Factory Shop Manual For Komatsu Wheel Loader. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Quantity of Manuals: 2

Pages: 1315; 1306

Number: SEN03911-03; SEN04162-07

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Komatsu Wheel Loader

WA320-6

SN 70001 And Up

WA320PZ-6

SN 70001 And Up

Contents

-INDEX AND FOREWORD

Index

Foreword And General Information

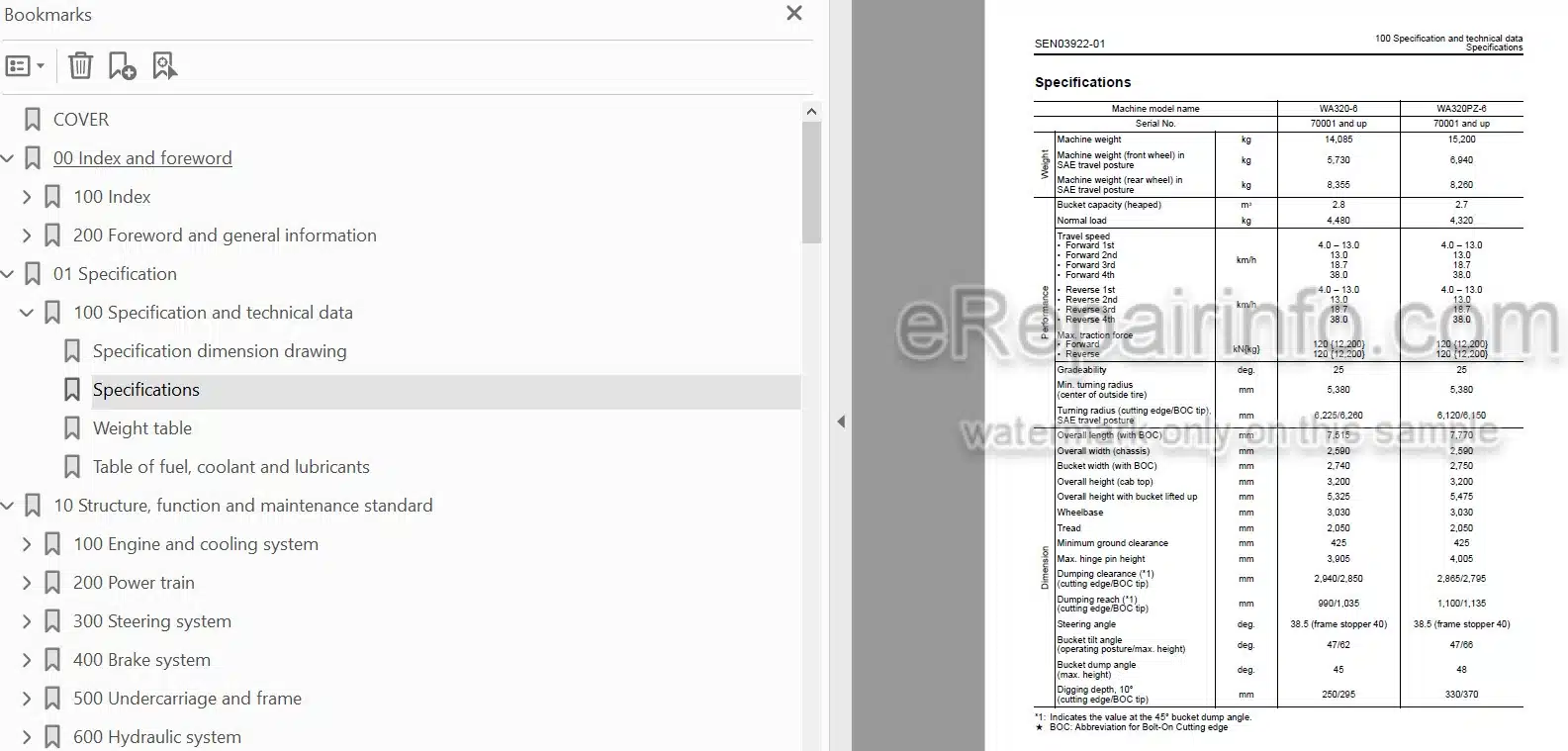

-SPECIFICATION

Specification Dimension Drawing

Specifications

Weight Table

Table Of Fuel, Coolant And Lubricants

-STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

Engine And Cooling System

Power Train

Steering System

Brake System

Undercarriage And Frame

Hydraulic System

Work Equipment

Cab And Its Attachments

Electrical System

-STANDARD VALUE TABLE

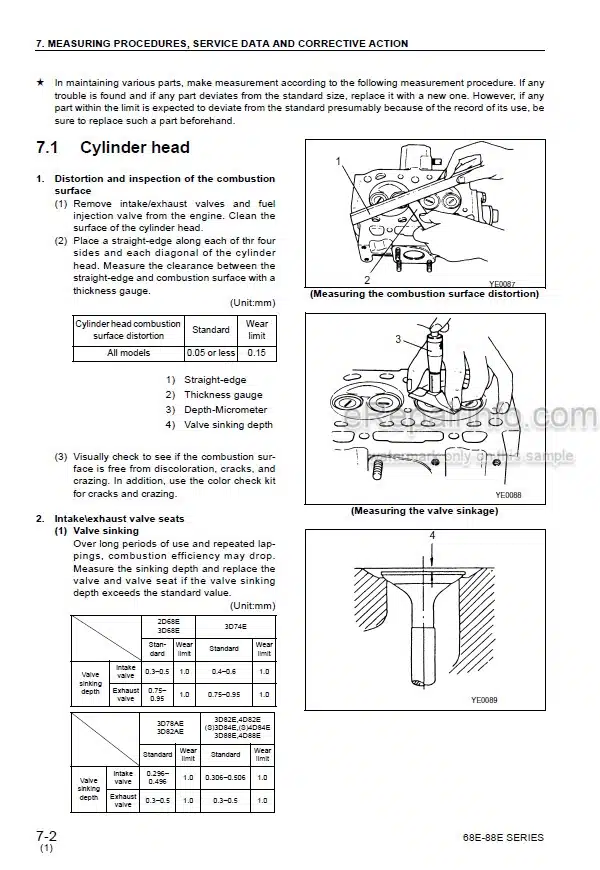

Standard Service Value Table For Engine

Standard Service Value Table For Chassis

-TESTING AND ADJUSTING

Tools For Testing, Adjusting, And Troubleshooting

Measuring Engine Speed

Measuring Exhaust Gas Color

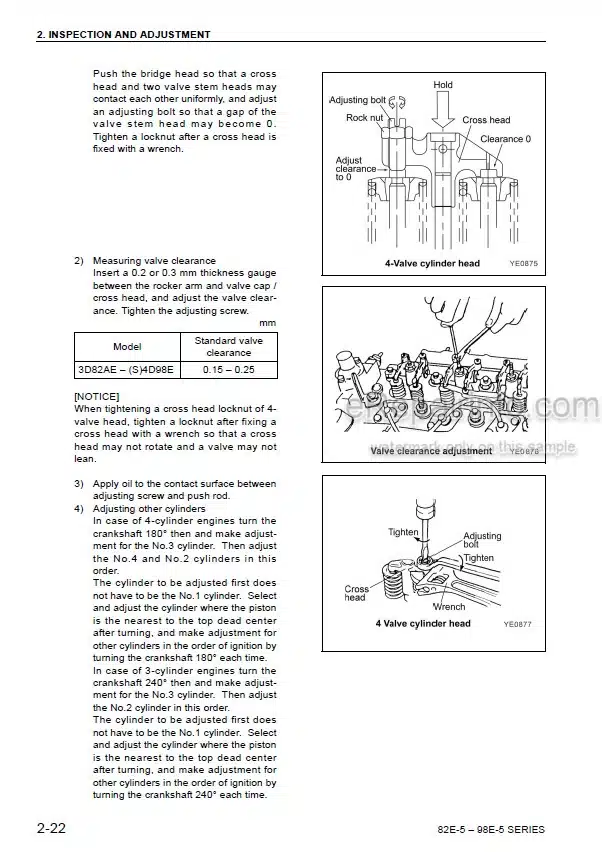

Adjusting Valve Clearance

Measuring Compression Pressure

Measuring Blow-By Pressure

Measuring Engine Oil Pressure

Measuring Intake Air (Boost) Pressure

Handling Fuel System Equipment

Releasing Residual Pressure In Fuel System

Measuring Fuel Pressure

Measuring Fuel Return Rate And Leakage

Bleeding Air From Fuel Circuit

Checking Leakage In Fuel System

Handling Cylinder Cut-Out Mode Operation

Handling No-Injection Cranking Operation

Handling Controller Voltage Circuit

Check Of Muffler And Muffler Stack For Looseness And Damage

Check Of Muffler Function

Check Of Installed Condition Of Cylinder Head And Manifolds

Check Of Engine Piping For Damage And Looseness

Testing And Adjusting Air Conditioner Compressor Belt Tension

Replacing Alternator Belt

Checking Operating Force Of Accelerator Pedal

Checking Directional Lever

Testing And Adjusting HST Oil Pressure

Testing Clutch Control Pressure

Testing And Adjusting Steering Wheel

Testing And Adjusting Steering Oil Pressure

Bleeding Air From Steering Circuit

Testing Hydraulic Fan

Measuring Brake Pedal

Testing And Adjusting Brake Pedal Linkage

Measuring Brake Performance

Testing And Adjusting Accumulator Charge Pressure

Testing Wheel Brake Oil Pressure

Testing Wear Of Brake Disc

Bleeding Air From Wheel Brake Circuit

Releasing Residual Pressure In Brake Accumulator Circuit

Testing Parking Brake Performance

Testing And Adjusting Parking Brake Control Cable

Measuring And Adjusting Work Equipment Control Lever

Testing And Adjusting Work Equipment Hydraulic Pressure

Testing Work Equipment PPC Oil Pressure

Bleeding Air From Hydraulic Circuit

Releasing Remaining Pressure In Hydraulic Circuit

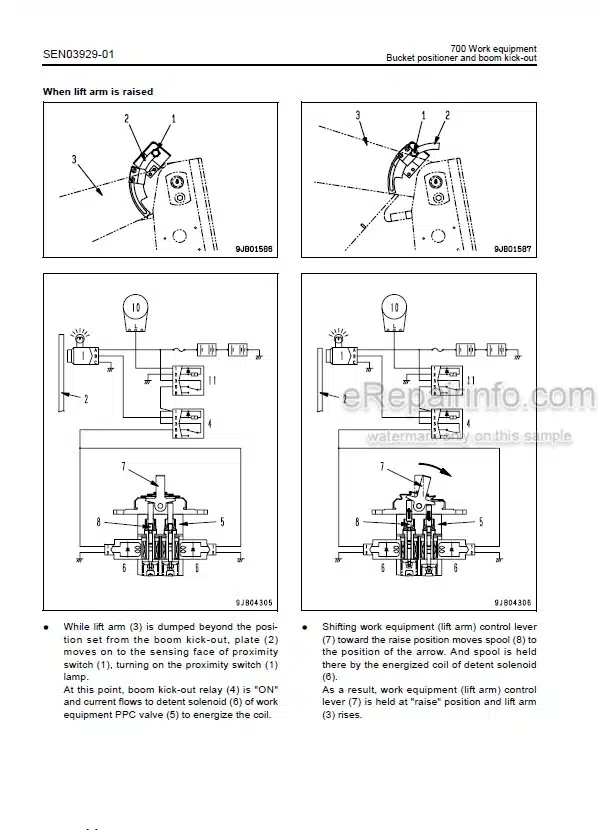

Testing And Adjusting Bucket Positioner

Testing And Adjusting Of Boom Kick-Out Switch

Checking Proximity Switch Operation Pilot Lamp

Procedure For Testing Diodes

Preparation Work For Troubleshooting For Electric System

Starting Komtrax Terminal Operations

Indicator Lamps Of Komtrax Terminal

Adjusting Machine Monitor

Adjusting Replaced, Reassembled Or Added Sensor, Controller, Etc. With Machine Monitor

Special Functions Of Machine Monitor (EMMS)

PM Clinic Inspection Chart

-TROUBLESHOOTING

Failure Code Table And Fuse Locations

General Information On Troubleshooting

Troubleshooting By Failure Code (Display Of Code)

Troubleshooting Of Electrical System (E-Mode)

Troubleshooting Of Hydraulic And Mechanical System (H-Mode)

Troubleshooting Of Engine (S-Mode)

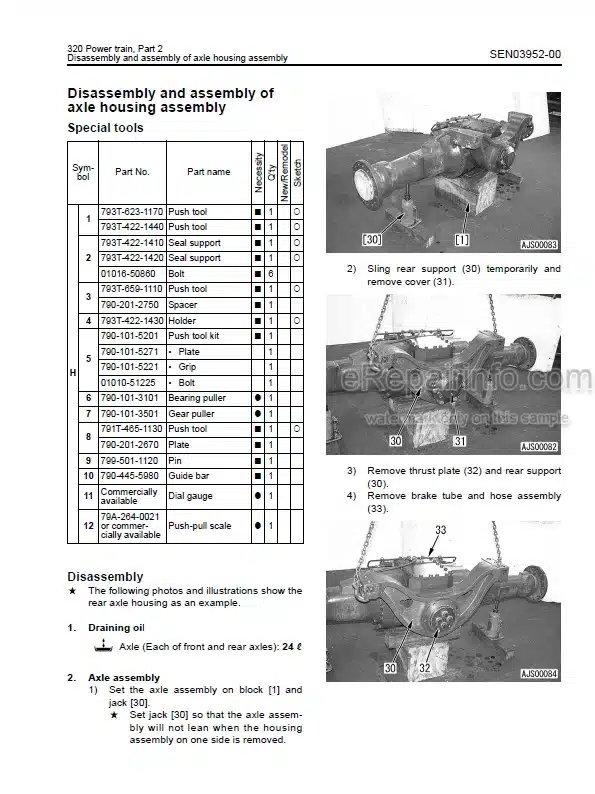

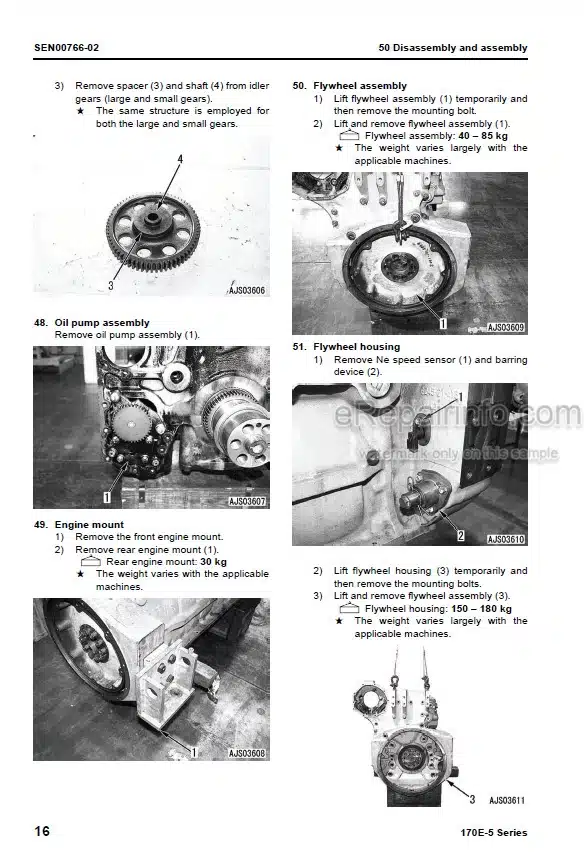

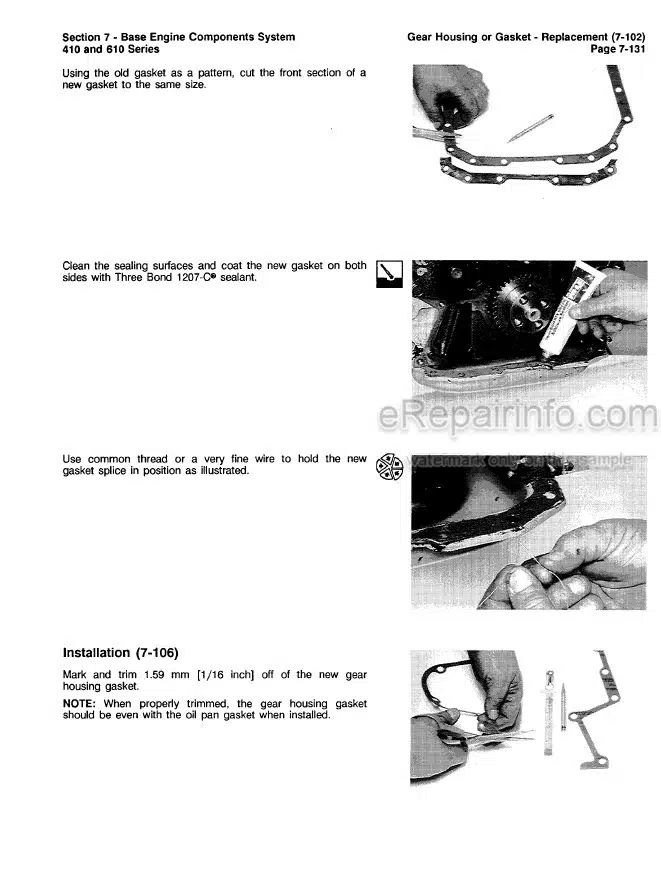

-DISASSEMBLY AND ASSEMBLY

General Information On Disassembly And Assembly

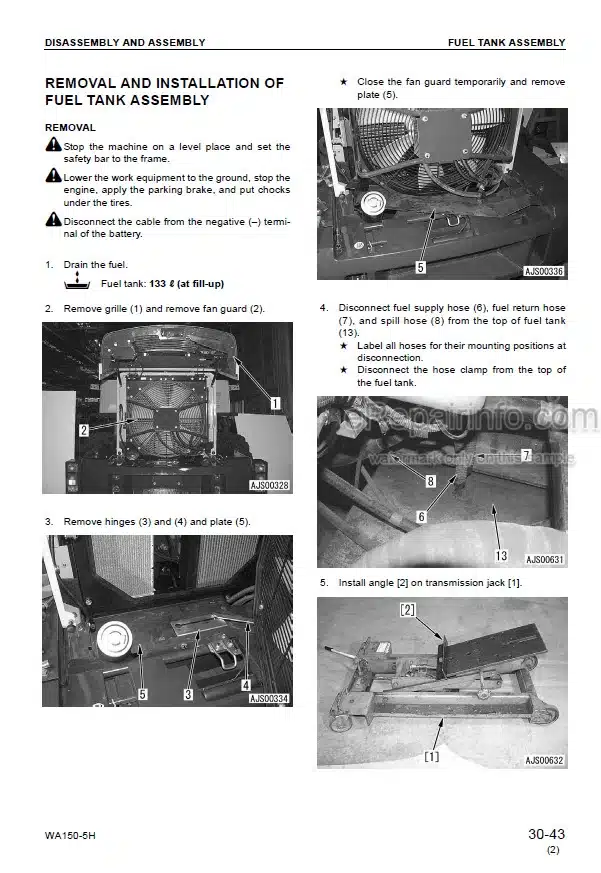

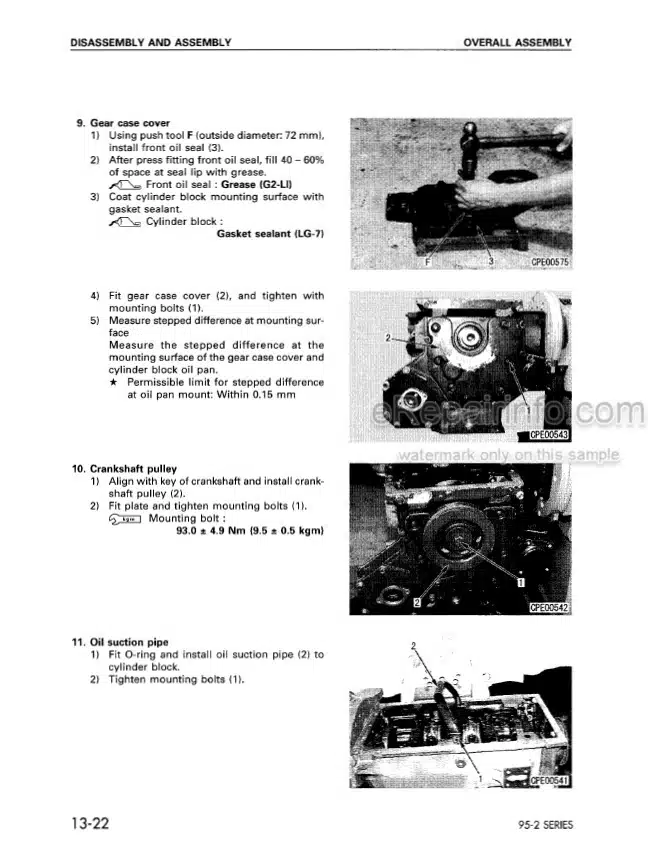

Engine And Cooling System

Power Train

Undercarriage And Frame

Hydraulic System

Work Equipment

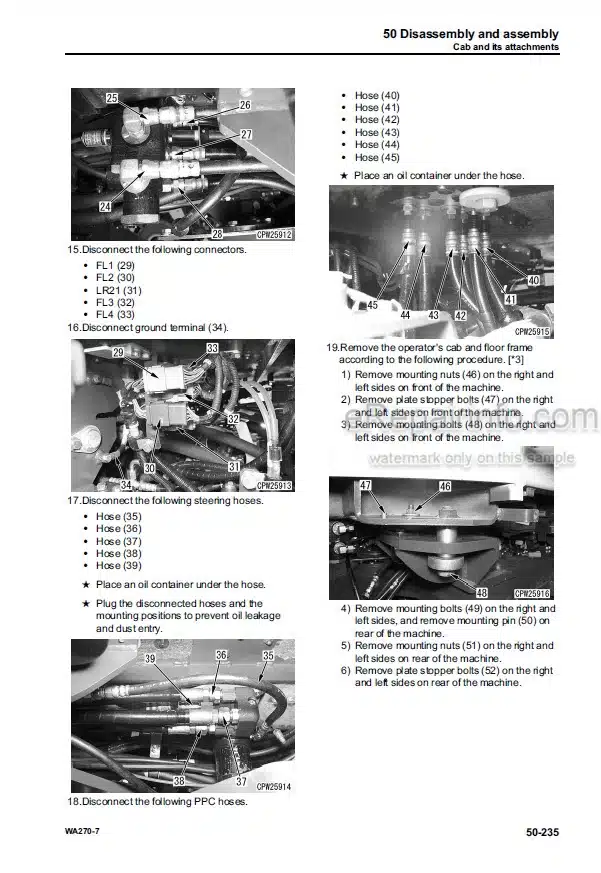

Cab And Its Attachments

Electrical System

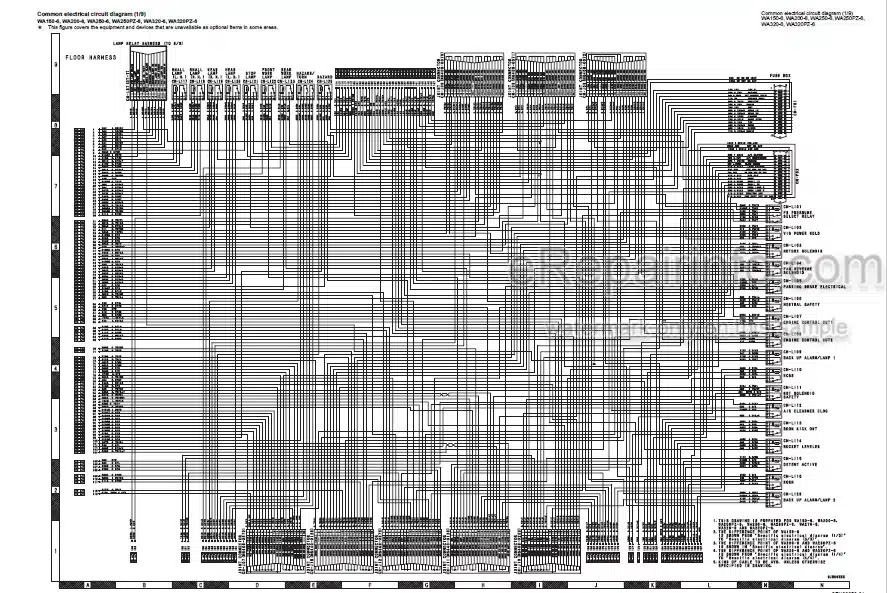

-DIAGRAMS AND DRAWINGS

Hydraulic Diagrams And Drawings

Electrical Diagrams And Drawings

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet