Factory Shop Manual For Komatsu Bulldozer. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 985

Number: SEBM026307 (october 2004)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Komatsu Bulldozer

D275A-5

SN 25001 And Up

Contents

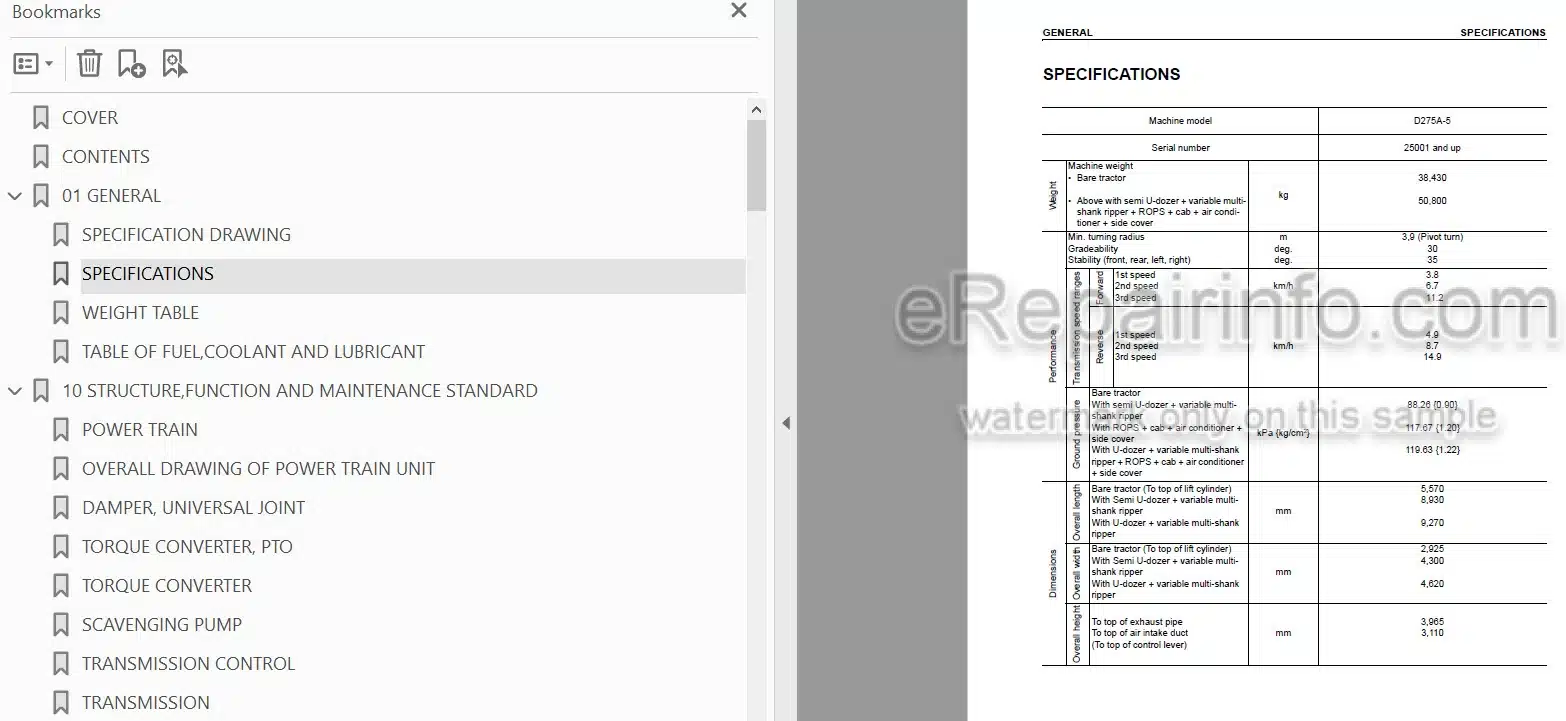

-GENERAL

Specification Drawing

Specifications

Weight Table

Table Of Fuel, Coolant And Lubricant

-STRUCTURE,FUNCTION AND MAINTENANCE STANDARD

Powertrain

Overall Drawing Of Powertrain Unit

Damper, Universal Joint

Torque Converter, PTO

Torque Converter

Scavenging Pump

Transmission Control

Transmission

Transmission ECMV

Main Relief Valve And Torque Converter Valve

Powertrain Pump, Steering Lubrication Pump

Lubrication Relief Valve

Steering, Brake Control

Bevel Gear Shaft, Steering Clutch And Brake

Steering Control Valve

Steering Clutch ECMV

Steering Brake ECMV

Parking Brake Valve

Sudden Brake Prevention Valve

Final Drive

Sprocket

Track Frame

Recoil Spring

Idler

Track Roller

Carrier Roller

Track Roller Bogie

Track Shoe

Main Frame

Suspension

Work Equipment Hydraulic Piping Diagram

PPC Control Piping Diagram

Work Equipment Control

Work Equipment Pump

Cooling Fan Pump

Cooling Fan Motor

Hydraulic Tank

Accumulator

PPC Lock Valve

PPC Valve (For Blade Lift, Blade Tilt)

PPC Valve (For Ripper)

Hydraulic Cylinder

Piston Valve

Quick Drop Valve

Pin Puller Switch

Pin Puller Solenoid Valve

Blade Control Knob

Pitch Selector Solenoid Valve

Control Valve

Operation Of Control Valve

Self-Reducing Pressure Valve

Cylinder Stay

Blade

Ripper Equipment

Cab Mount

Cab

Air Conditioner

Engine Control

Engine Control System

Deceleration Potentiometer

CRI Engine Control System

Monitor System

Monitor Panel

Sensors

Mode Selection System (For SSC Specification)

Electrical Equipment

Palm Command Control System

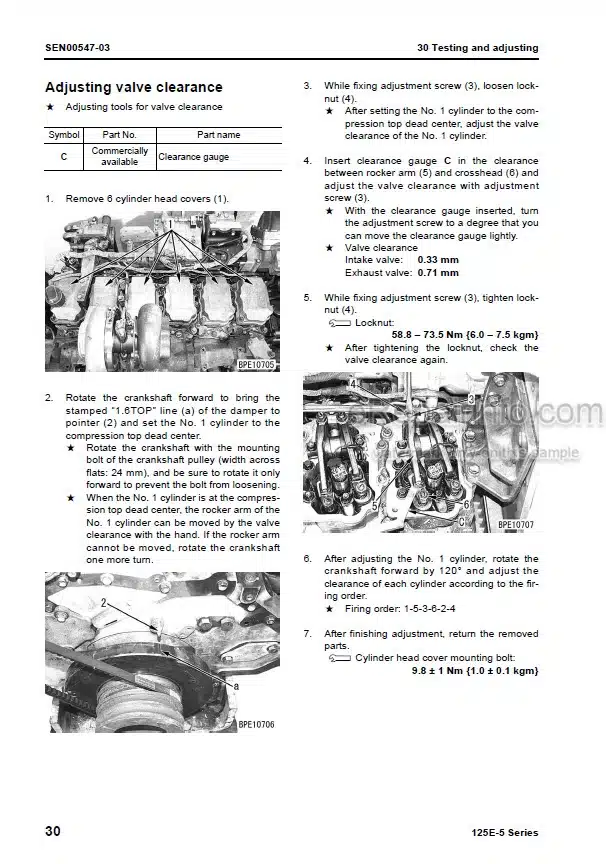

-TESTING AND ADJUSTING

Standard Value Table For Engine

Standard Value Table For Chassis

Testing And Adjusting

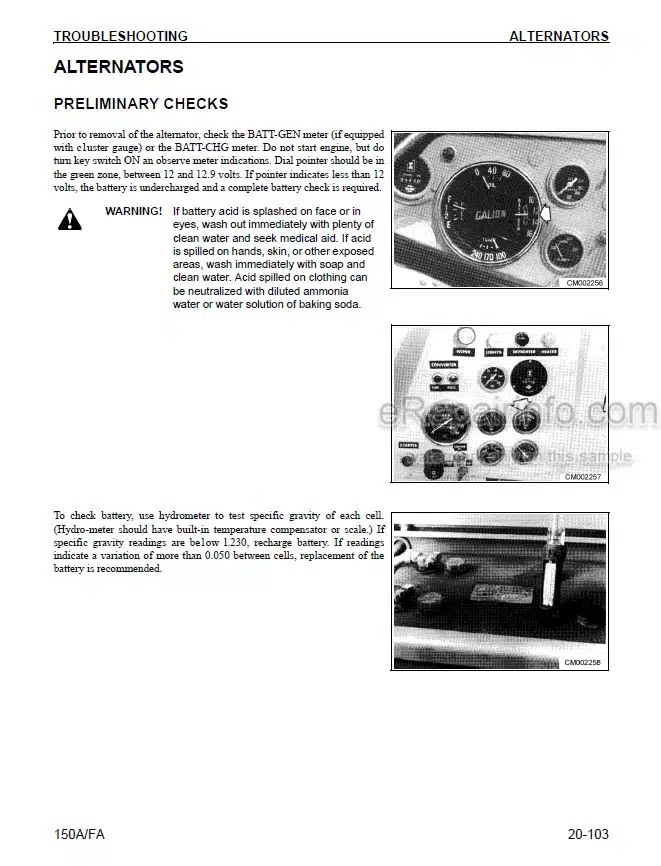

Troubleshooting

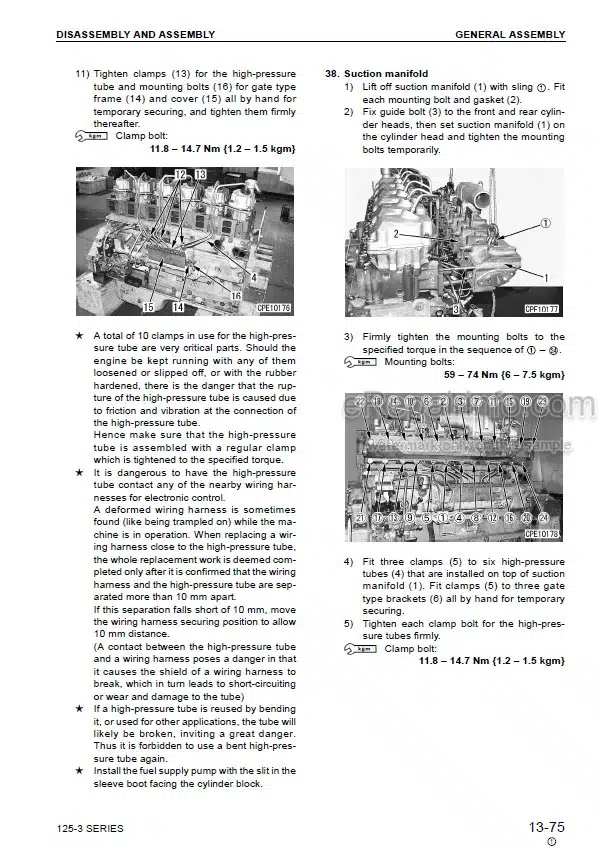

-DISASSEMBLY AND ASSEMBLY

Precautions When Carrying Out Operation

Special Tool List

Removal And Installation Of Fuel Supply Pump Assembly

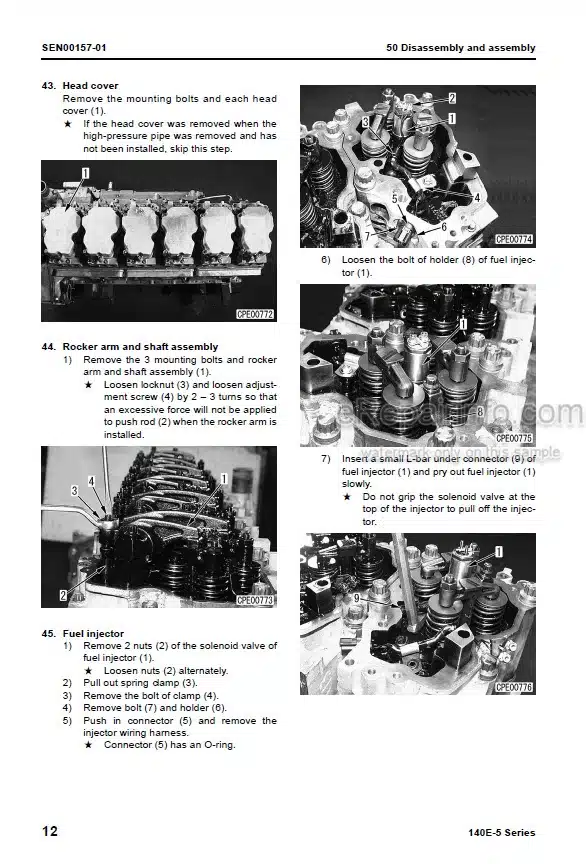

Removal And Installation Of Fuel Injector Assembly

Removal And Installation Of Nozzle Tip

Removal And Installation Of Engine Front Seal

Removal And Installation Of Engine Rear Seal

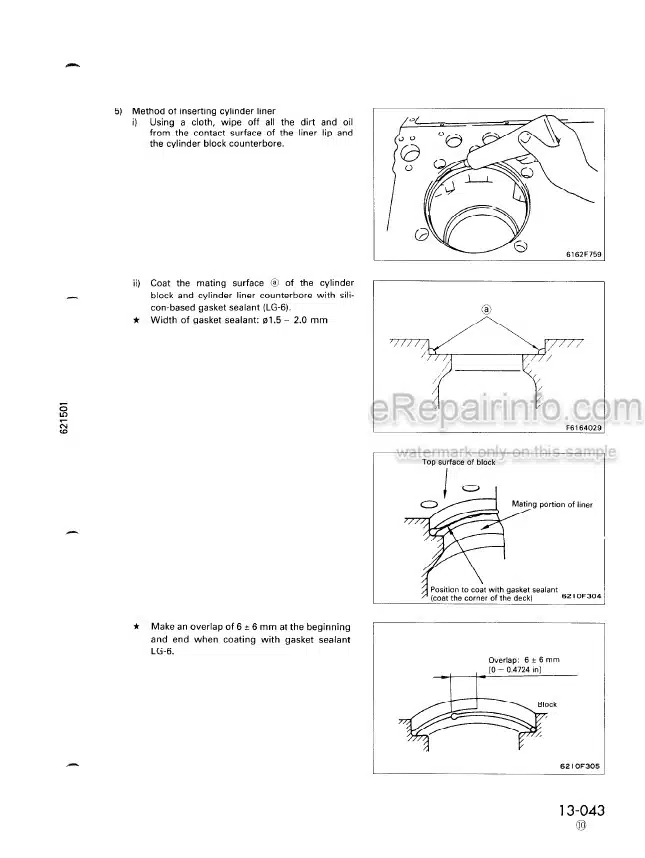

Removal And Installation Of Cylinder Head Assembly

Removal And Installation Of Fuel Tank Assembly

Removal And Installation Of Main Radiator Assembly

Removal And Installation Of Sub-Radiator Assembly

Removal And Installation Of Hydraulic Oil Cooler Assembly

Removal And Installation Of Radiator Guard Assembly

Removal And Installation Of Engine

Removal And Installation Of Damper Assembly

Disassembly And Assembly Of Damper Assembly

Removal And Installation Of Powertrain Unit Assembly

Disconnection And Connection Of Power Train Unit Assembly

Disassembly And Assembly Of PTO Assembly

Disassembly And Assembly Of Torque Converter Assembly

Disassembly And Assembly Of Torqflow Transmission Assembly

Disassembly And Assembly Of Steering Case Assembly

Removal And Installation Of Scavenging Pump

Removal And Installation Of Work Equipment Pump Assembly

Removal And Installation Of Fan Pump Assembly

Removal And Installation Power Train And Steering Lubricating Oil Pump Assembly

Removal And Installation Of Final Drive Assembly

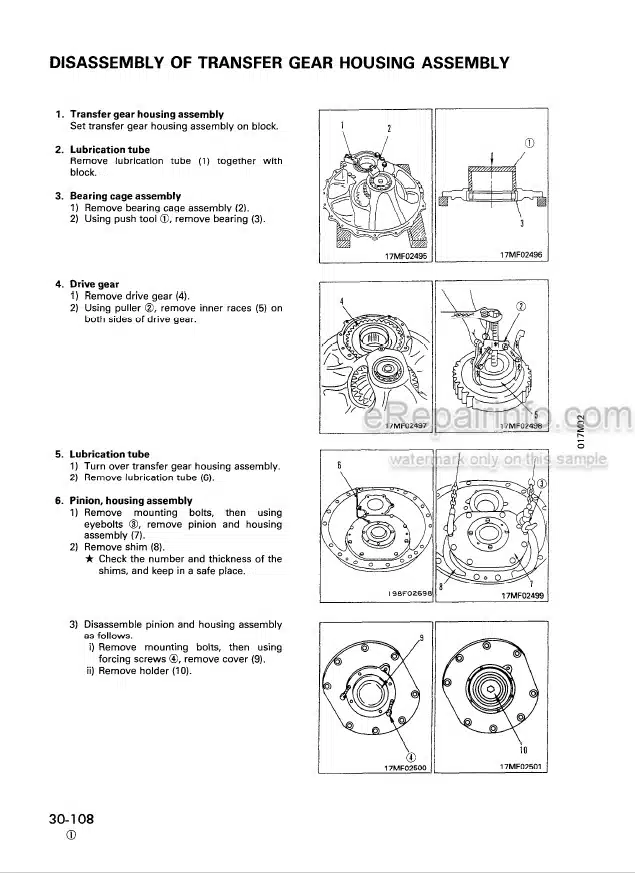

Disassembly And Assembly Of Final Drive Assembly

Removal And Installation Of Track Frame Assembly

Removal And Installation Of Idler Assembly

Disassembly And Assembly Of Idler Assembly

Removal And Installation Of Recoil Spring Assembly

Disassembly And Assembly Of Recoil Spring Assembly

Removal And Installation Of Track Roller Assembly

Disassembly And Assembly Of Track Roller Assembly

Removal And Installation Of Carrier Roller Assembly

Disassembly And Assembly Of Carrier Roller Assembly

Removal And Installation Of 1St Bogie Assembly

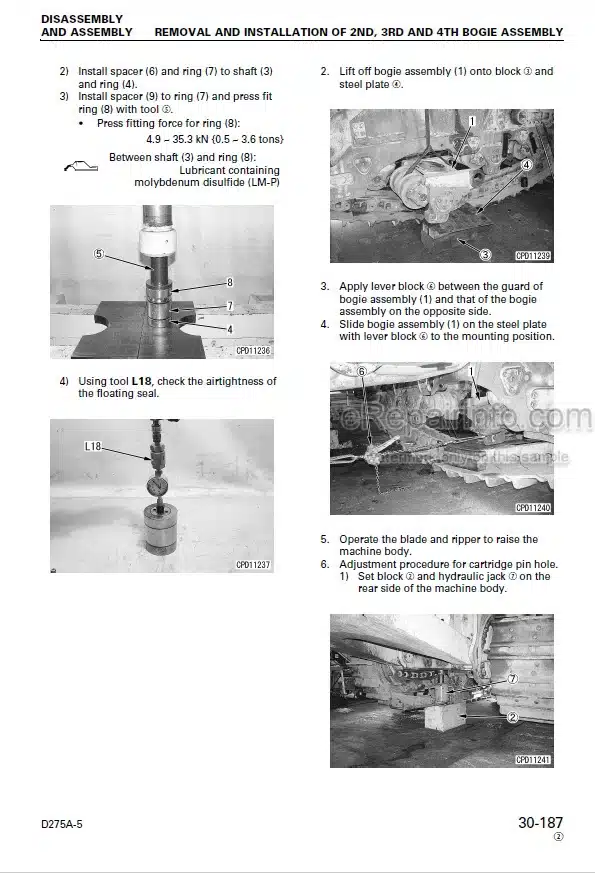

Removal And Installation Of 2Nd, 3Rd And 4Th Bogie Assembly

Disassembly And Assembly Of Bogie Assembly

Expanding And Installing Track Shoe Assembly

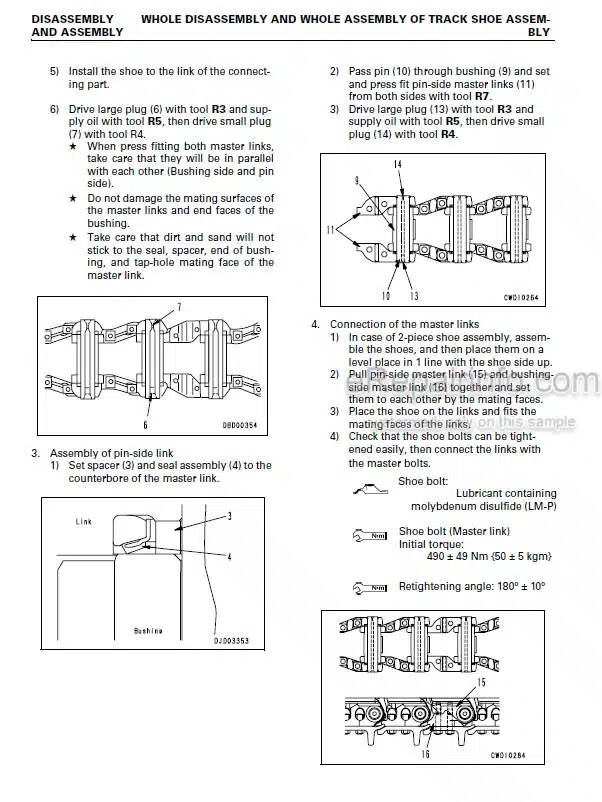

Whole Disassembly And Whole Assembly Of Track Shoe Assembly

Removal And Installation Of Pivot Shaft Assembly

Removal And Installation Of Equalizer Bar Assembly

Disassembly And Assembly Of Equalizer Bar Bushing

Removal And Installation Of Work Equipment Control Valve Assembly

Disassembly And Assembly Of Work Equipment Control Valve Assembly

Disassembly And Assembly Of Hydraulic Cylinder Assembly

Removal And Installation Of Blade Assembly

Disassembly And Assembly Of Ripper Assembly

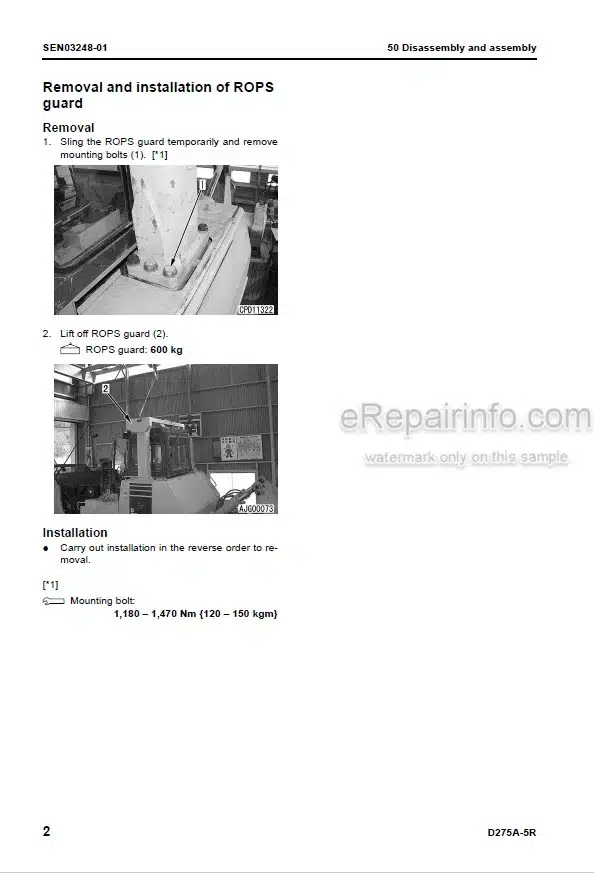

Removal And Installation Of ROPS Guard

Removal And Installation Of Operator’s Cab Assembly

Removal And Installation Of Floor Frame Assembly

Removal And Installation Of Transmission Controller Assembly

Removal And Installation Of Steering Controller Assembly

Removal And Installation Of Engine Controller Assembly

Removal And Installation Of Engine Hood Assembly

Removal And Installation Of Fan Drive Assembly

Removal And Installation Of Fan Motor

-OTHERS

Power Train Hydraulic Circuit Diagram

Work Equipment Hydraulic Circuit Diagram (Single Tilt Spec)

Work Equipment Hydraulic Circuit Diagram (Dual Tilt Spec)

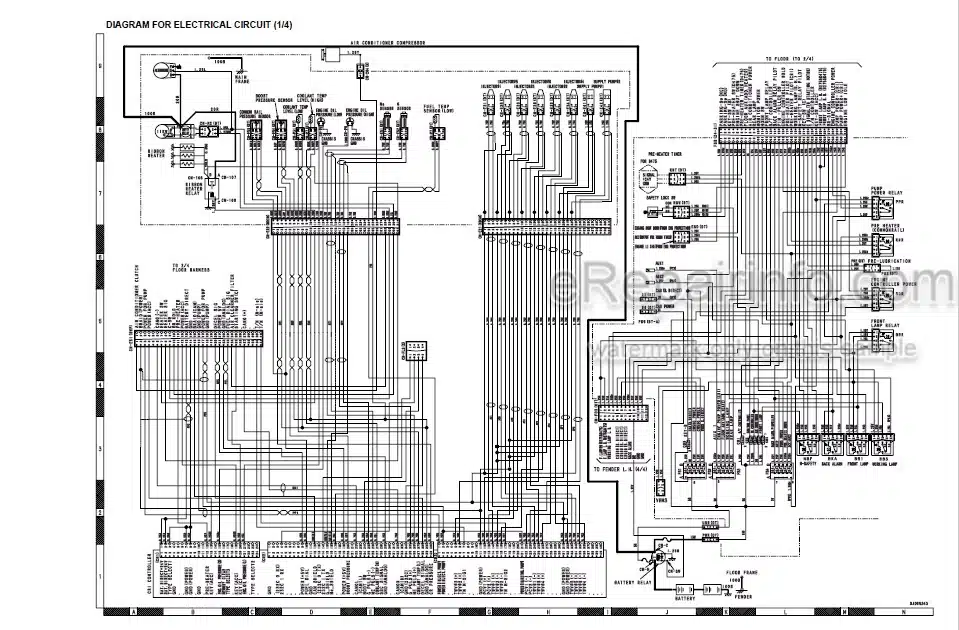

Diagram For Electrical Circuit

Diagram For Electrical Circuit Of Air Conditioner

Electric Circuit Diagram Of Inside Cab

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet