Factory Operators Manual For Case IH Tractor. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: English

Pages: 377

Issue: november 1999

Bookmarks: Yes

Searchable: Yes

Model

Case IH Tractor

Maxxum MX10

Maxxum MX120

Maxxum MX135

PIN JJE0961233 and after

Maxxum MX150

Maxxum MX170

PIN JJE0981633

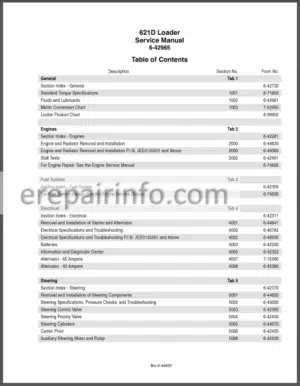

Contents

TO THE OWNER

-IDENTIFICATION NUMBERS/MACHINE COMPONENTS

Product Identification And Serial Numbers

Machine Components

-SAFETY/DECALS

Intended Use

General Safety And Accident Prevention Regulations

Transporting Passengers

Neutral Start System

Operator Presence System

Operation

Leaving The Tractor

Implements

Pto Operation

Service

Battery Safety

Hazardous Chemicals

Personal Safety

Fire Safety

Basic Rule

Safety Decals

Roll Over Protective Structure (ROPS)

-INSTRUMENTS/CONTROLS

Tractor Access

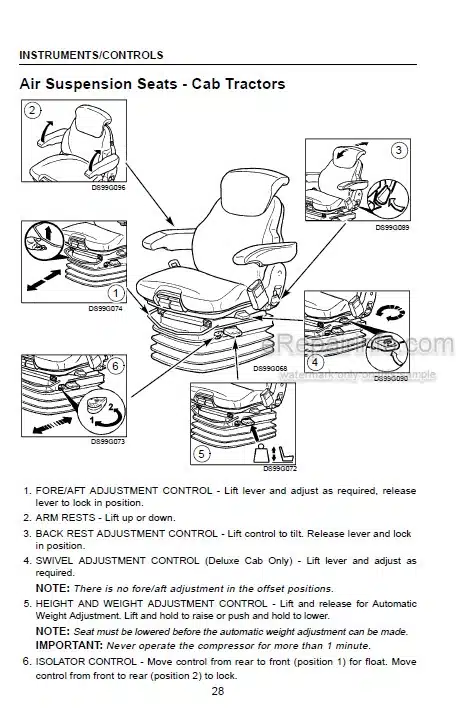

Operators Seat

Steering Column Adjustment

Standard (Analog) Instrument Cluster

Deluxe (Digital) Instrument Cluster

Operating Controls

Operator Cab Environment Controls

Additional Cab Features

Rear View Mirrors

-OPERATING INSTRUCTIONS

Before Starting The Engine

Run In Procedure

Master Disconnect Switch

Service Indicator Lamps And Gauges

Normal Starting Procedure

Cold Temperature Operation

Parking The Tractor

Operating The Transmission

Cab Environment

Drawbar

Height Adjustable Trailer Hitches

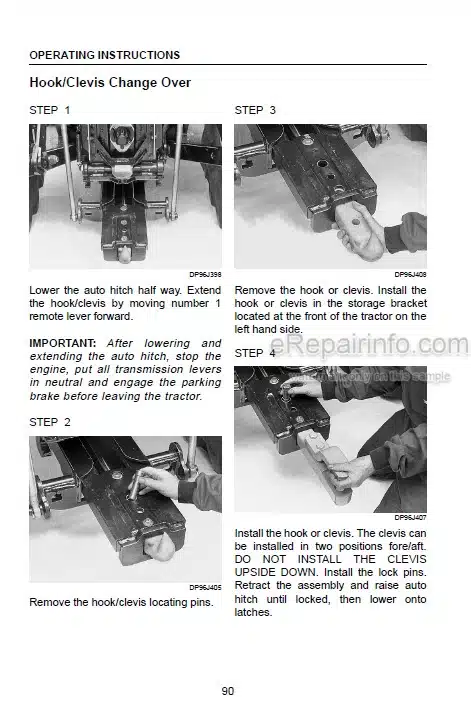

Auto Hitch

Implement/Trailer Drawbar Dimensions

Trailer Brake Couplings

Auxiliary Electrical Power Sockets

Towing The Tractor

How To Transport The Tractor

-FIELD OPERATION

Transmission Creeper Operation

Wheel Slip Indicator

Programming The Digital Instrument Cluster

Distance Function Operation

Area Function Operation

Rear Power Takeoff

Front Power Takeoff Operation

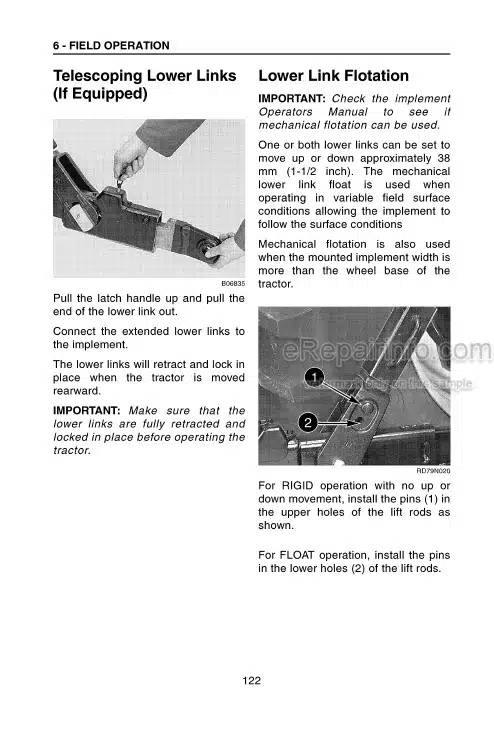

Rear Three Point Hitch Preparation

Rear Three Point Hitch Operation

Ride Control

Rear Three Point Hitch Diagnostic Display

Differential Lock Control

Mechanical Front Drive (MFD) Operation

Operating The Independent Front Suspension

Front Hitch Preparation

Front Hitch Operation

Remote Hydraulic Valves

Remote Hydraulics Operation

Implement Cable Access

Foldable ROPS Frame

-TYRES/WHEELS/SPACING/BALLAST

Tyre Pressures And Load Capacities

Tyre And Wheel Service

Instrument Cluster Programming For Different Tyre Sizes

Setting The Front Wheel Toe-In

Axle – Steering Stops

Two Wheel Drive Front Axle Tread Adjustment

MFD Front Wheel Tread Widths

Front Wheel Bolt Torques

Front To Rear Tyre Size Combinations

Front Wheel Fenders

Rear Wheel Tread Adjustment

Tractor Ballast

-LUBRICATION/MAINTENANCE

Environment

Plastic And Resin Parts

Service Parts

Tool Box

Hourmeter

Hood And Side Panels

Lubricants And Capacities

Regular Service Intervals

10 Hours Or Daily Service

50 Hour Interim Service

100 Hour Interim Service

300 Hour Interim Service

600 Hour Interim Service

1200 Hour Main Service

1200 Hour Main Service

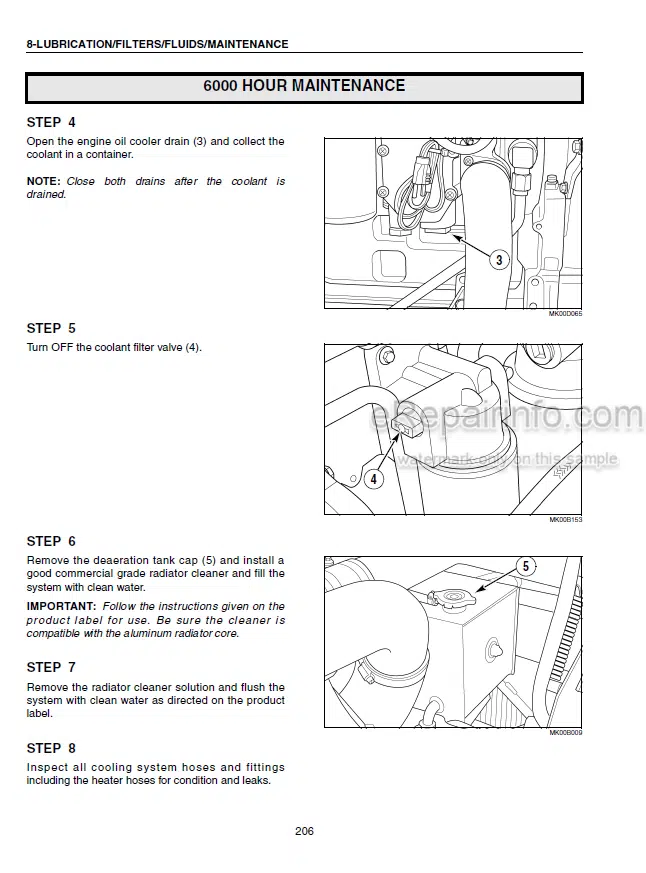

2400 Hour Main Service

General Maintenance

-ELECTRICAL SYSTEM

Batteries

Bulb And Lamp Replacement

Fuses And Relays

Relays

MACHINE STORAGE

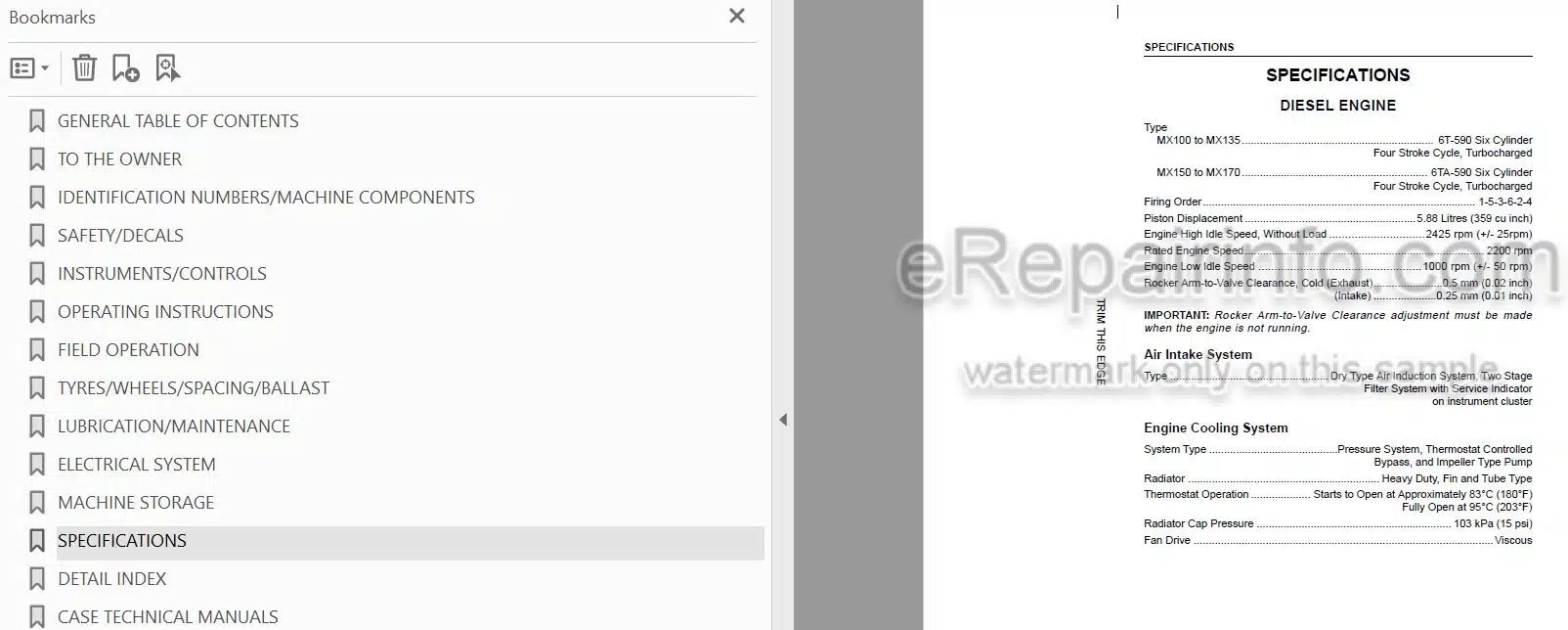

-SPECIFICATIONS

Diesel Engine

Electrical System

General Machine

Travel Speeds

Approximate Tractor Dimensions

Approximate Tractor Weights

Noise Levels

DETAIL INDEX

CASE TECHNICAL MANUALS

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet