Factory Operating Instructions For Bomag Paver. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: ENG

Pages: 194

Number: 00808181 (october 2015)

Bookmarks: Yes

Searchable: Yes

Model

Bomag Paver

BF900C

S/N 821 893 08 1001>

S/N 821 893 09 1001>

Contents

-INTRODUCTION

Foreword

Machine Type Plate And Engine Type Plate

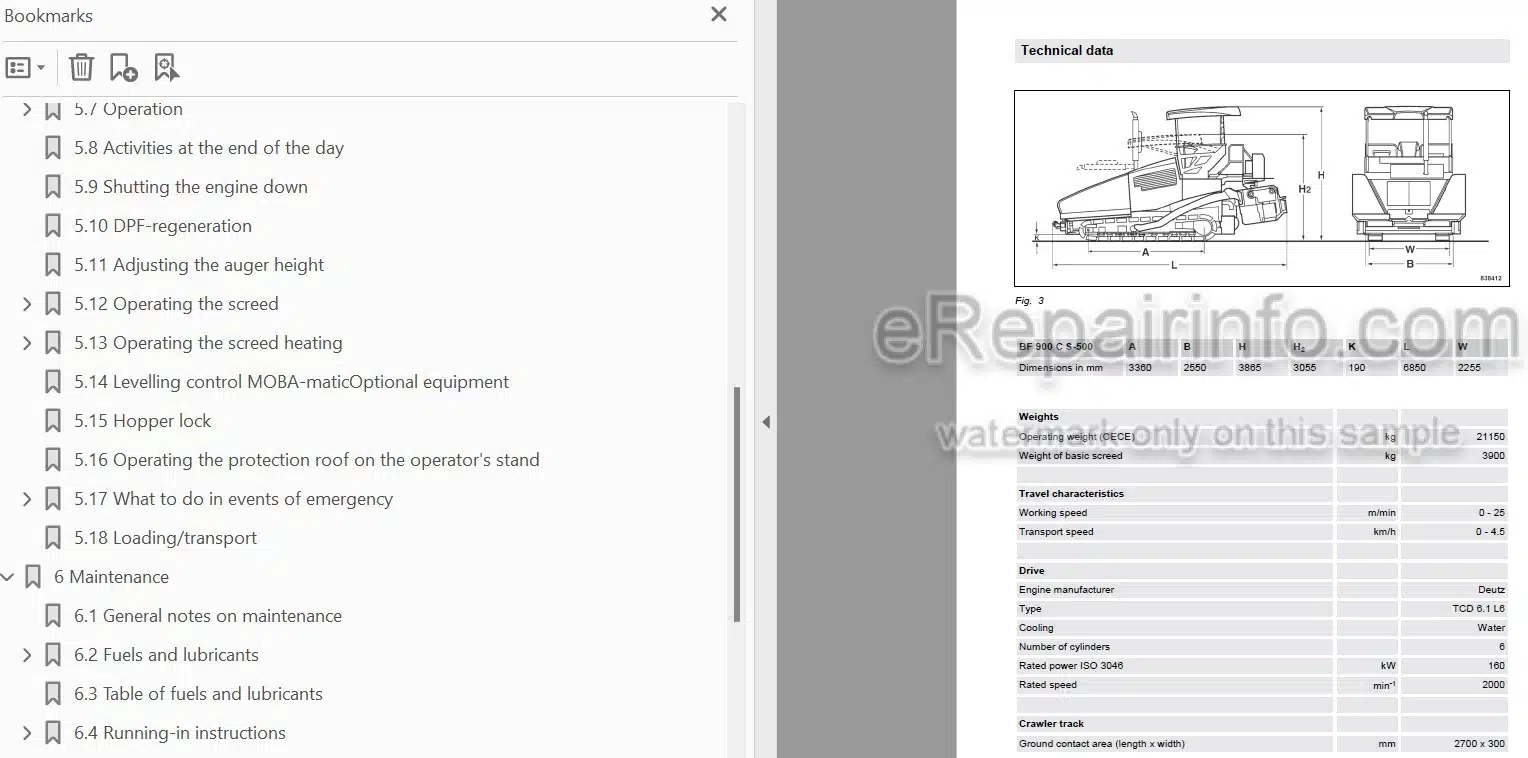

TECHNICAL DATA

-SAFETY REGULATIONS

Stickers And Decals

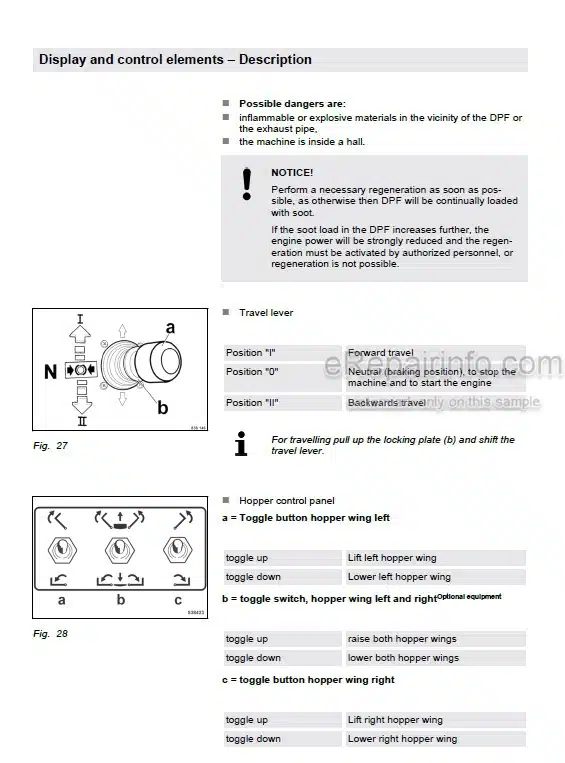

-DISPLAY AND CONTROL ELEMENTS

View Of Main Control Panel

Description

View Of External Operator Stations

Control Elements On External Operator Stations

Screed Operating Console

Operating Console For Screed Heating

View Of Levelling Control

-OPERATION

General

Tests Before Taking Into Operation

Adjusting The Driver’s Seat And Displacing The Driver’s Platform

Starting The Engine

Driving The Machine In Transport Speed Mode

Preparing For Work

Operation

Activities At The End Of The Day

Shutting The Engine Down

DPF-Regeneration

Adjusting The Auger Height

Operating The Screed

Operating The Screed Heating

Levelling Control Moba-Matic Optional Equipment

Hopper Lock

Operating The Protection Roof On The Operator’s Stand

What To Do In Events Of Emergency

Loading/Transport

-MAINTENANCE

General Notes On Maintenance

Fuels And Lubricants

Table Of Fuels And Lubricants

Running-In Instructions

Maintenance Table

Every 10 Operating Hours

Every 250 Operating Hours

Every 500 Operating Hours

Every 1000 Operating Hours

Every 2000 Operating Hours

Every 4000 Operating Hours

Every 6000 Operating Hours

As Required

-TROUBLESHOOTING

Preliminary Remarks

Starting The Engine With Jump Leads

Screed Heating Fault Code Display

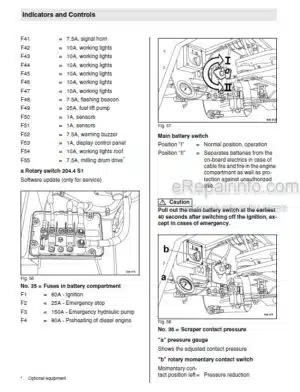

Fuse Assignment

Fault Code Display

Engine Faults

-DISPOSAL

Final Shut-Down Of Machine

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet