Factory Use And Maintenance Manual For Claas Arion 510 520 530 540 610 620 630 640 Tractors.

Format: PDF

Language: English

Pages: 324

Bookmarks: Yes

Searchable: Yes

Model

Claas ARION 510, 520, 530, 540, 610, 620, 630, 640

Contents

-Identification – Certification – Safety

–Identification

Tractor Plate

Engine Plate

–Certification

–Safety

Safety

Safety Stickers With Warning Pictograms

-Driving Position

–Operating And Working Environment

Instrumentsand Controls (Driving Position)

Instrumentsand Controls (Panel)

Stowage And Accessories

–Lighting, Indicators And Safety

Description

Driving Lights And Horn

Working Lights And Rotating Beacon

Overhead Light

Rear View Mirrors

–Key-Operated Ignition Switch

Description

–Multifunction Armrest

Adjustment

–Seat

Operation

–Steering Wheel

Adjustment

–Instrument Panel

Description

Operation

Operation

Calibration

–Display

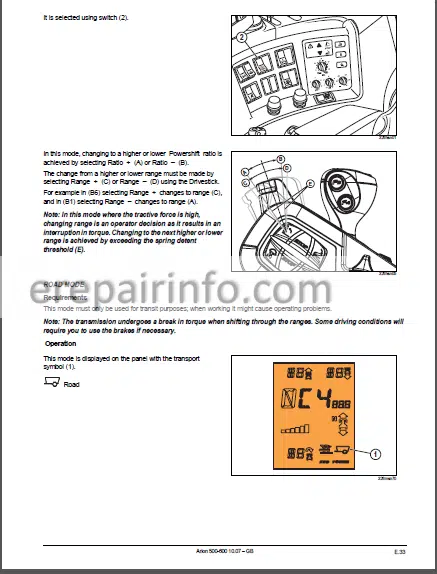

Transmission Display (Digital)

–Natural Ventilation And Windows

Operation

–Heating – Ventilation – Manual Air Conditioning

Description

Operation

–Heating/Ventilation/Automatic Climate Control

Description

Operation

–Cab Suspension

Adjustment

-Electrical System

–Trailer/Implement Light Socket

Description

–Electric Cabinet Supply Socket

Description

–Event Counter Socket

Description

–Iso Socket

Description

–Prefitments For Installing A Control Box In The Cab

Fitting Box Mounting

Cable Routing

–Battery

Description

–Battery Master Switch

Description

–Fuses And Relays

Recommendations

Cab-Mounted Services Fuse Box

Cab Top Fuse Box

Primary Services Fuse Box

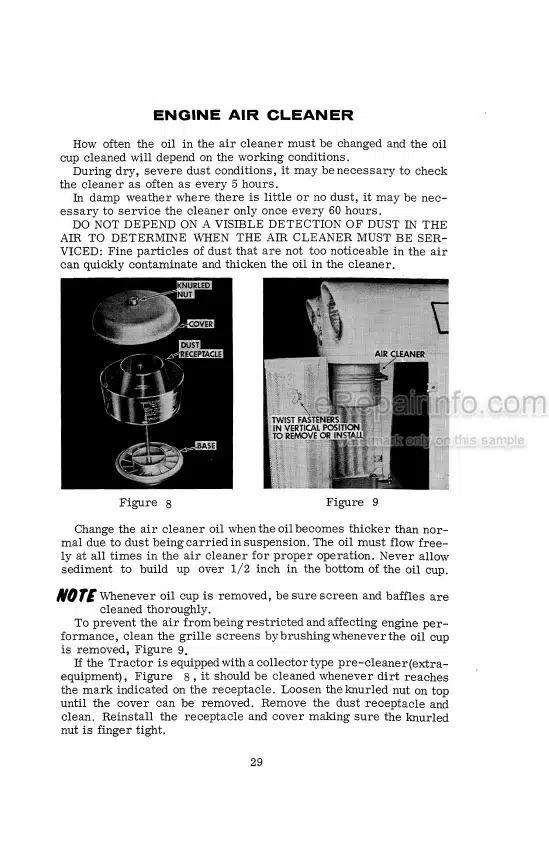

-Engine

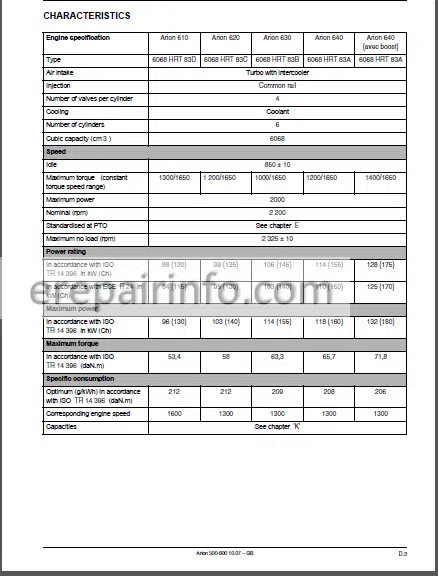

–Characteristics

–Displays

Description

–Safety

Safety: Mechanical Protection

–Engine Control

Starting The Engine

Accelerator Controls

Stopping The Engine

–Claas Power Management

Operation

–Fuel

Recommendations

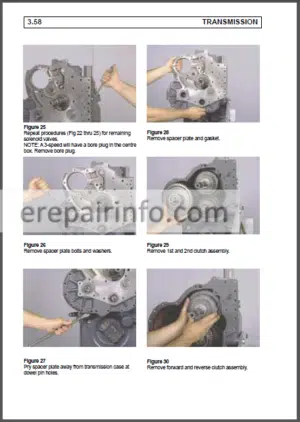

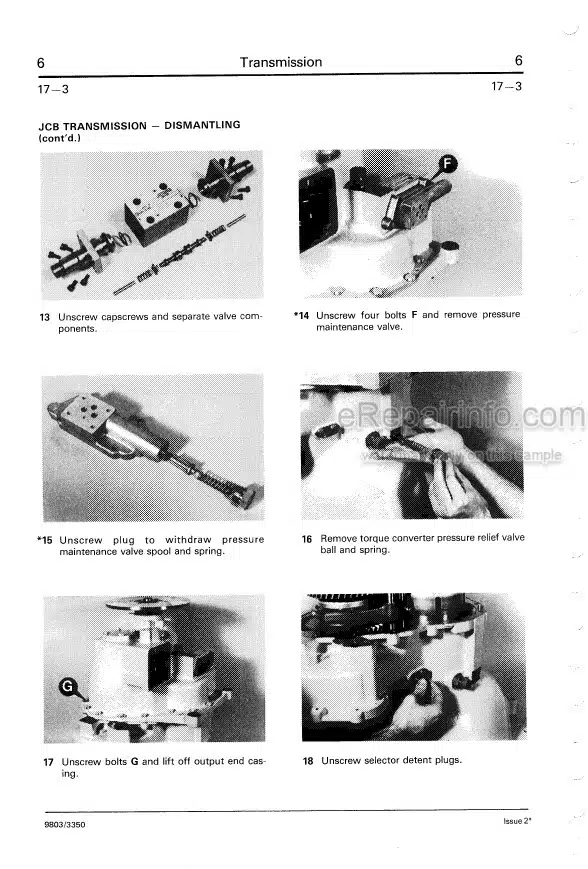

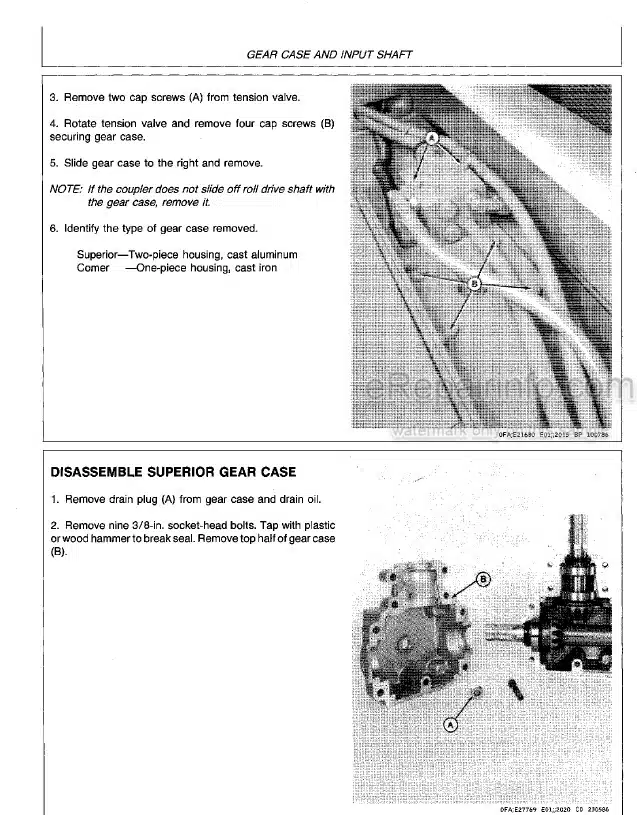

-Transmission

–Transmission Specifications

Gearbox

Road Speed

Rear Axle

Pto

–Displays

Transmission Display (Digital)

Instrument Panel

–Safety

Reverser Neutral

Transmission Neutral

Mechanical Protection

–Gearbox

Starting The Tractor

Manual Gear Changes

Automatic Gear Changes

Ratio Management

Low Range

–Rear Axle

Differential Lock

Tractor Brakes

Trailer Brake

Pto

–Stationary Working

Requirements

–Towing

Requirements

-Front Axle

–Characteristics

–Mechanical Protection

Operation

Instrument Panel

–Front Axle Engagement

Operation

Automatic Mode

Permanent Mode

–Proactiv Suspension

Operation

Fixed Mode

Automatic Mode

-Hydraulics – Rear Linkage And Hitch

–Characteristics

Hydraulic Systems

Linkage

Hitch

–Hydraulic Systems

Auxiliary Spool Valves

Power Beyond

–Lift

Controls

Safety

Using The Linkage

Mode Selection

Position Control

Force Control

Upper Limit

Lowering Speed

Transport Damper

Active Wheel Spin Management

External Controls

–Hitch

Recommendations

Adjustable Links

Top Link

Stabilisers

Automatic Hooks

Draw Bar Couplings

Tow Hook

Automatic Pick-Up Hitch

-Front Power Takeoff Linkage And Front Coupling

–Front Loader

Characteristics

Electropilot

Flexpilot

Unhitching Of The Frontal Loader

Linkage Of The Frontal Loader

Linkage Of The Tool

Unhitching Of The Tool

Level Indicator

“Pch System*

Maintenance On The Tractor With Frontal Loader

-On-Board Computer

Claas Information System

Description

Operation

-Wheels And Tyres

–Tyres

Recommendations

Inflation Pressure

Twin Wheels

–Track Widths

Characteristics: Setting The Track

Front Track

Rear Track

Tyre Combinations

–Special Cases

Tools Operating At Great Depth

-Dimensions Weights Capacities And Ballast

–Dimensions And Weights

Description

–Capacities

Description

–Ballast

Description

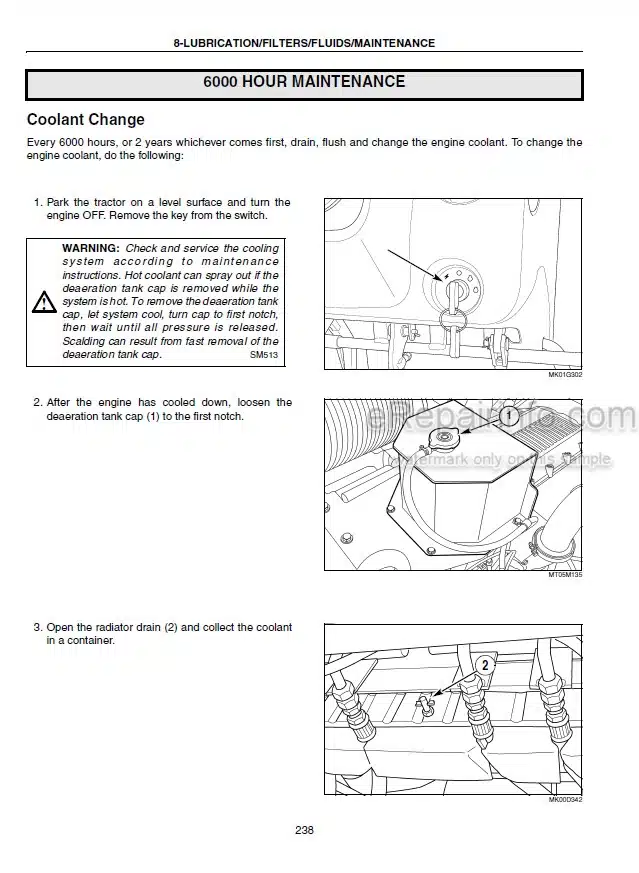

-Maintenance

–General

Recommendations

–Frequency

Summary Table

Operations

–Bleeding Air From The Injection System

Description

–Maintenance Logbook

Recommendations

-Operations That Are Mandatory Under The Guarantee

–Operations Mandatory Under The Terms Of The Contractual Guarantee

Pre-Delivery Inspection – Handing Over To The Customer

Mandatory Routine Maintenance

Mandatory Inspections

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Anonymous (verified owner) –

👍