Factory Service Training For Bomag Sanitary Landfill Compactor. The Bomag Service Training Manual Describes The Disassembly, Dismantling, Assembly, Installation And Repair Of Components And Assemblies. Manual Addresses The Professionally Qualified Personnel Or The After Sales Service Of Bomag, And Should Be Of Help And Assistance In Correct And Efficient Repair And Maintenance Work.

Format: PDF

Language: English

Pages: 602

Number: 00891809 (april 2012)

Bookmarks: Yes

Searchable: Yes

Wiring Diagram: Yes

Hydraulic Diagram: Yes

Model

Bomag Sanitary Landfill Compactor

BC972RB-2

BC1172RS-2

S/N 101 570 84 … >

S/N 101 570 85 … >

S/N 101 570 86 … >

S/N 101 570 87 … >

Contents

-GENERAL

Introduction

Safety Regulations

General Repair Instructions

Tightening Torques

-BOMAG REFUSE COMPACTOR

BOMAG Refuse Compactor

-TECHNICAL DATA

Technical Data

-MAINTENANCE

General Notes On Maintenance

Fuels And Lubricants

Table Of Fuels And Lubricants

Running-In Instructions

Maintenance Table

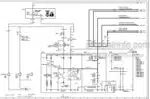

-E-PLAN WIRING DIAGRAMS

Understanding Wiring Diagrams

Circuit Symbols In The Circuit Diagram

Identification Of Switch Blocks In The Wiring Diagram

Designation Of Components In The Wiring Diagram

Terminal Designations In Wiring Diagram

-ELECTRICS

Battery Service, Checking The Main Battery Switch

Starting The Engine With Jump Leads

Main Battery Switch

Main Fuse

Hydraulic Oil Temperature

Pressure Switch, Hydraulic Oil Filter

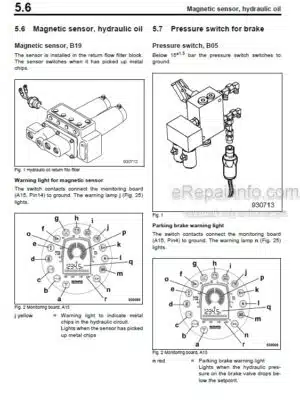

Magnetic Sensor, Hydraulic Oil

Pressure Switch For Brake

Level Sensor In Diesel Tank (R03)

Blower Monitoring Module A53

Electric Installation Box

Fuses

Fuse, Cabin

Cab Electrics

Machine Related Electrics

Electronic Control Units

Checking The Voltage Supply For The Control Unit

Diagnostics Concept

-ELECTRONIC CONTROL

ESX Control

-ENGINE ELECTRICS

Engine Control Unit

Pin Assignment

System Faults Indicated By Flashing Code

Flashing Code

Diagnose With Serdia

Diagnose With Can-Bus

Diagnostics Interface

Emr3 List Of Fault Codes

Sensors

Oil Pressure Sensor

Fuel Temperature Sensor

Charge Air Temperature – Charge Air Pressure Sensor

EMR Coolant Temperature Sensor

Rotary Speed Sensor For Crankshaft

Rotary Speed Sensor For Camshaft

Preheating System

Checking The Preheating System. Maintenance In Case Of Frost

Sensor, Water In Fuel

Air Filter Vacuum Switch

Coolant Temperature Sensor

Float Switch, Coolant Tank

Charge Control Light, Engine Rpm-Meter

Generator

Replacing The Voltage Regulator

Electric Starter

-ENGINE

Diesel Engine

Engine Description TCD 2015 V 8 Cylinder

Lubrication Oil Circuit TCD 2015

Coolant Circuit TCD 2015

Fuel Circuit TCD 2015

Injection System (MVS) TCD 2015

Exhaust Gas Recirculation TCD 2015

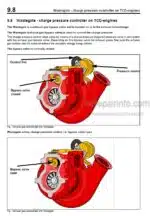

Wastegate – Charge Pressure Controller On TCD-Engines

Checking, Adjusting The Valve Clearance

Checking The Engine Oil Level

Changing Engine Oil And Oil Filter

Replace The Fuel Filter

Check, Clean The Water Separator

Checking Condition Of Radiator, Intercooler And Hydraulic Oil Cooler, Clean, Cleaning The Engine

Checking The Coolant Level

Changing The Coolant

Check The Anti-Freeze Concentration And The Condition Of The Coolant

Checking The Thermostat In Disassembled State

Servicing The Fan V-Belt

Servicing The Generator V-Belt

Check The Engine Mounts

Check Fastening Of Engine / Turbocharger / Combustion Air Hoses

Intercooler, Draining Off Oil/Condensation Water

Checking The Crankcase Pressure

General Trouble Shooting Chart TCD 2015

Special Tools, Deutz Engine (TCD 2015)

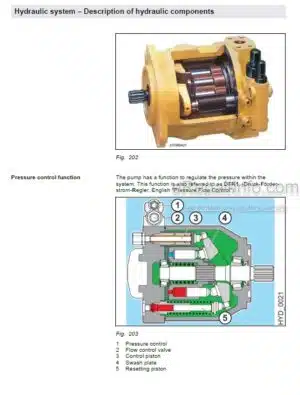

-HYDRAULICS

Hydraulic Circuit

Travel Pump A4VG110 DA

Travel Pump A4VG110 HT

Steering And Working Pump, HA10VO 100 & HA 10 VO 100

Axial Piston Swash Plate Principle

Troubleshooting Axial Piston Pumps

Travel Motor, A6Vm 215Ep

Trouble Shooting, Variable Displacement Axial Piston Motor

External Gear Pumps

Travel System

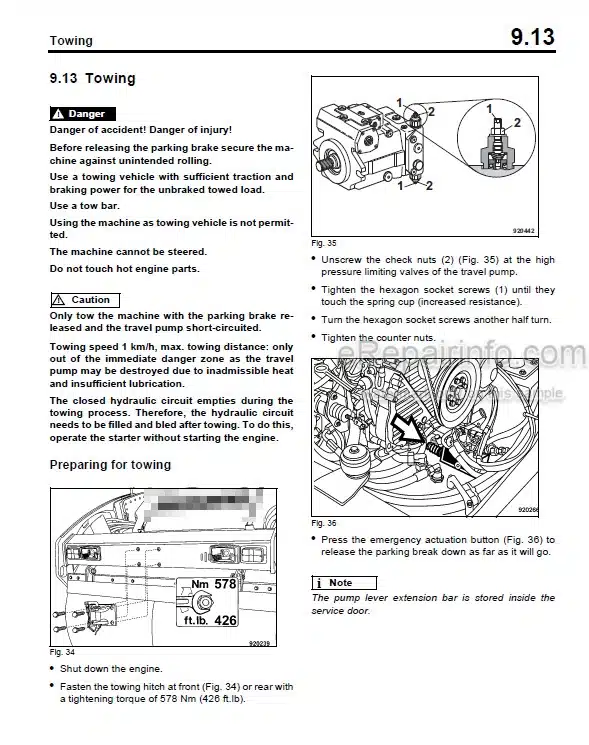

Towing The Machine

Cooling

Steering And Working Hydraulics

Measuring And Adjustment Points On Control Valve Block

Control Valve Block For Steering And Dozer Blade

Replacing Control Block Components

Check The Hydraulic Oil Level

Replace Hydraulic Oil Filter

Changing Hydraulic Oil And Breather Filter

Checking The Oil Level In The Transfer Box

Change Oil And Filter In The Transfer Box

-AUTOMATIC AIR CONDITIONING

Overview

Physical Basics

Refrigerant Rl34A

Compressor Oil / Refrigeration Oil

Working Principle Of The Air Conditioning System

Monitoring Devices

Description Of Components

Climatronic Control

Measuring The Compressor Oil Level

I Checking The Magnetic Clutch

Inspection And Maintenance Work

Servicing The Air Conditioning

Servicing The Air Conditioning Compressor V-Belt

Drying And Evacuation

Emptying In Case Of Repair

Leak Test

Filling Instructions

Trouble Shooting In Refrigerant Circuit, Basic Principles

Trouble Shooting, Refrigerant Circuit Diagram

Trouble Shooting Procedure

Steam Table For Rl34A

-CENTRAL LUBRICATION SYSTEM

System Layout

Technical Description

Control

Lubrication Process

Progressive Distributor

Lubrication Oil Pump

Check The Central Lubrication System, Top Up

Faults And Causes

Fault – Cause – Remedy

Failure Of Central Lubrication System (Grease Emerges From Relief Valve)

-CIRCUIT DIAGRAMS

Hydraulic Diagram

Wiring Diagram

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet