Factory Operators Manual For Manitowoc Crane. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: English

Quantity of Manuals: 2

Pages: 288; 312

Number: CTRL039-14 (january 2013); CTRL241-01 (june 2016)

Bookmarks: Yes

Searchable: Yes

Model

Manitowoc Crane

2250

Contents

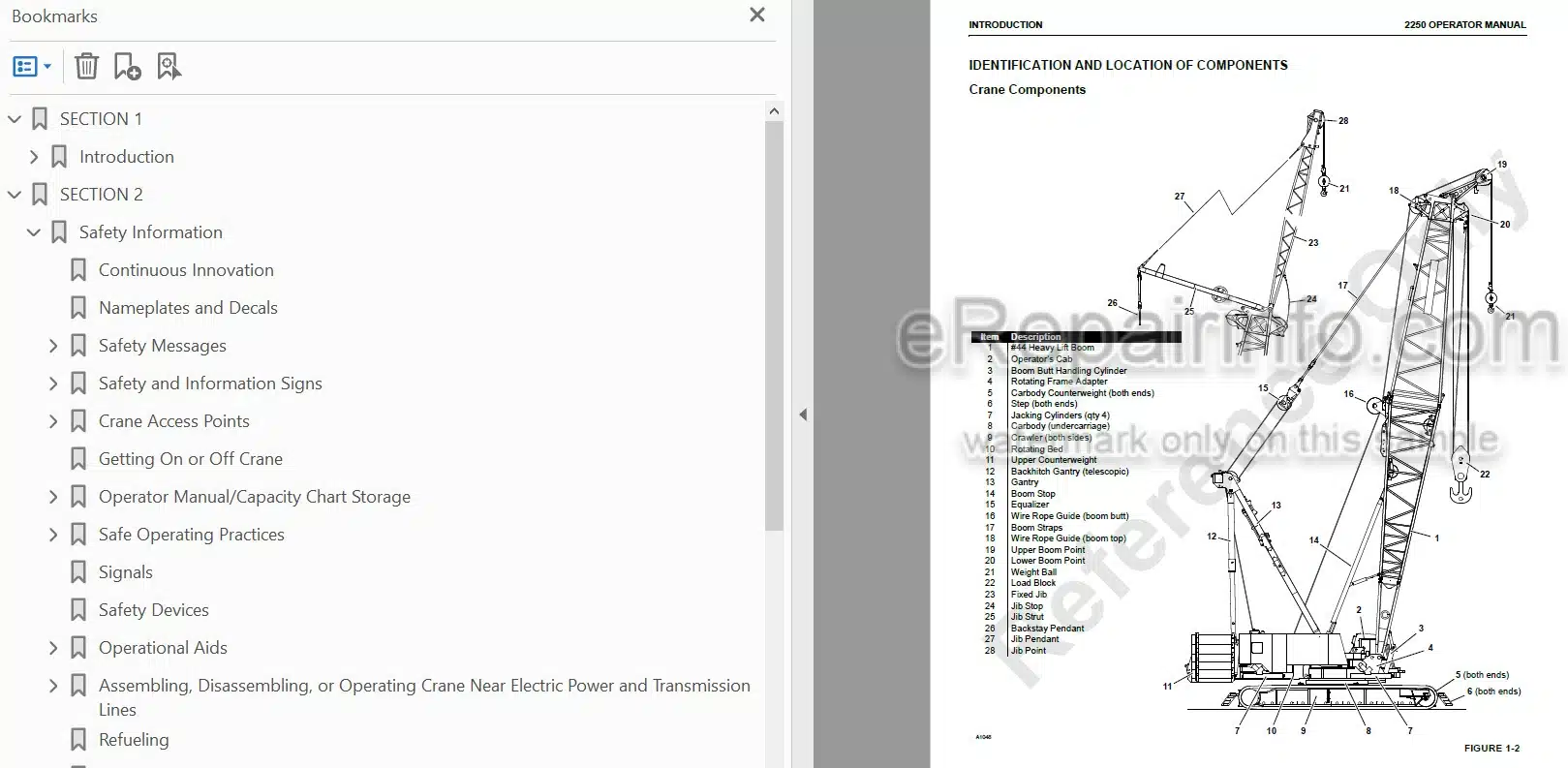

-INTRODUCTION

Crane Data

Crane/Attachment Identification

Change of Ownership Registration

Crane Orientation

Identification and Location of Components

Outline Dimensions

Crane Weights

English and Metric Conversions

Manitowoc Dealer

-SAFETY INFORMATION

Continuous innovation

Nameplates and Decals

Safety Messages

Safety and Information Signs

Crane Access Points

Getting On or Off Crane

Operator’s Manual/Capacity Chart Storage

Safe Operating Practices

Signals

Safety Devices

Operational Aids

Assembling, Disassembling, or Operating Crane Near Electric Power and Transmission Lines

Refueling

Fire Extinguishers

Accidents

Safe Maintenance

Environmental Protection

Boom Disassembly Safety

Personnel Handling Policy

Pedestal/barge Mounted Cranes

-OPERATING CONTROLS AND PROCEDURES

Standard Hand Signals for Controlling Crane Operations

Symbol Identification

Front Window Operation

Controls Identification and Function

Limit Devices

Seat Controls

Preparing Crane For Operation

Operation

Stopping Engine / Leaving Crane Unattended

Special Controls

Remote Controls

Programmable Controller Calibration Procedures

Digital Display Readings

Diagnostic Display

Engine Diagnostics (Cummins QSX15 Engine)

Drum Interlock

Swing Speed/Torque Adjustment

Swing Limiter Operation

Swing Drive Disconnect Operation

Pile Driving System Controls

Wind Conditions

Cold Weather Heater Package

Preparation for Cold Weather

Circuit Breakers

-SET-UP AND INSTALLATION

Rigging Drawings

Optional Attachments

General Safety

Crane Orientation

FACT Components

Assembly and Disassembly Notes

Assist Crane Requirements

Assembly and Disassembly Area

Accessing Parts

Crane Weights

Retaining Connecting Pins

Miscellaneous Loose Parts Box

Shipping Crane Components

Component Weights

Special Blocking Requirements

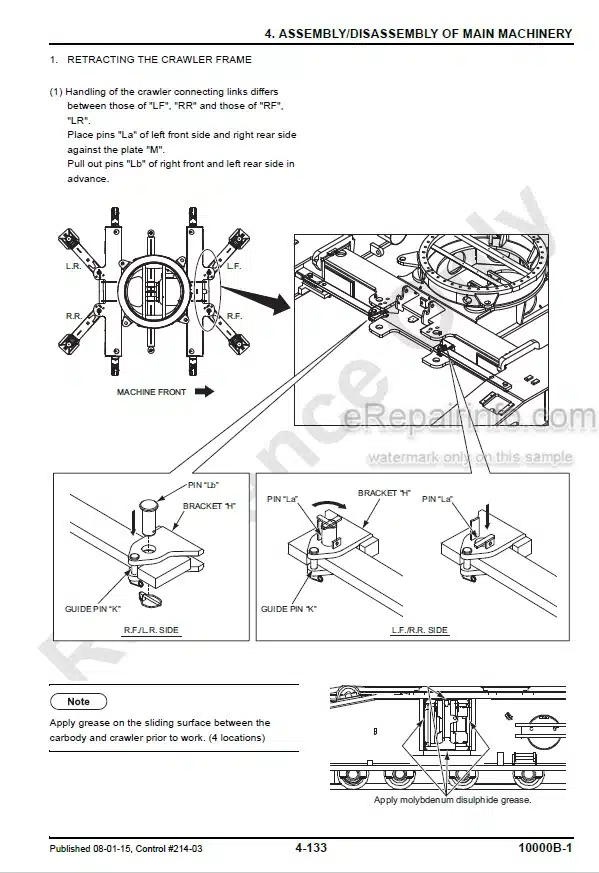

Under Carriage Lubrication at Assembly

Crane Assembly — Without Self-Erect

Disassembly — Without Self-Erect

Tapered Mounting Pin Installation

Elevated Cab Assembly – 35 ft Tower

Drum Spacer/Lagging Installation

Counterweight Installation And Removal

Counterweight Installation and Removal — with Auxiliary Engine

Gantry Raising And Lowering — Without Boom Butt Handling Cylinder

Drum 5 Installation and Removal

Boom Ladder Assembly — with #44 Boom

Boom Rigging Guide — #44 HL and LR

Lower Boom Point Sheaves

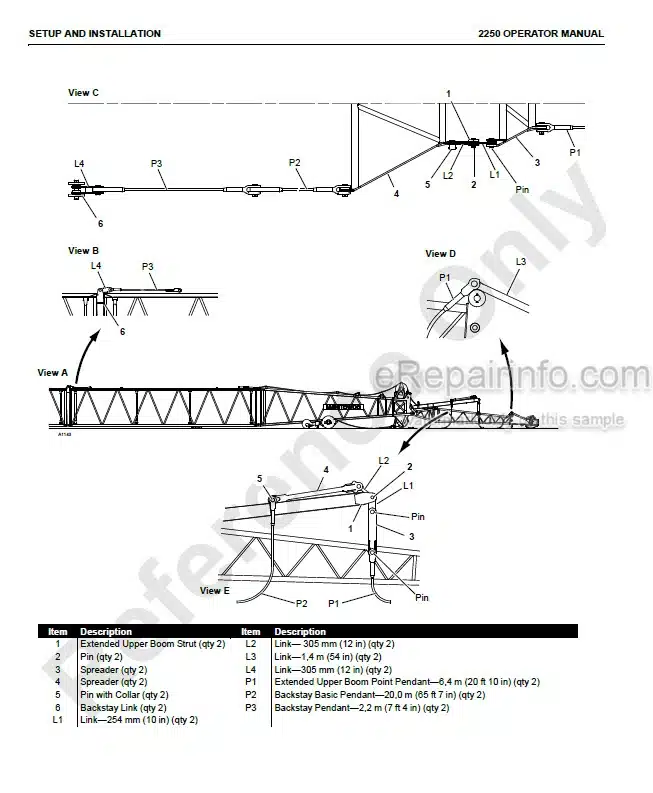

Extended Upper Boom Point Rigging Guide

Boom Handling — with Intermediate Gantry Position

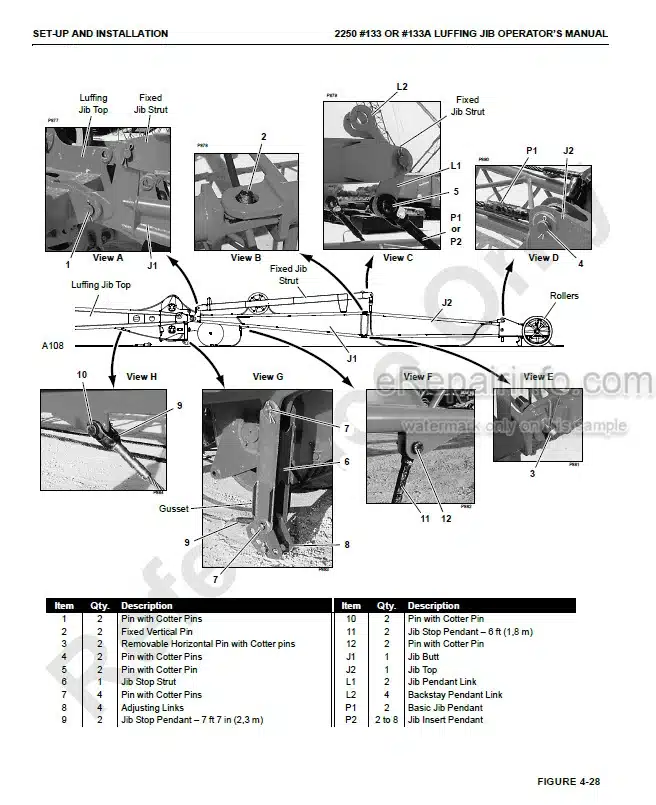

Jib Installation — #132 Jib

Jib Removal — #132 Jib

Wire Rope Installation

Pad Eye Usage for Wire Rope Reeving

Load Line Reeving

Universal Anchor Joint

Load Block Tieback

-LUBRICATION

Lubrication Guide

Lube and Coolant Product Guide

-MAINTENANCE CHECKLIST

Inspection and Maintenance Checklist

Fiberglass Maintenance

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet