Factory Service Repair Manual For Claas Renault Ares 816 Tractor. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 1271

Bookmarks: Yes

Searchable: Yes

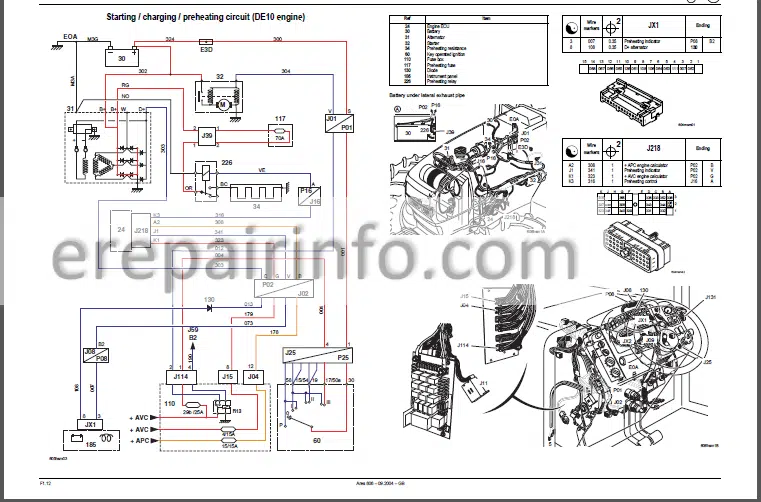

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Claas Renault Ares 816

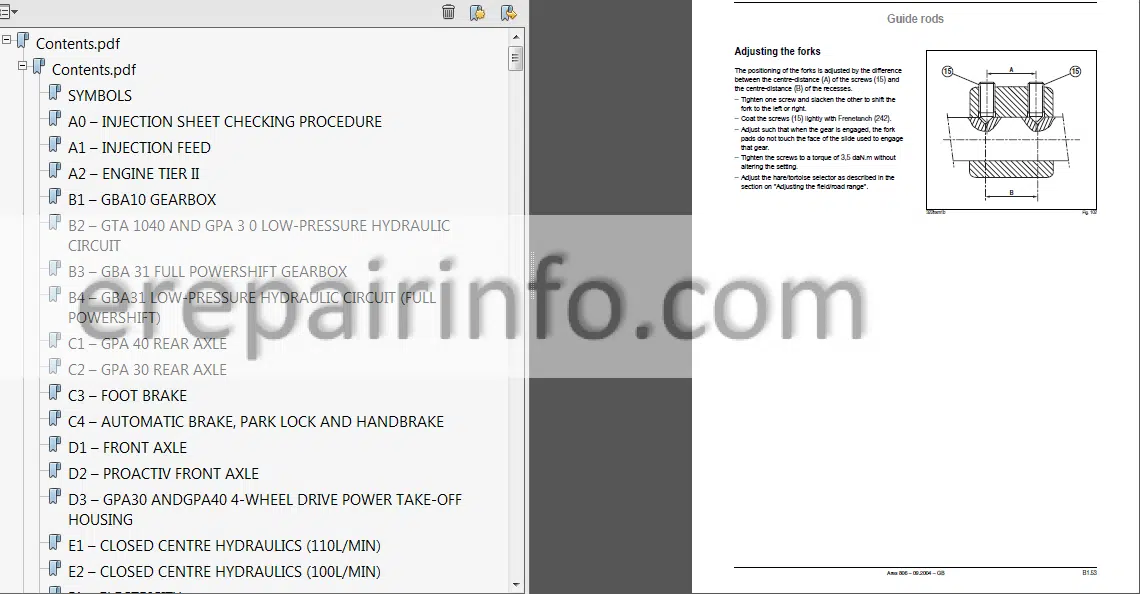

Contents

- -INJECTION SHEET CHECKING PROCEDURE

–CHECKING PROCEDURE

Checking Procedure

–MEASUREMENT SHEET

Measurement Sheet

–PRESSURE CONNECTION (APPENDIX)

100 B’minls Circuit

110 L’min Ls Circuit - -INJECTION FEED

–IDENTIFICATION

Injection Pumps Identification

–TIGHTENING TORQUES

Tightening Torques

–OPERATING PRINCIPLES

Pre-Filter

Fuel Filter

Injection Pump

Injectors

Situation Of The Different Sensors

–CHECKS/ADJUSTMENTS

Accelerator Control Adjustment

Adjusting The Engine Injector

Supply Pressure Check

–REMOVAL/REFITTING

Fuel Filter Replacement

Injection System Bleeding

Injection Pump Removal

–DIAGNOSTICS

Sheet Ne 1 “Engine Start-Up Defect”

Sheet Ne 2 “Irregular Engine Operation”

Sheet Ne 3 “Grey Or Black Smoke Emission”

Sheet Ne 4 “White Smoke Emission”

Sheet Ne 5 “Check The Fuel Feed Circuit” - -ENGINE TIER II

–GENERAL SPECIFICATIONS

Identification Of The Engines

Engines 6 Cylinders

–DIMENSIONAL SPECIFICATIONS

Cylinder Head And Valves

Cylinder Block

Liners And Pistons

Connecting Rods

Crankshaft Bearingsand Flywheel

Camshaft

Distribution

Lubrication

Cooling

Turbocharger

–TIGHTENING TORQUES

Front Chassis/ Engine Link

Enginbtransmission Link

Crankshaft With Straight Front End

Crankshaft With Tapering Front End

–CHECKS/ADJUSTMENTS

Checking Compression

Check Of Engine Oil Pressure

Check Of Valve Lift (Engine Cold)

Valve Clearance (Engine Cold)

Valve Adjustment Sequence

Checking The Turbocharger Pressure

Check Of The Belt And The Tensioner Spring

Procedure For Checking The Viscous Fan Coupling

–REMOVAL/REFITTING

Preliminary Operations

Separate Enginefront Axle

Separate Enginbgearbox

Engine Installation Specifications

Cylinder Head

Camshaft

Cylinder Block

Liners

Pistons And Connecting Rods

Crankshaft Bearings And Flywheel

Changing The Front Bearing Seal

Camshaft Balancer Shafts And Distributor

Lubrication

Cooling

Turbocharger

–DIAGNOSTIC SHEETS

“Excessive Oil Consumption’ Sheet

Inspection Procedure Of The Cylinder Head Gasket

“Engine Oil Pressure Too High’ Sheet

Checking Procedure Of The High Oil Pressure In The Crankcase

“Engine Oil Pressure Too Low Sheet

“Coolant Temperature Too High” Sheet

“Coolant Temperature Too Low” Sheet

Failure Searching Procedure Of Cylinder Head Seal

–TOOLS

Engine Tools - -GBA 10 GEARBOX

–GENERAL SPECIFICATIONS

Meaning Of Transmission System Designations

Introduction To The Gba 10

Transmission Kinematics

Gta 1041 Overdrive

Gta 1042 And 42+ Overdrive

Gta 1044 Overdrive

Gta 1044 Non-Overdrive

Gba 10 Removalrefitting Procedure

–TIGHTENING TORQUE

Enginb’gearbox Coupling

Gearboxrear Axle Coupling

–MAIN ADJUSTMENTS

Main Adjustments

–REVERSHIFT

Clutch Function

Shuttle Reverser Operaton

–FRONT CLUTCH

Exploded View

Removal/Refitting (Stage 1 Page B19)

Removal

Refitting

Adjustment

Preparing For Adjustment

–REAR CLUTCH

Exploded View

Removal/Refitting (Stage 2 Page B19)

Removal

Refitting The Epicyclic Gear Set

Refitting The Assembly

–QUADRISHIFT UNIT

Operating Diagram

Exploded View

Removal/Refitting (Stage 3 Page Bl 9)

Removing The Front Brake And Clutch

Removing The Planet Carrier Assembly

Assembling The Planet Carriers

Removing The Rear Brake And Clutch

Removing The Secondary Shaft

Refitting And Adjusting The Secondary Shaft

Refitting The Rear Brake And Clutch

Refitting The Front 8Rake And Clutch

Adjusting The Planet Carrier

Refitting The Quadrishift Unit

–GEARSHIFT COVER

General

Removing/Refitting The Cover

Replacing The Range Piston Seals

Removing And Refitting The Gear Selector

Adjusting The Field’road Range

–GUIDE RODS

General

Exploded View

Removing The Guide Rods

Refitting The Guide Rods

Adjusting The Forks

–OUTPUT SHAFT

General

Exploded View

Removing The Shaft

Refitting The Shaft

Adjusting The Shaft

–INPUT SHAFT

General

Exploded View

Removing The Shaft

Removing The Shaft

Refitting The Shaft

Adjusting The Shaft

–COUNTERSHAFT

General

Exploded View

Removing The Shaft

Adjusting The Shaft

Refitting The Shaft

Adjusting The Bearings

–CRAWLER SPEEDS

General

Exploded View

Removing/Refitting The Housing

Removing Adjusting And Refitting The Control System

Setting The Controls - -GTA 1040 AND GPA 30 LOW-PRESSURE HYDRAULIC CIRCUIT

–LS 100 UMIN LOW-PRESSURE CIRCUIT ON GTA 1040

Circuit Layout On Beam

Hydraulic System

Gearbox And Rear Axle Lubrication

Axle Tube Lubrication

–LS 110 UMIN LOW-PRESSURE CIRCUIT ON GTA 1040

Circuit Layout On Beam

Hydraulic System

Gearbox And Rear Axle Lubrication

Axle Tube Lubrication

–LS 110 UMIN LOW-PRESSURE CIRCUIT ON GPA 30

Circuit Layout On Beam

Hydraulic System

Rear Axle Lubrication

Axle Tube Lubrication

–LOW-PRESSURE HYDRAULIC COMPONENTS

Ls 100 Umin Distribution Valve

Ls 110 Umin Distribution Valve

Revershift And Quadrishift Control

Independent Lubrication On Gba 10

–SOLENOID VALVE MEASUREMENT AND CHECKING POINTS

Electrical Tests On The Solenoids

–GBA 10 DISTRIBUTION UNIT MEASUREMENT AND CHECKING POINTS

Distribution Unit Supply Pressure Check

Revershift Supply Pressure Check

Quadrishift Supply Pressure Check

–“HYDRAULIC INSPECTION RESULTS” SHEET

Hydraulic Inspection Results Sheet

–GBA 10 LUBRICATION MEASUREMENT AND CHECKING POINTS

Independent Lubrication Check

–“HYDRAULIC INSPECTION RESULTS” SHEET

Hydraulic Inspection Results Sheet

–LS 110 L/MIN MEASUREMENT AND CHECKING POINTS

Lubrication Pressure Check

Gba 10 Lubrication Pressure Check

Checking The Control Pressure

Lubricating Oil Flow Rate Through The Cooler At 60‘C

–“HYDRAULIC INSPECTION RESULTS” SHEET

Hydraulic Inspection Results’ Sheet

–LS 100 L/MIN MEASUREMENT AND CHECKING POINTS

Checking The Flow Coming From The Steering Box

Checking The Control Pressure

Cooler Inlet Pressure Check

Lubrication Pressure Check

–“HYDRAULIC INSPECTION RESULTS” SHEET

Hydraulic Inspection Results Sheet

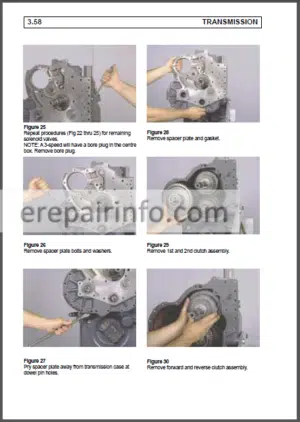

-GBA 31 FULL POWERSHIFT GEARBOX

–GENERAL

Characteristics

Description Of The Transmission System

Gearbox Arrangement Diagram

Operation And Power Transmission

–REPAIR

Replacing The Input Shaft Seal

Removing The Gearbox Completely

Tightening Torques - -FULL POWERSHIFT LOW PRESSURE HYDRAULIC CIRCUIT

–GENERAL

Operation

Characteristics

–DESCRIPTION

Transmission Hydraulic Circuit

Transmission Circuit Layout

Oil Filter

Thermostatic Valve

–REPAIR

Pump Gerotor Type

Pressure Control Valve

Proportional Solenoid Valve

Discharge Valve

–MEASUREMENT AND CHECKING POINTS

Checking The Control Pressure

Lubrication Pressure Check

Checking The Clutch Feed Pressures

Electrical Check On The Solenoids

–“INSPECTION RESULTS” SHEET

“Inspection Results” Sheet

–TOOLS

Low-Pressure Hydraulics And Gearbox Tools - -GPA 40 REAR AXLE

–TIGHTENING TORQUES AND MAIN ADJUSTMENTS

Gearbox’rear Axle Coupling

Rear Axle’pto Housing Coupling

General Cross-Section

5′ Differential

Nd Axle Tubes

Hd And Hd+Axle Tubes

Hde Axle Tubes

–GPA 40 DRIVE PINION

General

Removal/Refitting

Setting And Adjusting The Protrusion Distance Of The Drive Pinion

–5″ DIFFERENTIAL

General

Removing/Refitting The Bearings

Removing/Refitting The Differential Case

Removing/Refitting The Differential Lock

Removing/Refitting The Planet Gears Sun Gears And Ring Gear

Adjusting The Backlash

Shimming The Differential Case Roller Bearings

–ND AXLE TUBES

General

Removal

Refitting

Removing The Planet Carrier

Refitting The Planet Carrier

Removing The Roller Bearings And Seals

Refitting The Roller Bearings And Seals

Shimming The Wheel Shaft Bearings

Replacing The Wheel Stud

–HD AND HD+ AXLE TUBES

General

Removal

Refitting

Removing The Planet Carrier

Refitting The Planet Carrier

Removing The Roller Bearings And Seals

Refitting The Roller Bearings And Seals

Shimming The Wheel Shaft Bearings

Replacing The Wheel Stud

–HDE AXLE TUBES

General

Removal

Refitting

Removing The Planet Carrier

Refitting The Planet Carrier

Removing The Roller Bearings And Seals

Refitting The Roller Bearings And Seals

Shimming The Wheel Shaft Bearings

Replacing The Wheel Stud

–GPA 40 POWER TAKE-OFF CLUTCH

General

Removal/Refitting

Removing The Clutch

Refitting The Clutch

–GPA 40 POWER TAKE-OFF UPPER SHAFT

General

Prevention System

Removal/Refitting

Removal/Refitting

Adjustment

Adjusting The Controls

–GPA 40 POWER TAKE-OFF LOWER SHAFT

General

Power Take-Off Brake

Removing/Refitting The Lower Shaft

Adjustment

–PROPORTIONAL POWER TAKE-OFF

General

Removing/Refitting The Selection System

Removing/Refitting The Gears

Adjusting The Bearings - -GPA 30 REAR AXLE

–TIGHTENING TORQUES AND MAIN ADJUSTMENTS

Gearbox Intermediate Housing Coupling

Intermediate Housing’rear Axle Coupling

Rear Axle’pto Housing Coupling

General Cross-Section

5′ Differential

Hd+Axle Tubes

Hde Axle Tubes

–GPA 30 DRIVE PINION

General

Removal/Refitting

Drive Pinion Protrusion Distance And Shimming

–5″ DIFFERENTIAL

General

Removing/Refitting The Bearings

Removing/Refitting The Differential Case

Removing/Refitting The Differential Lock

Removing/Refitting The Planet Gears Sun Gears And Ring Gear

Adjusting The Backlash

Shimming The Differential Case Roller Bearings

–GPA 30 POWER TAKE-OFF CLUTCH

General

Removal/Refitting

Removing The Clutch

Refitting The Clutch

–GPA 30 POWER TAKE-OFF UPPER SHAFT

Removal/Refitting

Adjustment

Gpa 30 Power Take-Off Lower Shaft

General

Removal

Refitting

Adjusting The Bearings

–GPA 30 CRAWLER GEARS

General

Removing/Refitting The Housing

Removing Adjusting And Refitting The Control System

Setting The Controls - -SERVICE BRAKES

–TECHNICAL SPECIFICATIONS

Footbrake

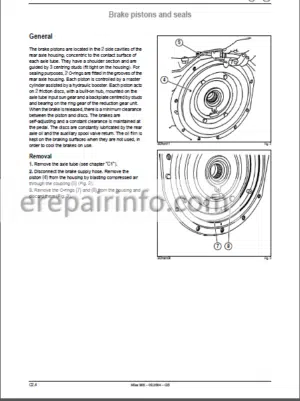

–BRAKE PISTONS AND SEALS

Draining The Service Brake Circuit

General

Removal

Refitting

Sealing Test

–BOOSTERS AND MASTER CYLINDERS

Description Of The Master Cylinders/Boosters

–REPLACING THE MASTER CYLINDERS

Adjusting The Brake Pedals

–BLEEDING THE BRAKE CIRCUIT

Bleeding The Circuit Manually

Closed-Centre Hydraulic Circuit On Gta 3130 (Ls 110 L/Min)

Closed-Centre Hydraulic Circuit On Gta 1040 (Ls 110 L/Min)

Closed-Centre Hydraulic Circuit On Gta 1040 (Ls 100 L/Min)

Bleeding The Brake Circuit With A Pressurising Device

Checking The Effectiveness Of The 110 L’min And 103 L/Min Circuit Air Bleed (Bosch Valve)

Checking The Snr Valve (100 Umin Circuit) - -AUTOMATIC BRAKE PARK LOCK AND HANDBRAKE

–AUTOMATIC BRAKE

Operating Principles

Exploded View Of Control Unit

Exploded View Of Brake Mechanism

Removing/Refitting The Automatic Brake Assembly

Removing/Refitting The Unit

Removing/Refitting The Parking Brake

Basic Parking Brake Adjustment

Adjusting The Parking Brake Control

–PARK LOCK

General

Remark

Overall View

Schematic Diagram

Operation

Removing/Refitting The Safety Switch

Safety Switch Adjustment

“Inspection Results” Sheet

–HANDBRAKE

General

Operation

Exploded View

Removing And Refitting The Handbrake Casing

Adjusting The Handbrake Control

Diagnosing Brake Disc Wear

Remark

–TOOLS

Gpa 40 Rear Axle – Gpa 30 Rear Axle – Service Brakes – Automatic Brake – Park Lock -Handbrake - -FRONT AXLE

–DESCRIPTION

General Characteristics – Rigid Axle

Drive Chain

–REMOVAL/REFITTING

Tightening Torques And Sealants

Adjusting The Wheel Alignment

–DISASSEMBLY PRIOR TO FRONT AXLE OPERATIONS

Preliminary Operations

–REMOVAL/REFITTING

Steering Cylinder

Removing The Reduction Gear And Wheel Hub

Refitting The Reduction Gear And Wheel Hub

Removing The Wheel Pivot

Refitting The Wheel Pivot

Refitting The Angle Sensor

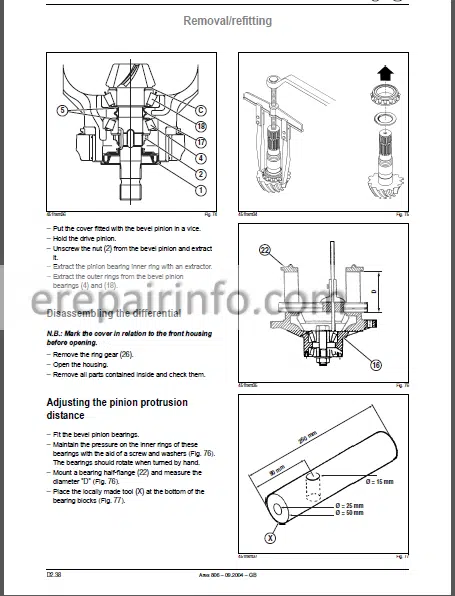

Removing The Bevel Gear And Differential

Disassembling The Differential

Adjusting The Pinion Protrusion Distance

Setting The Bevel Pinion Preload

Adjusting The Meshing Backlash

Preloading The Differential Bearing Blocks

Checking The Settings

Final Reassembly

–HYDRAULIC MEASUREMENT AND CHECKING POINTS

Checking The Differential Lock Circuit Pressure

–“HYDRAULIC INSPECTION RESULTS” SHEET

Checking The Differential Lock Circuit Pressure - -PROACTIV FRONT AXLE

–DESCRIPTION

General Characteristics – Rigid Axle

Characteristics

–REMOVAL/REFITTING

Tightening Torques And Sealants

Adjusting The Wheel Alignment

–DISASSEMBLY PRIOR TO FRONT AXLE OPERATIONS

Preliminary Operations

–REMOVAL/REFITTING

Steering Cylinder

Epicyclic Reduction Gear And Wheel Hub

Removing The Epicyclic Reduction Gear

Removing The Wheel Hub

Wheel Pivot And Upper Arm

Removing The Angle Sensor

Removing The Wheel Pivots

Removing The Upper Arm

Suspension Cylinder And Lower Arm

Removing The Torsion Bar

Removing The Lower Arm

Refitting The Lower Arm

Refitting The Torsion Bar

Refitting The Upper Arm

Universal Shafts

Refitting The Wheel Pivots

Refitting The Wheel Hub

Refitting The Epicyclic Reduction Gear

Refitting The Suspension Position Sensor

Setting The Suspension Sensors

Locally Made Test Harness

Calibrating The Suspension

Refitting The Angle Sensor

Final Steps

Bevel Gear And Differential

Sectional View

Exploded View

Disassembling The Differential

Adjusting The Pinion Protrusion Distance

Setting The Bevel Pinion Preload

Adjusting The Meshing Backlash

Checking The Settings

Final Reassembly

Suspension Control Unit

–HYDRAULIC MEASUREMENT AND CHECKING POINTS

Suspension Cylinder Pressure Check

Checking The Differential Lock Circuit Pressure

–HYDRAULIC MEASUREMENT AND CHECKING POINTS

Suspension Cylinder Pressure Check

Differential Locking Circuit Pressure Check

–ELECTRIC CHECKS

Control Switches

Suspension Control Solenoids

–BREAKDOWN DIAGNOSIS

Values To Be Checked

Interpreting Error Codes - -GPA 30 AND GPA 40 4-WHEEL DRIVE POWER TAKE-OFF HOUSING

–DESCRIPTION

General

Cross-Sectional View Of The 4-Wheel Drive Housing (Gpa 30 Axle)

Cross-Sectional View Of The 4-Wheel Drive Housing (Gpa 30 Axle)

Exploded View Of The 4-Wheel Drive Housing (Gpa 30 Axle)

Cross-Sectional View Of The 4-Wheel Drive Housing (Gpa 40 Axle)

Cross-Sectional View Of The 4-Wheel Drive Housing (Gpa 40 Axle)

Exploded View Of The 4-Wheel Drive Housing (Gpa 40 Axle)

–REMOVING/REFITTING THE HOUSING

Removal Of Clutch

Removing The Clutch

Refitting The ClutchI

Fitting Shims To The Clutch “Ji”I

Fitting Shims To The Shaft ’J2″I

Refitting The ShaftI

–SOLENOID VALVE MEASUREMENT AND CHECKING POINTS

Owoff Solenoid ValveI

–HYDRAULIC MEASUREMENT AND CHECKING POINT

Checking The Front Axle Engagement PressureI

–“HYDRAULIC INSPECTION RESULTS” SHEET

Checking The Front Axle Engagement PressureI

–TOOLS

Front Axle – 4 Wd Power Take-Off Housing - -CLOSED CENTRE HYDRAULICS (110 L/MIN)

–DESCRIPTION

Characteristics

Hydraulic Circuit Diagram – Quadrishift Transmission

Component Layout – Quadrishift Transmission

Hydraulic Circuit Diagram – Full Powershift Transmission

Component Layout – Full Powershifttransmission

Sectional View Of Gpa 40 Rear Axle

Sectional View Of Gpa 30 Rear Axle

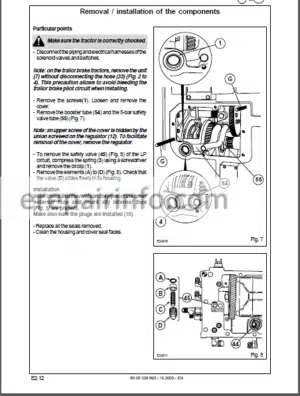

–REMOVING/REFITTING THE COMPONENTS

External View Of Right-Hand Cover Without Brake Valve

External View Of Right-Hand Cover With Brake Valve

Internal View Of Right-Hand Cover

Exploded View Of Right-Hand Cover

Identification Of Ports And Lines

Schematic Diagram Of The Variable Displacement Pump Regulator

Priority Unit (No Trailer Brake)

Priority Units (With Trailer Brake)

Schematic Diagram Of Priority Units

Removal Of Right Cover

Replacing The Rh Cover

Adjusting The Speed Sensor

Variable Displacement Pump

Exploded View Of The Left-Hand Cover

Sectional View Of The Left-Hand Cover

Sectional View Of The Gpa 30 Left-Hand Cover

Sectional View Of The Gpa 40 Left-Hand Cover

Removal Specifications

Refitting Specifications

Booster Pump

Replacement Of Pump Seals

Fitting Spool Valves On The Gpa 40 Rear Axle

Fitting Spool Valves On The Gpa 30 Rear Axle

Hydraulic Diagram Of The Lift Spool Valve And The Electrohydraulic Spool Valve

Hydraulic Diagram Of The Lift Spool Valve And Mechanical Spool Valve

Removing The Spool Valve Block

Refitting The Spool Valve Unit

Linkage Spool Valve

Linkage Spool Valve (Neutral Position)

Linkage Spool Valve (Down Position)

Linkage Spool Valve (Up Position)

3-Position “Zp Auxiliary Spool Valve With Optional ‘ko*

Four-Position “Zp Auxiliary Spool Valve

4-Position ’Zp Auxiliary Spool Valve With Optional T<0*

Auxiliary Spool Valve With Electrohydraulic Controls

Closing Plate With Safety Solenoid Valve

Auxiliary Spool Valve Control Adjustments

Linkage Rams

Steering Unit Ospq 100/160 Ls (110 Bmin Circuit)

Exploded View Of Steering Unit Ospq 100’160 Ls (110 L/Min Circuit)

Hydraulic Diagram Of Steering Unit Ospq 100/160 Ls (110 L’min Circuit)

Steering Unit Ospc 135 On (100 Bmin Circuit)

Exploded View Of Steering Unit Ospc 135 On (100 L’min Circuit)

Hydraulic Diagram Of Steering Unit Ospc 135 On (100 Bmin Circuit)

Access To Steering Unit

Specific Points Relating To Removabrefitting

–HYDRAULIC MEASUREMENT AND CHECKING POINTS

Variable Displacement Pump Boost Pressure Check

Standby Pressure And ’Xls* Pressure Check

Maximum Pressure And Flow Rate Check On The Auxiliary Spool Valves

Flow Regulator Check On The Auxiliary Spool Valves

Trigger Pressure Check On The (Ko) Spool Valve

Maximum Rear Lift Pressure Check

Braking Valve Check

–“HYDRAULIC INSPECTION RESULTS” SHEET

Variable Displacement Pump Boost Pressure Check

Standby Pressure And ’Xls* Pressure Check

Maximum Pressure And Flow Rate Check On The Auxiliary Spool Valves

Flow Regulator Check On The Auxiliary Spool Valves

Trigger Pressure Check On (Ko) Spool Valves

Maximum Rear Lift Pressure Check

–HYDRAULIC MEASUREMENT AND CHECKING POINTS

Steering Pressure Check

Maximum Steering Cylinder Pressure Check

Shockproof Valve Opening Pressure Check

–“HYDRAULIC INSPECTION RESULTS” SHEET

Steering Pressure Check

Maximum Steering Cylinder Pressure Check

Shockproof Valve Opening Pressure Check - -CLOSED CENTRE HYDRAULICS (100 L/MIN)

–DESCRIPTION

Characteristics

General Hydraulic Circuit Diagram Of 100 L “Load Sensing” Closed-Centre Circuit

Hydraulic Circuit Diagram – Quadrishift Transmission

Exterior View Of The Right-Hand Cover

Interior And Exterior View Of The Right-Hand Cover

Description Of The Circuit Selector (Load Sensing Signal)

–REMOVING/REFITTING THE COMPONENTS

Brake Valve

Sectional View Of The Braking Valve (Bosch)

Exploded View Of Braking Valve (Bosch)

Sectional View Of The Braking Valve (Snr)

Exploded View Of Braking Valve (Snr)

Geographical Location Of The Hydraulic Components On The Priority Unit

Pressure Limiter Dsvl (210 Bar)

Removal Of Right Cover

Removal/Refitting The Main Pump

Replacing The Rh Cover

Overall View Of The Left-Hand Cover

Removing The Left-Hand Cover

Refitting The Left-Hand Cover

Removal/Refitting The Steering Pump

–HYDRAULIC MEASUREMENT AND CHECKING POINTS

Checking The Standby Pressure Of The 14 Cm’ Pump

Pressure Check For A Flow Rate Of Less Than 40-Umin And A Flow Rate Of 60 L’min

Test At 20 Umin

Test At 20 Umin

Minimum/Maximum Flow Rate Check On The Auxiliary Spool Valves

Braking Valve Check

–“HYDRAULIC INSPECTION RESULTS” SHEET

Minimum/Maximum Flow Rate Check On The Auxiliary Spool Valves

Checking The Standby Pressure Of The 14 Cm’ Pump

Check The Pressure For A Required Flow Less Than 40 Umin And A Flow Of 60 L’min

–HYDRAULIC MEASUREMENT AND CHECKING POINTS

Checking The Steering Pump

Maximum Steering Cylinder Pressure Check

Shockproof Valve Opening Pressure Check

–“HYDRAULIC INSPECTION RESULTS” SHEET

Checking The Steering Pump

Maximum Steering Cylinder Pressure Check

Shockproof Valve Opening Pressure Check

–TOOLS

Hydraulic Circuit Tooling

-ELECTRICITY

–GENERAL CONTENTS

Item List

Wiring And General Lists

Schematic Diagrams According To Functions

Connector And Harness Tracking

–TOOLS

Electricity Tools

-INSTRUMENT PANEL

–OPERATING PRINCIPLES

Description Of Panel

Allocation Of Light Bulbs To Indicator Lights

–CHARACTERISTICS

Indicator Operation

Warning Lights (Red)

Secondary Warning Lights (Orange)

Other Indicator Lights

Input’output By Function (Rev Counter Various Speeds And Hour Counter)

Input’output By Function (Gauge And Temperature)

Input&’outputs Relating To Red Lights

Input&’outputs Relating To Other Lights

Connection And Functions Of The Wires Of The Single Connector ‘jxv

Connection And Functions Of The Wires Of The Double Connector *Jx2*

Transmission Oil Pressure Sensor (17 Bar)

Blockage Indicator

Engine Oil Pressure Sensor

Transmission Oil Temperature Sensor

Speed Sensors

–REMOVAL/REFITTING

Connectors ‘jxl’And ’Jx2’ - -CALIBRATION

Calibration Over 100 Metres

Other Operations

-TCE 15/25 AND TCE 15 T ELECTRONIC LIFT

–DESCRIPTION

Tce 15/Tce25

Access To The Installed Software Version (Tce 15 Or Tce 25)

Lift Operating Conditions

Error Codes

Tce 15T

Lift Operating Conditions

Error Codes

–CHECKS AND ADJUSTMENTS

Connections To Tce 1ЭTCE 25 Units

Connections To Tce 15T Unit

Position Sensor On Gpa 30 Axle

Position Sensor On Gpa 40 Axle

Draft Sensor On Gpa 30 And Gpa 40 Axles

Theoretical Forward Speed Sensor On Gpa 30 And Gpa 40 Axles

Radar (Tce 25 Only)

Lift Spool Valve Solenoid Valves - -TRANSMISSION/AXLE CONTROL

–DRIVETRONIC III

Location Of The Ls 1OЭ L/Min Components And Sensors

Location Of The Ls 110 L/Min Components And Sensors

Toc Boc Switches And Angle Detector

Drivetronic Electronic Unit

Shuttle Reverser Lever Characteristics (Illustrated In Neutral)

Range And Declutching Control

Clutch Pedal Switches

Quadrishift Ii (244) And Quadractiv (245) Control Switches

Solenoid Valve

Control Pressure Switch

Lubricatiomboost Pressure Switch 3 Bar

Blockage Indicator

Speed Sensors

Temperature Sensor

Adjustment Of Toc Boc And Angle Detector Switches

Static Calibration Of Clutches

Adjusting The Calibration Procedures

Inputs/Outputs By Functions And Automatic Systems

Steering Angle Calibration

General Schematic Diagram

–DRIVETRONIC V

Inputs/Outputs And Automatic Systems

Switch And Solenoid Valve Check

Error Codes

–FULL POWERSHIFT

Location Of Components And Sensors

Layout On The Rear Axle

Features/Settings

Clutch Pedal Switches

Schematic Diagram Of Tc/Rcc - -ENGINE MANAGEMENT

–DE 10 PUMP

Location Of Components And Sensors

Characteristics Of The Components

Adjusting The Accelerator Detector

Diagnostic Harness

–VP 44 PUMP

Location Of Components And Sensors

Characteristics Of The Components

Schematic Diagram

Adjusting The Accelerator Detector

Diagnostic Harness - -ENGINE MANAGEMENT

–DE 10 PUMP

Location Cf Components And Sensors

Characteristics Of The Components

Adjusting The Accelerator Detector

Diagnostic Harness

–VP 44 PUMP

Location Of Components And Sensors

Characteristics Of The Components

Schematic Diagram

Adjusting The Accelerator Detector

Diagnostic Harness - -INFOTRAC AND ISO SOCKET

–DESCRIPTION

Functions Of The On-Board Computer

Operating Principles

Use

–REMOVAL/REFITTING AND ELECTRICAL CHECKS

Removing The Unit And Changing The Bulbs

Iso Socket

Iso Unit

External Temperature Probe

Schematic Diagram

Functions Of Connector Wires

Electrical Check On The Iso Socket

Outside Air Temperature Sensor

Forward Speed Calibration

Maintenance Function - -ELECTROPILOT

–DESCRIPTION

Controls

Joystick Connections

Dc Power Switch Connections

Connections On Module

Electrohydraulic Spool Valve (‘deh”)

–REMOVAL/REFITTING

Electrohydraulic Spool Valve (‘deh”)

Control Handle

–MEASUREMENT AND CHECKING POINTS

Checking The Safety Solenoid Valve

Checking The Control Pressures

–“INSPECTION RESULTS” SHEET

Checking The Safety Solenoid Valve

Checking The Control Pressure

–TOOLS

Instrument Panel – Electronic Lift (And Radar) – Transmission’axle Control – Engine Management – Infotrac And Iso Socket – Electropilot - -CAB LIFT

–DESCRIPTION

Identification

Right Side (Location Of Operations)

Left Side (Location Of Operations)

–FULL CAB REMOVAL

Safety Measure

Sling Specifications

–REMOVAL/REFITTING

Operations 1 To 4

Preparing The Lifting Bar

Installing The Lifting Bar

Taking The Weight Of The Cab

Operations 5 To 6

Operations 7 To 9

Operations Wto 12

Operations 13 To 14

Operations 15 To 18

Operation N* 19

Operation № 20

Operation N* 21

–REFITTING THE CAB

Special Points

Tightening Torques

Adjustments

–REMOVING/REFITTING THE ROOF

Full Removal With The Air Conditioning Fans

Refitting - -HEATING/AIR CONDITIONING

–DESCRIPTION

Characteristics

Diagram Of Operating Principle

Control Panel

–REMOVAL/REFITTING

Engine Layout

Cab Layout

Heating Radiator Unit And Fans

Heating Radiator

–TROUBLESHOOTING GUIDE

Diagnostics - -BONDING THE WINDOWS

–REMOVAL/REFITTING

Warning!

List Of Equipment To Use – Special Instructions

Removal

Preparing The Windscreen Before Applying Primer

Applying Primer

Preparing The Two-Pack Sealant

Replacing The Ploughing Window

–TOOLS

Cab Lift – Heating/Air Conditioning – Bonding The Windows - -LIFT AND FRONT POWER TAKE-OFF

–FRONT LIFT

Characteristics

Exploded Views Of 3 500 And 6 600 Dan Front Lifts

Tightening Torques

–MEASUREMENT AND CHECKING POINTS

Checking The Cylinder Pressure

–“INSPECTION RESULTS” SHEET

Checking The Cylinder Pressure

–FRONT POWER TAKE-OFF

Characteristics

Exploded View Of The Front Power Take-Off Assembly

Exploded View Of The Unit

Removing The Pto Housing

Exploded View Of The Clutch

Removing The Clutch

Refitting The Clutch

–MEASUREMENT AND CHECKING POINTS

Checking The Clutch Feed Pressure

–“INSPECTION RESULTS” SHEET

Checking The Clutch Feed Pressure - -PNEUMATIC BRAKING

–HOW IT WORKS

Measurement And Checking Points

With The Engine Running And Trailer Connected No Action Of Brakes

With The Engine Running And Trailer Connected Service Brakes Applied

With The Engine Running And Trailer Connected Hand Brake Applied

–MAIN COMPONENTS

Pneumatic Circuit Layout On Gta 3230

Compressor

Pressure Regulator

Tank

Trailer Control Valve

Solenoid Valve

Principal Control Valve

Bleeding The Hydraulic And Pneumatic Trailer Braking System

–TOOLS

Lift, Front Power Take-Off And Pneumatic Braking Tools

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet