Factory Service Manual For New Holland Tractor. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 1992

Number: 84127307

Bookmarks: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

New Holland Tractor

TV6070 Master

Contents

-GENERAL INFORMATION

Precautionary Statements

Safety Precautions

General Considerations

Tractor Identification

Engine Identification

Service Techniques

Minimum Hardware Tightening Torques

Standard Torque Data

Recommended Lubricants and Coolants

Recommended Sealants

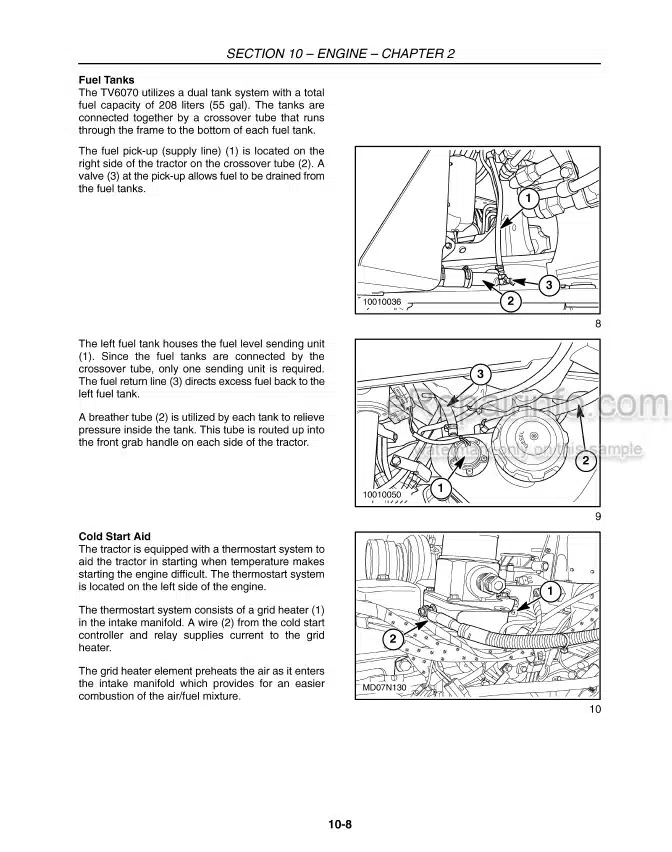

-ENGINE

Fuel System

Air Induction System

Exhaust System

Cooling System

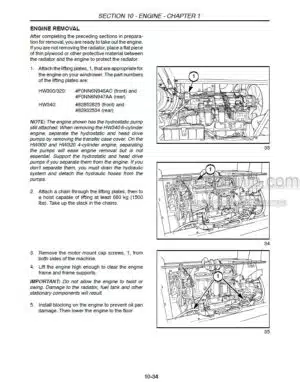

Engine Removal And Testing

-TRANSMISSIONS

Transmissions – General Information Specifications And Operations

Hydrostatic Drive – Troubleshooting And Testing

Drivelines

Hydrostatic Motor Pump And Control Cables

Auxiliary Pump Drive

Splitter Box Removal Disassembly And Assembly

-ENGINE-END AXLE

Specification

Axle Shaft Preload

Axle Shaft Spacer Selection Table

Differential Bearing Preload

Differential Bearing Shim Table

Drive Pinion Preload

Drive Pinion Spacer Table

Torque Specifications

Special Tools

Introduction

Drive Path

Drive Pinion

Differential

Planetary Assembly

Axle Shaft And Trumpet Housing

Differential Lock

Troubleshooting

Low Pressure Pilot Circuit Test

Disassembly And Repair

Trumpet/Axle Disassembly

Planetary Disassembly

Planetary Inspection

Planetary Reassembly

Planetary Ring Gear Removal

Planetary Ring Gear Installation

Trumpet/Axle Inspection

Trumpet/Axle Reassembly

Pinion Gear Removal

Pinion Gear Disassembly

Pinion Gear Inspection

Center Housing Inspection

Pinion Gear Reassembly

Pinion Bearing Preload

Pinion Gear Installation

Differential Disassembly

Differential Inspection

Differential Reassembly

Differential Bearing Preload

Differential Bearing Shim Table

Differential Lock Internal Operating Components Overhaul

Differential Lock Valve And Tube Removal

Differential Lock Valve And Tube Inspection

Differential Lock Valve And Tube Installation

Oscillating Components

Rear Trunnion Inspection

Rear Trunnion Installation

Front Trunnion Removal

Front Trunnion Inspection

Front Trunnion Installation

Diff Lock Switch Removal

Diff Lock Switch Inspection

Diff Lock Switch Installation

Apply Solenoid And Valve Removal

Apply Solenoid And Valve Inspection

Apply Solenoid And Valve Installation

Breather Removal

Breather Inspection

Breather Installation

Repair Time Schedule

-CAB-END AXLE

Specifications

Torque Specifications

Special Tools

Introduction

Overview

Description Of Operation

Troubleshooting

Complete Rear Axle Removal And Repair

Repair Time Schedule

-POWER TAKE-OFF

Cab Enad PTO

Engine And PTO

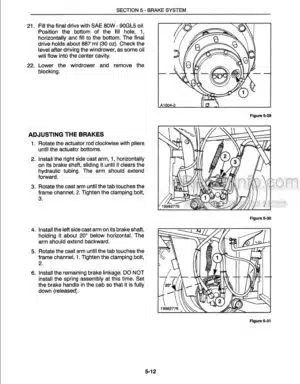

-BRAKES

Specifications

Torque Specifications

Special Tools

Introduction

Overview

Description Of Operation

Troubleshooting

Testing

Adjustments

Removal And Installation Of Components

Brake Disc Components

Foot Pedal Linkage

Master Cylinder

Reservoir

Hose – Reservoir To Master Cylinder

Tubes – Pressure Supply

Park Brake Lever

Park Brake Cables And Links

Brake Pedal Switch

Park Brake Switch

Repair Time Schedule

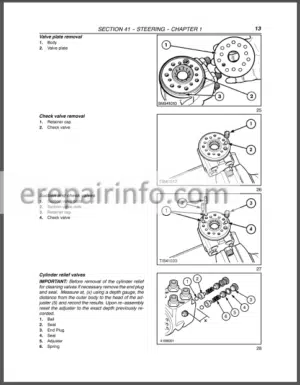

-HYDRAULIC SYSTEMS

Hydraulics and Steering

Special Tools

Engine-End Hitch

-WHEELS, TIRES, AND BALLASTING

Wheels and Tires

Ballasting

-FRAMES

Specifications

Torques

Special Tools

Description of Operation

Introduction

Troubleshooting

Overhaul

Engine Hood

Hood Support Assembly

Side Panels, Right-hand and Left-hand

Front Grille

Cab-end Fenders

Engine-end Fenders

Heatshield

Engine End Drawbar

Cab End Drawbar

Front Axle Support

Frame Side Rails

Steering Pins

Pivot Pins

Front Frame

Rear Frame

Repair Time Schedule

-CLIMATE CONTROL

Specifications

Special Tools

Description and Operation

R134a Refrigerant Information

The Basics of Refrigeration

Individual Component Operation

Compressor and Clutch

Condenser

Receiver-drier

Thermal Expansion Valve

Evaporator/Heater Assembly

Blower Motor Assembly

Thermostatic Switch

High and Low Pressure Switches

Heater Control Valve

Switched Power: Fuses and HVAC Relay

Air Filtration

Troubleshooting and Testing

General Safety and Service Precautions

Recovering R134a Refrigerant With OEM 1598

System Evacuation and Recharging With OEM 1598

Oil Level Check Or Adjustment

Leak Detection

Performance Testing

Pressure/Temperature Relationship Chart

Conditions For Performance Testing

Gauge Readings and Interpretations

Performance Test and Diagnosis Summary

General Troubleshooting Summary

Heating System

Air Conditioning System

Air-conditioning Component Removal and Installation

Thermal Expansion Valve and Evaporator

Heater Core Assembly

Condenser

High and Low Pressure Switches

Receiver-drier

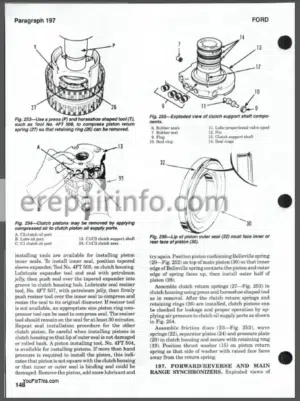

Compressor

Compressor Clutch

Air Conditioning Hoses

Heater Control Valve

Recirculation Door Control

Blower Speed Control

Heater Hoses

Repair Time Schedule

-ELECTRICAL SYSTEM

Specifications

Torque Specifications

Special Toots

Introduction

Electrical Components

Using Schematics

Circuit Troubleshooting

Description of Operation – Batteries

Starting and Charging Systems

Air Conditioning

Differential Lock

Power Take Off

Cab-End 3-Polnt Lift (HPL)

Engine-End 3-Point Lift (HPL)

Hitch Calibration

Auxiliary Power

Auxiliary Drive

Starter

Troubleshooting – Batteries

Testing the Batteries

Charging the Batteries

Starter System Testing On Tractor

Starter Testing Off Tractor

EICS Error Codes

EICS Connector Chart

Calibrating the Electronic Instrument Control System

Entering EIC Calibration Mode

-ACCESSORIES

Introduction

Electrical Kits and Accessories

Frame and Platform

Hydraulic and PTO Kits

Loader Kits and Accessories

-CAB

Cab – General Information

Cab Removal And Installation

Cab Exterior

Cab Interior

Cab Control Consoles

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Anonymous (verified owner) –

This is very convenient, I can download the manual and use it immediately. I am a service manager at a tractor dealership and we don’t only work on our brand so I need access to manuals for other brand so that my techs can perform the job in a timely manner. We bill the manual to the customer on the repair order and they don’t mind because they can’t get anyone else to work on their equipment.