Factory Service Repair Manual For Same Same Silver 110 130 Tractors. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 584

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Same Silver 110, 130

Contents

- -GENERAL INFORMATION

SAFETY RULES

General Information

Starting

Operation

Stopping

MAINTENANCE

General Information

Engine

Electrical System

Hydraulic System

Tyres And Wheels

Recognise The Safety Warnings

Understand The Safety Terms

Protecting The Environment

Follow The Safety Rules

Prepare For Emergencies

Wear Protective Clothing

Protect Yourself Against Noise

Inspect The Tractor

Use The Handholds And Steps

Adjust The Driver’S Seat

Fasten The Seat Belts

Only Operate The Tractor From The Driver’S Seat

Never Carry Passengers On The Tractor

Avoid Accidents When Reversing

Avoid Accidents Caused By Movement Of The Tractor

CARRY OUT MAINTENANCE IN SAFE CONDITIONS

Warn Others That Maintenance Work Is In Progress

Keep Well Clear Of Moving Parts

Protect Yourself From Flying Splinters

Dispose Of All Waste In An Appropriate Manner

Work In A Clean Area

Ensure The Work Area Is Well Illuminated

Wash The Tractor Regularly

Avoid Acid Burns

Starting The Engine Using Auxiliary Batteries

Avoid Battery Explosions

Avoid Burns

Keep The Tractor Clean

Be Careful Of Fluids Under Pressure

Avoid The Danger Of Bursting Tyres

Handle Fluids Safely – Prevent Fires

Prevent Fires

Evacuation In Case Of Fire

Exhaust Gas

Use The Proper Tools

Do Not Apply Heat Near Pressurised Pipes

Do Not Heat Pipes Containing Inflammable Fluids

Remove Paint Before Welding Or Heating Parts

TIGHTENING TORQUES

Part

Tightening Torques (In Nm) For Bolts, Nuts And Studs

Lubricants Chart

List Of Tools

List Of Bulbs - -CHARACTERISTICS AND DATA

DIMENSIONS AND WEIGHTS

TECHNICAL DATA

Clutch

Gearbox

Rear Pto

Front Pto

Ground Speed Pto

Front Axle

Brakes

Steering

Hydraulic Rear Lift

Front Lift

Cab And Electrical System

SPEEDS

18+18 Gearbox – Speeds In Km/H With 520/70R38 Tyres

24+24 Gearbox— Speeds In Km/H With 520/70R38 Tyres

24+12 Gearbox — Speeds In Km/H With 520/70R38 Tyres

36+18 Gearbox— Speeds In Km/H With 520/70R38 Tyres

48+24 Gearbox— Speed In Km/H With 520/70R38 Tyres

72+72 Hml Gearbox- Speeds In Km/H With 520/70R38 Tyres

Tractor And Implement Combination

Rear Implement And Front And/Or Rear Implement Combinations

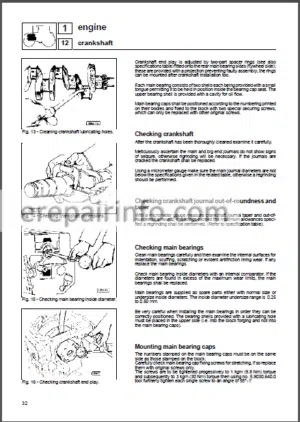

Mounted Front Implement - -ENGINE

ENGINE REMOVAL

REFITTING THE ENGINE

Final Operations - -CLUTCH

REMOVAL OF THE CLUTCH

Separation Of The Tractor Between The Engine Flange And Intermediate Transmission Casing

DISASSEMBLY OF THE CLUTCH

Cab Side

Engine Side

CLUTCH OVERHAUL

Checks

CLUTCH ASSEMBLY

Engine Side

Cab Side

REFITTING THE CLUTCH

Re-Attachment Of The Engine Flange To The Intermediate Transmission Casing

Bleeding The Hydraulic Clutch System - -GEARBOX

REMOVAL OF GEARBOX FROM REAR TRANSMISSION CASING

Disassembly Of The Super-Reduction

Removal Of The Lift Oil Filters

GEARBOX DISASSEMBLY

Removal Of The Fast Range Gears And Shuttle From The Gearbox/Rear Transmission Casing Flange

REFITTING THE GEARBOX

Refitting The Fast And Shuttle Gears On The Gearbox/Rear Transmission Casing Flange

Calculation Of The Shim Thickness For End Float Adjustment Of The Reduction Gear Shaft

Assembly Of Gearbox To Rear Transmission Casing 20

Refitting The Lift Oil Filters

Primary Shaft End Float Adjustment

Assembly Of The Super-Reduction Unit

Adjustment Of The Hml Unit End Float

OVERHAUL OF THE HML UNIT

Disassembly

Assembly

Gearbox/Transmission Diagram

Gearbox Detail

Hml Clutches Detail

Hml Control Valve Diagrams

Components Of The “L” And “Sr” Reduction Control

“L” And “Sr” Reduction Control Diagram (1)

Components Of The Shuttle Control (1)

Components Of The 1St -2Nd Speed Control (2)

SHUTTLE (1) AND 1ST -2ND SPEED (2) CONTROL DIAGRAM

Components Of The 3Rd -4Th Speed Control

3Rd -4Th Speed Control Diagram

Components Of The Shuttle Control

Componentsof The Gear Control

Shuttle And Gear Control Diagram46

Components Of The Min-Reduction Control (1)

Components Of The 5Th -6Th Speed Control (2)

Mini-Reduction (1) And 5Th -6Th Speed (2)Control Diagram

Components Of The “V” And “N” Reduction Control

“V” And “N” Reduction Control Diagram - -REAR TRANSMISSION

DISASSEMBLY OF THE REAR TRANSMISSION CASING

Checks And Adjustments

Checking The Play Between The 4Wd Clutch Plates

ASSEMBLY OF THE REAR TRANSMISSION CASING

Assembly Of The Ground Speed Pto

Assembly Of The Pto

Assembly Of The Parking Disc Brakes

Assembly Of The 4Wd Clutch

ADJUSTMENT AND ASSEMBLY OF THE BEVEL DRIVE

Adjustment Of The Crown Wheel Bearing Preload

Adjustment Of The Pinion Mounting Distance

Adjustment Of The Crown Wheel-Pinion Backlash

REAR DIFFERENTIAL WITH MECHANICAL LOCKING

Diagramme Of Rear Differential With Mechanical Locking

Diagramme Of Rear Differential With Electro-Hydraulic Locking (2-Planet Version)

Rear Differential With Hydraulic Control (4-Planet Version) - -POWER TAKE-OFFS

DISASSEMBLY OF THE POWER-TAKE-OFFS

Disassembly Of The Pto

Removal Of The Pto Clutch

Disassembly Of The Pto

Disassembly Of The Ground Speed Pto

ASSEMBLY OF THE POWER TAKE-OFFS

Assembly Of The Ground Speed Pto

Assembly Of The Pto

Refitting The Pto Clutch

Assembly Of The Economy Pto

CHECKS AND ADJUSTMENTS

Adjustment Of Economy Pto Engagement

Adjustment Of The Pto Selector Rod

Checking The Play Between Clutch Plates In The Hydraulic Pto Clutch - -BRAKES

DISASSEMBLY OF THE FRONT BRAKES

ASSEMBLY OF THE FRONT BRAKES

Bleeding The Front Brake Circuit

DISASSEMBLY OF THE REAR BRAKES

ASSEMBLY OF THE REAR BRAKES

Calculation Of Brake Adjustment Shim Thickness 6

Bleeding The Rear Brake Circuit

“SEPARATE BRAKES” VALVE

Right Pedal Only Depressed (Off)

Left Pedal Only Depressed (Off)

Right Pedal Only Depressed (On)

Left Pedal Depressed Only (On) - -AXLES AND WHEELS

REMOVAL OF THE FRONT AXLE

Preliminary Operations

REFITTING THE FRONT AXLE

Final Operations

REMOVAL OF THE FRONT DIFFERENTIAL

Preliminary Operations

REFITTING THE FRONT DIFFERENTIAL

Final Operations

OVERHAUL OF THE FRONT DIFFERENTIAL

Disassembly

Assembly

Adjustment Of The Bevel Drive

REMOVAL OF FRONT AXLE COMPONENTS

Preliminary Operations

Removal Of The Front Reduction Unit

Disassembly Of The Front Brakes

Disassembly Of The Stub Axle Housing

Removal Of The Front Halfshaft

REFITTING THE FRONT AXLE COMPONENTS

Refitting The Front Halfshaft

Assembly Of The Stub Axle Housing

Adjustment Of The Kingpin Bearing Preload

Assembly Of The Front Brakes

Refitting The Front Reduction Unit

Final Operations

OVERHAUL OF THE FRONT REDUCTION UNIT

Disassembly

Assembly

Shimming The Bearings Of The Reduction Unit

OVERHAUL OF THE CONSTANT VELOCITY JOINTS

Disassembly

Assembly

REMOVAL OF THE REAR REDUCTION UNIT

Disassembly Of The Halfshaft And Planet Carrier

Assembly Of The Halfshaft And Planet Carrier

Adjustment Of The Rear Halfshaft Bearings

REFITTING THE REAR AXLE CASING

EXTENDIBLE HALFSHAFT

Disassembly

Assembly

Adjustment Of The Differential Lock Disc Play

Adjustment Of The Differential Lock

Adjustment Of The Differential Lock Engagement Control

Section Views Of Extendible Halfshaft - -STEERING

DISASSEMBLY OF THE POWER STEERING UNIT

Main Safety Valve

ASSEMBLY OF THE POWER STEERING UNIT

Preliminary Operations

Instructions For O-Ring/Kin-Ring Assembly

Assembly Of The Non-Return Valve

Anti-Cavitation Valves

Main Safety Valve

Checking The Setting Of The Main Safety Valve - -CAB

REMOVAL OF THE CAB

REFITTING THE CAB

Final Operations - -HYDRAULIC SYSTEM

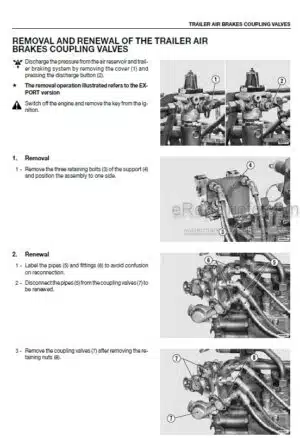

REMOVAL OF LIFT AND COMPONENTS

REFITTING THE LIFT UNIT

OVERHAUL OF THE POWER LIFT

Disassembly

Assembly

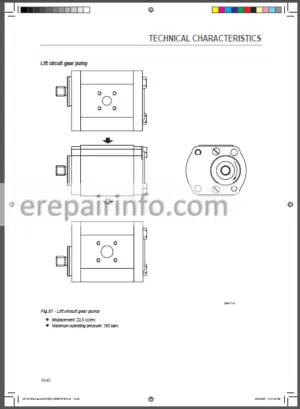

OVERHAUL OF HYDRAULIC PUMPS

Disassembly

Checks And Adjustments

Assembly

ELECTRONIC LIFT CONTROL VALVE

Component Positions

Oil Conditions

Control Valve In Lifting Condition

Control Valve In Neutral Condition

Control Valve In Lowering Condition

Hydraulic Schematic

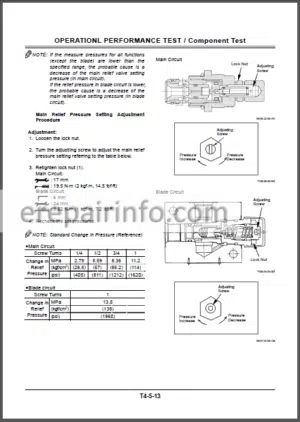

OVERHAUL OF THE MECHANICAL LIFT CONTROL VALVE

Checks With Control Valve Assembled

Disassembly Of The Control Valve

Checks And Adjustments

Assembly

ADJUSTMENT OF THE MECHANICAL LIFT

Adjustment Of Max Lifting

Adjustment Of The Safety Stop

Checking Float Operation

Counterweight Drop Test (With Counterweight Of At LeastKg)

Adjustment Of The Position Control Lever

Adjustment Of The Draft Control Lever

Sensitivity Control

SENSING DEVICES

Dismantling The Electronic Lift Sensing Device

Dismantling The Mechanical Lift Sensing Device

SENSING DEVICE COMPONENTS

Electronic Lift

Mechanical Lift

Front Hydraulic Lift - -ELECTRICAL-ELECTRONIC SYSTEM

General Warnings

General Precautions For Electronic Components

Earthing And Electromagnetic Compatibility

Practical Hints

GENERAL DESCRIPTION OF THE SYSTEM

System Characteristics

Fuse And Relay Box

CAB

Position Of Components In The Cab

Central Instrument Panel (Dashboard)

Right-Hand Instrument Panel – Data Monitor

Calibration Of The Data Monitor

Instrument Operation Test

Electronic Lift

Description Of The Operation Of The Pto Control Unit

Description Of The Operation Of The Hml Electronic Control Unit

Description Of Components

Battery (Maintenance-Free Type)

Bosch Kw Starter Motor

A Alternator With “W”

Starter Switch

Steering Column Switch Unit

Multifunction Control On Armrest

Hand Throttle

Direction Indicators Control Unit

Electronic Governor Control Unit

Hml Control Unit

SBA Control Unit (Option Available Only With Mechanical Rear Lift)

Rear Pto Control Unit

Preheating Control Unit

Glowplug

Check Panel

Engine Oil Pressure Gauge

Battery Voltage Gauge

Coolant Temperature Gauge

Fuel Gauge

30 Km/H Multimeter

40 Km/H Multimeter

Upper Worklights Switch

Lower Worklights Switch

Rear Worklights Switch

Flashing Light Control Switch

Corner Worklights Switch

Rear Screen Wiper Switch

Hazard Warning Lights

Heating Fan Switch

Lift Raise/Lower Switch

Spot Light Switch

4Wd Control Switch (With Latch)

Sealed Switch

Electrical Load On Contacts

Start Enabling Switch (Under Clutch Pedal)

5A Brake Pedals Switch (Sba System)

Diff Lock Control Switch (With Latch)

Sba System Control Switch (With Latch)

Pto Control Switch Rear (With Latch)

Front Pto Control Switch (Without Latch)

Lift Control Switch (On Rear Fender)

Relay 12V — 30A

4-Position Blower Control Knob

Rear Pto Solenoid Valve Solenoid Valve

Diff Lock Solenoid Valve

Hml/4Wd Solenoid Valve

Radar

Pressure Switch – Clogging Sensor For Oil Filter On Delivery Line To Services Sv

Pressure Switch – Oil Filter Clogging Sensor

“Service” Oil Pressure Switch

Pressure Switch – Air Cleaner Clogging Sensor

Engine Coolant Temperature Sensor

Engine Speed Inductive Sensor

Lift Draft Sensor (60Kn)

Lift Position Sensor And Steering Angle Sensor

Accelerator Pedal Potentiometer

Windscreen Wiper Motor

Rear Screen Wiper Motor

Fuel Level Sender

Compressor For R134A

Receiver-Drier For R134A

Outlet Socket (+12V)

BULKHEAD CONNECTORS

KEY TO WIRE COLOURS

DIAGNOSTIC INSTRUMENTS57

List Of Components (Ordered By Component Number)

List Of Components (Ordered By Component Designation)

List Of Components (Ordered By Component Code)

List Of Fuses

List Of Relays

List Of Ground Connections

List Of Wiring Connections

WIRING KEY

Perspective view

Layout diagram

Wiring diagram

FUNCTIONAL CARD KEY

Perspective View

Layout Diagram

Schematic Diagram

LOCATION OF COMPONENTS ON VEHICLE

Table I – Components on rear frame

Table 2 – Components on front frame

Table 3 – Upper cab components

Table 4 – Lower cab components

EXAMPLE (ELECTRICAL WIRING DIAGRAMS AND WIRING)

EXAMPLE OF FUEL LEVEL SYSTEM FAULT

WIRING

1,2 – Battery Wires

3, 4, 5- Front Wiring

6 – Central Wiring

11 – Wiring Under Foot Mat

12 – Rear Wiring

13 – Cab Overhead Wiring

14 – Electronic Governor Wiring For Manipulator

15 – Electronic Governor Wiring

16 -Electronic Lift Wiring “Slh”

17 – Conditioner Wiring

18 – Heater Wire

19 – Trailer Brakes Air Pressure Indicator Wire

20 – Sba Wiring

21 – Potentiometer Wire (Steering Angle Sensor) Sba

22 – Electronic Sba Button Wire

23 – Italia Brakes Wire

24 – Germania Brakes Wire

Board 1 – Starting – Recharge – Pre-Heating

FUNCTIONAL BOARDS

Board 2 – Instruments

Board 3 – Visual Indicators

Board 4 – Interior Roof Lighting – Services

Board 5 – Side/Tail Lights – Dipped Headlights – Full Beam Headlights Horns – Trailer Fitting1

Board 6 – Direction Indicators – Hazard Warning Light – Vehicle Stop

Board 7 – Worklights – Flashing

Board 8 – Windscreen And Rear Screen Wipers

Board 9 – Conditioner – Heater

Board 10 – Electronic Lift Without Sba

Board 10 – Electronic Lift Without Sba

Board 11 – Electronic Lift With Sba

Board 12 – Electronic Lift And Sba Device (control unit)

Board 13 – Electronic governor without manipulator

Board 14 – Electronic governor with manipulator

Board 15 – Perspective SBA device without Electronic lift

Board 16 – PTO device - -TROUBLESHOOTING

ALL ROUND TESTER – CONNECTION AND POWER UP

ENGINE TROUBLESHOOTING WITH THE ALL ROUND TESTER

Presentation screen

Engine test

1 Parameters display

2 Auto programming

3 Test

4 Manual Programming

5 Pedal sensor

6 Actuator

7 Engine rpm reading

8 Self-diagnosis

Engines List -Wheel Constant

APPENDIX 1

ELECTRONIC LIFT DIAGNOSIS WITH THE ALL ROUND TESTER

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet