Factory Technical Manual and Workshop Manual For Hitachi EX60-5 75UR-3 75URLC Excavators. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Hitachi EX60-5, EX75UR-3, 75URLC-3

Contents

1.Technical Manual

-GENERAL

–SPECIFICATION

Specifications

Working Ranges and Machine Transportation Dimensions

–COMPONENT LAYOUT

Main Components

Electrical System (Overall System)

Electrical System (Monitor and Switches)

Pump Device

Swing Device

Travel Device

–COMPONENT SPECIFICATION

Engine

Engine Accessories

Hydraulic Component

Electrical Equipment

-SYSTEM

–CONTROL SYSTEM

Outline

Engine Control

Pump Control

Precise Swing Mode Control (EX75UR-3 and EX75URLC-3)

–FRONT CONTROL SYSTEM

Outline

Front Function Control

Front Function Limit Control

Group 3 Hydraulic System

Outline

Pilot Circuit

Main Circuit

–ELECTRICAL SYSTEM

Outline

Power Circuit (Key Switch:OFF)

Bulb Check Circuit

Preheat Circuit

Starting Circuit (Key Switch:Start)

Charging Circuit (Key Switch:ON)

Surge Voltage

Prevention Circuit

Accessory Circuit

Engine Stop Circuit

-COMPONENT OPERATION

–PUMP DEVICE

Outline

Main Pumpl

Main Pump 2 and Pilot Pump

–SWING DEVICE

Outline

Swing Motor

Parking Brake Switch Valve

Valve Unit

Swing Reduction Gear

–CONTROL VALVE

Outline

Control Valve Layout

Hydraulic Circuit

Flow Combiner Valve

Main Relief Set Pressure Change

Boom Anti-Drift Valve (EX60-5)

Main Relief Valve

Overload Relief Valve

–PILOT VALVE

Outline

Operation

–TRAVEL DEVICE

Outline

Travel Motor

Parking Brake

Travel Brake Valve

Travel Reduction Gear

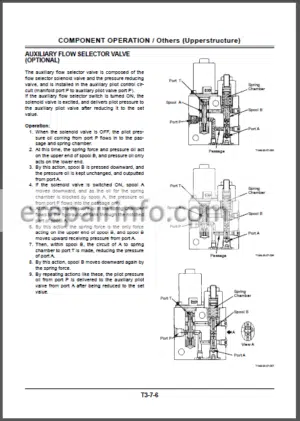

–OTHERS (UPPERSTRUCTURE)

Pilot Shut-Off Valve

Swing Mode Control Valve

Shockless Valve

7-Spool Solenoid Valve Unit (EX75US-3)

Pilot Relief Valve

EC Motor

–OTHERS (UNDERCARRIAGE)

Swing Bearing

Center Joint

Track Adjuster

-OPERATIONAL PERFORMANCE TEST

–INTRODUCTION

Operational Performance Tests

Preparation For Performance

Test

–STANDARD

Operational Performance Standard Table

Main Pump P-Q Diagram

Sensor Activating Range

–ENGINE TEST

Engine Speed

Engine Compression Pressure

Valve Clearance

Nozzle Check

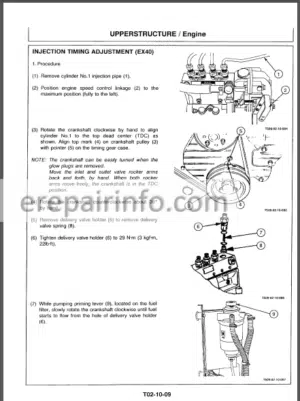

Injection Timing

–EXCAVATOR TEST

Travel Speed

Track Revolution Speed

Mistrack Check

Travel Motor Leakage

Swing Speed

Swing Function Drift Check

Swing Motor Leakage

Maximum Swingable Slant Angle

Swing Bearing Play

Hydraulic Cylinder Cycle Time

Dig Function Drift Check

Control Lever Operating Force

Control Lever Stroke

Boom Raise/Swing Combined Operation Check

Bucket/Cab Collision Prevention System Check (EX75UR-3)

–COMPONENT TEST

Primary Pilot Pressure

Secondary Pilot Pressure

Main Relief Valve Set Pressure

Overload Relief Valve Set Pressure

Main Pump Flow Rate Measurement

Swing Motor Drainage

Travel Motor Drainage

–ADJUSTMENT

Engine Speed Adjustment and Engine Learning

Boom Lowering Method when Engine Stalling

Check of Governor Lever and Fuel Cut Lever Position

-TROUBLESHOOTING

–GENERAL

Introduction

Diagnostic Procedures

DrEX Operation

Main Controller Fault Code List

Auto-MARCCINO Control Unit Fault Code List (EX75UR-3)

Main Controller Monitoring Function

Auto-MARCCINO Control Unit Monitoring Function (EX75UR-3)

DrEX Special Function (Service Mode) (EX75UR-3)

–COMPONENT LAYOUT

Main Components

Electrical System (Overview)

Electrical System (Monitor and Switches)

Pump Device

Swing Device

Travel Device

Component in Control Valve

–TROUBLESHOOTING A

Troubleshooting A Procedure

Fault Code 01 (Abnormal EC Sensor)

Fault Code 07 (Abnormal Engine Control Dial Angle)

–TROUBLESHOOTING B

Troubleshooting B Procedure

Relationship between Machine Trouble Symptoms and Suspected Parts

Correlation between Trouble Symptoms and Part Failures

Engine System Troubleshooting

All Actuator Control System Troubleshooting

Front Attachment Control System Troubleshooting

Swing System Troubleshooting

Travel System Troubleshooting

Blade System Troubleshooting

–TROUBLESHOOTING C

Troubleshooting C Procedure (Troubleshooting for Monitor)

Malfunction of Coolant Temperature Gauge

Malfunction of Fuel Gauge

Malfunction of Indicator Light Check System

Malfunction of Alternator Indicator

Malfunction of Engine Oil Pressure Indicator

Malfunction of Overheat Indicator

Malfunction of Fuel Level Indicator (EX75UR-3, EX75URLC-3)

Malfunction of Air Filter Restriction Indicator

Malfunction of Electrolyte Level lndicator(EX75UR-3 EX75URLC-3)

Malfunction of Buzzer

Malfunction of Hour Meter

–TROUBLESHOOTING D

Troubleshooting D Procedure (EX75UR-3)

Auto-Marccino Control Unit

System Fault Code List

Fault Code 03

Fault Code 07

Fault Code 08

Fault Code 11, 12 13

Fault Code 14 15 16 20

Fault Code 40 41 42,44

Fault Code 43 45 47

Fault Code 50 51 52

Fault Code 60 61 62

Fault Code 80 81 82

Fault Code 90

–ELECTRICAL SYSTEM INSPECTION

Precautions for Inspection andB Maintenance

Instructions for Disconnecting Connectors

Fuse Continuity Test

Fusible Link Inspection

Bзпeгу Voltage Check

How to Troubleshoot Alternator Malfunctions

Continuity Check

Voltage and Current Check

Check by False Signal

Test Hamess

2.Workshop Manual

SAFETY

-GENERAL INFORMATION

–PRECAUTIONS FOR DISASSEMBLING AND ASSEMBLING

Precautions for Disassembling and Assembling

Maintenance Standard Terminology

–TIGHTENING TORQUE

Tightening Torque Specification

Torque Chart

Piping Joint

-UPPERSTRUCTURE

–CAB

Remove and Install Cab

Dimensions of the Cab Glass

–COUNTERWEIGHT

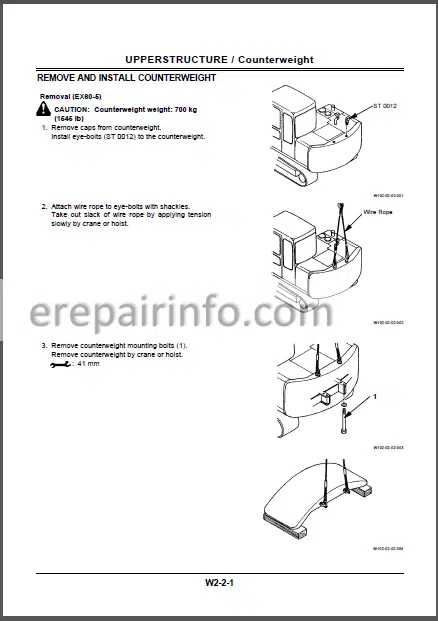

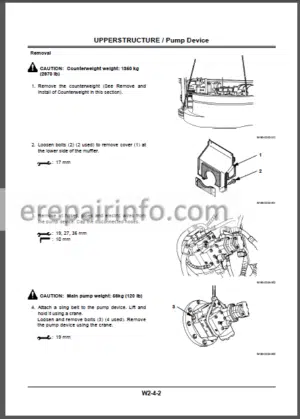

Remove and Install Counterweight

–MAIN FRAME

Remove and Install Main Frame

–PUMP DEVICE

Remove and Install Pump Device

Disassemble Main Pump

Assemble Main Pump

Disassemble and Assemble Pilot Pump

Disassemble and Assemble Gear Pump

Maintenance Standard

–CONTROL VALVE

Remove and Install Control Valve

Disassemble Control Valve

Assemble Control Valve

Disassemble Blade Control Valve

Assemble Blade Control Valve

–SWING DEVICE

Remove and Install

Swing Device

Disassemble Swing Reduction Gear

Assemble Swing Reduction Gear

Disassemble Swing Motor

Assemble Swing Motor

Maintenance Standard

–PILOT VALVE

Remove and Install Pilot Valve

Disassemble Pilot Valve for Front Attachment

Assemble Pilot Valve for Front Attachment

Disassemble Offset Pilot Valve

Assemble Offset Pilot Valve

–PILOT SHUT-OFF VALVE

Remove and Install Pilot Shut-off Valve

Disassemble Pilot Shut-off Valve

Assemble Pilot Shut-off Valve

–SHOCKLESS VALVE

Remove and Install Shockless Valve

Disassemble and Assemble Swing Shockless Valve

Disassemble and Assemble Front Attachment Shockless Valve

–SOLENOID VALVE

Remove and Install Solenoid Valve Unit

Disassemble and Assemble 7-Spool Solenoid Valve Unit

Disassemble Proportional Solenoid Valve

Assemble Proportional Solenoid Valve

–PILOT RELIEF VALVE UNIT

Remove and Install Pilot Relief Valve Unit

Disassemble Pilot Relief Valve Unit

Assemble Pilot Relief Valve Unit

–SWING MODE CONTROL VALVE

Remove and Install Swing Mode Control Valve

Disassemble and Assemble Swing Mode Control Valve

-UNDERCARRIAGE

–SWING BEARING

Remove And Install Swing Bearing

Disassemble Swing Bearing

Assemble Swing Bearing

–TRAVEL DEVICE

Remove And Install Travel Device

Disassemble Travel Device

Assemble Travel Device

Disassemble Travel Motor

Assemble Travel Motor

Disassemble And Assemble Brake Valve

Maintenance Standard

–CENTER JOINT

Remove And Install Center Joint

Disassemble Center Joint

Assemble Center Joint

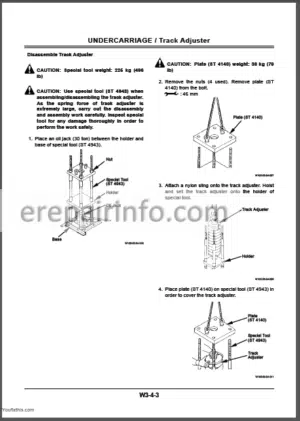

–TRACK ADJUSTER

Remove And Install Track Adjuster

Disassemble Track Adjuster

Assemble Track Adjuster

–FRONT IDLER

Remove And Install Front Idler

Disassemble Front Idler

Assemble Front Idler

Maintenance Standard

–UPPER ROLLER AND LOWER ROLLER

Remove and Install Upper Roller

Remove and Install Lower Roller

Disassemble and Assemble Lower Roller

Maintenance Standard

–TRACK LINK

Remove and Install Track

Maintenance Standard

Remove and Install Rubber Track

Maintenance Standard

–FRONT ATTACHMENT

–FRONT ATTACHMENT

Remove and Install

Front Attachment

Maintenance Standard

Standard Dimensions for Arm and Bucket Connection

–CYLINDER

Remove and Install Cylinder

Disassemble Cylinder

Assemble Cylinder

Maintenance Standard

-ENGINE AND ACCESSORY

–GENERAL

Engine Specification

Identification

Lubrication

–INSPECTION AND MAINTENANCE

Engine Main Body

Lubricating System

Cooling System

Fuel System

Intake And Exhaust System

Electrical System

–ENGINE SERVICING

Manifold

Rocker Cover

Rocker Shaft

Cylinder Head

Gear Train

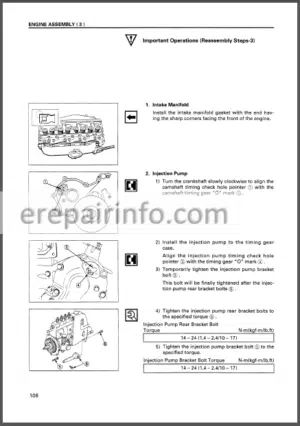

Injection Pump

Oil Pan

Oil Cooler

Oil Pump

Water Pump

Thermostat

–ENGINE MAIN BODY OVERHAULING

Precaution for Overhauling

Engine Main Body Overhauling

–SERVICE DATA

Engine Major Component Tightening Torque

Engine Main Body Specifications

Standard Tightening Torque

–TROUBLESHOOTING

Trouble Shooting Chart

Hou to Use the Chart

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet