Factory Service And Repair Manual For Tigercat EHS Transmission. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 60

Number: 47733AENG (august 2019)

Bookmarks

Searchable

Model

Tigercat EHS Transmission

Contents

-SAFETY

Caution

Clean And Inspect

Danger

Fastener Torque And Reuse

General Safety Precautions

Guide Pins

Hazardous Materials Safety

Injection Injuries, High Pressure

Injection Injuries, Pneumatic Grease Guns

Material Lifting And Handling

Notice

Personal Protective Equipment

Pictograms

Read This Manual First

Record Keeping

Required Tools

Safety Symbols

Safety Words, Understanding

Shipping Components

Thread Locking/Adhesive Compounds And Sealants

Torque Chart, General

Warning

Work Conditions And Tools

-DISASSEMBLY

Baffle, Remove

Clean And Inspect

Clutch, Disassemble

Disassemble The Clutch

Disassembly Tasks

Gearbox Cover And Gasket, Remove

Input Bearing Carriers, Remove

Input Gear Bearings, Remove

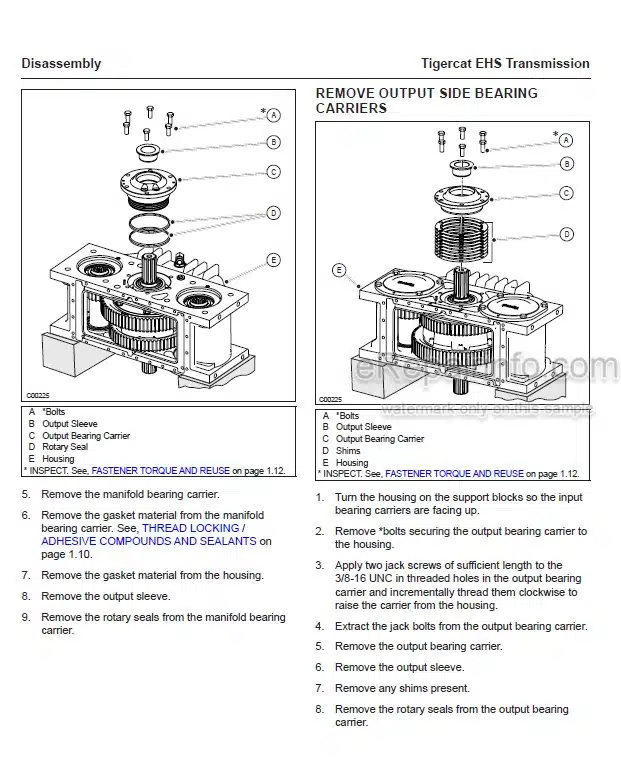

Manifold Bearing Carrier, Remove

Output Bearing Carriers, Remove

Output Shaft, Remove

Roller Bearing/Gear Sleeve, Disassemble

Safety

-ASSEMBLY

Assembly, Prior To

Baffle, Install

Bearing Carrier Manifold

Bearing Installation

Bearings And Sleeves, Cooling

Bleed Screws, Fittings And Plugs, Install

Carrier Manifold, Bearing

Cleaning And Inspection

Clutch

Gearbox Gasket And Cover

Gear Contact Pattern Test

Heater, Bearing Induction

Housing

Input Gear Installation

Manifold Bearing Carrier

Motor Bore Runout Measurement

Output Bearing Carrier-

Output Bearing Manifold

Output Gear

Quad Rings, Inner And Outer

Roller Bearing/Gear Sleeve

Safety

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet