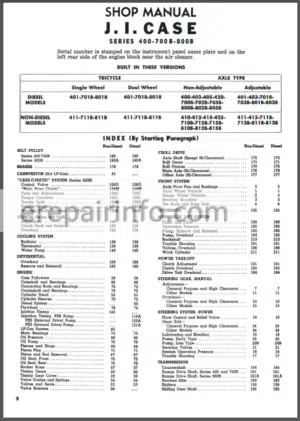

Factory Service Manual For Case 135, 150, 165, 180 Maxxum Tractor. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 1069

Number: 73403962 (may 2009)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Case Tractor

Maxxum 135

Maxxum 150

Maxxum 165

Maxxum 180

Contents

-SPECIFICATIONS

General Instructions

Safety Norms

Refuelling

-ENGINE

General Specifications

Assembly Dimensions

Tightening Torques

Special Tools

Engine Cold Start

Cooling System

Lubrication System

Fault Diagnosis

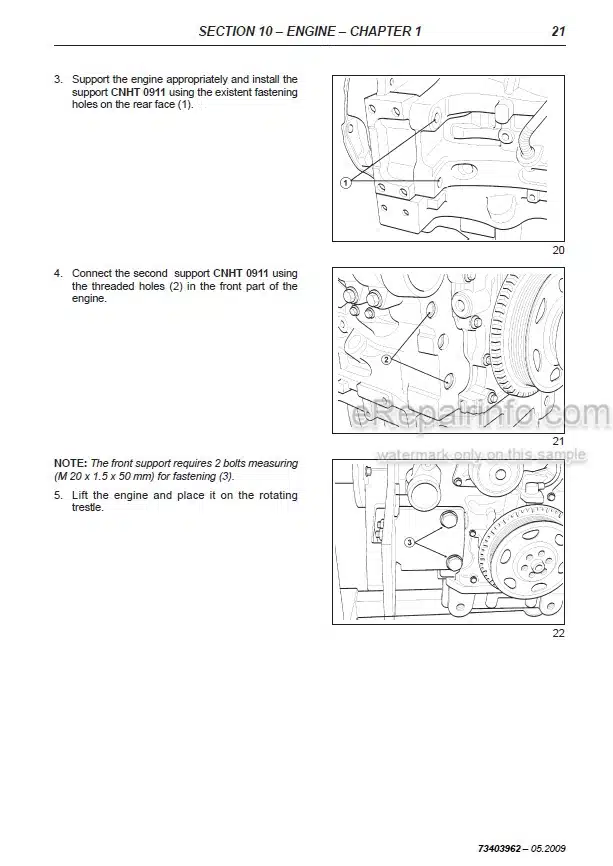

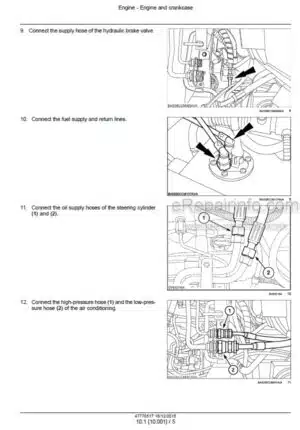

Removing And Installing The Engine In The Tractor

Disassembling The Engine

Assembling The Engine

Checking And Measuring

Valve Clearance Adjustment

Rotary Injection Pump Removal, Installation And Synchronization

-CLUTCH

Specifications

Tightening Torques

Sections

Special Tools

Description And Operation

Troubleshooting

LUK Clutch (Removal – Installation)

Hydraulic Clutch Control (Removal – Installation)

Hydraulic Clutch Control (Disassembly-Assembly)

–TRANSMISSION

Semi-powershift (range command) transmission

Range command transmission (semi-powershift) calibration, troubleshooting, testing the pressure and creeper

Mechanical Transmission 15×12 (“Synchro Command”)

Mechanical Transmission 16×16

-TRANSMISSION SHAFTS

Specifications

Tightening Torques

Special Tools

Sections

Troubleshooting

Description And Operation

Hydraulic Flow Charts

Transmission And Bearing Shaft (Disassembling – Installing)

Transmission Box Shaft Oil Seal (Replacing With The Transmission Box Shaft Removed From The Tractor)

Electro-Hydraulic Clutch Transfer Box (Disassembling – Installing)

-FRONT MECHANICAL SHAFT

Specifications

Tightening Torques

Special Tools

Sections

Description And Operation

Troubleshooting – Hydraulic Differential Lock

Mechanical Shaft Set (Disassembling – Installing)

Planetary Gear Set (Disassembly – Installation)

Wheel Hub And Articulated Pins Set (Disassembling – Installing)

Steering Angle Potentiometer (Replacement)

Sprocket Gear/ Differential Transporter (Installing – Disassembling)

Front Clutch Differential Lock (Servicing)

Pinion Of The Front Shaft And Sprocket Gear (Servicing)

Adjusting The Pinion And Sprocket Gear

Front Shaft Differential Set (Servicing)

Articulated Pins And Bearings (Replacement)

Front Wheel Toe-In Test

Front Clutch Differential Lock (Servicing)

-MECHANICAL REAR-WHEEL DRIVE

Specifications

Tightening Torques

Special Tools

Sections

Description And Operation

Troubleshooting

Rear Axle Housing (Disassembling – Installing)

Rear Axle Housing (Replacement)

Sprocket Gear And Pinion Adjustments

Adjusting The Hydraulic Pump Intermediate Pinion

Hydraulic Lock Differential Set (Disassembling – Installing)

Rear Differential Lock Set (Disassembling – Installing)

Final Drive Housing (Left Or Right Hand Side) (Disassembling – Installing)

Flywheel Shaft (Disassembling – Installing)

Epicyclical Reducer Set (Disassembling – Installing)

-POWER TAKE OFF

Specifications

Tightening Torques

Special Tools

Section Views

Descnption And Operation

Troubleshooting

Power Take Off (PTO) (Removal – Installation)

-BRAKES

Specifications

Tightening Torque

Section Views

Special Tools

Description And Operation

Troubleshooting

Brakes, Right Or Left (Disassembling – Installing)

Main Hydraulic Brake Cylinder (Disassembling – Installing)

Hydraulic Brake System

Parking Brake Set (Disassembling – Installing)

Manual Brake Control

-HYDRAULIC SYSTEM

Hydraulic Circuits

Variable Flow Hydraulic Pump

Fixed Displacement Gear Pumps

Electronic Effort Control

Closed Center Remote Control Valves

Open Center Remote Control Valves

Trailer Brake Auxiliary Valve

Auxiliary Cylinder

-STEERING

Specifications

Special Tools

Description And Operation

Troubleshooting

System Tests

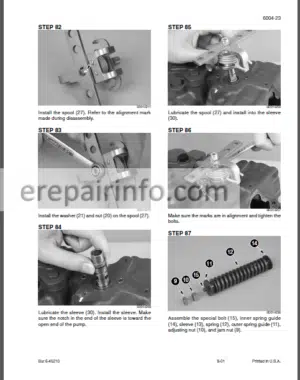

Hydraulic Steering Distributor (Service)

Disassembling And Installing The Steering Rod

Four-Wheel Drive Vehicles Steering Cylinder – Disassembling And Installing

-AUXILIARY UNITS

Specifications

Torques

Special Tools

Safety Measures

Principles Of The Air Conditioner

System Components – Description And Operation

Troubleshooting And Testing The Air Conditioning System

Performance Test Diagnostic

Testing For Leaks, Discharging And Reloading, Washing The System

Servicing The Components (Excluding The Compressor)

Compressor – Servicing (Disassembling The Compressor)

Servicing The Cylinder Head

– ELECTRICAL SYSTEM

Introduction

Electronic Instrument Cluster

Analog/Electronic Instrument Panel

Starting System

Charge System

Battery

Electric Schematics

“H” Menu Diagnostic Routines

-CAB

Replacing the Glass

Internal Cab Components

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet