Factory Service Manual For New Holland Tractor. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 1272

Number: 6035445100

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Model

New Holland Tractor

TN75FA

TN85FA

TN95FA

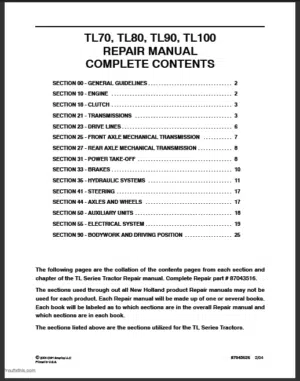

Contents

-GENERAL GUIDELINES

General Instructions

Safety Regulations

Consumables

-ENGINE

Summary

General Specifications

Fuel System Data

Injection Pump Calibration And Engine Performance Data

Engine Block Data

Crankshaft Data

Connecting Rod Data

Piston Data

Timing Gear Data

Cylinder Head Data

Lubrication And Cooling System Data

Tightening Torques

Tools

Cross-Sectional Views Of Engine

Lubrication Diagrams

Engine Cooling System Diagram

Fault Diagnosis

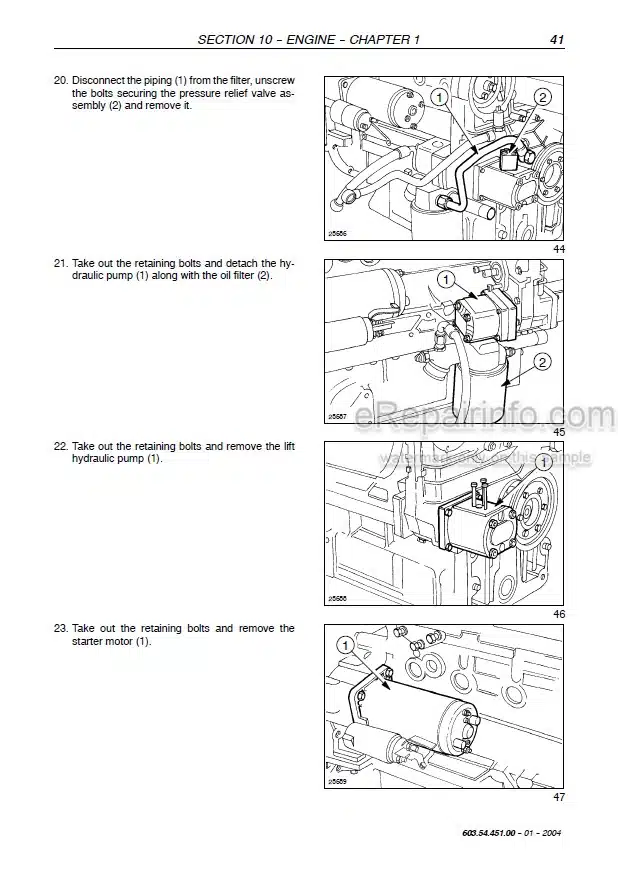

Engine Removal – Installation

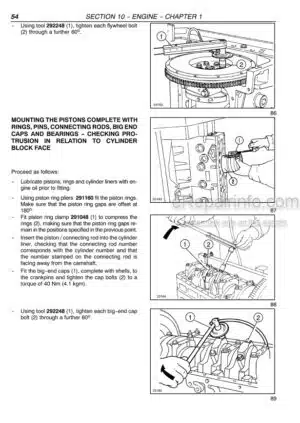

Engine Disassembly – Assembly

Checks And Measurements

Replacing Valve Guides

Re-Facing Valve Seats

Replacing Injector Sleeves And Support

Checks And Measurements – Rotating Counter-

Weights

Checks And Measurement Removal-Installation Radiator

Removal-Installation Crankshaft Front Seal

Removal-Installation Coolant Pump

Removal-Installation Thermostat Valve

Removal – Installation Bosch Injection Pump

Bosch Injection Pump

Removal-Installation – Injectors

Valve Clearance Adjustment

Coolant Pump Overhaul

Compression Test

-CLUTCH

Data

Tightening Torque – Tools Cross-Sectional Views

Fault Diagnosis

Removal-Installation – Clutch

Clutch Overhaul

Checks And Measurements – Clutch

Adjustments

PTO Clutch Lever Adjustment

PTO Clutch Servo Control Adjustment

PTO Clutch Servo Control

-TRANSMISSIONS

Transmission And Range Gear (16X16)

Mechanical Transmission And Splitter

Power Shuttle Transmission

-DRIVELINES

Data

Tightening Torques

Cross-Sectional Views

Description And Operation Fault Diagnosis

Removal – Installation

Drive Gear Casing

Disassembly-Assembly – Drive Gear Casing

Diagnosis

Faults Code Signals

Calibrations

HH Menu Access

System Configuration (H3)

Software Revision Level (H4)

Control Switch Diagnostics (H5)

Deleting The Non Volatile Memory (NVM) (EEPROM) (H8)

Voltmeter Function (H9)

Four-Wheel Drive Engagement Position (HD)

Faults Saved In The Nonvolatile ECU Memory (ECU) (HF)

First Start-Up Procedure

Diagnostics

Front PTO And 4WD Electronic Control Unit Input/Out-Put Wiring Diagram

-FRONT MECHANICAL TRANSMISSION

Data

Tightening Torques

Tools

Cross-Sectional Views

Description And Operation

Fault Diagnosis

Removal-Installation

Front Axle

Disassembly-Assembly

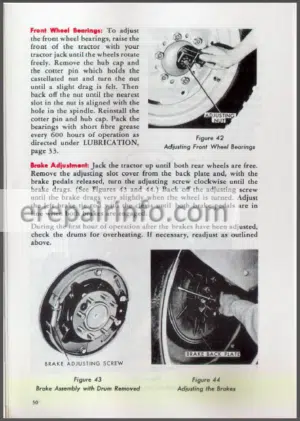

Adjustments – Steering Knuckle Bearings

Removal-Installation

Front Axle Bevel Drive Support And Differential

Overhaul – Differential Lock Unit

Overhaul – Front Axle Bevel Drive

Adjustments – Bevel Drive

Overhaul – Front Differential

Replacing Steering Knuckle Pins And Bearings

-REAR MECHANICAL TRANSMISSION

Data

Tightening Torques

Tools

Cross-Sectional Views

Description And Operation

Fault Diagnosis

Disassembly-Assembly -Transmission-Gearbox Casing

Adjustment – Differential Lock Engagement Sleeve Position

Adjustments – Bevel Drive

Removal-Installation – Side Gear Casing

Disassembly-Assembly – Drive Wheel Shaft

Disassembly-Assembly -Epicyclic Final Drive

-POWER TAKE-OFF

Mechanical Power Take-Off

-BRAKES

Data

Tightening Torques

Cross-Sectional Views

Tools

Description And Operation Fault Diagnosis

Removal-Installation – Service Brake

Removal-Installation – Service Brake Pump

Adjustments – Service Brake Pedals Travel

Service Brake Circuit Air Bleeding

Removal-Installation Parking Brake

Adjustments – Parking Handbrake Travel

-HYDRAULIC SYSTEMS

Rear Mechanical Hydraulic Lift

Auxiliary Control Valves Open Centre System

Auxiliary Control Valve For Trailer Brakes

Electronically Controlled Hydraulic Lift

Constant Flow Gear Pump

Electronic Lift And Front Power Take–Off

-STEERING

Steering

Constant Flow Gear Pump

-AXLE AND WHEELS

Data

Front Wheel Track Diagram

Cross-Sectional Views

Tightening Torques

Tools

Fault Diagnosis

Removal-Installation Front Axle

Disassembly-Assembly -Wheel Axle Hub

Stub Axle Hub Overhaul

Checking Leading Wheel Alignment

-CAB AIR CONDITIONING SYSTEM

Safety Regulations

Main Specifications

Tools

Operating Principles

Components Of Cab Air Conditioning System

Cab Controls

Instructions For Use – Air Conditioning System

Refrigerant Recovery – Recycling And Evacuation – Charging Stations

Dehydration, Recharging And Refrigeration Check

System Recharging Function Check

Fault Diagnosis

Air Conditioning System Maintenance

Compressor Drive Belt Tension Adjustment

Removal-Installation – Air Conditioning Unit

-ELECTRICAL SYSTEM

Instruments

Components

Starting System

Charging System

Battery

Electrical Circuits

-PLATFORM, CAB, BODYWORK

Cab Removal–Installation

Removal Of Cab Internal Components

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet