Gehl RT175 GEN2, RT210 GEN2, RT250 Service Manual Compact Track Loader 50940164

Overview

The Factory Service Manual for Gehl RT175 GEN2, RT210 GEN2, RT250 Compact Track Loaders is an essential resource for technicians and owners responsible for the maintenance, service, and repair of these robust machines. This comprehensive manual provides detailed illustrations, step-by-step instructions, and diagrams to ensure proper removal and installation, assembly and disassembly, service, inspection, repair, troubleshooting, and tune-ups.

Key Features

- Format: PDF

- Language: English

- Pages: 362

- Manual Number: 50940164 (April 2014)

- Searchable: Yes

- Wiring Diagrams: Yes

- Hydraulic Diagrams: Yes

Models Covered

This manual specifically covers the following Gehl compact track loader models:

- Gehl RT175

- Gehl RT175 Gen2

- Gehl RT210

- Gehl RT210 Gen2

- Gehl RT250

Comprehensive Contents

The manual is organized into clear sections for easy navigation, providing detailed information on a wide range of topics:

Introduction

- Safety Symbol

- Contents and Use of this Manual

- Safety Symbol and Signal Words

- Machine Orientation

- Proper Machine Use

- Service and Registration

- Component Identification

- Fields of Application

- Using Attachments

- Vibration Information

- Fire Extinguisher

- Manufacturer Information

- Indicator and Operation Symbols

Safety

- Safety Symbol and Signal Words

- Mandatory Safety Shutdown Procedure

- Before Starting

- During Operation

- Applications with Load-Handling Devices

- Parking the Machine

- Electrical Energy

- Maintenance and Service Safety Practices

- Battery Hazards

- Fire Hazards

- Additional Safety Equipment

- Crystalline Silica Exposure

- Transporting the Machine

- Lifting the Machine with a Crane

- Loading and Transporting the Machine

- Safety Decals (ANSI-Style and ISO-Style)

Specifications

- Fluids/Lubricants Types and Capacities

- Dimensions

- Payloads/Capacities

- Weights

- Track Drive

- Coolant Compound Table

- Engine Specifications

- Hydraulic System Specifications

- Electrical System Specifications

- Sound Power/Pressure Levels

- Vibration Levels

- Features (Standard and Optional)

- Common Materials and Densities

Controls

- Multi-Function Display

- Switches/Indicators

- Multi-Function Display Screens

- Control Joysticks

- Straight Tracking Adjust

- Parking Brake/Work Hydraulics Lock-out

- Cab Heat and Air Conditioning (Option)

- Operator’s Seat

- Seat Belt

- Armrest/Joystick Console Adjustment

- Throttle Controls

- Travel Controls

- Travel Speed Range Selection

- Lift Arm Float Button

- Hydraglide Button (Option)

- Work Lights

- Battery Disconnect Switch (Option)

- Windshield Wipers/Washers

Operation

- Operational Checks

- Before Operation

- Starting the Engine

- Warm Up

- Run-In Period

- Stopping the Engine

- Engine Stalling

- Diesel Particulate Filter (DPF) Regeneration Procedures

- After Operation

- Jump-Starting

- Travel Drive Operation

- Lift Arm Operation

- Self-Leveling

- Lift Arm Float

- Hydraglide Ride Control System (Option)

- Hydraulics Control Lock

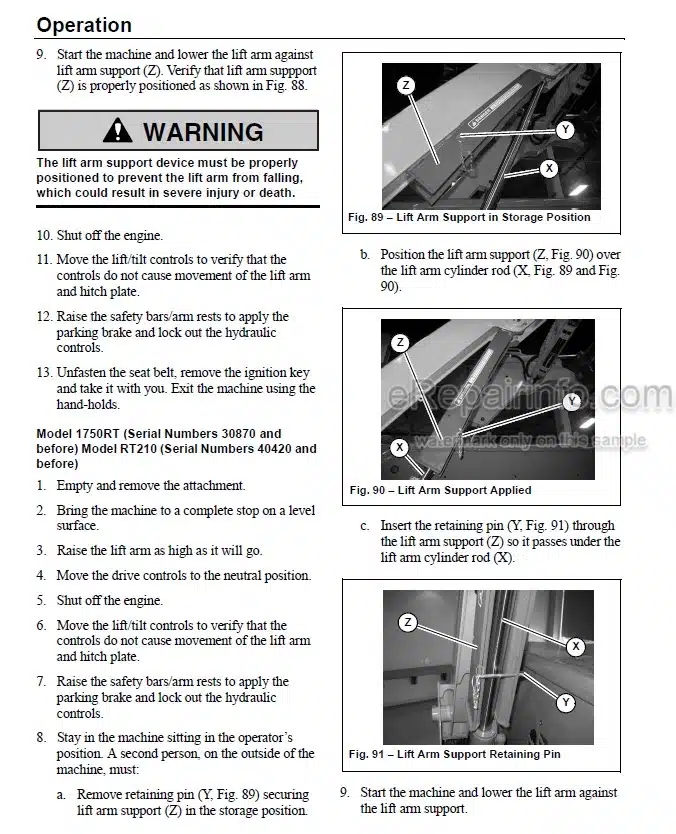

- Lift Arm Support

- Connecting/Disconnecting Attachments

- Powering Attachments with Hydraulic Function

- Optional 14-Pin Connector

- Working with Buckets

- Working with Pallet Forks

- Lifting the Machine using a Crane

- Loading and Transporting the Machine on a Transport Vehicle

- Storage Box

Maintenance

- Maintenance Schedule

- Maintenance Interval

- Engine Maintenance

- DPF Service

- Fuel System Maintenance

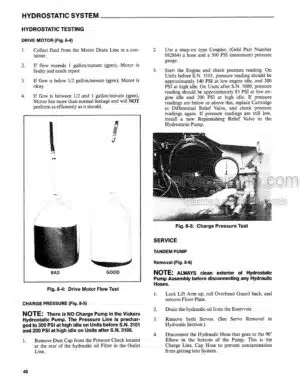

- Hydraulic System Maintenance

- Hydraulic Hose Maintenance

- Travel Motor Maintenance

- Track Maintenance

- General Lubrication

- Tilting ROPS/FOPS

- Electrical System

- Long-Term Storage

- Air Conditioning Maintenance

- Windshield Washer Reservoir

- Final Shutdown/Decommissioning

- Maintenance Log

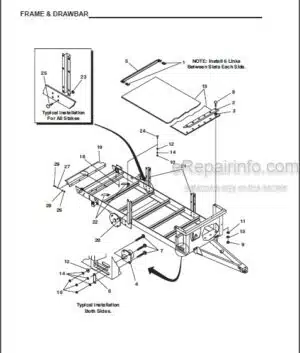

Lift Arm and ROPS/FOPS

- Lift Arm Removal

- Lift Arm Installation

- ROPS/FOPS Removal

- ROPS/FOPS Installation

Model RT250 Engine Removal/Installation

- Engine Removal – Model RT250

- Engine Installation – Model RT250

Models RT175/RT210 Tier 4 Engine Removal/Installation

- Engine Removal

- Engine Installation

Models RT175/RT210 Engine Removal/Installation

- Engine Removal

- Engine Installation

Hydraulic Equipment

- Detailed hydraulic system maintenance and repair procedures

Detailed Illustrations and Diagrams

The manual includes high-quality illustrations and diagrams to simplify complex procedures:

- Wiring Diagrams: Assist with diagnosing and repairing electrical issues.

- Hydraulic Diagrams: Help troubleshoot and repair hydraulic systems.

User-Friendly Features

The PDF format ensures easy accessibility and navigation. The manual is fully searchable, allowing users to quickly find the information they need.

Ideal for Technicians and Owners

Whether you are a professional technician or a compact track loader owner, this manual is an invaluable tool. It provides clear, concise instructions and detailed diagrams to guide you through every aspect of loader repair and maintenance.

How to Use This Manual

- Step-by-Step Instructions: Follow the detailed, step-by-step instructions for disassembly, inspection, and reassembly of components.

- Routine Maintenance: Regular maintenance guides ensure your compact track loader operates at peak performance.

- Inspection and Repair: Use the inspection and repair sections to diagnose and fix issues effectively.

- Electrical and Hydraulic Systems: Refer to the wiring and hydraulic diagrams for clear visual guidance.

Get Your Copy

Ensure the longevity and optimal performance of your Gehl compact track loaders by utilizing this comprehensive service manual. With 362 pages of detailed information, this manual is your ultimate guide to maintaining and repairing your equipment.

Invest in the Gehl RT175 GEN2, RT210 GEN2, RT250 Service Manual Compact Track Loader 50940164 today and keep your loaders in top working condition.

Anonymous (verified owner) –

Excellent service. Very very quick download. 362 pages of a top notch service manual matched to my serial number. I’ll use this site again and often.