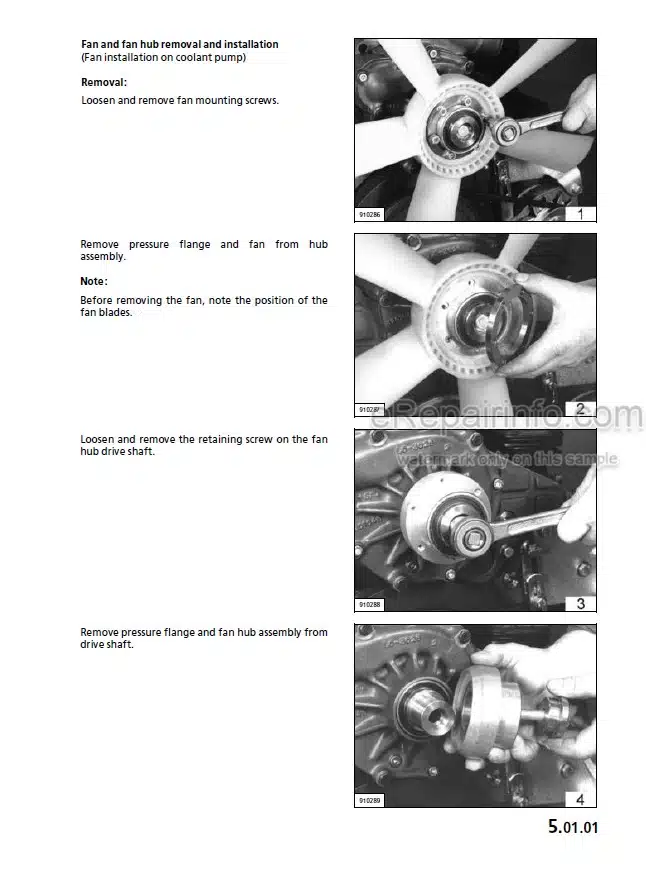

Fan Removal And Installation

Fan Drive Removal And Installation

Fan Drive Removal And Installation (Belt Drive)

Fan Drive Removal And Installation (Belt Drive)

Fan Drive With Fan Coupling / Removal And Installation

Fan Drive Disassembly, Inspection And Assembly

Fan Drive Disassembly, Inspection And Assembly (Belt Drive)

Fan Drive Disassembly, Inspection And Assembly (Belt Drive)

Fan Drive With Fan Coupling / Disassembly, Inspection And Assembly

Coolant Temperature Sending Unit Replacement

Coolant Pump Removal And Installation

Coolant Pump Removal And Installation, With Collar Bearings

Coolant Pump Disassembly And Assembly Up To Engine S/N 9712 02 99

Coolant Pump Disassembly And Assembly From Engine S/N 97 12 0300

Coolant Pump Disassembly And Assembly, With Collar Bearings

V-Belt Pulley And Vibration Damper Removal And Installation

Fan Side Crankshaft Seal Replacement

-COMPONENTS – FLYWHEEL SECTION

Flywheel Removal And Installation

Flywheel Ring Gear Replacement

Replacement Of Crankshaft Seal Running Surface On Flywheel

Flywheel Side Crankshaft Seal Replacement

Mechanical Tachometer Drive Removal, Repair And Installation

-FUEL INJECTION SYSTEM

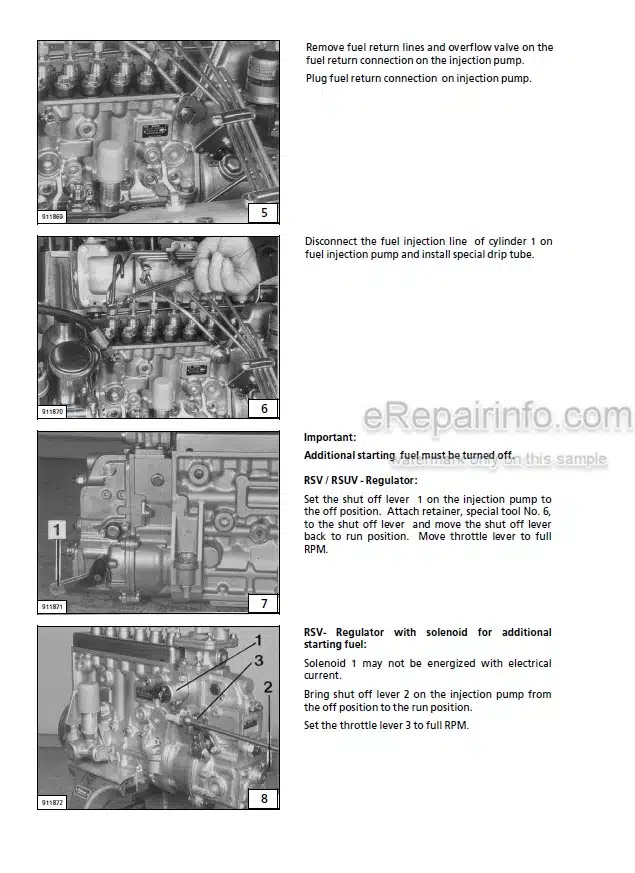

Remove And Install Injection Pump, Injection Pump Type”P” With Mechanical Regulators Installed On Injection Pump Drive

Remove And Install Injection Pump, Injection Pump Type MP” With”EDC” (Electronic Regulation) Installed On Injection Pump Drive

Remove And Install Injection Pump, Injection Pump Type “P” With Mechanical Regulators Installed On Injection Pump Drive

Remove And Install Injection Pump, Injection Pump Type”P” With”EDC” (Electronic Regulation) Installed On Injection Pump Drive,

Remove And Install Injection Pump, Injection Pump Type “H-Rp43” (Control Sleeve Fuel Injection Pump) With “EDC” (Electronic Regulation) Installed On Injection Pump Drive

Injection Pump Drive Removal And Installation (Without Injection Timing Device)

Injection Pump Drive Disassembly, Check And Assembly (Without Injection Timing Device)

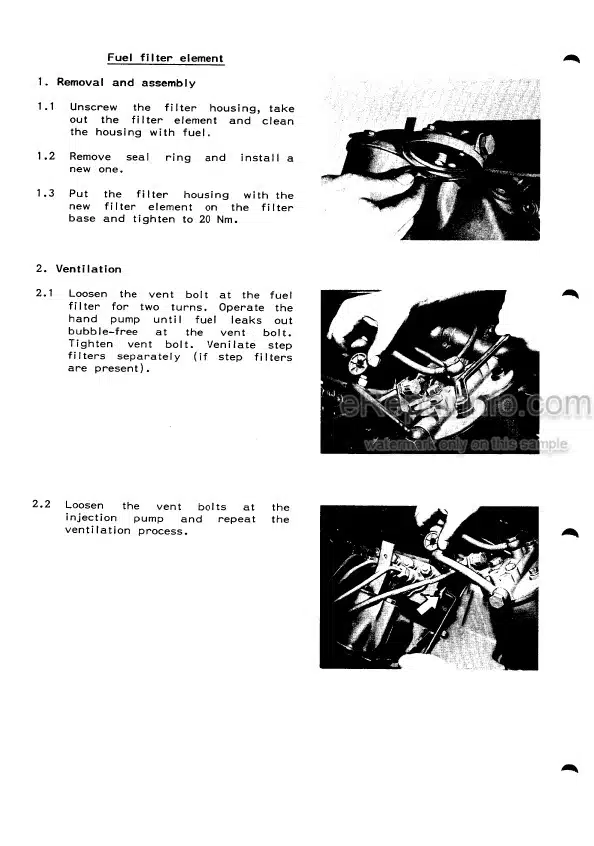

Injection Pump Overflow Valve Replacement And Inspection

Fuel Injector Removal And Installation

Bleeding The Fuel System

-PUMPS / ADD-ON COMPONENTS

Air Compressor Removal And Installation

Alternator Removal And Installation

Air Conditioner Compressor And Alternator Removal And Installation

Starter Removal And Installation

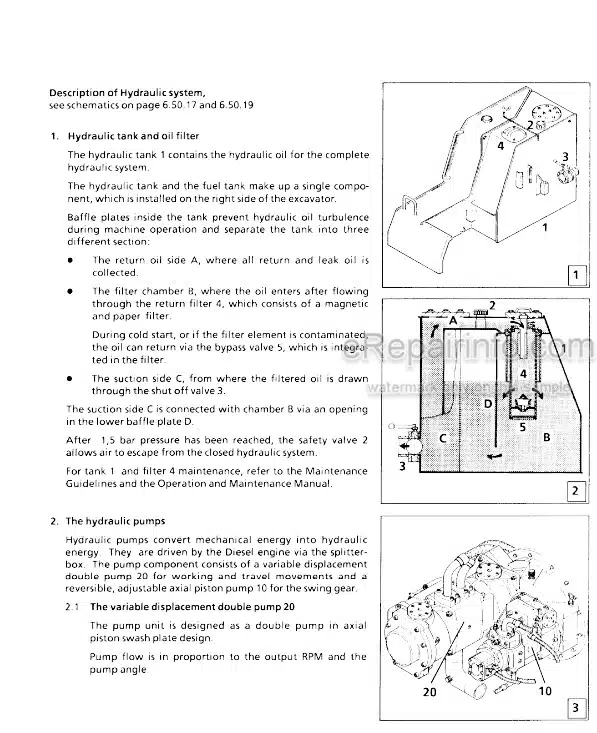

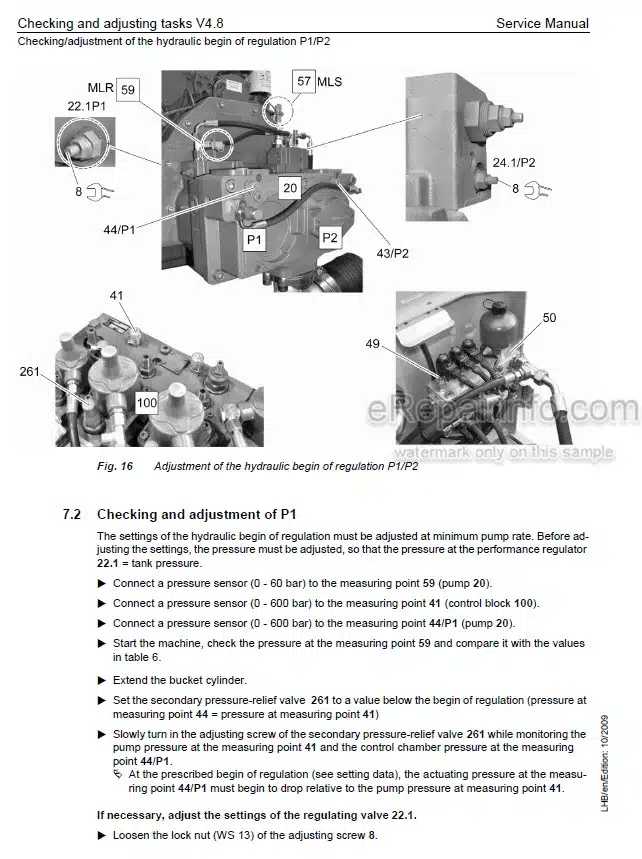

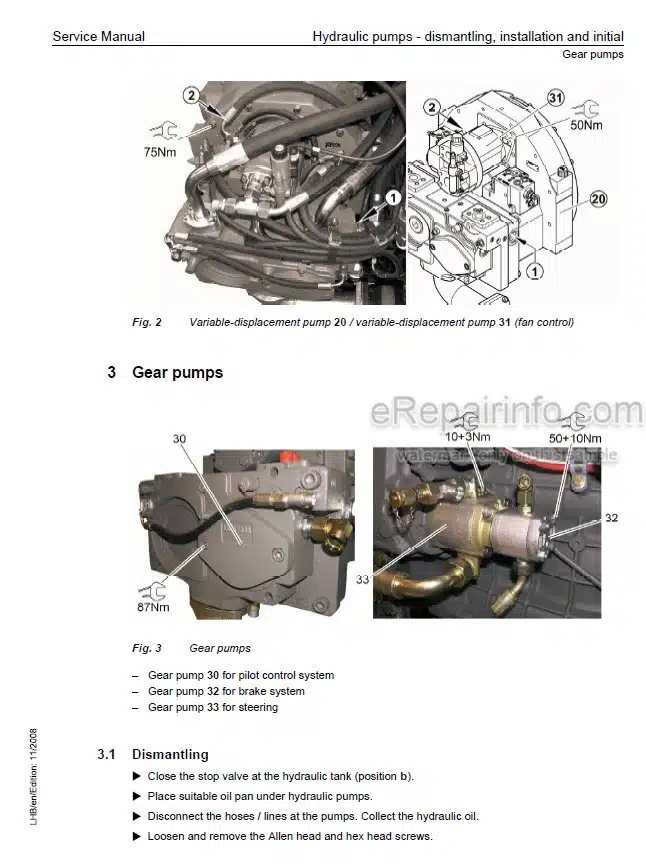

Hydraulic Pumps / Removal And Installation

Hydraulic Pump Drive Removal And Installation

Hydraulic Pump Drive Disassembly, Inspection And Assembly (Input Drive Bushing With Collar Bushing)

Hydraulic Pump Drive Disassembly, Inspection And Assembly (Input Drive Bearing With Bushings And Thrust Rings)

Hydraulic Pump Drive Disassembly, Inspection And Assembly (Drive Controllable)

Hydraulic Pump Drive Disassembly, Inspection And Assembly (Installation On Timing Case Cover)

Oil Pan Removal And Installation

Lube Oil Line Removal And Installation

Lube Oil Pump Removal, Inspection And Installation

Piston Cooling Nozzle Removal, Inspection And Installation

Gear Lubrication Nozzle Removal, Inspection And Installation

Oil Pressure Sending Unit And Oil Pressure Switch Replacement

Oil Cooler Housing, Oil Cooler And Oil Filter, Oil Cooler Bypass Valve Removal / Installation (For “Hanging” Oil Filter Installation)

Oil Cooler Housing, Oil Cooler And Oil Filter, Oil Cooler Bypass Valve Removal / Installation (For “Standing” Oil Filter Installation)

Oil Cooler Housing, Oil Cooler And Oil Filter, Oil Cooler Bypass Valve Removal / Installation (Filter Installed “Away” From Oil Cooler Hsg.)

Exhaust Manifold Removal And Installation

Air Intake Manifold Removal And Installation

Connector Line From Turbo Charger To Air Intake Manifold Removal And Installation

Engine Brake Removal And Installation

-DISASSEMBLY / ASSEMBLY OF BASIC ENGINE

Timing Case Removal And Installation

Removal, Inspection And Installation Of Fan And Coolant Pump Drive From Camshaft

Balancer Removal And Installation

Balancer Disassembly, Inspection And Assembly

Flywheel Housing Removal And Installation

Crankshaft Removal And Installation

Camshaft And Cam Follower Removal And Installation

Gear Drive-Fan Side

Gear Drive – Flywheel Side

Resealing Of Crankcase Cover

-TURBOCHARGER

Guidelines For Servicing Turbocharged Engines

Recommendations – Operation And Maintenance

Possible Malfunctions On Turbocharged Diesel Engines Without Pressure Sensing Control Valve

Schematic Of Turbocharged, 6 Cylinder, 4 Cycle Diesel Engines

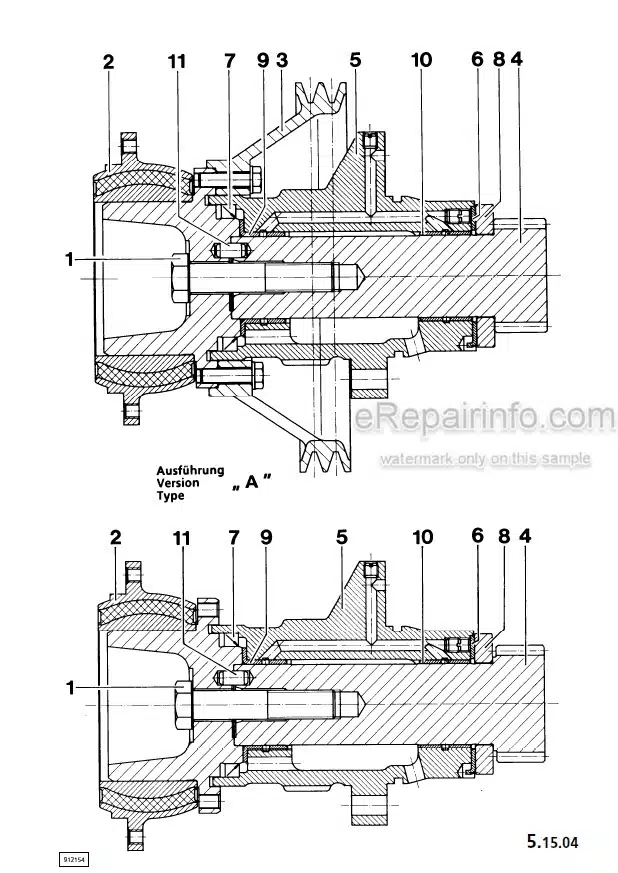

K2 Turbocharger, Sectional And Exploded View

Turbocharger, Removal And Installation

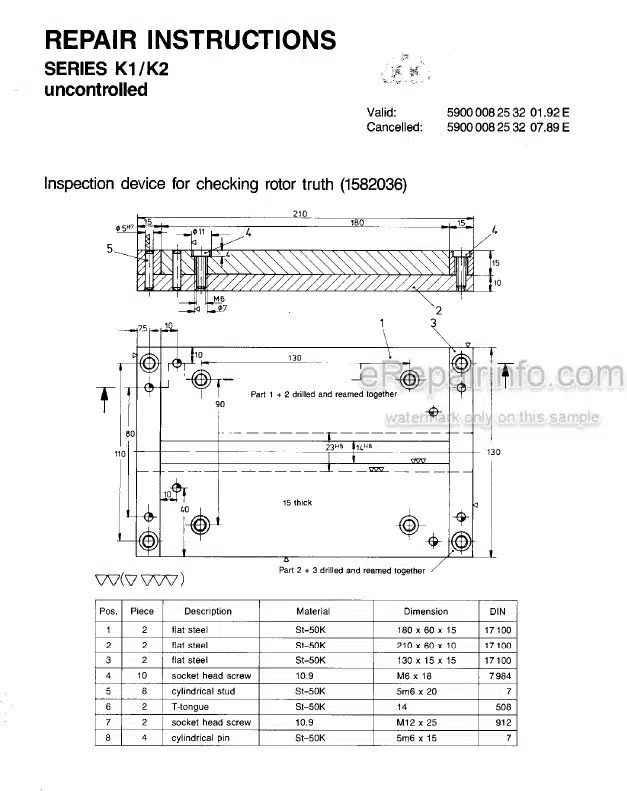

Repair Instructions, K1 / K2 Turbocharger

Repair Instructions, Schwitzer Turbocharger

Injection Pump With Load Pressure Dependent Full Load Stop (LDA)

-SPECIAL TOOLS

Measuring And Testing Tools

Removal, Installation And Assembly Fixtures And Tools

Assembly And Installation Aids, Special Wrenches

Cylinder Head Remachining Tools

Installation Bushings And Guide Pins

Removal And Installation Punches And Punchplates

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Anonymous (verified owner) –

Delivery very fast, good quality.