Factory Operators Manual For Tigercat Feller Buncher. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: English

Pages: 244

Number: 39182AENG (december 2019)

Bookmarks

Searchable

Model

Tigercat Feller Buncher

860C

870C

L870C

Serial Number 86012601 To 86013500

Serial Number 87012601 To 87013500

Serial Number 87022601 To 87023500

Contents

INTRODUCTION

STANDARDS ROPS, TOPS, FOPS, OPS

NON-APPROVED FIELD PRODUCT CHANGES

-SAFETY

Backover Accidents-Avoiding

Battery Disconnect Switch

Battery Safety

Cab Exits

Cable Assist

Cooling System

Emergency Cab Exits

Engine Doors

ER Boom Function – Switchable

ER Boom System Precautions

Exhaust Fumes

Felling Trees

Fire Prevention

Fluid Injection Injury

Fluid Leaks

Grease Injection Injury

Hazard Zone

Hydraulic Pressure Hazard

Interlock Switch

Lightning Safety Awareness

Liquid Starting Aid

Loose Clothing Hazard

Machine Stability And Traction

Noise Level Inside Cab

Parking Hazards

Parking The Machine;

Protective Clothing

Refuelling

Safety Hazards – Operating

Safety Hazards – Viton Seals

Safety Interlock Switches On Cab Doors

Safety Labels

Safety Precautions, General

Safety Precautions, Operating

Safety Precautions, Servicing

Safety Symbols

Signal Words

Vibration And Noise Levels Inside Cab

Viton Seals

Welding, Prior To

Working With Oil

-USING HIGH-SPEED DISC SAWS SAFELY

Comments And Instructions

Dangers

Foreword

Housing Types

Saw Head Do Nots

Type Of Housing Makes A Difference

-CONTROLS & OPERATION

Accumulation Mode Feature

Adjustment Procedure

Air Conditioner/Heater Controls

Air Filters

Air Intake System, Engine

AM/FM Stereo CD

Anti-Stall – Switch With Light

Auxiliary Power Outlet

Battery Booster Jumper Plug

Battery Disconnect Switch

Boom Controls

Bottom Fueling System

Care Of The Machine

Case Drain Strainers

Cigarette Lighter

Clamp Arms Control, Joystick

Cleaning

Cold Weather Starting

Computer

Control Panel

Cooling Assembly

Cooling Fan – Switch

Critical Messages, Red

Default Settings Table

Diesel Heater Controls

Doors, Service Access

Emergency Exits

Optional

Engine Air Intake System

Engine Anti-Stall – Switch With Light

Engine Diagnostics Connection

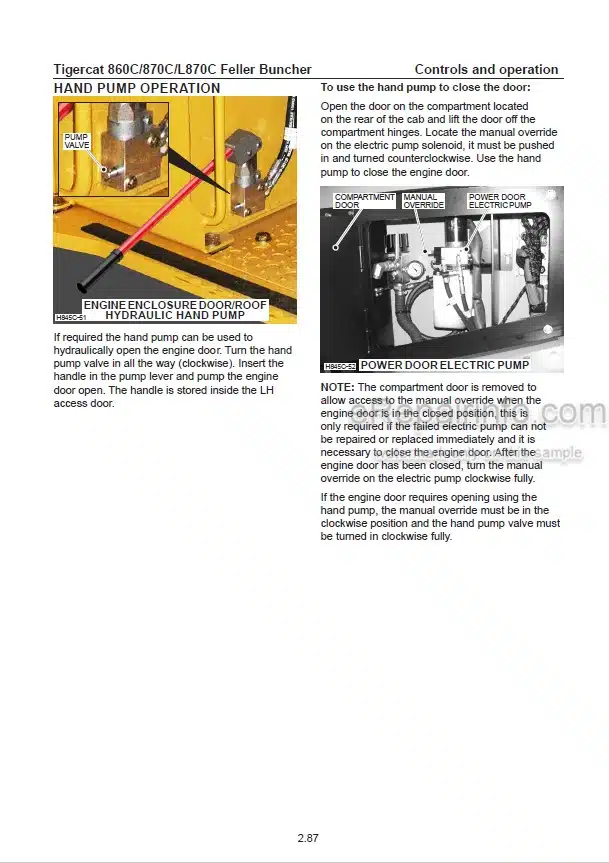

Engine Enclosure, Door/Roof Hydraulic Hand Pump

Engine Enclosure, Power Door Roof Electric Pump

Engine Fault Code Messages

Engine Hot Water Shut-Off Valves

Engine, Restarting After Engine Runs Out Of Fuel

ER Boom System, Special Operating Instructions

Felling Head Operating Instructions

Filter Fresh Air – A/C Unit

Filter Re-Circulating Air-A/C Unit

Filter Restriction Indicator

Filters

Filters, Hydraulic Oil

Fire Suppression System, Optional

Foot Pedals Track Drive

Fuel, Bottom Fueling System

Fuel Heater Switch

Fuel, Refueling Procedure

Fuel Tank

Fuel Tank, Optional High Capacity

Fuel Tank, Standard

Fuse And Relay Rear Panel

Fuses And Relays, Cab

Fuses And Relays, Engine Compartment

Graffiti Removal

Hand Pump Operation

Horn, Safety Alert – Switch

Hot Water Shut-Off Valves (Engine)

Hydraulic Oil Fill Pump -Electrical

Hydraulic Oil Heater, Optional

Hydraulic Oil Tank

Ignition Key Switch

Information Messages, Blue

Inspection Of The Fire Suppression System

Instrument Panel

Interior Lights

Joysticks, Left And Right Hand

Key Switch

Leveling Controls, Joysticks

Lights, Interior

Lights, Service

Load Sensing, Operating Tips

Machine Preparation

Manual Override

Master Alarm

Master Alarm Light

Master Disconnect Switch

Md3 Computer Electronic Control And Display

Md3 Computer Main Display

Md3 Messages

Measuring Track Sag

Oil Heater Hydraulic Optional

Operating Machine

Operating Tips With Load Sensing

Pictogram Descriptions

Pilot System Interlock Switch (Front Door)

Pilot System “Off Push Button Switch

Pilot System Reset – Push Button Switch

Portable Fire Extinguishers, Location

Power Door

Power Engine Door/Roof – Switch

Pump, Electrical, Engine Enclosure Door/Roof, Hydraulic

Pump, Hand, Engine Enclosure Door/Roof, Hydraulic

Pump, Hydraulic Oil Fill, Electrical

Refueling Procedure

Refueling Procedure, Bottom Fueling Option

Relays And Fuses, Cab

Relays And Fuses, Engine Compartment

Removal Of Anti-Corrosion Spray (If Applicable)

Saw-Switch

Screen Saver Adjustment

Seat

Service Access Doors

Service Lights

Slope Indicators

Starting Engine

Stereo AM/FM Radio/CD

Swing Brake – Switch With Light

Swing Control, Joystick

Throttle Switch

Track Components

Track Drive, Foot Pedals

Track, Low/Drive – Switch With Light

Travelling (Boom Raised)

Travel Speed Control Lever

Unloader Valve, Engine Air Cleaner

USB Port – Md3 Computer

Vacuum Switch, Hydraulic Oil Tank

Warmup Mode

Windows

Work Lights Switch

-LUBRICATION & MAINTENANCE

Air Conditioning System Checking The System

Air Intake System Engine

Approved Hydraulic Oils

Bottom Fueling System

Case Drain Strainers

Conversion Chart Units

Diffusers/Strainers Hydraulic Tank

Emergency Exits Check Monthly

Engine Air Intake System

ER Boom System

Filter Restriction Indicator Engine

Filter Restriction Pressure Switch

Filters

Fire Prevention

Fuel Bottom Fueling Option

Fuel Refueling Procedure

Fuel Tank

Fuel Tank Optional High Capacity

Fuel Tank Standard

Fuel Tank Strainer

Hydraulic Fill Pump Filter – Electrical

Hydraulic Oil Fill Pump -Electrical

Hydraulic Oil Filters

Hydraulic Oil Operating Range

Hydraulic Oil Return Filters

Hydraulic Oil Tank

Hydraulic Tank Breather

Hydraulic Tank Clean-Out Cover

Hydraulic Tank Pressurization Instructions

Leveler Lubrication Points

Lubrication Points Diagram

Lubrication Points Diagram Leveller

Lubrication Schedule

Measuring Track Sag

New Machine Maintenance

Oil Analysis Kits

Oil Analysis Program

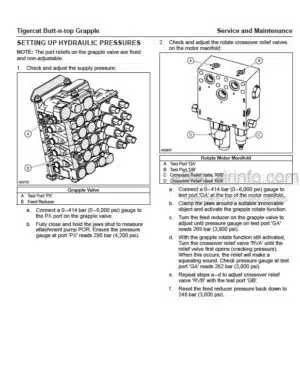

Pressure And Speed Setting

Pressure Setting Procedures, See Service Manual

Preventive Maintenance Schedule

Pump Hydraulic Oil Fill Electrical

Refueling Procedure

Refueling Procedure Bottom Fueling Option

Return Tube Diffusers/Strainers

Scheduled Maintenance

Service And Lubrication Points

Strainers/Diffusers Hydraulic Tank

Swing Drive Lubrication

Torque Chart

Torque Chart General

Torque Fluid Connections

Torque Specifications General

Track Chain Sag

Track Components

Track Operation And Wear Prevention

Tracks, Protecting Steel Tracks

Unit Conversion Chart

Unloader Valve Engine Air Cleaner

Weights Of Commercial Wood

Wire Colour Code Chart

Wood Weights Of Commercial Wood

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet