Factory Operators Manual For New Holland 8670, 8770, 8870, 8970 Tractor. Manual for owners and operators. It contains important information and instructions for maintenance description of the functions and capabilities of the system. Description of possible faults / problems and their solution.

Format: PDF

Language: English

Pages: 312

Number: 86588682

Bookmarks: Yes

Model

New Holland Tractor

8670

8770

8870

8970

Serial #D420957 and above

Contents

Adapting Ballast To Work Load And Ground Speed

Adding Diesel Fuel

Adjustable Pressurizer Vents

Adjusting Drawbar Length

Adjusting Rear Wheels

Air Conditioner Activation Switch

Air Conditioning Operation

Antifreeze

Attaching And Detaching Trailed Equipment

Attaching Equipment To The Pto Shaft

Attaching 3-Point Equipment

Audible Alarm

Auto Shift

Automatic Display Information

Automatic Engine Shutdown

Auxiliary Connector, Seven Pin

Auxiliary Connector, Single Pin

Auxiliary Connector, Three Pin

Auxiliary Control Mounting Locations

Auxiliary Control Cable Routing

Ballast Limitations

Ballast, Selecting

Ballasting

Ballasting And Tires

Ballasting Front End For Transport

Ballasting Four Wheel Drive Tractors

Ballasting, Points To Remember

Ballasting Two Wheel Drive Tractors

Bar Graph Displays

Battery Cover

Before Operating

Bleeding Remote Cylinders

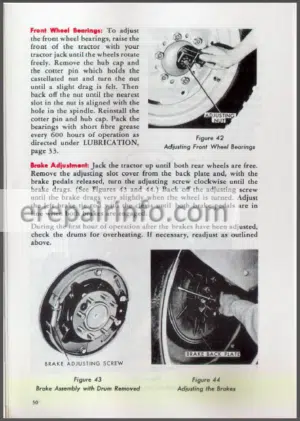

Brakes

Brakes Specifications

Brake Locking Plate

Breaking-In Procedure

Cab

Cab Identification

Cancel Flashing Service Indicator

Capacities

Central Display (Lcd)

Changing The Pto Output Shaft

Check Wheel Slippage

Cigar Lighter

Cleaning Fault Codes

Cleaning The Cab Interior

Closing The Hood

Cold Start Aid Switch

Cold Weather Starting

Connecting Double-Acting Cylinders

Connecting Single-Acting Cylinders

Controls

Control And Instruments, Overview

Control Levers

Cooling System Specifications

Creeper Gears

Creeper Switch

Delivery Reports

Determining Maximum Front Ballast

Determining 3-Point Hitch Mode Of Operation Diesel Fuel

Diesel Fuel Selection Chart

Differential Lock

Differential Lock, Engaging And Disengaging Differential Lock Switch

Digital Display

Disconnecting The Negative Battery Cable Doors

Draft Control Operation

Drawbar Height Adjustment

Drawbar Length

Drawbar Specifications

Drawbar-Towing Attachments

Driving The Tractor

Drop Rate Control Knob

Dual Rear Wheels

Eic Lighting Display

Eic Tractor Performance Monitor (Tpm)

Electronic Instrument Cluster

Electrical Specifications

Eliminating Ballast Requirements

Emergency Stopping And Parking Brake

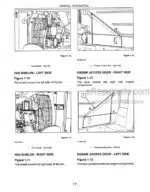

Engine Access Doors

Engine Access Door, Left Side

Engine Access Door, Right Side

Engine Block Heater

Engine Hood

Engine Identification

Engine Lubricant

Engine Shutdown Override

Engine Specifications

Engine Speed-Digital Display

Entering The Cab

Exiting The Set Up Mode

External 3-Point Hitch Controls

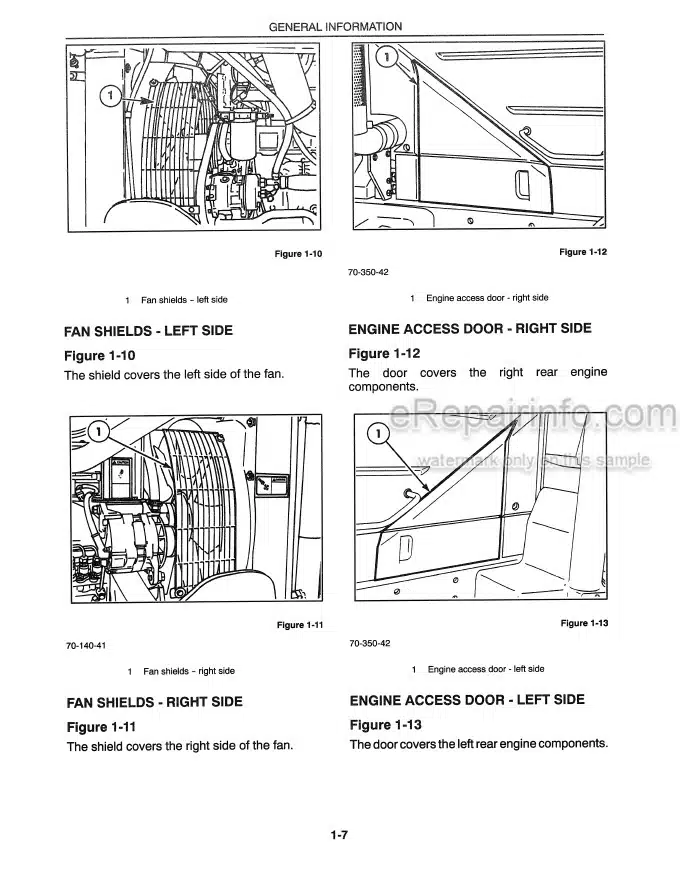

Fan Shields, Left Side

Fan Shields, Right Side

Fast Raise/Work Switch

Fault Codes

Fault Codes On/Off

Field Operation

Flexible Link Ends

Flexible Maintenance Intervals

First 50-Hour Service

Flow Control Adjustment

Foot/Floor Controls

Foot Brakes

Foot Brake Pedals

Foot Throttle

Forward Operator Controls

Four Wheel Drive (Fwd)

Four Wheel Drive (Fwd), Engaging And Disengaging

Four Wheel Drive (Fwd) Front Axle Identification

Four Wheel Drive (Fwd) Front Axle Track Spacing

Four Wheel Drive Operating Precautions

Four Wheel Drive Steering Stops

Four Wheel Drive (Fwd) Switch

Four Wheel Drive Tire Combinations

Four Wheel Drive Track Adjustment

Front Tires – Liquid Weight

Front Weights – Cast Iron

Front Wheel Positions

Front Wheel Track Spacing

Front/Rear Lights

Front Wheel Position (2Wd)

Front Windshield Wiper/Washer Switch

Fuel Requirements

Fuel Storage

Fuel System Specifications

Fueling The Tractor

Fuse Replacement

General Dimensions

General Information

Ground Speed Charts

Guide Blocks, Spacers And Shims

Hand Throttle Control Lever

Hardware Torque Values

Hauling The Tractor On A Transporter

Hazard Warning Light Switch

Hazard Warning Lights

Headlight Flash

Headlights High/Low Beams

Heater Operation

Height Limit Control Knob

Hitch Pin

Hood

Horn

Hydraulic Motor Application

Hydraulic Oil Sump Heater

Hydraulic Systems Introduction

Hydraulic System Specifications

Implement To Cab Clearance

Inch Hardware And Locknuts

Inching Pedal

Indicator Warning Lamps And Audible Alarm Installing Cast Iron Weights

Installing Front Weights

Interior Lights

Interior Rearview Mirror

Introduction

Key Start/Stop Switch

Lift Control Lever

Lift Rods

Light And Accessory Power Points

Lights, Control Console Illumination

Linkage Category Conversion

Low Pressure Return Circuit

Lower Link Float

Lubricants

Lubrication And Maintenance

Lubrication And Maintenance Chart

Lubrication And Maintenance, As Required

Lubrication And Maintenance, Every 10 Hours Or Daily

Lubrication And Maintenance, Every 50 Hours

Lubrication And Maintenance, Every 300 Hours

Lubrication And Maintenance, Every 600 Hours

Lubrication And Maintenance, Every 900 Hours Or 12 Months

Lubrication And Maintenance, Every 1200 Hours Or 12 Months

Lubrication And Maintenance, Every 2400 Hours Or 24 Months

Lubrication And Maintenance, General Maintenance

Main Distribution Panel

Master Light Switch

Maximum Tractor Operating Angel

Mega Flow Tractor

Metric Hardware And Locknuts

Minimum Hardware Tightening Torques

Modes Of Operation

Multi-Function Switch

Oil Change Intervals

Opening The Access Doors

Opening The Hood

Operating Continuous Flow

Hydraulic Equipment

Operating Remote Equipment Simultaneously

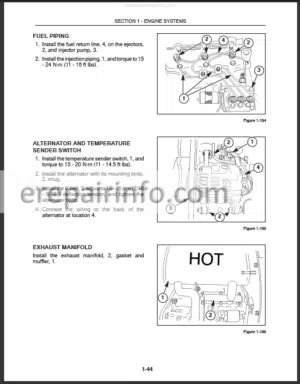

Operating The Engine

Operation

Operator Prompt

Operator Calibration

Operator’S Manual Holder

Operator’S Seat

Overhead Controls

Panel Dim Control

Parking Brake

Position/Draft Sensitivity Control Knobs

Powershift Transmission Control Lever With Neutral Lock

Power Take-Off (PTO) Independent

Power Take-Off Specifications

Precautionary Statements

Pre-Operation Checks

Preparation For Tractor Storage

Preparing The Tractor For Use After Storage

Preparing To Start The Tractor

Pressurizer Fan Speed Switch

Pressurizer Operation

Pressurizer Vents

Programming Reverse Gear Ratios

Programming The Up/Down Shift

Programmable Up Shift-Down Shift

Protecting The Electronic/Electrical Systems During Charging Or Welding

Protective Shielding

PTO Engagement Switch

PTO Master Shield

PTO Operation

PTO Status Light

Publications Order Form

Quick Couplers

Quick Hitch

Radio

Rear Axle Identification

Rear Tire Weighting

Rear Wheel Cast Iron Rear Wheel Weights

Rear Wheel Track Adjustment

Rear Wheel Track Spacing

Rear Window

Rear Window Wiper/Washer Switch

Relay

Remote Control Valves

Remote Hydraulic Valve Control Levers

Removing Equipment

Removing Shields

Removing The Access Doors

Removing The Battery Cover

Replace Headlight Assembly Bulbs

Replace Work Sealed Beam Units

Right Hand Console

Right Side Console Controls

Right Side Console Position

Right Side Window

Road Speeds

Rotary Beacon

Rotary Beacon Switch

Rotary Lockout Gates

Rotary Lock Gates

Safety

Safety Decals

Seat Adjustments

Seat Belt

Selectable Displays

Selectable Display Information

Service Engine Air Cleaner

Service Reports

Shielding

Shield Locations

Shuttle Operations

Slip Limit Control Knob

Specifications

Speed Matching

Standard Flow Tractors

Starter Solenoid Shield

Starting The Engine And Moving Forward

Starting The Engine And Moving In Reverse

Starting The Engine In Warm Weather Or When Engine Is Hot

Starting The Tractor With Jumper Cables

Steering Column Telescopic Adjustment Control Knob

Steering Column Tilt Control Lever

Steering Specifications

Steering Wheel And Column

Stopping The Engine

Sway Blocks

Swinging Drawbar

Temperature Control Switch

Three-Point Lift

3-Point Hitch Controls

3-Point Hitch Fast Raise/Work Switch

3-Point Hitch Float

3-Point Hitch Height Limit Control

3-Point Hitch Lift Control

3-Point Hitch Linkage

3-Point Hitch Position/Draft Control

3-Point Hitch Rate Of Drop Control

3-Point Hitch Slip Control

3-Point Hitch Status Light

Tire Pressures And Permissible Loads

Tire Pressures And Permissible Loads Charts

Tires

Tires And Ballasting

Toolbox

Top Link

Towing The Tractor

Tractor Identification

Tractor Identification Data

Tractor Identification Plate

Tractor Master PTO Shield

Tractor PTO Stub Shaft Cover

Tractor Hauling

Tractor Towing

Transmission

Transmission Auto Shift Switch

Transmission Gear Shift Position Display

Transmission Identification

Transmission Programming

Transmission Specifications

Transmission Up/Down Shift Switch

Troubleshooting

Troubleshooting And Fault Finding

Troubleshooting, Brakes

Troubleshooting, Cab

Troubleshooting, Electrical System

Troubleshooting, Engine

Troubleshooting, Hydraulic System

Troubleshooting, 3-Point Hitch

Troubleshooting, Transmission

Turn Signals

2Wd Axle Adjustment

2Wd Front Axle Track Spacing

2Wd Front Wheel Track Spacing

2Wd Front Wheel Toe-In

Ultra-Command Powershift Transmission

Universal Symbols

Warning Lamp

Weight Specifications

Wheel Toe-In (Fwd)

Wide Swinging Roller Drawbar

Windshield Wiper/Washer, Front/Rear

Work Lights

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet