Factory Operators Manual For Case IH Square Baler. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: English

Pages: 346

Searchable: Yes

Model

Case IH Square Baler

LBX322

LBX332

LBX422

LBX432

Contents

-GENERAL INFORMATION AND SAFETY

Intended Use

Product Identification

Airborne Noise Emission

Electromagnetic Compatibility (EMC)

Vibration Level Information

Legal Obligations

Precautionary Statements

Safety Precautions

Wheels And Tyres

Angle Of Operation

Safety Decals

Needles/Knotter Safety Lock

Access To Machine Components

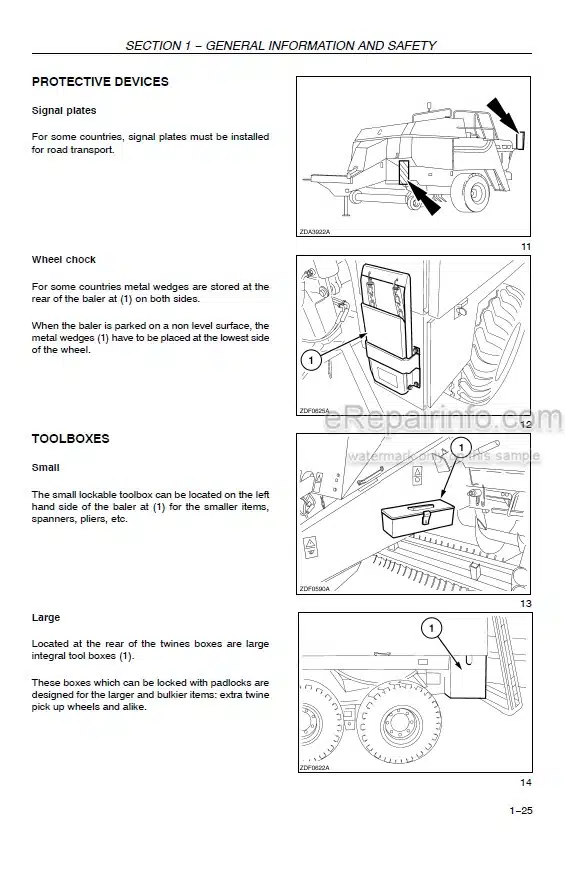

Protective Devices

Toolboxes

Lifting The Baler

-CONTROLS, INSTRUMENTS AND OPERATION

Controls, Indicators And Gauges

Flywheel Brake

Jack

Tractor Requirements

Horsepower Requirements

Tractor Drawbar / Tow Hitch

Tractor Wheel Setting

Power Take-Off Shaft

Attaching The Baler To The Tractor

PTO Shaft Phasing

Adjustable Low Hitch (Standard)

Adjustable High Low Hitch For Standard Or Packer-Cutter Units

Adjustable High/Low Hitch For Standard Or Packer-Cutter Units (High Position)

Adjustable High/Low Hitch For LBX422, LBX432 Rotor-Cutter Units (High Position Shown)

Attachment Of The PTO Shaft

Safety Chain / Safety Cable (Not For France)

Braking Systems Fail Safe Brake Control (France Only)

Tractor Hydraulic Brake Connections (If Fitted*)

Tractor Pneumatic Brake Connections (If Fitted On The Baler*)

Tractor Hydraulic Connections

Tractor Electrical System

Baler Electrical System

Monitor Installation

Monitor Operation

Monitor Messages

Menu Bar Functions

User Settings

Pick-Up Compensation Cylinder

Transporting The Baler

Starting The Baler

Parking The Baler

Pressure Gauge

Bale Length Mechanical Control

Mechanical Bale Counter

-FIELD AND SITE OPERATION

Description Of Operation

Product Feeding

Pick-Up

Crop Cutting Controls

Packer Units

Packer-Cutter Units

Rotor-Cutter Units

Unplugging The Rotor-Cutter System

Pre-Compression Chamber

Stuffer Trip Lock (Where Fitted)

Stuffer Trip Sensitivity Lever

Stuffer

Charge Holding Fingers

Pressing

Plunger/Bale Chamber

Hay Dogs

Bale Density System

General

Automatic Bale Density Control

Manual Bale Density Control

Manual Override Bale Density Control

Tying

General

Knotter Needle Drive Components

Threading The Baler

Knotters

Monitoring Flags

Missed Knots

Ejection

Bale-Chute

Bale Ejecting System (If Fitted)

Removing A Bale From The Bale Chamber

Tandem Auto-Steer Axle (If Fitted)

Operation

Auto-Steer Lock-Out Valve

Shearbolts

Baling

Windrow/Swath Size

Before Using The Machine

Knives

Starting To Bale

Empty Bale Chamber Start-Up

Continued Baling

Performance Checks

-LUBRICATION AND MAINTENANCE

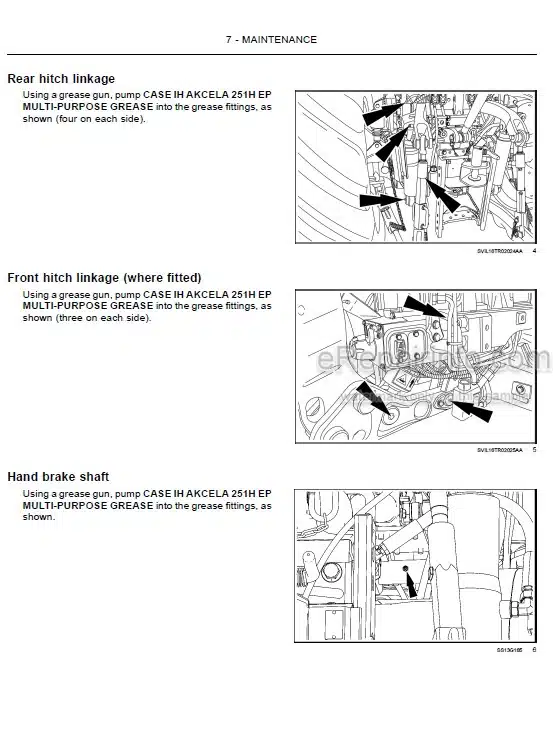

Lubrication

General Information

Lubrication And Maintenance Quick Reference

Centralized Greasing System

Automatic Greasing System (If Installed)

Remaining Conventional Grease Points

PTO Drive Line Greasing

Automatic Oiling System

Linkages, Threaded Rods And Pivots

Ball Ring Hitch And Wear Plate

Main Drive Gearbox

Stuffer Drive Gearbox

Knotter Drive Gearbox

Bale Density Hydraulic Circuit

General Information

Chains

Packer/Rotor Drive Chain

Pick-Up Main Drive Chain And Pick-Up Reel Drive Chain

Pick-Up Auger Drive Chain

Main Drive

PTO Drive Slip Clutch

Flywheel Brake

Product Feeding

Pick-Up Slip Clutch

Pick-Up Tine Replacement

Auger Stripper Plates

Packer Slip Clutch

Rotor Cut-Out Clutch

Knife Drawer Adjustments

Cutter Knife Sharpening

Pressing

Stuffer Brake

Stuffer Fingers To Plunger Timing

Crop Holding Fingers

Stuffer Adjustment

Plunger/Bale Chamber

Hay Dogs

Twine Tying Mechanism

Twine Tension

Description Of The Knotter Assembly

Knotter Adjustments

Knotter Trip Mechanism

Needle Adjustment

Maximum Needle Penetration

Needles To Plunger Timing / Knotter Drive Shearbolt Replacement

Tucker Arm Alignment

Needle Carriage Support

Needle Brake

Needle Protection Linkage

Twine Fingers

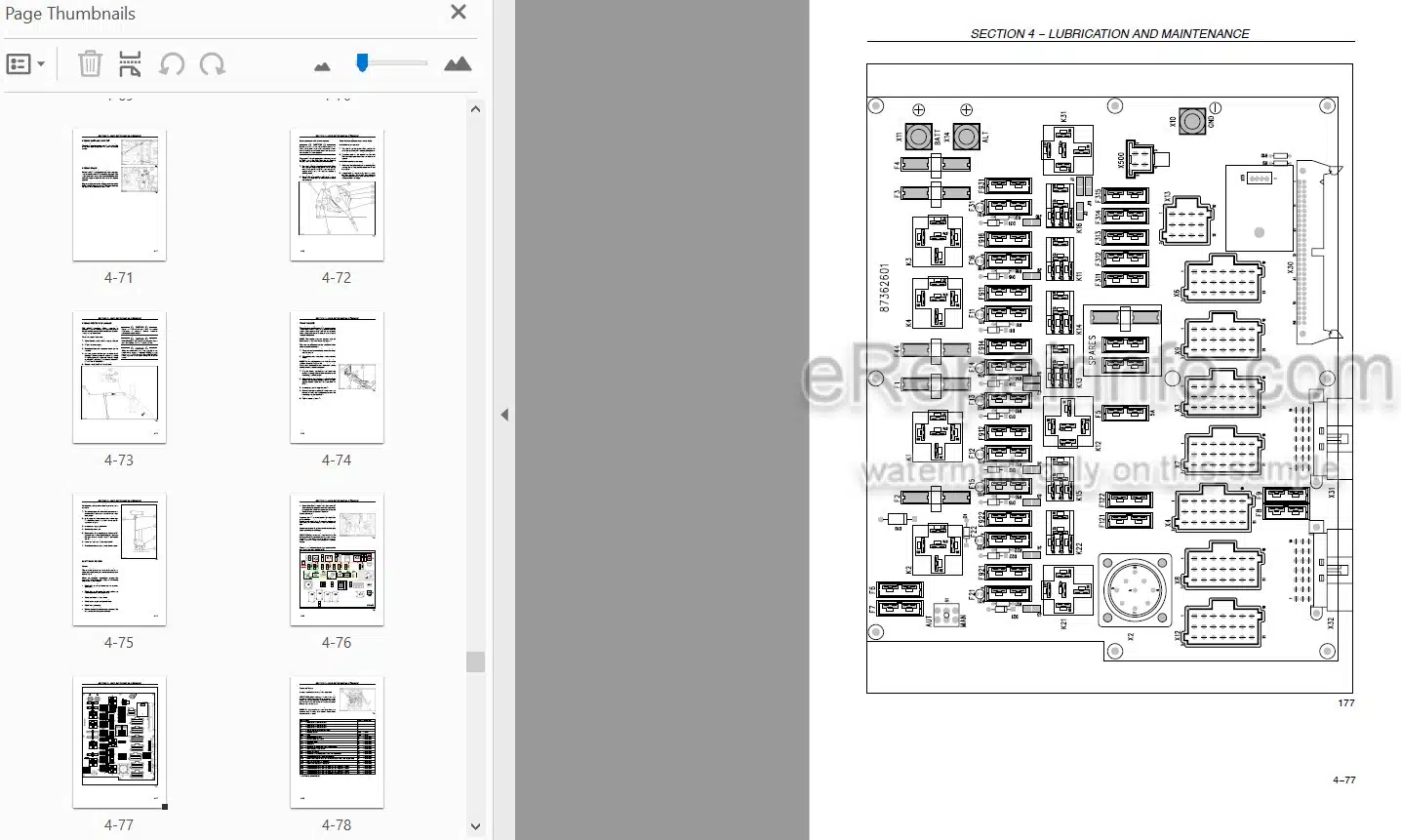

Electrical System

Power Distribution

System Override

Sensor Types

Lights-Bulb Replacement

Hydraulic System

Wheels And Tyres

Brake System (If Fitted)

Hydraulic Brake System (If Fitted)

Air Brake System (If Fitted)

Cleaning The Baler

-FAULT FINDING

Tying

Product Feeding

Drives

Bale Shape

Integrated Automatic Oiler

Bale Density Regulation

Packer-Cutter System

Rotor-Cutter System

Electrical System

-VEHICLE STORAGE

End-Of-Season Service

Ordering Parts And/Or Accessories

Pre-Season Service

-ACCESSORIES

Tractor Drawbar Swivel Ball Kit

Tractor Drawbar Fixed Ball Hitch Kit

X3 Standard Work Light Kit (DIA Or Configured)

X2 Extra Working Light Kit

Inspection Light Kit

Revolving Flashlight

Baler Performance Monitor Support

Automatic Greasing Pump

Quick Fill Pump

Bale Ejecting System

Fill Flow Kit

Plate Bale Chute

Roller Bale Chute

Printer

Pick Up Stop (Rotor-Cutter Only)

Moisture Sensor System

Bale Length Trip (Electronic)

VT Cable Kit

Roller Windguard

-SPECIFICATIONS

Overall Measurements

Technical Data

Overall Measurements

Technical Data

-1ST 50 HOUR SERVICE SHEETS

Check And Adjust, As Required (Dealer Copy)

Check And Adjust, As Required (Customer Copy)

INDEX

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet