Factory Service Manual For JLG Skytrak Telehandler. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 342

Number: 8990163 (february 2005)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

JLG Skytrak Telehandler

6036

S/N 9B0500 thru 14833

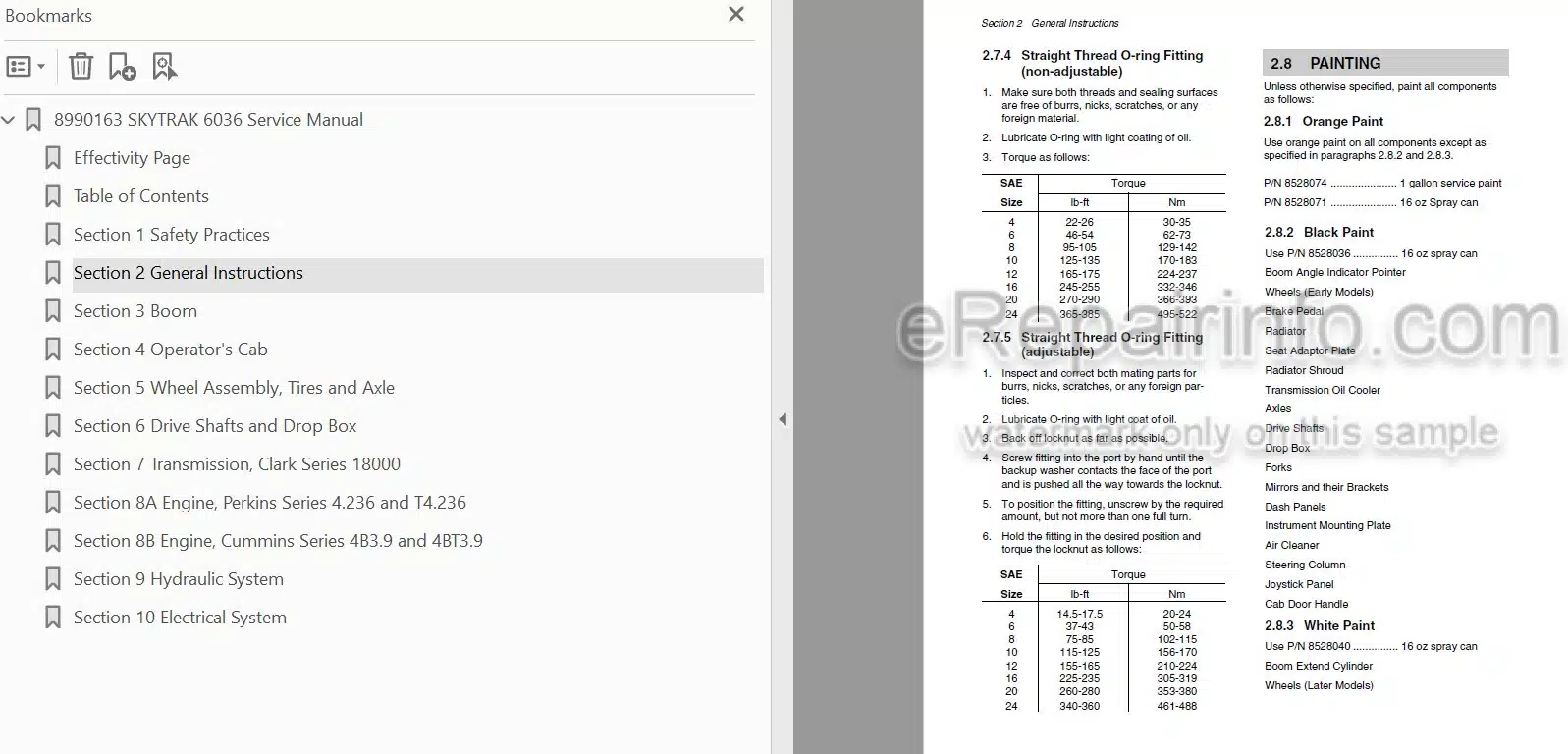

Contents

-SAFETY PRACTICES

Introduction

Signal Words

Personal Considerations

Equipment Considerations

General Considerations

Operational Considerations

Final Word

-GENERAL INSTRUCTIONS

Introduction

Cleaning

Replacement

Hoses And Tubes

Bearings

Pressure Testing And Adjustment

Torques

Painting

After Service Startup And Checks

Fluid Levels And Lubrication

-BOOM

Boom Assembly

Emergency Boom Lowering

-OPERATOR’S CAB

Seat

Mechanical Hand Controls

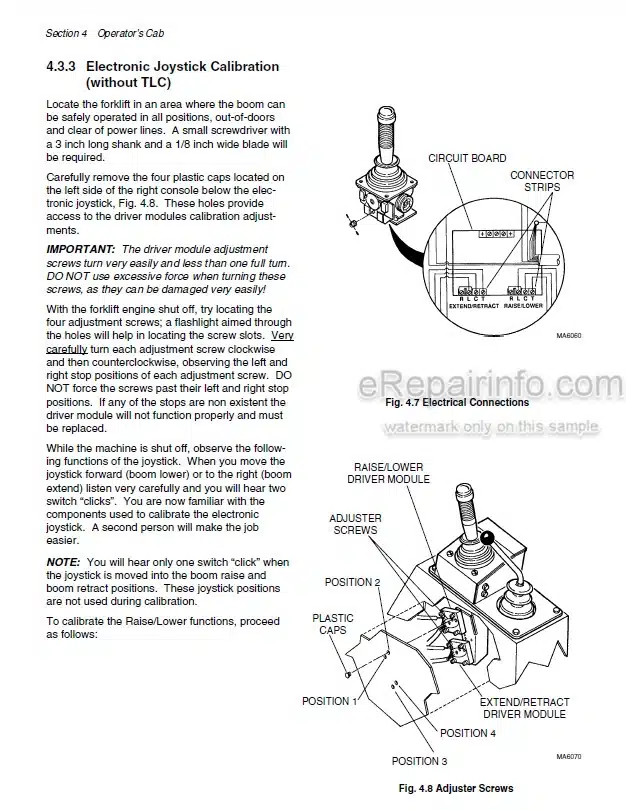

Electronic Joystick

Mechanical Foot Controls

Rear View Mirrors

-WHEEL ASSEMBLY, TIRES AND AXLE

Wheel Assembly And Tire

Axle Assembly

Axle Lubrication

Specifications

Troubleshooting

-DRIVE SHAFTS AND DROP BOX

Drive Shafts

Drop Gear Box For S/N 9N0941 And Before

Drop Gear Box For S/N 9N0942 And After

Specifications

-TRANSMISSION, CLARK SERIES 18000

Transmission Preventive Maintenance

How To Tow The Forklift

How To Drain Transmission

How To Back Flush Oil Cooler

Transmission Removal

Transmission Replacement

Internal Servicing

Installation

Troubleshooting

Specifications

-ENGINE, PERKINS SERIES 4236 AND T4236

Safety Considerations

Disclaimer And Scope

Standard Practices

Unified Threads

Engine Maintenance

Engine Maintenance

Engine Oil Specifications

Engine Cooling System

Engine Electrical System

Engine Fuel System

Engine Exhaust System

How To Remove Engine From Forklift

How To Overhaul The Engine

How To Install The Engine In Forklift

How To Torque Cylinder Head Screws And Nuts

Engine Storage

Troubleshooting

-ENGINE, CUMMINS SERIES 4B39 AND 4BT39

Safety Considerations

Disclaimer And Scope

Standard Practices

Engine Maintenance

Engine Maintenance Daily Before Operating Engine

Engine Maintenance Every 250 Hours Or 3 Months

Engine Maintenance Every 500 Hours Or 6 Months

Engine Maintenance Every 1000 Hours Or Annually

Engine Oil Specifications

Engine Cooling System

Engine Electrical System

Engine Fuel System

Engine Exhaust System

How To Remove Engine From Forklift

How To Overhaul The Engine

How To Install The Engine In Forklift

Engine Storage

Troubleshooting

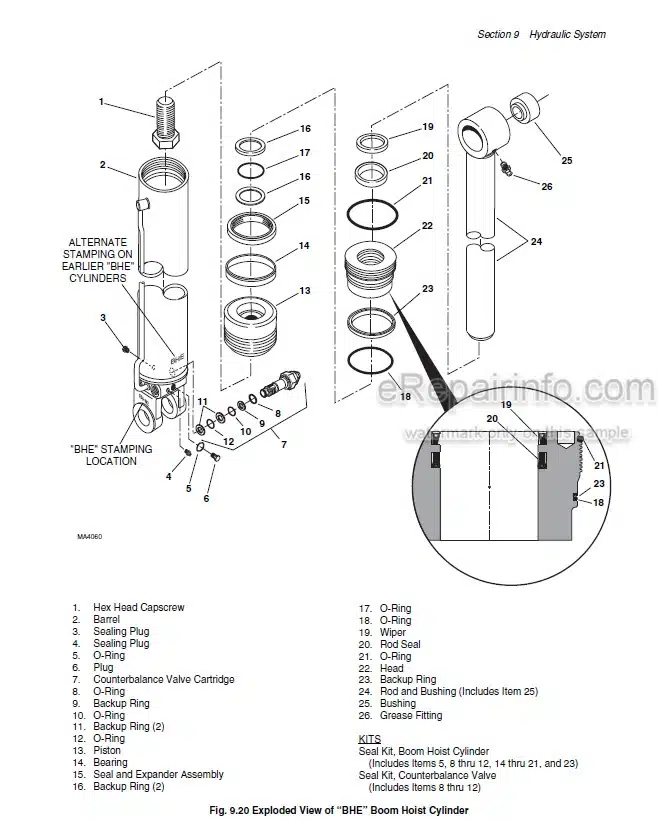

-HYDRAULIC SYSTEM

System Operation

Main Control Valve Operation Cable Control

Main Control Valve Operation Electronic Control

Secondary Control Valve Operation

Cylinders

Valves

Pumps

Troubleshooting

Specifications

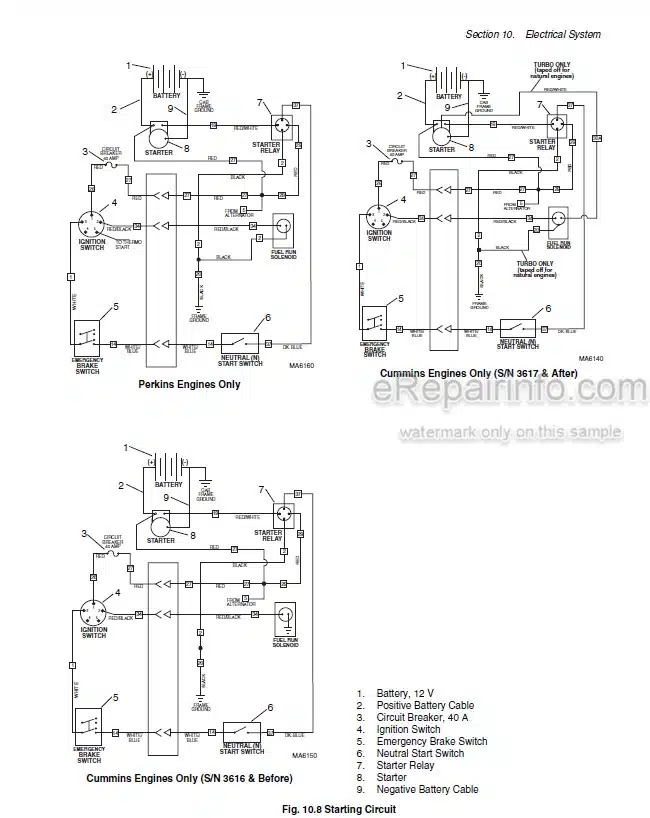

-ELECTRICAL SYSTEM

System Components

Warning Devices

Wiring Harnesses

Circuit Breakers And/Or Fuses

Starting Circuit

Charging Circuit

Switches And Solenoids

Gauges And Indicator Lights

Optional Lighting System

Windshield Washer/Wiper

Fan Switch And Fan Motor (Optional)

Cab Heater (Enclosed Cab Only)

Troubleshooting

Specifications

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet