Factory Repair Manual For Caterpillar 226B3 Skid Steer Loader. Illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 2440

Bookmarks: Yes

Searchable: Yes

Model

Caterpillar 226B3

AS200001-UP

MWD00001-UP

SNA00001-UP

Contents

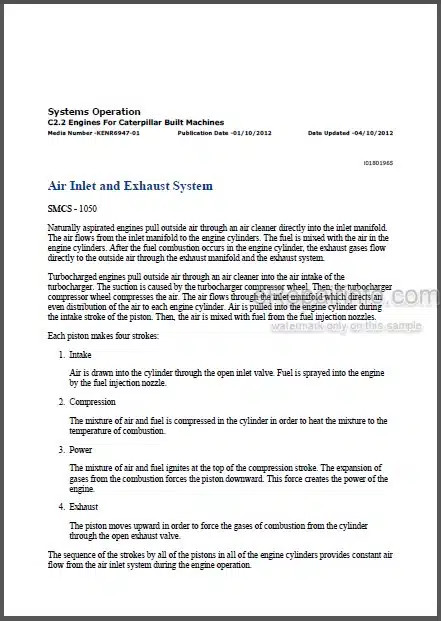

-AIR INLET AND EXHAUST SYSTEM.

Air Inlet and Exhaust System

Air Inlet and Exhaust System – Inspect

Wastegate – Test

Exhaust Temperature – Test

Air Cleaner – Remove and Install

Exhaust Manifold – Remove and Install

Exhaust Manifold

Muffler – Remove and Install

Turbocharger

Turbocharger – Remove and Install

-BASIC ENGINE

CP Basic Engine

CP Finding Top Center Position for No. 1 Piston

Gear Group (Front) – Time

Engine Crankcase Pressure (Blowby) – Test

Compression – Test

Engine Valve Lash – Inspect Adjust

Valve Depth – Inspect

Valve Guide – Inspect

Excessive Bearing Wear – Inspect

Piston Ring Groove – Inspect

Connecting Rod – Inspect

Connecting Rod Bearings – Inspect

Main Bearings – Inspect

Cylinder Block-Inspect

Cylinder Head – Inspect

Piston Height – Inspect

Flywheel – Inspect

Flywheel Housing – Inspect

Gear Group – Inspect

Belt Tension Chart

Camshaft

Camshaft – Remove

Camshaft – Disassemble

Camshaft – Assemble

Camshaft – Install

Crankshaft

Connecting Rod Bearing Journal

Main Bearing Journal

Crankshaft Rear Seal – Remove and Install

Crankshaft Wear Sleeve (Rear) – Remove and Install

Crankshaft Pulley – Remove and Install

Crankshaft Front Seal – Remove and Install

Crankshaft Main Bearings – Remove

Crankshaft Main Bearings – Install

Crankshaft – Remove

Crankshaft – Install

Bearing Clearance – Check

Cylinder Block

Crankshaft Main Bearings – Remove)

Crankshaft Main Bearings – Install

Fuel Injection Nozzles

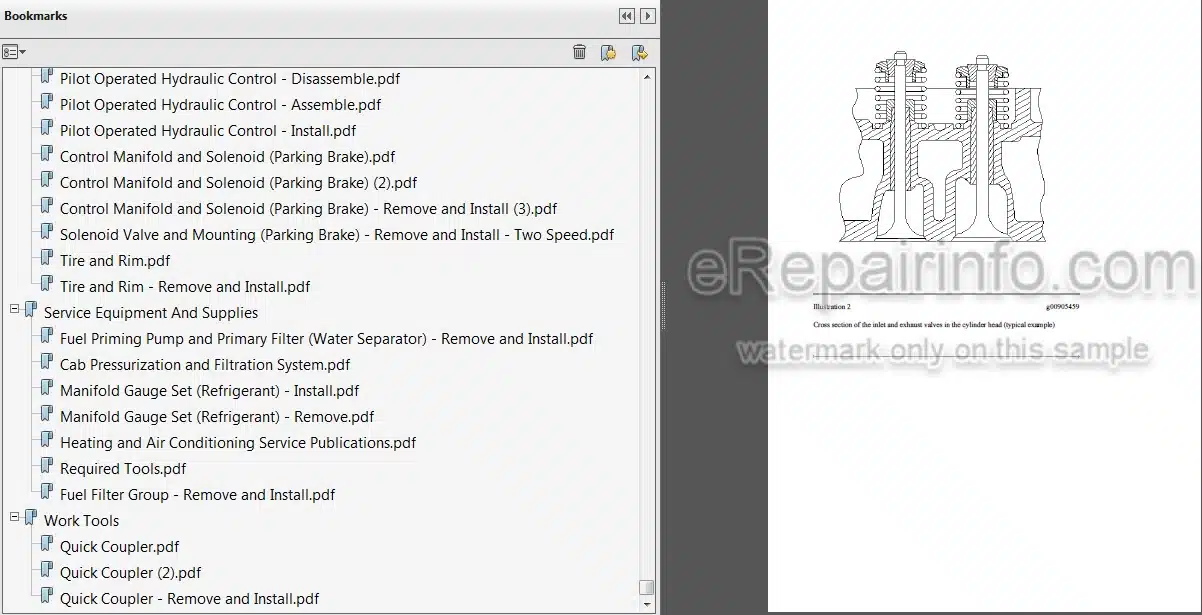

Cylinder Head Valves

Cylinder Head

Inlet and Exhaust Valve Springs – Remove and Install

Inlet and Exhaust Valves – Remove and Install

Cylinder Head – Remove

Cylinder Head – Install

Fan Drive

Flywheel

Flywheel Housing

Flywheel – Remove

Flywheel – Install

Gear Group (Front)

Flywheel Housing – Remove and Install – Engines with Flywheel Housing and Back Plate

Housing (Front)

Housing (Front) – Remove

Housing (Front) – Disassemble

Housing (Front) – Assemble

Housing (Front) – Install

Engine Lifting Bracket

Engine Oil Pan

Engine Oil Pan – Remove and Install

Connecting Rod

Piston and Rings

Pistons and Connecting Rods – Remove

Pistons and Connecting Rods – Disassemble

Pistons and Connecting Rods – Assemble

Pistons and Connecting Rods – Install

Connecting Rod Bearings – Remove – Connecting rods in position

Connecting Rod Bearings – Install – Connecting rods in position

Bearing Clearance – Check

Crankshaft Pulley

V-Belts – Remove and Install

Lifter Group

Rocker Shaft

Valve Mechanism Cover

Valve Mechanism Cover – Remove and Install

Rocker Shaft and Pushrod – Remove

Rocker Shaft – Disassemble

Rocker Shaft – Assemble

Rocker Shaft and Pushrod – Install

Lifter Group – Remove and Install

-COOLING SYSTEM

Cooling System

Cooling System – Check – Overheating

Cooling System – Inspect

Cooling System – Test

Water Temperature Regulator – Test

Water Pump – Inspect

MID 039 – CID 1076 – FMI 03

MID 039 – CID 1076 – FMI 06

Radiator and Oil Cooler Mounting

Engine Oil Cooler – Remove and Install

Radiator and Hydraulic Oil Cooler

Radiator and Hydraulic Oil Cooler (Fan)

Gear Motor (Fan)

Gear Motor (Fan, Demand)

Fan Drive

Fan – Remove and Install

Water Temperature Regulator

Water Temperature Regulator Housing – Remove and Install

Water Temperature Regulator – Remove and Install

Water Temperature Regulator – Remove and Install

Water Pump – Remove and Install

Water Pump – Remove and Install

Radiator and Hydraulic Oil Cooler

Radiator and Hydraulic Oil Cooler (Fan)

Radiator and Oil Cooler Mounting

Radiator and Hydraulic Oil Cooler – Remove

Radiator and Hydraulic Oil Cooler – Install

Water Temperature Regulator (2)

Water Temperature Regulator – Remove and Install

Water Temperature Regulator Housing – Remove and Install

-ELECTRICAL AND STARTING SYSTEM

General Information

Features

Location of Electrical Components

Electrical Input Components

Electronic Control Module

Electrical Output Components

Electrical System

Calibration

Electrical Connector – Inspect

Wiring Harness (Open Circuit) – Test

Wiring Harness (Short Circuit) – Test

Electronic Control Module (ECM) – Flash Program

Electronic Control Module (ECM) – Replace

System Schematic

Alternator – Test

Battery – Test

Charging System – Test

Coolant Temperature Switch – Test

Electric Starting System – Test

Engine Oil Pressure Switch – Test

Fuel Shutoff Solenoid – Test

Glow Plugs – Test

Service Tools

Connector Locations

Diagnostic Capabilities

Symptom Troubleshooting

Emerging Symptom Information

Indicator Lamp Does Not Illuminate During the Power Up SelfTest

Indicator Lamp Is On Continuously

Diagnostic Code List

Using Caterpillar Electronic Technician to Determine Diagnostic Codes

MID 039 – CID 0041 – FMI 03

MID 039 – CID 0041 – FMI 04

MID 039 – CID 0070 – FMI 03

MID 039 – CID 0070 – FMI 04

MID 039 – CID 0110 – FMI 03

Power Supply Circuit of Electronic Control Module

Starting System

Switch Circuits

Alternator and Regulator

Alternator – Remove and Install

Alternator – Remove and Install – 65 Amp and 85 Amp Alternators

Alternator – Remove and Install – 55 Amp Alternator

Battery and Battery Cable – Separate and Connect

Glow Plugs

Glow Plugs – Remove and Install

Machine Frame and Mounting

Fuel Shutoff Solenoid

Fuel Shutoff Solenoid – Remove and Install

Electric Starting Motor

Electric Starting Motor – Remove and Install

Coolant Temperature Switch

Engine Oil Pressure Switch

Coolant Temperature Switch – Remove and Install

-ENGINE ARRANGEMENT

General Information

Troubleshooting

Engine Speed – Check

Engine Design

Engine – Remove

Engine – Install

-FRAME AND BODY

Machine Frame and Mounting

Axle – Remove

Axle – Install

Engine Enclosure

Engine Enclosure – Remove and Install

Lift Arm Cylinder and Mounting Accumulator – Remove and Install

Tire and Rim – Remove and Install

-FUEL SYSTEM

Governor Control

Fuel System

Fuel System – Inspect

Air in Fuel – Test

Fuel Injection Timing – Check

Fuel Injector – Test

Fuel Quality – Test

Fuel System – Prime

Fuel System Pressure – Test

Governor – Adjust

Fuel Shutoff Solenoid – Test

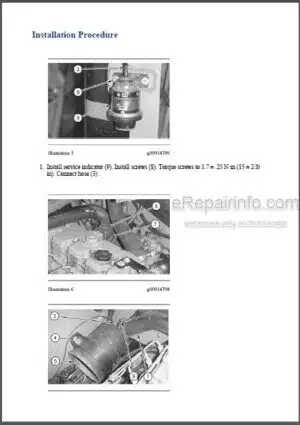

Fuel Priming Pump and Primary Filter (Water Separator) – Remove and Install

Fuel Filter Base – Remove and Install

Fuel Injection Lines

Fuel Injection Lines – Remove and Install

Fuel Injection Pump

Fuel Injection Nozzles.odf

Fuel Injection Pump – Remove and Install

Fuel Injector – Remove and Install

Fuel Priming Pump and Primary Filter (Water Separator) – Remove and Install

Fuel Transfer Pump

Fuel Transfer Pump – Remove and Install – Mechanical Fuel Transfer Pump

Fuel Transfer Pump – Remove and Install – Electrical Fuel Transfer Pump

Fuel Priming Pump and Primary Filter (Water Separator) – Remove and Install

Fuel Shutoff Solenoid

Fuel Shutoff Solenoid – Remove and Install

-HYDRAULIC SYSTEM

General Information

Gear Pump

Work Tool Hydraulic System

Control Valve (Work Tool)

Control Manifold and Solenoid (Work Tool Positioner) – If Equipped

Machine Preparation

Visual Inspection

Operational Checks

Hydraulic System Troubleshooting

System Pressure – Release

Hydraulic Oil Contamination – Test

Main Relief Valve – Test and Adjust

Line Relief Valve – Test and Adjust

Accumulator (Pilot) – Test and Charge

Pilot System Pressure – Test

Pump Flow – Test

Worksheets – Troubleshoot

Symptom Troubleshooting

System Pressure – Release – Hydraulic

Hydraulic Accumulator (Pilot Oil)

Accumulator – Remove and Install

Radiator and Hydraulic Oil Cooler

Radiator and Hydraulic Oil Cooler (Fan)

Radiator and Hydraulic Oil Cooler – Remove

Radiator and Hydraulic Oil Cooler – Install

Lift Cylinder

Tilt Cylinder – Right Hand

Tilt Cylinder – Left Hand

Coupler Cylinder

Lift Arm Cylinder and Mounting

Coupler Cylinder – Remove and Install

Tilt Cylinder – Remove and Install

Lift Cylinder – Remove and Install – Extended Reach Machines

Lift Cylinder – Remove and Install – Radial Arc Machines

Return Manifold

Control Manifold and Solenoid (Parking Brake)

Control Manifold and Solenoid (Work Tool Positioner)

Control Manifold (Quick Coupler)

Gear Motor (Fan)

Gear Motor (Fan, Demand)

Gear Motor (Fan) – Remove

Gear Motor (Fan) – Disassemble

Gear Motor (Fan) – Assemble

Gear Motor (Fan) – Install

Gear Motor – Remove

Gear Motor – Disassemble

Gear Motor – Assemble

Gear Motor – Install

Gear Pump

Gear Pump – High Flow or Boost Flow

Gear Pump – Remove

Gear Pump (Implement and Charge) – Disassemble

Gear Pump – Disassemble – High Flow

Gear Pump (Implement and Charge) – Assemble

Gear Pump – Assemble – High Flow

Gear Pump – Assemble

Gear Pump – Install

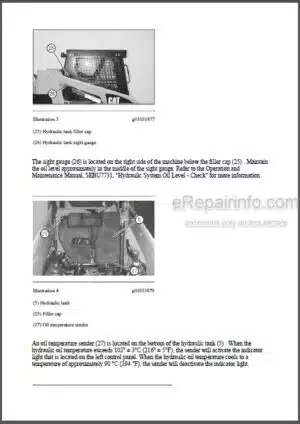

Hydraulic Tank

Hydraulic Tank – Remove

Hydraulic Tank – Install

Control Valve (Work Tool) – Remove

Control Valve (Work Tool) – Disassemble

Control Valve (Work Tool) – Assemble

Control Valve (Work Tool) – Install

Diverter Valve – Remove and Install

Pilot Operated Hydraulic Control

Pilot Operated Hydraulic Control – Hydrostatic

Pilot Operated Hydraulic Control – Remove

Pilot Operated Hydraulic Control – Disassemble

Pilot Operated Hydraulic Control – Assemble

Pilot Operated Hydraulic Control – Install

Solenoid Valve and Mounting (Coupler) – Remove and Install

Solenoid Valve (Compressor Motor) – Remove and Install

-IMPLEMENTS

Lift Arms – Remove – Extended Reach Machines

Lift Arms – Remove – Radial Arc Machines

Lift Arms – Install – Extended Reach Machines

Lift Arms – Install – Radial Arc Machines

Lift Arms – Remove – Extended Reach Machines

Lift Arms – Remove – Radial Arc Machines

-LUBRICATION SYSTEM

Lubrication System

Engine Crankcase Pressure (Blowby) – Test

Engine Oil Pressure – Test

Engine Oil Pump – Inspect

Excessive Engine Oil Consumption – Inspect

Crankcase Breather – Remove and Install – Naturally Aspirated Engines

Crankcase Breather – Remove and Install – Turbocharged Engines

Engine Oil Filter

Engine Oil Lines

Engine Oil Relief Valve

Engine Oil Line – Remove and Install

Engine Oil Relief Valve – Remove and Install

Engine Oil Pump

Engine Oil Pump – Remove

-MACHINE ARRANGEMENT

Symptom Troubleshooting

Emerging Symptom Information

Heating and Air Conditioning Service Publications

-OPERATOR STATION

Indicator Lamp Does Not Illuminate During the Power Up SelfTest

Indicator Lamp Is On Continuously

MID 039 – CID 1187 – FMI 04

MID 039 – CID 1188 – FMI 04

MID 039 – CID 1190 – FMI 04

Air Conditioner and Heater – Remove

Air Conditioner and Heater – Disassemble

Air Conditioner and Heater – Assemble

Air Conditioner and Heater – Install

Refrigerant Condenser – Remove and Install

Refrigerant Accumulator – Remove and Install

Refrigerant Compressor – Remove and Install

Solenoid Valve (Compressor Motor) – Remove and Install

Gear Motor – Remove

Gear Motor – Disassemble

Gear Motor – Assemble

Gear Motor – Install

Refrigerant Compressor and Support Housing – Remove and Install

Gas Spring Group (Cab)

Cab – Tilt

Cab – Remove

Cab – Install

Gas Spring – Remove and Install – Extended Reach

Pilot Operated Hydraulic Control

Pilot Operated Hydraulic Control – Hydrostatic

Pilot Operated Hydraulic Control – Remove

Pilot Operated Hydraulic Control – Disassemble

Pilot Operated Hydraulic Control – Assemble

Pilot Operated Hydraulic Control – Install

ROPS Mounting

Accumulator – Remove and Install

Seat – Remove and Install

Window Wiper Motor – Remove and Install

General Information

Identifying the Refrigerant

Identifying the Air Conditioning System

Identifying the Heating System

Refrigerant Expansion Valve System

Refrigerant Orifice Tube System

Refrigerant Compressor

Refrigerant Condenser

Refrigerant Receiver-Dryer

Refrigerant Expansion Valve

In-line Refrigerant Dryer

Refrigerant Orifice Tube Assembly

Evaporator Coil

Refrigerant Accumulator

Refrigerant Compressor Protection System

Temperature Control

Cab Pressurization and Filtration System

Condensate Drainage System

Service Intervals

Glossary of Terms

Machine Preparation for Testing and Adjusting

Air Conditioning Performance – Test

Refrigerant Leakage – Test

Manifold Gauge Set (Refrigerant) – Install

Refrigerant Recovery

Refrigerant System – Flush

Refrigerant Oil – Test

Refrigerant Compressor – Test

Refrigerant System – Evacuate

Refrigerant System – Charge

Manifold Gauge Set (Refrigerant) – Remove

Compressor Protection System – Test

Electronic Heat Control – Test

Heater Performance – Test

Required Tools

Machine Preparation for Troubleshooting

General Troubleshooting Information

Visual Inspection (Troubleshooting)

Air Conditioning System Troubleshooting

Heating System Troubleshooting

Troubleshooting Heating and Air Conditioning Control System

Troubleshooting Condensate Drainage System

System Capacities for Refrigerant (Skid Steer Loaders)

Machine Preparation for Disassembly and Assembly

Air Conditioner Lines – Remove and Install

Refrigerant Expansion Valve – Remove and Install

Refrigerant Receiver-Dryer – Remove and Install

In-Line Refrigerant Dryer – Remove and Install

Refrigerant Orifice Tube Assembly – Remove and Install

-POWER TRAIN

Hydrostatic System

Piston Pump (Hydrostatic)

Piston Motor (Hydrostatic)

Tandem Drive and Axle

Machine Preparation

Visual Inspection

Operational Checks

System Pressure – Release – Hydraulic

Axle

Axle – Remove

Axle – Disassemble – Heavy Duty

Axle – Disassemble

Axle – Assemble – Heavy Duty

Axle – Assemble

Axle – Install

Control Manifold and Solenoid (Parking Brake) – Remove and Install

Pump Mounting – Remove and Install

Chain (Drive) Tension – Adjust

Pump Mounting (Hydrostatic)

Tandem Drive

Pump Mounting – Remove and Install

Axle – Remove

Axle – Install

Chain (Drive) – Remove

Chain (Drive) – Install

Hydraulic Oil Filter

Return Manifold

Accumulator – Remove and Install

Motor Mounting (Hydrostatic)

Piston Motor (Hydrostatic) – Remove

Piston Motor (Hydrostatic) – Disassemble – Two Speed

Piston Motor (Hydrostatic) – Disassemble

Piston Motor (Hydrostatic) – Assemble – Two Speed

Piston Motor (Hydrostatic) – Assemble

Piston Motor (Hydrostatic) – Install

Piston Pump (Hydrostatic) – Remove

Piston Pump (Hydrostatic) – Disassemble

Heavy Duty Dual Face Seal – Install

Pilot Operated Hydraulic Control

Pilot Operated Hydraulic Control – Hydrostatic

Pilot Operated Hydraulic Control – Remove

Pilot Operated Hydraulic Control – Disassemble

Pilot Operated Hydraulic Control – Assemble

Pilot Operated Hydraulic Control – Install

Control Manifold and Solenoid (Parking Brake)

Solenoid Valve and Mounting (Parking Brake) – Remove and Install – Two Speed

Tire and Rim

Tire and Rim – Remove and Install

-SERVICE EQUIPMENT AND SUPPLIES

Fuel Priming Pump and Primary Filter (Water Separator) – Remove and Install

Cab Pressurization and Filtration System

Manifold Gauge Set (Refrigerant) – Install

Manifold Gauge Set (Refrigerant) – Remove

Heating and Air Conditioning Service Publications

Required Tools

Fuel Filter Group – Remove and Install

-WORK TOOLS

Quick Coupler

Quick Coupler – Remove and Install

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet