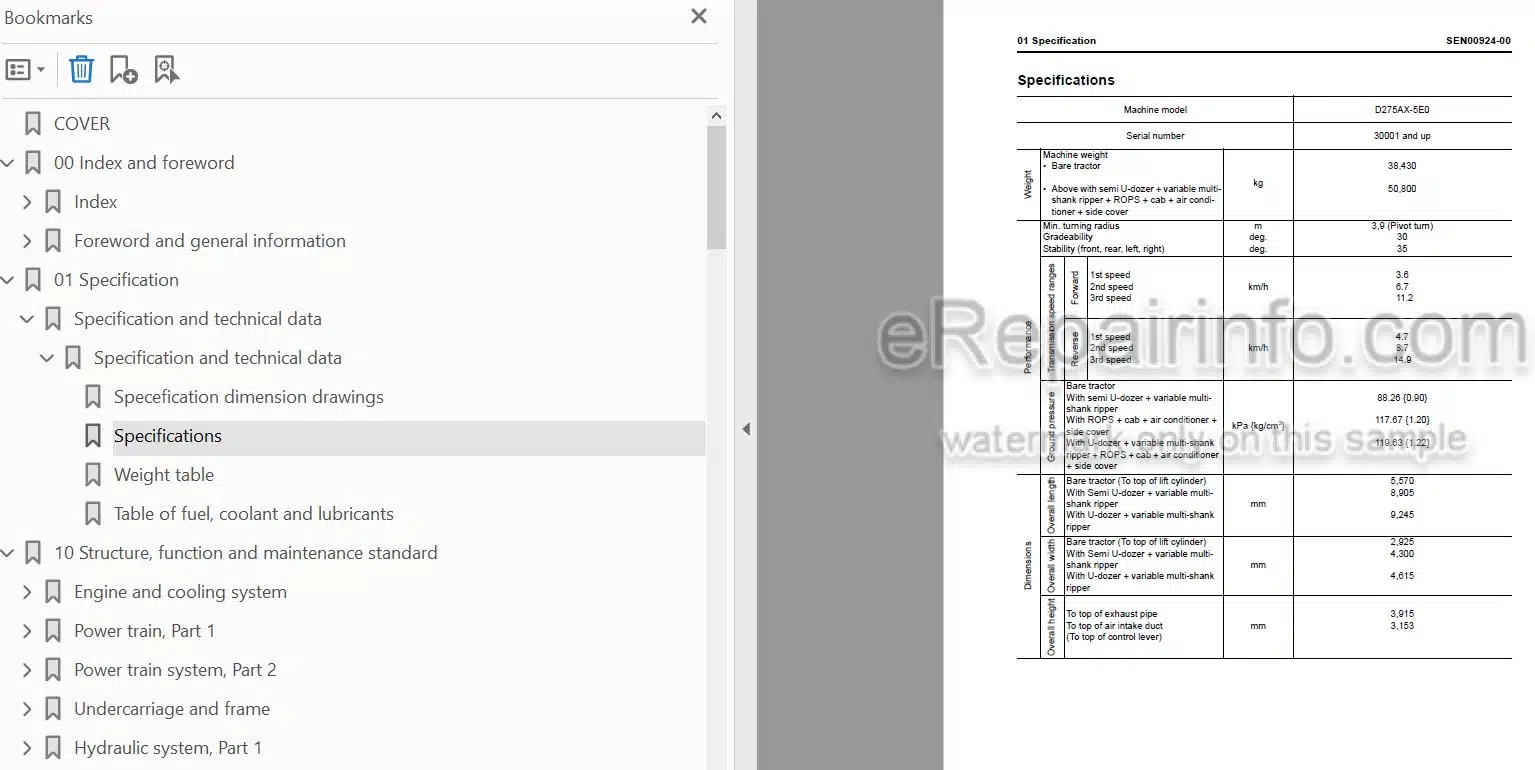

Factory Shop Manual For Komatsu Bulldozer. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 1508

Number: SEN00919-10 (june 2010)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Komatsu Bulldozer

D275AX-5E0

SN 30001 And Up

Contents

-INDEX AND FOREWORD

Index

Foreword And General Information

-SPECIFICATION

Specification Dimension Drawings

Specifications

Weight Table

Table Of Fuel, Coolant And Lubricants

-STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

Engine And Cooling System

Power Train System

Undercarriage And Frame

Hydraulic System

Work Equipment

Cab And Its Attachments

Electrical System

-STANDARD VALUE TABLE

Standard Value Table For Engine

Standard Value Table For Machine

-TESTING AND ADJUSTING

Tools For Testing, Adjusting, And Troubleshooting

Testing Engine Speed

Testing Intake Air Pressure (Boost Pressure)

Testing Exhaust Temperature

Testing Exhaust Gas Color

Adjusting Valve Clearance

Testing Compression Pressure

Testing Blow-By Pressure

Testing Engine Oil Pressure

Testing EGR Valve And Bypass Valve Drive Oil Pressure

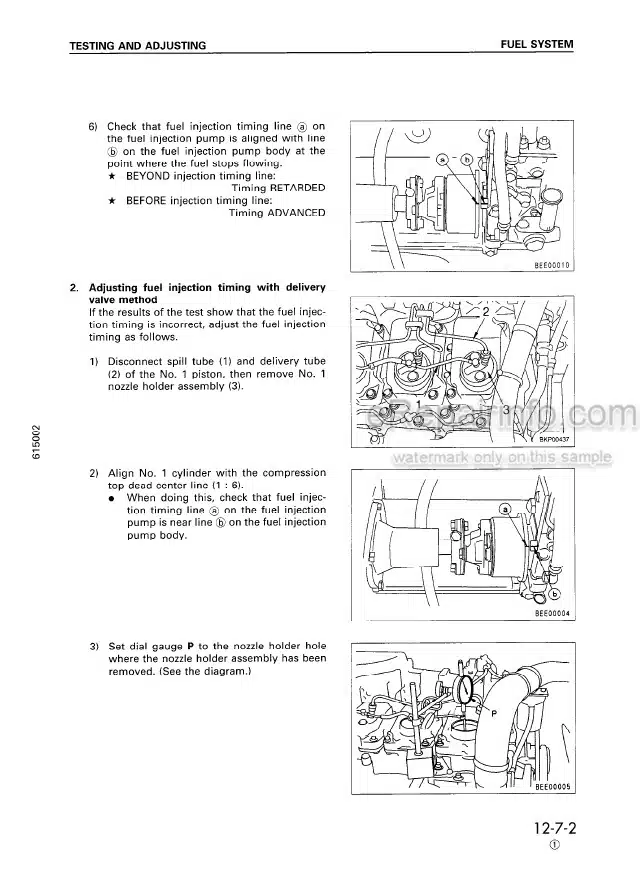

Handling Of Fuel System Devices

Releasing Residual Pressure From Fuel System

Testing Fuel Pressure

Testing Fuel Return Rate And Fuel Leakage

Bleeding Air From Fuel Circuit

Testing Fuel Circuit For Leakage

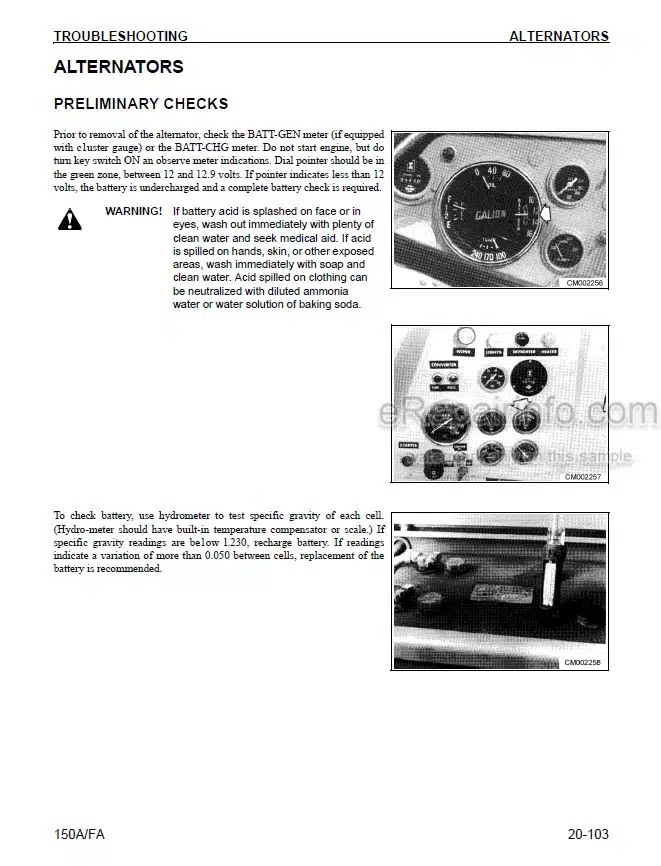

Testing And Adjusting Alternator Belt Tension

Handling Controller Voltage Circuit

Testing And Adjusting Air Conditioner Compressor Belt

Testing Fan Speed

Testing Fan Circuit Oil Pressure

Bleeding Air From Fan Pump

Adjusting Fuel Control Dial And Decelerator Pedal

Testing Power Train Oil Pressure

Testing And Adjusting HSS Oil Pressure

Adjusting Transmission Speed Sensor

Bleeding Air From HSS Pump

Simple Method Of Testing Brake Performance

Adjusting Brake Pedal And Parking Brake Lever

Adjusting PCCS Lever Console Position

Emergency Escape Method When Power Train Has Trouble

Adjusting Clearance Of Idler

Inspecting Wear Of Sprocket

Testing And Adjusting Track Shoe Tension

Testing And Adjusting Work Equipment Oil Pressure

Testing Control Circuit Main Pressure

Testing PPC Valve Output Pressure

Adjusting Play Of PPC Valve

Testing Outlet Pressure Of Ripper Pin Puller Solenoid Valve

Testing Parts Which Cause Hydraulic Drift Of Blade And Ripper

Testing Internal Leakage Of Work Equipment Cylinder

Adjusting Ripper Lever Position

Adjusting Work Equipment Lock Lever

Adjusting Blade

Testing And Adjusting Operator’s Cab

Special Functions Of Machine Monitor (EMMS)

Adjustment Method When Controller Has Been Replaced

Method Of Starting Use Of Komtrax Terminal

Indication By Komtrax Terminal Lamps

Preparation Work For Troubleshooting For Electric System

Handling Of Optional Devices

PM Clinic Service

-TROUBLESHOOTING

Failure Code Table And Fuse Locations

General Information On Troubleshooting

Troubleshooting By Failure And Error Codes

Troubleshooting Of Electrical System (E-Mode)

Troubleshooting Of Hydraulic And Mechanical System (H-Mode)

Troubleshooting Of Engine (S-Mode)

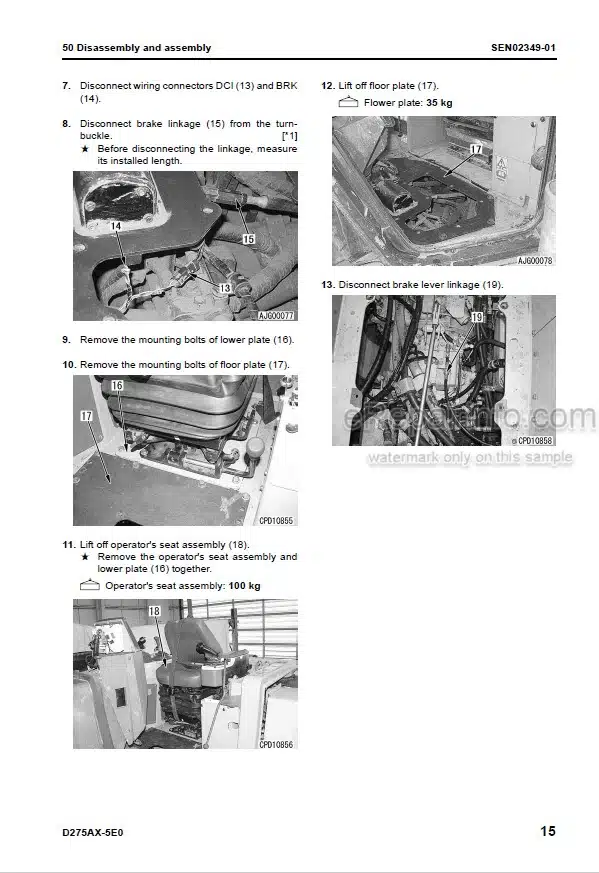

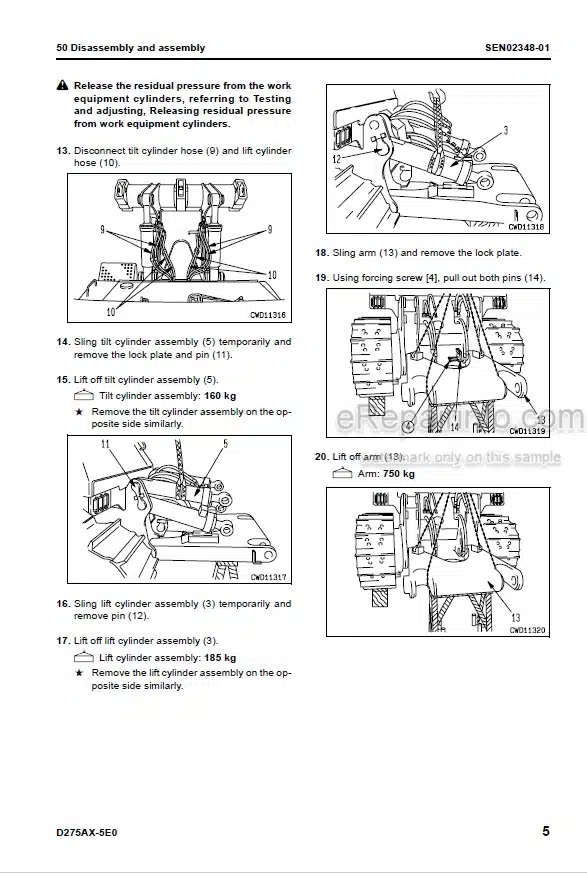

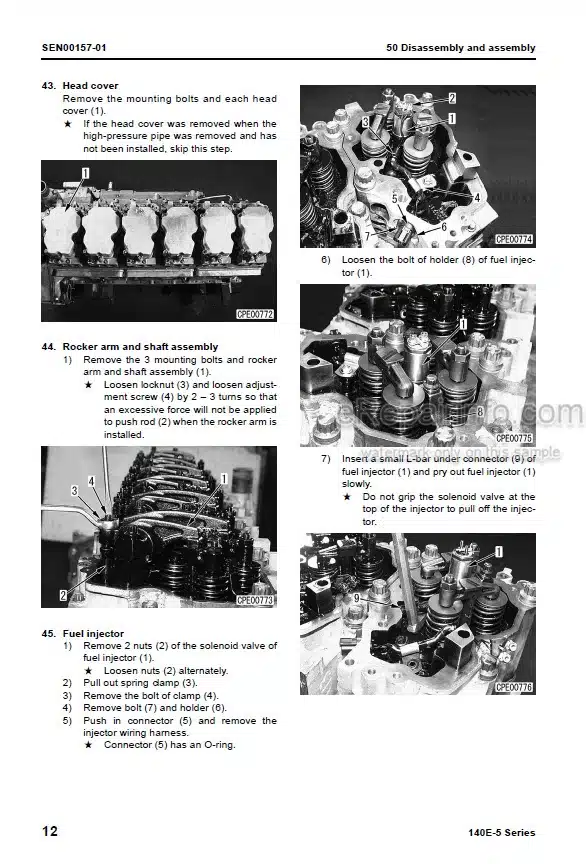

-DISASSEMBLY AND ASSEMBLY

General Information On Disassembly And Assembly

Engine And Cooling System

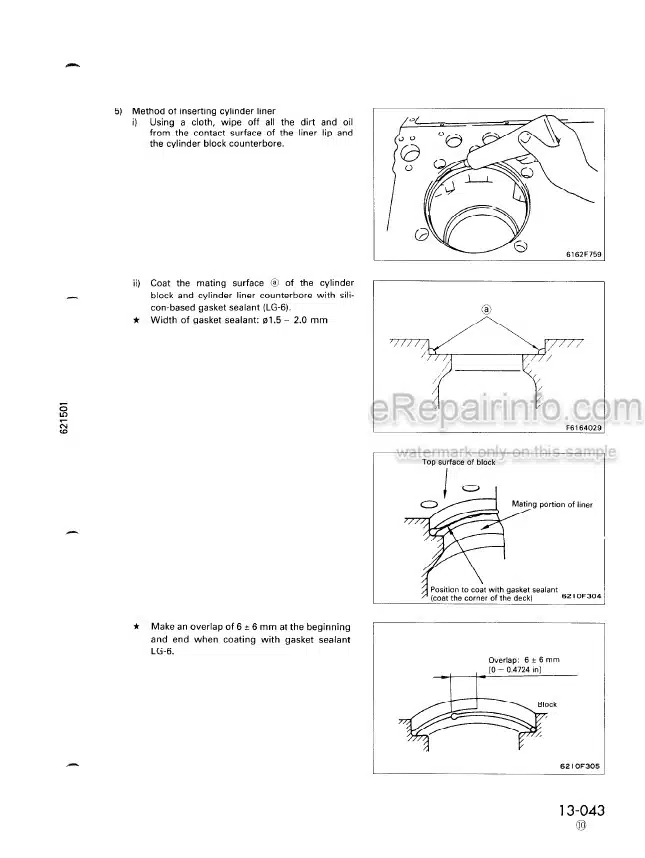

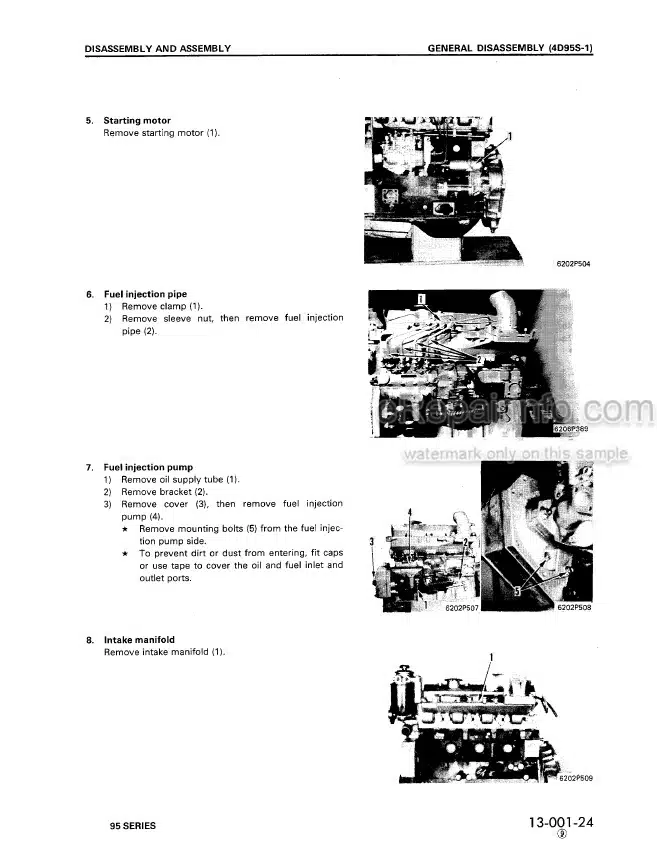

Engine

Power Train

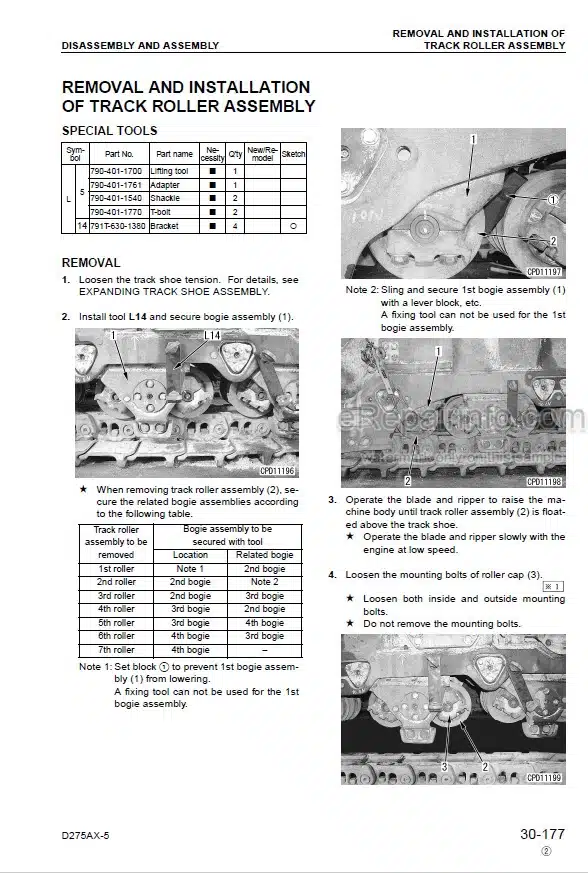

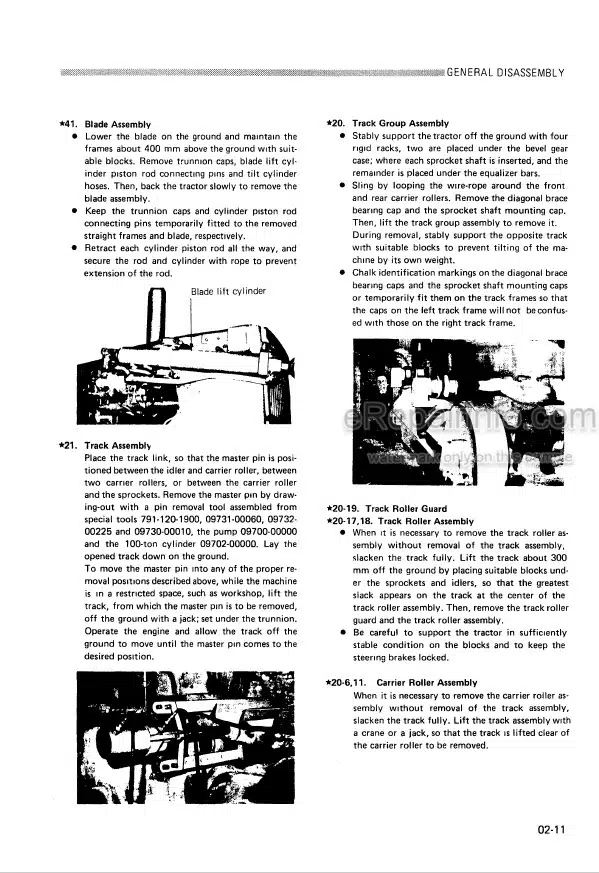

Undercarriage And Frame

Hydraulic System

Work Equipment

Cab And Its Attachments

Electrical System

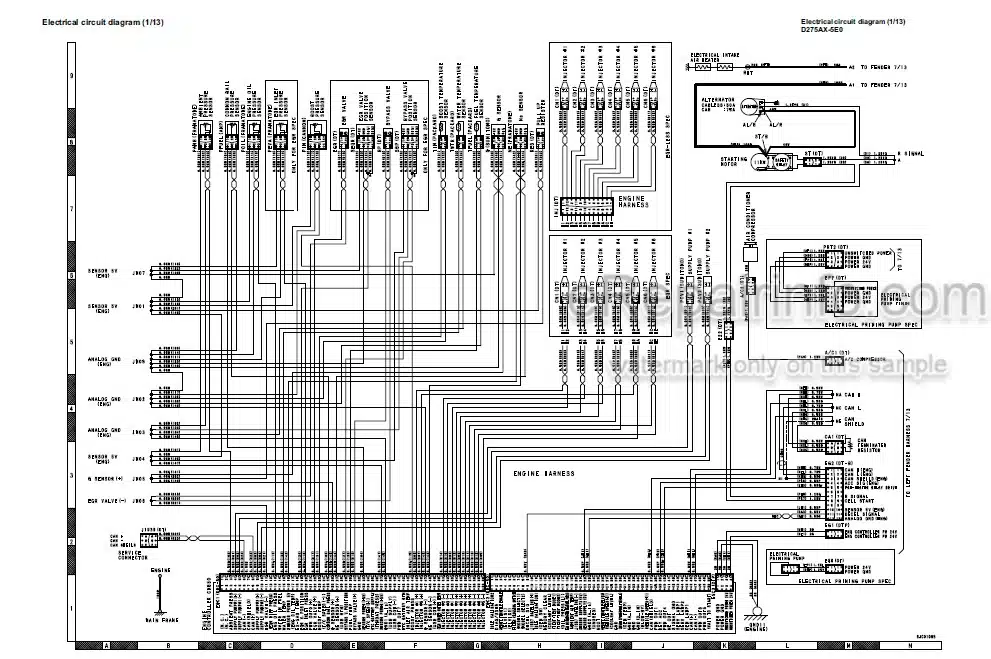

-DIAGRAMS AND DRAWINGS

Hydraulic Circuit Diagram

Electrical Diagrams And Drawings

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet