Factory Shop Manual For Daewoo Solar 330LC-3 Hydraulic Excavator. Illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 344

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Model

Daewoo Hydraulic Excavator

Solar 330LC-3

Contents

-SAFETY

To the Operator of a Daewoo Excavator

General Safety Essentials

Locations of Safety Labels

Summary of Safety Precautions for Lifting in Leveling Mode I

Work-site Precautions

Operation

Equipment

Maintenance

Shipping and Transportation

Excavator Rated Lift Capacity Tables

-SPECIFICATIONS

Excavator Machinery Plan

Excavator Engine Specifications

Engine Performance Curves

Hydraulic System Component Specifications

Hydraulic Pump Performance Characteristics

Specifications

General Dimensions

Working Range Dimensions

Reference Table – Approximate Weight of Workload Materials

Excavator Rated Lift Capacity Tables

Performance Standards

Performance Tests

-UPPER STRUCTURE

Operator’s Cab Removal Procedure

Falling Object Protective Structures (F O P S )

Front Attachment Pin Specifications

Bucket Tooth Inspection and Replacement

Shimming Bucket Linkage

Bucket Attachment, Removal and Reversal

Removal and Installation of Front Attachment

Operation of Hydraulic Cylinders

Attachment Cylinder Components

Cylinder Assembly and Disassembly

Cylinder Reassembly

Welding Precautions and Guidelines

Accumulator

Engine Components and Accessories

Fuel Tank Removal and Installation

Engine Cooling System: Radiator/Oil Cooler

Counterweight Removal and Installation

Swing Bearing Maintenance

Swing Bearing Rebuild

Center Joint (Swivel) Overhaul/Repair

Hydraulic System General Notes

Hydraulic System Schematic

Operation of Working Components

Main Pump Assembly Description

Pump Regulator Description

Hydraulic System General Precautions

Maintenance Service and Repair Procedure

Troubleshooting – Main Pump

Main Pump Parts List

Main Pump Disassembly and Reassembly

Reassembly of Main Pumps and Valve Block

Pump Regulator Parts List

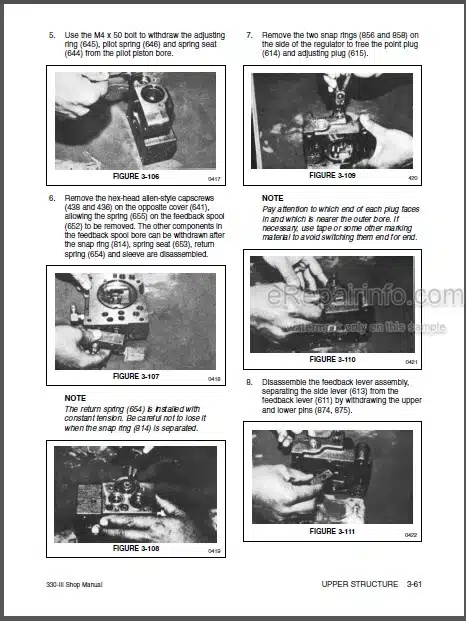

Pump Regulator Disassembly and Reassembly

Swing Motor Basic Operation

Rebuilding the Swing Motor – Disassembly

Swing Motor Parts List

Rebuilding the Swing Motor – Assembly

Swing Gearbox – Disassembly

Swing Gearbox – Assembly

Main Control Valve Disassembly

Main Control Valve Reassembly

Remote Control Valve Parts List

Remote Control Valve Disassembly and Reassembly

Travel Control Valve Parts List

Travel Control Valve Disassembly and Reassembly

-LOWER STRUCTURE

General Description

Travel Motor and Reduction Gearbox

Travel Motor Assembly Parts List

Travel Motor Operation

Travel Brake

Travel Motor (Hi/Lo) Tilting Valve

Travel Motor Final Drive (Gearbox)

Travel Motor Final Drive (Gearbox) Parts List

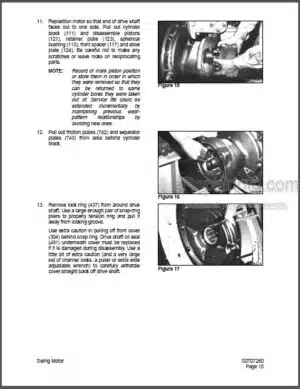

Travel Motor and Final Drive Disassembly

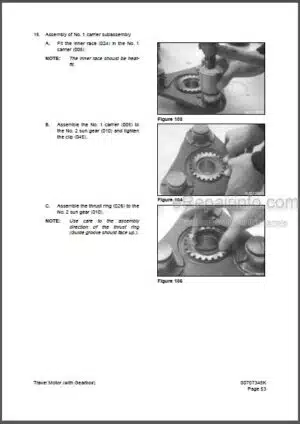

Travel Motor and Final Drive Reassembly

Service Standards for Replacing Worn Parts

Final Drive (Reduction Device)

Travel Motor and Final Drive (Gearbox) Troubleshooting

Front Idler Roller

Lower Roller

Upper Roller

Track Spring and Track Adjusting Cylinder

Service Standards for Lower Travel Frame Components

Track Shoe Link and Assembly

Lower Roller

Upper Roller

Idler

Track Tensioning

-ELECTRICAL SYSTEM

General Description

Volt Operation

Engine Start-up and Shutdown

Cylinder Preheat – Intake Air Electrical Heater

Alternator Circuit

Low Current Electrical Circuits

Wiring Color Code for Electrical Schematic Diagrams

Climate Control (Air Conditioning) Circuit

Power Mode System Operating Components

Instrument Panel

Instrument Panel LED Displays and Terminal Connections Input

Instrument Panel Connector Arrangement

Instrument Panel Selector Switches

Instrument Panel Coolant Overheating Circuit

Instrument Panel Indicator Lights

Instrument Panel Engine Oil Pressure Circuit

Start-up Electrical Test Circuit

Interior Lighting

Hydraulic Pump Discharge Pressure Sensor

Power Mode Circuit Instrument Panel Summary

Power Mode System Basic Operation

Power Mode III

Power Mode II

Power Mode I

Swing Priority Circuit

Swing and Arm Dump Combined Operation

Swing Priority and Arm Crowd Recovery Function

Loading Work Mode

Leveling Mode

Boom Up, Arm Crowd and Bucket Crowd Combined Operation

Leveling Mode I: Boom Up and Arm Crowd Combined Operation

Forward Travel: Swing During Straight Travel

Forward Travel: Arm Operation or Boom Operation While Traveling

-ENGINE

Engine Specifications

Wear Limits of Major Engine Components

Engine Oil Pump Overhaul and Rebuilding

Fuel Injection and Pump Installation, Alignment and Timing

Cylinder Headbolt Torque Requirements

Engine Throttle Controller

Engine Speed Sensor

-INSPECTION, MAINTENANCE AND ADJUSTMENT

Periodic Inspection and Maintenance

Table of Recommended Lubricants

Inspection and Maintenance

Daily or Every 10 Operating Hours

Weekly or Every 50 Operating Hours

150 Operating Hours

Monthly or Every 250 Operating Hours

Three Months or Every 500 Operating Hours

Six Months or Every 1000 Operating Hours

General Maintenance Procedures

Engine Speed Control Adjustment

Torque Specifications

Torque Wrench Extension Tools

Flange and Thread Sealant Assembly Compounds

Welding Maintenance Procedures

Hydraulic System Cleanliness and Oil Leaks

Reference Notes for Electrical Schematic

-TESTING, TROUBLESHOOTING AND ADJUSTING

Troubleshooting Recommendations

Troubleshooting – Engine Problems

Engine Throttle Controller

Troubleshooting – Electrical System

Flow Meter and Flow Meter Kit Installation and Testing

Pilot Pressure

Negacon, Negative Control

Power Mode Valve

Boom/Swing Priority

Pressure Up Valve

Pump Input Power Control

Swing System Troubleshooting

Troubleshooting – Hydraulic Problems

Troubleshooting – Control Valve

Troubleshooting – Travel Control Valve

Troubleshooting – Joystick Control Valve

Troubleshooting – Swing System

Troubleshooting – Swing Gearbox

INDEX

What you get

You will be given access to the link for downloading high quality PDF Manual (.pdf / .zip file) immediately after you pay.

Reviews

There are no reviews yet