Factory Service Repair Manual For Terex Atlas 1305 1505 1605 1705 Excavator. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 508

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: No

Hydraulic Diagrams: Yes

Model

Terex Atlas 1305, Atlas 1505, Atlas 1605, Atlas 1705

Contents

- Contents

Technical data - – Display and controls

General view of cab

Seat with consoles

Left switch panel

Right switch panel

Control and display

Control panel heating and air conditioning - – Engine

EMR

Application of the EMR

System description

Basic equipment

System functions

Pressure maintenance valves

Technical data - – Vehicle engine

Instructions for repairs to the vehicle engine

Cross section vehicle engine

Cross section travel motion control valve - – Pump

Instructions for the repair of a variable pump

Study view of the variable pump - – Pilot control equipment

Dozer blade/support pads

Principle of hydraulic function

Folding jib, slewing, lifting/lowering, bucket/grab

Structure

Function

Sectional view pilot control equipment

Diagram regulating piston - – Control block

Function of the control block

Control block construction

Control Block Picture - – Main rotation connection

Rotation connection and rotary transmission lead-through

Maintenance of the rotary connection - – Slewing gear gears and motor

Gearbox

Disassembly Gearbox

Assembly Gearbox

AF 10 FD slewing gear motor - – Pressure setting tables/setting regulations

Pressure setting table

7Setting regulations

Test ports

Bleeding the equipment

Fuel admission pressure

Pilot control

LS regulator, Dp setting

Pressure cut-off

Secondary valves

Raising the pressure P

Setting the secondary valve

Setting the pressure P

“Slew” secondary valve

Setting the “slew left/right” secondary valve

Setting the brake pressure

Setting the TC valve

Reverse current throttles

reverse current throttle device

Lifting cylinder open-circuit guard

Setting the switch-on of the locking piston

Adjusting the “lower” reverse-current throttle device

Secondary valves

Open-circuit guard for the articulated cylinder

Checking/adjusting the cardan shaft speed

Checking/adjusting the “drive” pilot control pressure

Centring actuator shut-off device with no oil overflow

Checking/adjusting the secondary valve - – Cylinders

Construction of the cylinders

Jointed cross shaft axle lock cylinder

Blade cylinder

Shovel tilting cylinder 1305

Articulated cylinder

Adjusting cylinder

Lifting cylinder - – Hydraulic accessories

Claw support – 4 supports

Operable at the same time

Check valve, pilot-operated

Integral check

Pilot control block

Power shift gear

Power brake system

Structure

SETTING REGULATION

Shut-off valve

Foot brake

Axle blocking

Functional description

Putting into operation and de-aeration

Trouble-shooting

Repair Guide (see picture 3)

Pendulum axle lock cylinder

Multi-function valve

Pipe break safety device

Function description RBS

Pipe-break safety device 1305

Pipe-break safety device 1505 / 1605 - – Air conditioner system

Use

Technical Data

Functions on the control elements

Overview

Control

Detailed description of the functions

Air distribution

Fan

Temperature plate

Switch for the air conditioner

Radio button for fresh air and ambient air

Description of the functions in the background

Auxiliary heating

Pressure switch in the refrigeration cycle

Temperature sensor

Combustion engine

Ignition key (terminal 15) and switching on the control unit

Switching off the ignition

Air conditioning of the cabin

Pane defrosting

Heating

Operation of the air conditioner

Heating air conditioner

Place of installation

Description of the cooling cycle components

Capacitor for the excavator models

Dryer with push button collector

Maintenance

Error diagnosis - – Power shift transmission

Valve block for Gearbox control

Operation

General

Driving and switching gears

Parking brake

General

Parking

Towing away

Maintenance

Type of oil

Checking the oil level

Oil change and oil fill-up quantity

Charts

INSTRUCTIONS FOR REPAIR

General instructions

Important information on working safety

Designation of statutory units

Tightening Torques

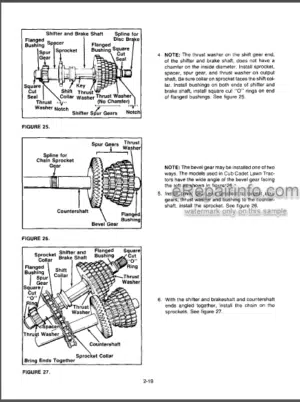

Gear structure

Instructions for commencement of operation, operating and maintenance

Installation overview and instructions on filling up with oil

Instructions on moving or towing away the vehicle in an emergency

Examples of tooth contact for Gleason-type gear teeth

RList of tools for assembling and disassembling

2 HL 100 switch protection

Shift protection device

Powershift transmission

Dismantling

Removing the clutch

Removing and dismantling the planetary drive

Switching off and removing and dismantling the spur wheel

Dismantling the shift protection device

Dismantling the drive output, axle drive housing and differential

ASSEMBLY

Axle drive housing, drive output and differential

Installing the helical gear and the shut-off device

Completing and installing the pinion cage

Pre-assembling and installing the coupling (on-the-road gear)

Checking the imperviousness and functioning of the coupling (Illustration 188…190)

Installing the brakes (off-the-road gear)

Mounting the drive housing

Checking that the brakes do not leak and that they function (off-road gear),

Pre-assembling and installing the shift protection

Installing the lubrication oil pump

Installing the screw plugs and the oil lines

Dismantling the drive output

Mounting the drive output

Gear switch protection

Dismantling, see also picture chart on pages 38 and 120!

Assembly, see also picture chart on pages 38 and 120 - – Electrical System

- -Axles

planetary steering axle

planetary rigid axle - – Hydraulic circuit diagrams

Control block, detailed view

hydraulic circuit diagram - – Maintenance

Safety instructions for maintenance

Renewing hydraulic fluid filter element

Renewing fuel filter

Changing engine oil, renewing engine oil filter

Maintenance schedule - – Miscellaneous

Repair Instruction for Welded Assemblies

Introduction

Service consultation

Area of application

General problems

Damage evaluation

General

Course of crack

Consulting the Service organization

General

Doubler of metal sheet

Drawings / Examples

Preparing the repair

Cleaning

Drilling

Grinding

Preheating the welding area

Qualification of the welding personnel

Selecting the filler metal

Welding wire selection

Repair sequence

Followup work

What you get

You will receive a PDF file with high-quality manual(s) on your email immediately after the payment.

Reviews

There are no reviews yet