Factory Service Repair Manual For New Holland D255 Crawler Dozer. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 337

Searchable: Yes

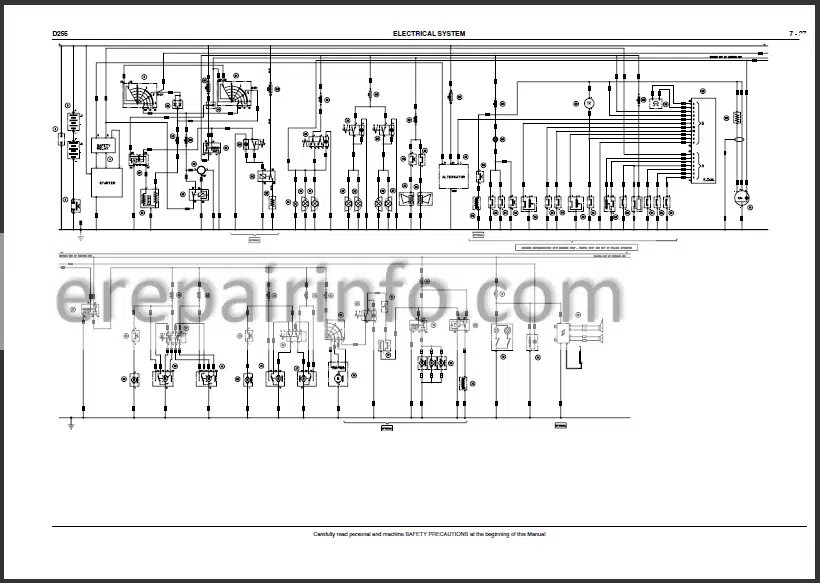

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

New Holland D255

Contents

- Generalities

- Engine

- Transmission-Torque Converter

- Steering Clutches – Brakes

- Final Drives

- Undercarriage

- Dozer Equipment

- Hydraulic System

- Electrical System

- Air Conditioning Unit

Full contents

-Generalities

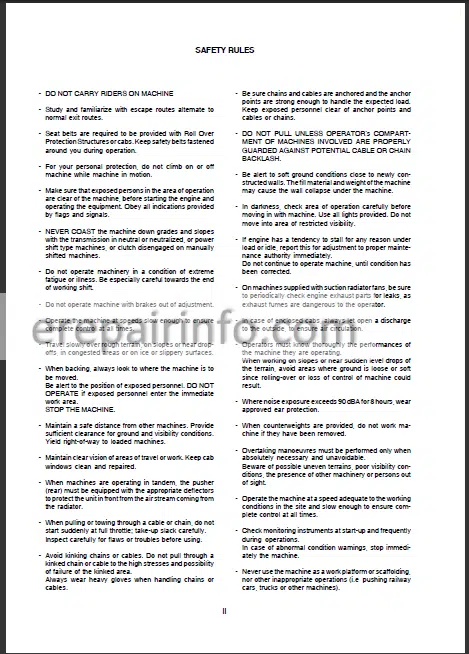

Safety Rules

Technical Data Tables

General Instructions

Diagnostic Checks

Measure Units

Classification Of Standard Parts

Tightening Torques

-Engine

General Specifications

Series “C” Engine Data

Diagrams Of Series “C” Engine

Mounting Of Engine On Frame

Aftercooler Fan Drive System

16 Throttle Linkage

-Transmission

General Description

Troubleshooting

–Converter

Removal

Disassembly

Checking Parts

Converter Safety Valve

–Transmission

Removal

Disassembly Transmission

Disassembly Clutch

Assembly Transmission

Lubrication Oil Pressure Regulating Valve

Relief Valve

Assembly Clutch

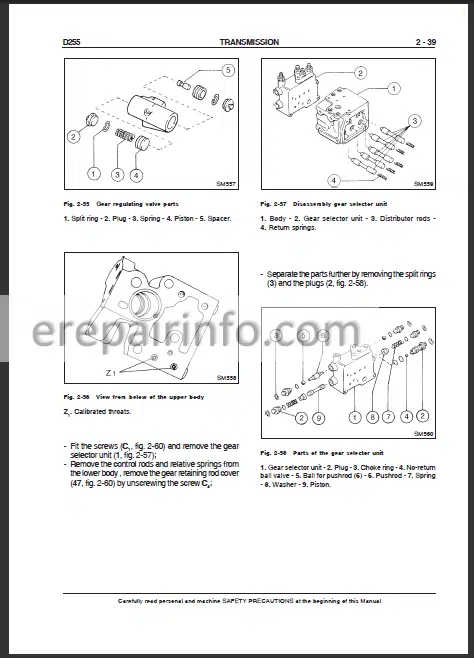

–Transmission Distributor

Removal And Disassembly

Checking Parts

–Control Lever

Disassembly

Operating Diagram

Checking Parts

Safety Deflector

–Converter/Transmission Hydraulic Pumps

Disassembly And Testing

Transmission Oil Heat Exchanger

Cleaning And Checking Parts

–Drive Shaft/Converter/Transmission

Disassembly And Testing

Assembly

–Oil Filter Converter – Transmission

–Testing Transmission/Converter On The Vehicle

Testing Gear Selection With Converter In Stall

Checking Transmission-Converter Pressure

Checking Clutch Pressure

Lubricating Oil Pressure

Converter Oil Pressure

Transmission Feed Pressure Check

—

Technical Data

Tightening Torques

Special Tools

-Steering Clutches And Brakes

General Description

Troubleshooting Of Major Malfunctions

–Central Reduction Bevel Gear Set

Disassembly

Assembly

Setting Of Bevel Gear

–Steering Clutches And Brakes

Removal Of Brake Bands

Disassembly

Inspection Of Clutch Packs

Assembly Of Steering Clutches

Installation Of Steering Clutches And Setting

–Brake Cylinder

Steering Clutch And Brake Hydraulic Pump

Inspection Of Components

–Oil Filters

Steering Clutch And Brakes Control Valve

Disassembly Of Control Valve

Inspection Of Components

–Brakes Control Valve

Disassembly

Inspection Of Components

–Control Pilot Valve

Disassembly Of Pilot Valve

Inspection Of Components

–Tests

Check Of Clutch-Brakes Control Valve Pressures

Adjustment Of Brake Pedal

Check Of Brakes System Pressures

—

Specifications And Data

Tightening Torques

Special Tools

-Final Drives And Sprockets

Description

Removal

Disassembly

Inspection Of Sprockets

Assembly

Installation

Specifications And Data

Tightening Torques

Special Tools

-Undercarriage

General Description

Troubleshooting Of Major Malfunctions

–Track Chains

Disassembly

Inspection Of Undercarriage Components

Replacement Of A Damaged Link

–Track Adjustment Mechanism

Disassembly

Setting Of Hydraulic Adjuster Cylinder Relief Valve

Inspection And Adjustment Of Track Chain Tension

–Track Idler Wheels

Removal

Overhaul

Installation And Adjustment

–Track Rollers

Removal

Overhaul

–Track Carrier Rollers

Disassembly

–Lubrication Of Rollers And Track Idler Wheels

–Track Frames

Inspection Of Track Frames

Track Frame Adjustment

Track Frame Pivots

—

Front Suspension

Specifications And Data

Tightening Torque

Special Tools

-Hydraulic System For Angledozer Equipment

–General Description

Rapid Release Valve

–Trouble Shooting

–Hydraulic Oil Tank And Oil Filters

Filters

Removal Of The Tank

–Hydraulic Pump

Removal

Overhaul Of The Control Pump

Pump Overhaul

Reassembly

Flow Testing

–Distributor

Removal

Disassembly And Overhaul

Reassembly

Hydraulic Bench Testing Of Distributor

Checking And Setting The Main Safety Valve On The Machine

—

Arch And Blade Of The Angledozer

Blade Raising And Lowering Control Cylinders

Rapid Release Valves

Ripper

Technical Data

Tightening Torques

Special Equipment

-Electrical System

Safety Rules

Location Of Main Electrical Components

–Fuses

Connection For Engine Starting External Electric Power Source

Electrical System Master Switch

Starter Motor

Engine Starting Key Switch

Engine Cut-Off Solenoid

Back-Up Alarm Pressure Switch

Back-Up Alarm

Diverter Box

Alternator

Right And Left Brake Failure Sensors

Engine Coolant Max Temperature Switch

Air Cleaner Clogging Sensor

Hydraulic Oil Filter Clogging Sensor

Transmission Oil Max Temperature Switch

Engine Oil Low Pressure Sensor

Fuel Level Sensor

Engine Coolant Level Sensor

Engine Oil Low Level Sensor

Transmission Oil Low Level Sensor

Transmission Oil Low Pressure Sensor

Buzzer

EDM Control Module

Air Conditioner Solenoid Switch

Services Solenoid Switch

Diodes Box

Cab Services Solenoid Switch

“Link” Fuses

Starter Safety Solenoid Switch

Wiring Diagram

-Air Conditioning Unit

–Air Conditioning Unit

Operating Instructions

Technical Data

Cab Climate Conditioner

Service Precautions

Tool Connections

Discharging

Refrigerant Charging

Leak Inspection

Special Tools

Troubleshooting

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet