Factory Service Training For Bomag Road Finisher. The Bomag Service Training Manual Describes The Disassembly, Dismantling, Assembly, Installation And Repair Of Components And Assemblies. Manual Addresses The Professionally Qualified Personnel Or The After Sales Service Of Bomag, And Should Be Of Help And Assistance In Correct And Efficient Repair And Maintenance Work.

Format: PDF

Language: English

Pages: 754

Number: 00892115 (february 2013)

Bookmarks: Yes

Searchable: Yes

Wiring Diagram: Yes

Hydraulic Diagram: Yes

Model

Bomag Road Finisher

BF300P

S/N 821 837 68 1001 ….

S/N 821 837 81 1001 ….

S/N 821 891 01 1001 ….

S/N 821 891 02 1001 ….

Contents

-GENERAL

Introduction

Safety Regulations

General Repair Instructions

Tightening Torques

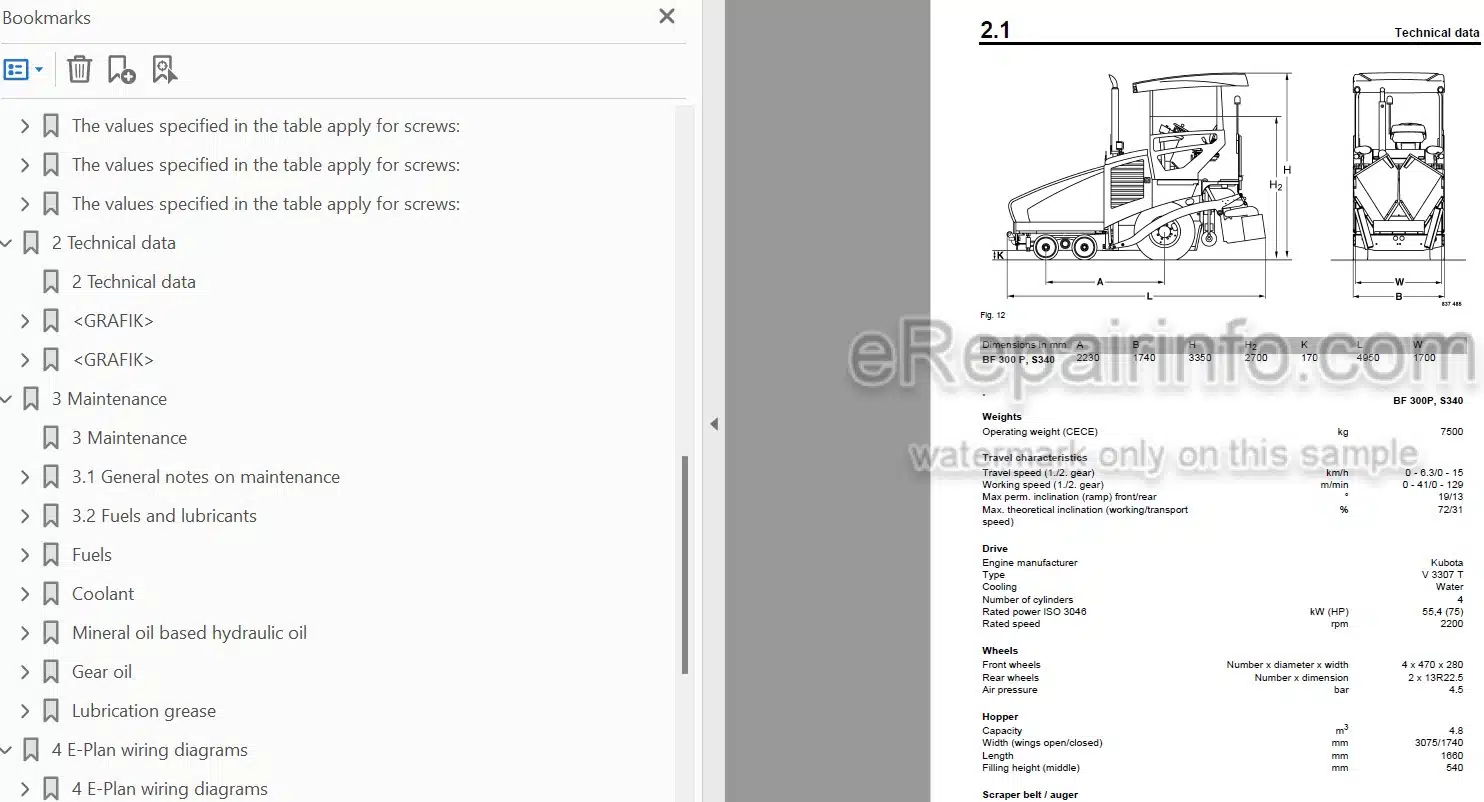

-TECHNICAL DATA

Technical Data

-MAINTENANCE

General Notes On Maintenance

Fuels And Lubricants

Table Of Fuels And Lubricants

Running-In Instructions

Maintenance Table

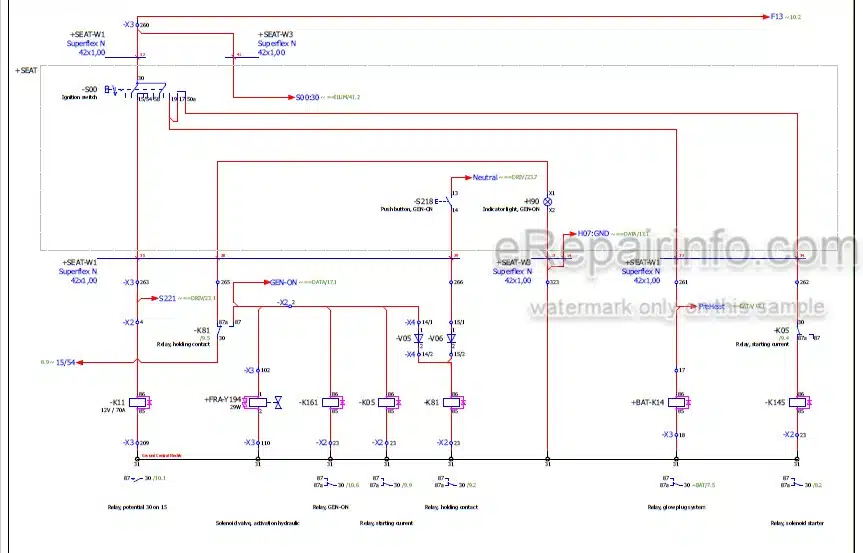

-E-PLAN WIRING DIAGRAMS

Understanding E-Plan Circuit Diagrams

Circuit Symbols In E-Plan

Identification Of Switch Blocks In The Wiring Diagram

Designation Of Components In The Wiring Diagram

Terminal Designations In Wiring Diagram

-ELECTRICS

Ecomode

Glow Plugs, R81-R84

Oil Pressure Switch (B06)

Coolant Temperature Switch (B53)

Air Filter Vacuum Switch (B03)

Coolant Float Switch (B55)

Charge Control Light

Glow Plugs

Water Separator In Fuel Filter (B124))

Level Sensor In Diesel Tank (R03)

Fuses

Fuse Assignment

Component Overview

Overview Of Wiring Looms

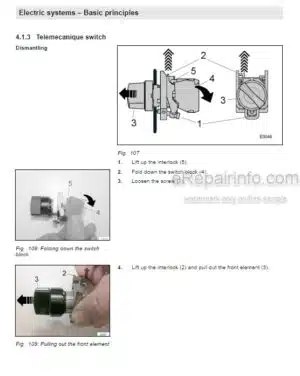

Control Elements

View Of Operator’s Stand

Monitoring Modules

View Of Outside Control Stand

View Of Screed Control

Functional Block Diagram Overview Of Functions, Complete

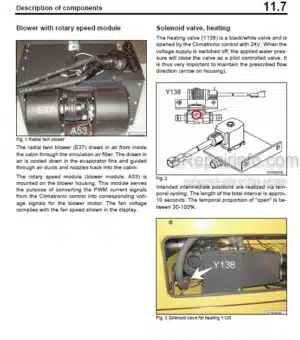

Block Diagram Components On Can

Block Diagram Can With Control Elements

Block Diagram Of Travel Circuit

Block Diagram Material Feed

Block Diagram Screed

Block Diagram Screed Levelling

Block Diagram Screed Heating

Functional Block Diagram Monitoring Functions

Functional Block Diagram Emergency Stop Function

Checking The Voltage Supply For The Control Unit

Diagnostics Concept

-INPUT CODES

Input Codes – Display: Functions And Operation

Teaching The E-Throttle Function:

Teaching The L.C.S. Function

Travel Signal By Button For Max, Screed Relief

Resetting To Factory Settings

Showing Stored Faults

Showing Saved Faults With Operating Hours

Deleting The Fault Log

Driving Against The Closed Brake

Adapting The Engine Speed

Deactivating / Activating The Front Drive

Deactivating / Activating The Brake Pedal Switch

-REPLACEMENT OF COMPONENTS

How To Proceed When Replacing Components

-ENGINE

Features

Cooling System

Removing And Installing The Thermostat

Checking The Thermostat In Disassembled State

Check The Coolant Level

Check The Anti-Freeze Concentration And The Condition Of The Coolant

Change The Coolant

Checking Radiator Hoses And Hose Clamps

Clean The Cooling Fins On Engine And Hydraulic Oil Cooler

Checking The Engine Oil Level

Changing Engine Oil And Oil Filter Cartridge

Fuel System

Replace The Fuel Filter

Checking, Cleaning The Water Separator

Changing The Fuel Filter, Bleeding The Fuel System

Check Fuel Lines And Clamps

Check The Fuel Injection Nozzles

Check The Fuel Injection Timing

Check The Fuel Injection Pump

Servicing The Generator V-Belt

Air Filter Maintenance

Check The Engine Mounts

Engine Conservation

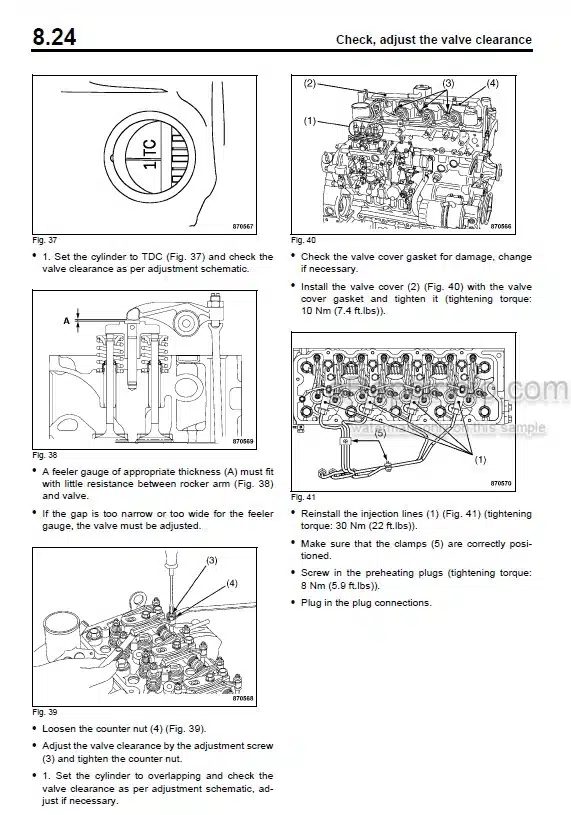

Check, Adjust The Valve Clearance

Engine Problems

-MATERIAL HOPPER, DESCRIPTION

Material Hopper And Transport

-VIBRATING SCREED, DESCRIPTION

Screed

-TRAVEL DRIVE, DESCRIPTION

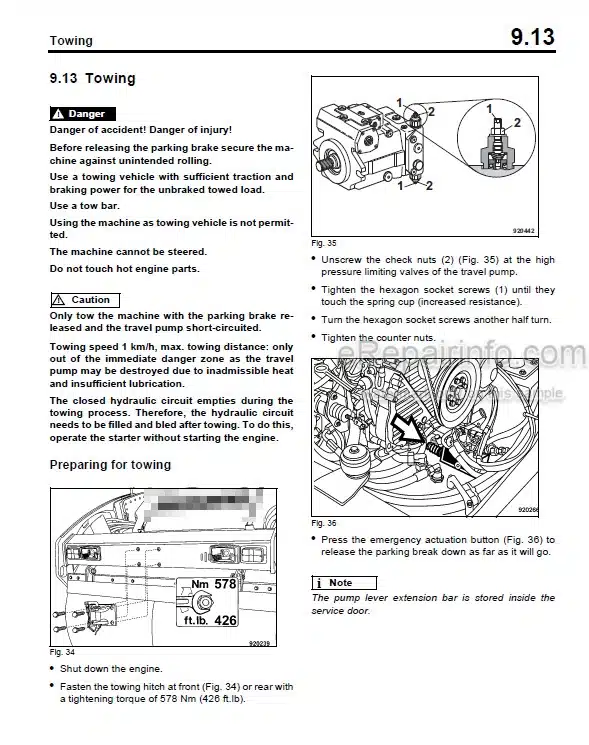

Travel System

-CLEANING KIT, DESCRIPTION

Cleaning Kit

-HYDRAULICS

Hydraulic Circuit

Travel Pump, A10VG45 EP

Travel Pump, A10VO28

Troubleshooting Axial Piston Pumps

Vibration And Tamper Pump, Haldex WP09 xxx

Vibration And Tamper Motor, Sauer Snm2Nn

Component Overview – Hydraulics

Travel Circuit

Vibration And Tamper Drive

Scraper Belt Drive

Auger Drive

Cylinder Functions

Check The Hydraulic Oil Level

Changing Hydraulic Oil And Filter

-TESTS AND ADJUSTMENTS

Special Tools, Tests And Adjustments

Checking And Adjusting The Vibration

Checking/Adjusting Tamping

Checking/Adjusting The Scraper Belts

Checking/Adjusting The Augers

Checking/Adjusting The Main Screed

Checking/Adjusting The Screed Levelling

Checking/Adjusting The Hopper Wings

Checking/Adjusting The Mobile Screed

-CENTRAL LUBRICATION SYSTEM

BF 300P Lubrication Plan

Filling The Lubricant Container

Electric Pump

Integrated Electronic Control

Progressive Distributor

Fault – Cause – Remedy

Repair Of A Blocked Distributor

-CIRCUIT DIAGRAMS

Hydraulic Diagram

Electric Circuit Diagrams

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet