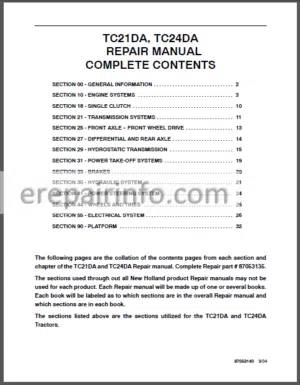

Repair Manual For New Holland FX(NA) Series Forage Harvesters. Illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-up.

Format: PDF

Language: English

Bookmarks: No

Searchable: Yes

Number: 60466121

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

New Holland FX30, FX30NA, FX40, FX40NA, FX50, FX50NA, FX60, FX60NA

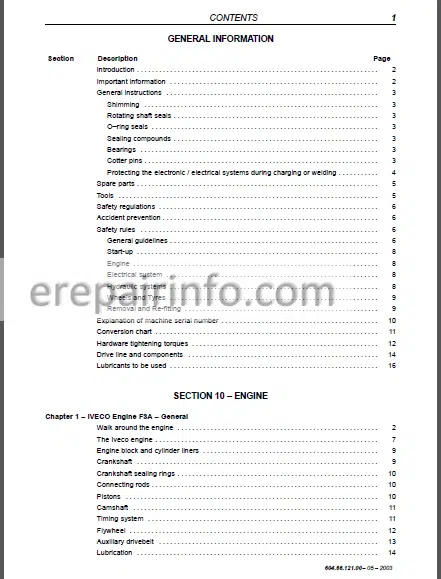

Contents

- – General Information

Introduction

Important Information

General Instructions

Shimming

Rotating Shaft Seals

O–Ring Seals

Sealing Compounds

Bearings

Cotter Pins

Protecting The Electronic / Electrical Systems During Charging Or Welding

Spare Parts

Tools

Safety Regulations

Accident Prevention

Safety Rules

General Guidelines

Start-Up

Engine

Electrical Sustem

Hydraulic Systems

Wheels And Tyres

Removal And Re-Fitting

Explanation Of Machine Serial Number

Conversion Chart

Hardware Tightening Torques

Drive Line And Components

Lubricants To Be Used - – Engine

–- Iveco Engine F3A – General

—Walk Around The Engine

Left Side View

Right Side View

Front View

Rear View

Top View

The Iveco Engine

Engine Block And Cylinder Liners

Crankshaft

Crankshaft Sealing Rings

Connecting Rods

Pistons

Camshaft

Timing System

Flywheel

Auxiliary Drivebelt

Lubrication

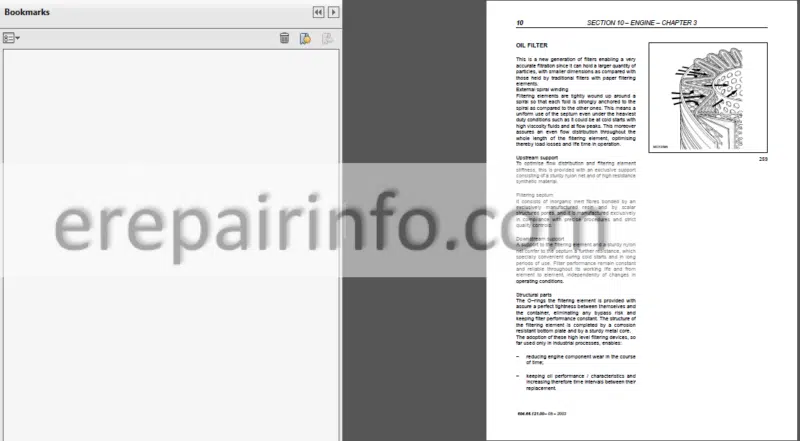

— Oil Filter

External Coil

Upstream Mount

Filter Septum

Downstream Mount

Structural Parts

Oil Sump

Cooling

— Electronically Controlled Injection System

Electronic Control Unit

— Pump Injector

Filling Stage

Injection Stage

Flowback Stage

–- Iveco Engine – F3A

General Specifications

Fuel System Data

Main Data

Torque Settings

Plan Of Tightening Sequence

Sub–Cranckcase

Cylinder Head

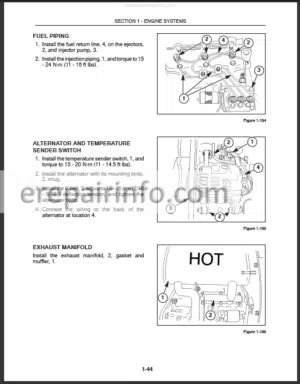

Exhaust Manifold

Turbocharger

Heat Exchanger

Engine Oil Sump

Rocker Arm Cover

Tools

Mechanical Troubleshooting

Preliminary Conditions

Engine – Disassembly – Assembly

General Notes

Cranckshaft

Pistons, Pistons Rings And Connecting Rods

Cylinder Head

Oil Pump And , Timing System Intermediate Gears

Engine Flywheel

Camshaft

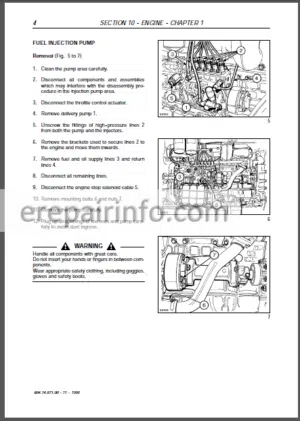

Injectors Pump

Rocker Arm Shaft

Completing The Engine

Assembly Diagram For Fan Drive Belt – Water Pump – Alternator

Crankcase, Cylinder Liners

Crankshaft, Bearings

Selecting Main And Big End Bearing Shells

Main Journals

Crankpins

Selecting Small End Bearings (Pins With Nominal Diameter)

Selecting The Main Bearing Shells (Pins With Nominal Diameter)

Selecting The Main Bearing Shells (Pins With Nominal Diameter)

Selecting The Main Bearing Shells (Ground Pins)

Selecting The Big End Bearing Shells (Pins With Nominal Diameter)

Selecting The Big End Bearing Shells (Ground Pins)

Checking Main Journal Assembly Clearance

Tightening Sequence Of The Screws Fixing The Sub–Crankcase Under The Crankcase

Remove The Sub–Crankcase

Checking Crankshaft End Float

Pistons

Connecting Rods

Piston And Connecting Rod – Assembly

Cylinder Head

Tappets And Camshaft

Valve Springs, Rocker Arm Shaft And Rocker Arms

Lubrication System

Cooling Circuit

Fuel Supply

Replacing The Valve Guides

Injector Case – Replacement

Cranckshaft Front Cover Seal – Replacement

Adjusting Clearance Of Rocker Arms To Valves And Pre–Load Of Pump Injector Rocker Arms

Pump Injector – Removal – Refitting

Bleeding The Fuel Supply System

Water Pump – Removal–Refitting

Thermostat – Removel – Refitting

-– IVECO Engine F3B – General

Engine Description

Engine Main Components

Cranckshaft

Crankcase Gas Ring

Connecting Rods

Pistons

Cylinder Head

Camshaft

Intake Valve Control

Exhaust Valve Control

Injector–Pump Control

Camshaft Drive

Camshaft Driving

Engine Flywheel

Auxiliary Component Control

Oil Sump

Oil Filter

Fuel Supply

Main Components Of The Ms6 Edc System

Pump Injector

Operation

Filling Phase

Injection Phase

Pressure Reduction Phase

Ms62 Electronic Control Unit

Control Unit Operation

Fuel Batching

Flow–Rate Correction Depending On Water Temperature

Flow–Rate Correction To Avoid Noises, Fumes Or Overloads

De–Rating

Electronic Injection Spark Advance Check

Speed Regulator

Engine Start–Up

Cold Start–Up

Hot Start–Up

Run Up

After Run

Cylinder Balancing

Synchronisation Search

Engine Coolant Temperature Sensor

Fuel Temperature Sensor

Supercharging Air Temperature Sensor

Supercharging Pressure Sensor

Flywheel Sensor

Distribution Sensor

Pre – After Heating Resistance

-– Iveco Engine F3B

General Specification

Fuel System Data

Main Data

Torque Settings

Plan Of Tightening Sequence

Tools

Mechanical Troubleshooting

Engine – Disassembly – Assembly

General Notes

Crankshaft

Pistons And Connecting Rods

Cylinder Head

Oil Pump And Intermediate Timing Gears

Engine Flywheel

Camshaft

Injectors Pump

Rocker Arm Shaft

Completing The Engine

Crankcase And Cylinder Liners

Crankshaft And Bearings

Selecting Main And Big End Bearing Shells

Preliminary Appraisal Of Data To Make The Selection

Main Journals

Crankpins

Selecting Small End Bearings (Pins With Nominal Diameter)

Selecting The Main Bearing Shells (Pins With Nominal Diameter)

Selecting The Main Bearing Shells (Pins With Nominal Diameter)

Selection Of Main Half-Bearings (Rectified Pins)

Selecting The Big End Bearing Shells (Pins With Nominal Diameter)

Selection Of Connecting Rod Half-Bearings (Rectified Pins)

Checking Main Journal Assembly Clearance

Remove The Sub–Crankcase

Checking Crankshaft End Float

Pistons

Connecting Rods

Piston – Connecting Rod Assembly

Cylinder Head

Valves

Tappets And Camshaft

Valve Springs, Rocker Arm Shaft And Rocker Arms

Lubrication System

Cooling System

Fuel Supply

Valve Guides – Replacement

Injector Case – Replacement

Crankshaft Front Cover Seal – Replacement

Clearance Of Valves To Rocker Arms And Pre–Load Of Pump Injector Rocker Arms

Pump Injector – Removal, Refitting

Bleeding The Fuel Supply System

Water Pump – Removal, Refitting

Thermostat – Removal, Refitting

-– Caterpillar Engine

General

New Holland – Caterpillar

Caterpillar Engine

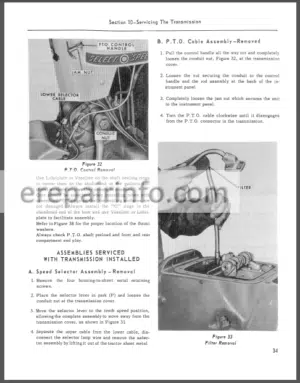

Service / Parts - – Transmission

Specifications

Tightening Torques And Adjustments

Special Tools

Gearbox Shafts

Shifting Diagram

–Disassembly Of Traction Gearbox

General

Removal Of Selector Forks And Shifter Shafts

Removal Of Drive Shaft

Removal Of The Countershaft

Removal Of Transmission Main Shaft

Removal Of The Half–Shaft From The Differential

Removal Of The Differential

–Assembly Of Traction Gearbox

Assembly Of The Differential

Assembly Of The Half+ Shafts Of The Differential

Assembly Of Transmission Main Shaft

Assembly Of The Countershaft

Assembly Of The Drive Shaft

Assembly Of Selector Shafts And Forks

Calculation Of Shims To Be Installed On The Shafts

Assembly Of The Cover - – 4Wd Lines

Specifications

Tightening Torques

Special Tools

Self–Made Tools

Gearbox Shafts

Wd Gearbox – Removal

Wd Gearbox – Components

Wd Gearbox – Disassembly

Intermediate Shaft

Input Shaft

Output Shaft And Clutch

Clutch Cylinder

Wd Gearbox – Assembly

Clutch Cylinder

Output Shaft And Clutch – Pre Assembly

Input Shaft – Pre Assembly

Intermediate Shaft – Installation

Input Shaft – Installation

Cover – Installation

Clutch Pre–Assembly – Installation

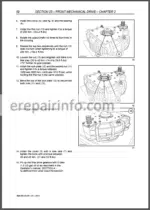

Wd Gearbox – Installation - – Front Mechanical Drive

-– Final Drives Fx30

—Final Drives – Disassembly

Output Shaft

Input Shaft

—Final Drives – Assembly

Input Shaft

End Play Adjustment

Output Shaft

Preload Adjustment

-– Final Drives Fx40–50–60

Specifications

Tightening Torques

Gearbox shafts

Wheel bolt – Replacement

Final drive – R/ I

— Final drive D/A

Disassembly

Assembly - – Hydrostatic System

Hydrostatic Circuit And Components

Circuit

Hydrostatic Pump And Motor Identification Plate

Hydrostatic Pump

Pump Operation

Circuit

Pump Characteristics

Multifunction Valve

Servo Valve

System In Neutral

Servo Solenoid Valve Energized

Hydrostatic Motor

Fixed Displacement Motors

Drive Motor Characteristics

Oil Cooler Bypass Valve

Filling And Bleeding The Hydrostatic System

Starting The Hydrostatic System - – Brakes And Control

–Brake System

General

Road Mode

— Parking Brake Adjustment

— Replacement Of The Brake Linings

Removal

Installation

— Bleeding The Brakes

Bleeding The Left–Hand Side Circuit

Bleeding The Connection Pipe Between The Two Main Cylinders

Bleeding The Right–Hand Side Circuit

— Disassembly And Assembly Of Brake Shoes And Discs

Disassembly Of Brake Shoes

Disassembly Of Brake Discs

Assembly Of Brake Discs

Assembly Of Brake Shoes - – Hydraulic System

-– General

Torque Tables For Hydraulic Components

Union Nuts

Ferrules

Metric Fittings

Unions

Connections

Swivel Nut With Ball-Type Nipple

Pump Group – Disassembly And Assembly

Disassembly Of The Pump Group

Removal Of The Triple Pump From The Hydrostatic Pump

Splitting Of The Triple Pump

Assembly Of The Pump Group

Installation Of The Pump Group To The Hydrostatic Pump

-– Work Hydraulics – Attachment Height Control

Circuit Diagrams 2

Work Hydraulics – Attachment Height Control 2

Hydraulic Oil Reservoir

Low Pressure Filter

Breather

High Pressure Filter

Non–Return Valve

Function

Work Hydraulics Pump

Specifications

High Pressure Relief Valve

Attachment Height Control Valve (Emr)

Neutral Position

Attachment Lifting Position

Attachment Lowering Position

Pressure Relief Valve H

Emergency Hand Buttons

Specifications

Attachment Compensation Valve

Specifications

Transport Mode

Compensation Mode

Stubble Height Mode

Pressure Sensor

Specifications

Hydropneumatic Accumulators

Filling

Attachment Lift Cylinders

-– Work Hydraulics – Base Unit

Circuit Diagrams – Base Unit

Stack Valve

Repair Of Control Valves

Load Sensing Valve

System In Neutral

Cutterhead Reverse Drive Motor

Specifications

Spout Rotation Pressure Relief Valve

Spout Rotation Motor

Specifications

Quick–Release Couplings

Specifications

Spout Lift Cylinder

Cylinder Disassembly And Assembly

Reinstallation Of Spout Lift Cylinder

-– Low Pressure Hydraulics

Circuit Diagrams – Low Pressure Hydraulics

Low Pressure Hydraulic Reservoir

Oil And Filter Change Procedure

Oil Pressure Check Procedure

Filling The System When (Re)Installing The Low Pressure Pump

Filling The System After (Re)Installing The Main Drive Transfer Gearbox

Low Pressure Pump

Specifications

Low Pressure Valve

Main Drive Belt Tensioning Cylinder

Spout Deflector Cylinder

-– High–Flow Hydraulics

Circuit Diagrams – High–Flow Hydraulics - – Cab Climate Control

Correct Use Of The Airconditioning System

Storage Maintenance

Air Conditioning Circuit

Components

Specifications

Refrigerant

Compressor

Compressor Clutch

Circuit Parameters

Low Pressure Switch

High Pressure Switch

Filter–Drier

Compressor Clutch Replacement

Clutch Removal

Clutch Installation

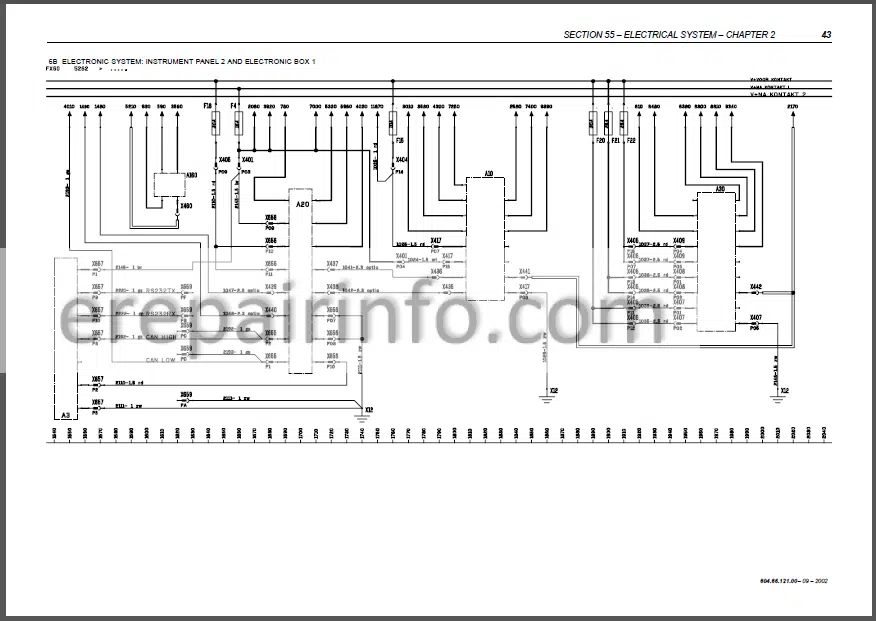

Ventilation Unit - – Electrical System

-– General

General Information

Wires2

Color Code

Wire Identification

Fuses

Symbols

Relays

Connectors

-– Wiring Diagrams Fx Europe

Wiring Diagrams Fx Europe

-– Wiring Diagrams Fx North America

Wiring Diagrams Fx Na

-– Can Network Basics

Can Network Basics

General Layout Electronic System

Electronic Components

Conclusion

Electronic System Layout

Input

Output

Analog Signals (From Input Or To Output)

Digital Information

Interfaces

Software

Calibrations

Additional Info:

Can Spy

Decimal And Hexadecimal Counting

Decimal

Hexadecimal

How To Use The Can Identifiers

How To Enter Can–Spy

Can–Spy In Practice

Error Codes Messages

Wiring Checking Procedure

Fault Finding Routine

-– Calibration

General

Special Tools

Machine Calibration With Est Tool

Configuration Item Selection Screen

Maximum Handle Position Calibration

Minimum Forward Pump Current Calibration

Minimum Reverse Pump Current Calibration

Vehicle Configuration

-– Software Update

Software Revision

Software Update With Est Tool

-– Troubleshooting

Machine Error Messages

Attachment Height Control Error Messages

Error Reports

Caterpillar Error Messages

List Of Can Identifiers

Detailed Analisys Per Function

Electric Conditions, Engine Running Or Not Running

Engine Protection

Harvest Mode

Cutterhead Engagement

Feed Rolls Forward Engagement

Feed Rolls Reverse Engagement

Power Reverse

Four–Wheel Drive

Spout Rotation

Raise / Lower Spout

Spout Deflector

Reverse Cutterhead

Auxiliary Front Hydraulics

Auxiliary Rear Hydraulics

Air Conditioning

Silage Additives Application

Knife Sharpening

Adjust–O–Matic Routine

Crop Processor

Metal Detector Operation And Troubleshooting

Attachment Height Control

Ground Speed

High Flow Hydraulics

Rotary Screens

Rotary Screen Brushes

Caterpillar Engine

Can Network - – Product Feeding

-– Feed rolls

—Metal Detector Roll

Removal

Disassembly

—Metal Detector Components – D/A

Disassembly

Assembly

Assembly

Installation

—Smooth Roll

Removal

Installation

—Upper Feed Rolls – R/I

Before Removal

Removal Of The Upper Feed Rolls As A Complete Assembly

Removal Of The Upper Feed Rolls As Separate Components

Replacing Wear Plates On The Upper Feed Rolls Frame

Installation

-– Hydroloc Gearbox

Hydroloc Gearbox – R/I

Removal

Installation

Gearbox Shafts

Specifications

Hydroloc Gearbox – D/A

Alternative Drive Shaft

Transfer Shaft

Upper Feed Rolls Drive Shaft

Selector Shaft

Smooth Roll Drive Shaft

Metal Detector Roll Drive Shaft

Reinstall The Alternative Drive Shaft

Install Seals And Covers

-– Attachments Drive Gearbox

—Attachments Drive Gearbox – R/I

Removal

Installation

–Gearbox Shafts

–Specifications

—Attachments Drive Gearbox – D/A

Assembly

Idler Shaft

Input Shaft

Transfer Shaft

Attachment Drive Shaft

Idler Shaft – Re–Installation

-– Upper Feed Rolls Drive Gearbox

–Special Tools

—Upper Feed Rolls Drive Gearbox – R/I

Removal

Installation

Gearbox Shafts

Specifications

—Upper Feed Rolls Drive Gearbox – D/A

Assembly

Upper Feed Rolls Drive Shaft

Front Upper Feed Roll Drive Shaft

Rear Upper Feed Roll Drive Shaft

Re–Install The Upper Feed Rolls Drive Shaft

Seals And Cover - – Chopping

-– Cutterhead

Splitting Of Components

—Rotor And Bearings – R/I

Removal

Assembly

–Shearbar – R/I

—Shearbar Support – R/I

Removal

Installation

-– Cutterhead Gearbox

—Cutterhead Gearbox – R/I

Removal

Installation

—Cutterhead Gearbox – D/A

Oil Cooler – D/A

Gearbox – Disassembly

Input Shaft

Output Shaft

— Gearbox – Assembly

Input Shaft

Output Shaft

Backlash - – Ejection

-– Blower Gearbox

Inspection Between Cutterhead And Blower

Blower – R/I

Blower Gearbox – R/I

—Blower Gearbox – D/A

Disassembly

Assembly

Input Shaft

Output Shaft

Adjusting The Shimming

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet