Factory Operating Maintenance Instructions For Bomag Refuse Compactor. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: ENG

Pages: 128

Number: 00816061 (march 1997)

Searchable: Yes

Model

Bomag Refuse Compactor

BC670RB

S/N 101 570 40 …. › Cummins LTA 10-C352

S/N 101 570 41 …. › Cummins MTA11-C350

Contents

TECHNICAL DATA

SAFETY REGULATIONS

-INDICATORS AND CONTROL ELEMENTS

Description Of Indicators And Control Elements

-OPERATION

Tests Before Starting To Operate

Starting The Engine

Driving The Machine

Emergency Exit

Operating The Dozer Blade

Shutting Engine Down

Dozer Blade, Emergency Control

Operating The Service Brake

Shutting The Engine Down

Operating The Hydraulic System Emergency Switch

Parking On A Slope

Towing The Machine

Transport Of Machine

-MAINTENANCE

General Notes On Maintenance

Fuels And Lubricants

Table Of Fuels And Lubricants

Running-In Instructions

Maintenance Chart

Checking The Engine Oil Level

Checking The Coolant Level

Draining The Water Separator In The Fuel System

Checking The V-Belt

Checking The Fuel Level

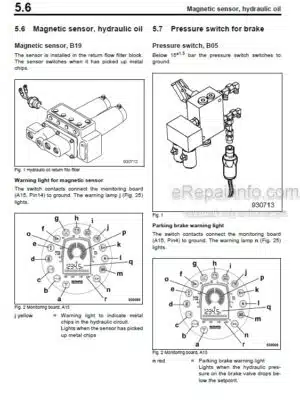

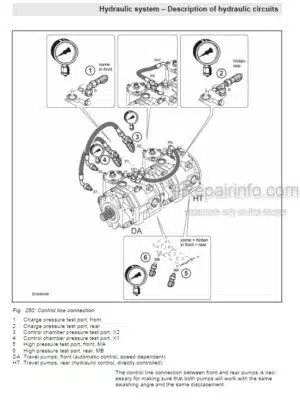

Checking The Hydraulic Oil Level

Lubricating The Dozer Blade

Checking The Machine For Damage And Leaks

Changing Engine Oil And Oil Filter Cartridge

Checking The Concentration Of Anti-Freeze Agent And The Coolant Additive

Changing The Coolant Filter

Changing The Fuel Filter Cartridges

Checking The Fastening Of The Scrapers

Checking The Oil Level In The Splitter Gear

Checking The Oil Level In The Planetary Drives

Checking The Engine Fasteners

Checking, Cleaning The Radiator And The Hydraulic Oil Cooler

Servicing The Battery, Checking The Main Battery Disconnect Switch

Checking, Filling The Central Lubrication System

Changing The Lubrication Cartridge On The Dozer Blade Cylinder

Greasing Hinges On Doors And Maintenance Flaps

Servicing The Air Conditioning (Summer Operation)

Checking The Condition And Tension Of The Generator V-Belt, Changing The V-Belt

Checking The Condition And Tension Of The Refrigerant Compressor V-Belt, Changing The V-Belt

Checking The Condition And Tension Of The Blower V-Belt, Changing The V-Belt

Checking, Adjusting The Injection Valves And The Valve Clearance

Checking The Fastening Of Engine / Turbo Charger / Combustion Air Hoses

Changing The Fuel Filter For The Cabin Heater (Diesel)

Checking, Cleaning The Oil Bath Air Filter For The Cabin Heater (Diesel)

Changing The Oil In The Planetary Drive

Changing The Oil In The Splitter Gear

Changing The Hydraulic Oil Fine Filter

Checking The Coolant Pump

Changing The Hydraulic Oil

Changing The Coolant

Draining The Fuel Tank Sludge

Checking The Condition Of The Articulated Joint

Maintenance Work, Which Has To Be Performed Every 6000 Operating Hours By A Specialist Workshop

Servicing The Combustion Air Filter

Cleaning The Condenser (Air Conditioning Unit)

Adjusting Scrapers And Edge Cutters

Replacing The Wheel Caps

Checking The Cutting Plates, Replace The Cutting Plates If Necessary

Tightening The Bolted Connections

Checking, Changing The Starting Aid Container (Ether)

Checking The Provision Container Of The Windscreen Washer System

Conservation

-TROUBLESHOOTING

General Notes

Engine

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet