Factory Service Manual For Kobelco Blade Runner Acera SR Hydraulic Excavator; Mitsubishi Diesel Engine. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 1096

Number: 87480999NA (June 2008)

Bookmarks: Yes

Searchable: Yes

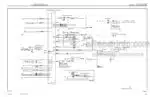

Wiring Diagrams: Yes

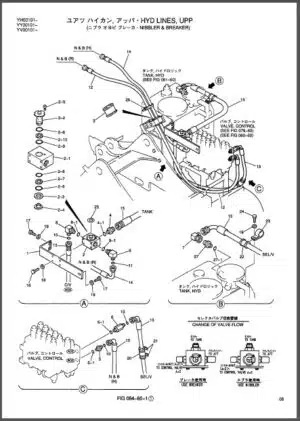

Hydraulic Diagrams: Yes

Model

Kobelco Excavator Dozer

ED150 Blade Runner

Acera SR

Tier 3

Mitsubishi Diesel Engine

DO4FR-TAA

Contents

1.KOBELCO ED150 BLADE RUNNER ACERA SR TIER SERVICE MANUAL EXCAVATOR DOZER.

2.MITSUBISHI DO4FR-TAA SERVICE MANUAL DIESEL ENGINE.

1.KOBELCO ED150 BLADE RUNNER ACERA SR TIER SERVICE MANUAL EXCAVATOR DOZER.

-SAFETY AND GENERAL INFORMATION

General Precautions For Making Repairs

Specifications

Attachment Dimensions

-MAINTENACE

Tools

Standard Maintenance Time Table Table Of Contents

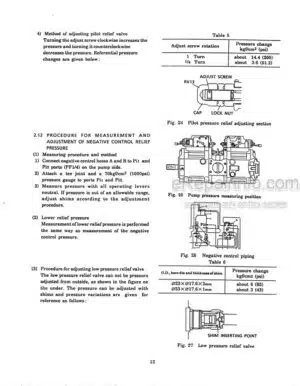

Maintenance Standard And Test Procedure

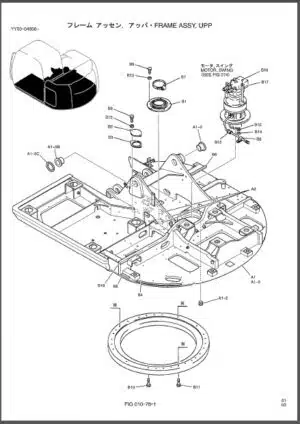

-DISASSEMBLY AND ASSEMBLY

Attachments

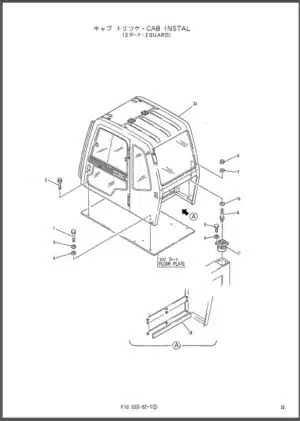

Upper Structure

Travel System

-TROUBLESHOOTING

Troubleshooting By Error Codes

Troubleshooting By Trouble

Troubleshooting By Diagnosis Mode

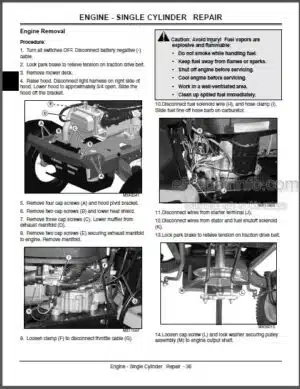

-ENGINE

2.MITSUBISHI DO4FR-TAA SERVICE MANUAL DIESEL ENGINE.

-GENERAL

External View

System Flow Diagrams

Engine Serial Number Location

Main Specifications

Tips On Disassembling And Reassembling

-SERVICE DATA

Maintenance Service Data

Tightening Torque Table

-SERVICE TOOLS

Special Toools

-DETERMINATION OF OVERHAUL

Determining Overhaul Timing

Testing Compression Pressure

-DISASSEMBLY OF BASIC ENGINE

Disassembling And Inspecting Cylinder Head And Valve Mechanism

Disassembling And Inspecting Flywheel

Disassembling And Inspecting Gear Case, Timing Gear And Camshaft

Disassembling And Inspection Crankcase, Crankshaft And Piston

-INSPECTION AND REPAIR OF BASIC ENGINE

Inspecting And Repairing Cylinder Head And Valve Mechanism

Inspecting And Repairing Flywheel

Inspecting And Repairing Timing Gear And Camshaft

Inspecting And Repairing Piston, Connecting Rod, Crankshaft And Crankcase

-REASSEMBLY OF BASIC ENGINE

Reassembling Piston, Connecting Rod, Crankshaft And Crankcase

Reassembling Timing Gear And Camshaft

Reassembling Flywheel

Reassembling Cylinder Head And Valve Mechanism

-FUEL SYSTEM

Environment Of Fuel System Service

Removing Fuel System

Disassembling And Inspecting Fuel Pump

Disassembling And Inspecting Common Rail

Installing Fuel System

-LUBRICATION SYSTEM

Removing And Inspecting Lubrication System

Disassembling, Inspecting And Reassembling Lubrication System

Installing Lubrication System

-COOLING SYSTEM

Removing Cooling System

Inspecting Cooling System

Installing Cooling System

-INLET AND EXHAUST SYSTEM

Removing Inlet And Exhaust System

Disassembling, Inspecting And Reassembling Inlet And Exhaust System

Installing Inlet And Exhaust System

-ELECTRICAL SYSTEM

Removing Electrical System

Disassembling, Inspecting And Reassembling Electrical System

Installing Electrical System

-ADJUSTMENT AND OPERATION

Adjusting Engine

Break-In Operation

Performance Test (JIS Standard)

-TROUBLESHOOTING

Troubleshooting By Diagnosis Codes

Scan Tester (32G91-00800, Main Unit: 32G91-00811, Interconnect Cable: 32G91-00812)

Scan Tester (32G91 -00600)

Diagnosis Code Cross Reference

Troubleshooting Reference Chart

Inspecting Sensors

Inspecting Wiring

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet