Factory Service Repair Manual For New Holland F106.6, F106.6A Graders. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 579

Bookmarks: No

Searchable: Yes

Number: 60413567

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

New Holland F106.6, F106.6A

Contents

- Safety Instructions

Fundamental Safety Instructions

Warnings And Symbols

Designated Use

Organizational Measures

Selection And Qualification Of Personnel

Basic Responsibilities

Safety Instructions Governing Specific Operational Phases

Special Work In Conjunction With Use Of The Machine

Maintenance And Repairs During Operation

Disposal Of Parts And Consumables

Warning Of Special Dangers

Transporting And Towing

Recommissioning

Warning And Instruction Signs

Left Side

Right Side

Operation

General Instructions

Refuelling

Refuelling System (Option)

Driving

Machine Recovery / Towing

Tow Rod Coupling

Transport

Crane Loading

Working Operation

Grader Deployment

Working Equipment

Securing The Machine

Inspection And Servicing

General Instructions

Fuel System

Electrical System

Powershift Transmission

Hydraulic System

Brakes

Tyres And Wheels

Air Conditioner (Option)

Repair Work - Technical Data

Dimensions

Main Dimensions

Travel Dimensions

Working Dimensions

Tyres

Types And Inflating Pressures

Wheel Nuts Tightening Torque

Max Speeds

Engine

Engine Specifications

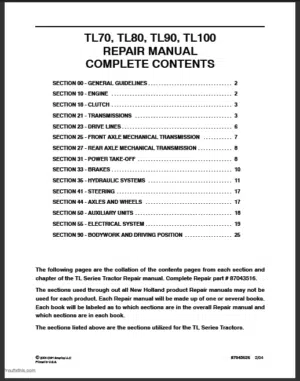

Transmission

Transmission Specifications

Transmission Ratios

Hydraulic System

Working Equipment Pump

Front Wheel Drive Pump (Only For F1066A)

Radial Piston Motor (Only For F1066A)

Blade Rotation Motor

Cylinders

Brakes

Brakes Specifications

Steering

Steering Specifications

Fluids And Lubricants - Engine

Engine F4Be0684K

Engine Coding

Main Engine Features

Graphic Indications And Symbols

Technical Data

Tightening Torques

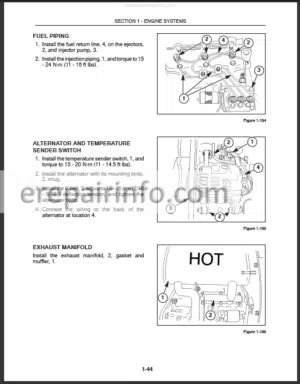

Engine Removal – Installation

Removal

Engine – Transmission Separation

Engine – Transmission Junction

Installation

General Remarks

Description Of Main Mechanic Engine Components

Injection Assembly

Recharge And Start-Up

Starter Motor

Alternator

Diagnostics - Transmission

Torque converter

Measuring point and connection

Powershift transmission

Hydraulic system

Electrical system

Maintenance

ZF DIAGNOSTIC SYSTEM

Generalities

Automatic calibration of the shifting elements

Diagnosis

Diagnostic inspection

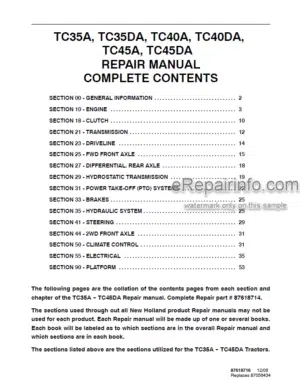

Troubleshooting - Rear Axle

Foreseen Uses

Product Identification

General Description

Technical Features

Filling And Checks

Service Schedule

Lubrication / Greasing: Grades And Application Range

Tightening Torques

Special Tools

Tandem Axle Removal – Installation

Side boxes

Wheel hub

Half axle

Differential

Pinion - Front Axle

Foreseen Uses

Product Identification

General Description

Technical Features

Sealing Compounds And Adhesives

Tightening Torques

Special Tools

Front Wheel Drive System (Only For F1066A)

Technical Data

Hydraulic System

Hydraulic Diagram

Components

Front Axle Removal – Installation

Hub and final drive (only for F1066A)

Body

Steering cylinder

Wheel rake cylinder

Hydraulic installation (only for F1066A) - Attachment

Central Attachment

Front Attachment

Rear Attachment

Front Frame - Hydraulic System

Field Of Application

Main Components

Power Generation Group

Hydraulic Diagrams

Main Functions

Working Equipments

Front-Wheel Drive (Only For F1066A)

Brake / Steer

Oil Cooling

Special Functions

Operation

Main Components

Control Block

Double Pump

Valve Block

Hydraulic Filter

Hydraulic Motor, Blade Rotating Unit (Geared Motor Orbit)

Blade Lift Cylinder Rh / Lh

Blade Slewing Cylinder

Slewing Arm Stop Bolt Cylinder

Blade Shifting Cylinder

Tip Cylinder, (Blade Cutting Angle Adjustment)

Offset Cylinder

Rear Ripper Cylinder (Option)

Front Grading Blade Cylinder (Option)

Wheel Rake Cylinder

Steering Cylinder

Radial Piston Motor (Only For F1066A)

Oil Rotating Feed Rotor

Maintenance

Maintenance Plan

Inspection Operations

Detailed Description Of The Inspection Operations

Actuator for working equipments

Valve block, control block (upper, lower), valves

Double pump

Radial piston motor (only for F1066A)

Oil rotating feed rotor - Brake System

Brake System Components – Operation Description

Accumulator Loading Valve – Cut-Off Valve

Brake Valve

Warning And Signalling Devices - Steering System

STEERING SYSTEM COMPONENTS – OPERATION DESCRIPTION

Collecting block steering/emergency steering

Steering servostat

Transverse flushing

Safety valve 12 bar - Electrical System

Wiring Diagram

Control Panel

Indicator Module

Key Module

Right Side Console

Fuses

Relays

Wiring Diagram Sheets

Connectors Tables

Connectors Chart

Can-Bus System

Description

Functional Test

Components Of Can-Bus System

Description Of Connections

Electric Functions - Operator’S Cab

Cab And Control Platform Removal-Installation

Cab Removal

Control Platform Removal

Control Platform Installation

Cab Installation

Operator’S Cab Components

Ventilation And Heating

Generalities

Ventilation

Heating

Air Conditioner (Option)

Switching On The Air Conditioner

Setting The Air Temperature

Switching Off The Air Conditioner

Air Conditioning Components

Safety Instructions For Inspection And Servicing Work

Inspection And Servicing Work

Troubleshooting

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet