Factory Service Training For Bomag Cold Milling Machine. The Bomag Service Training Manual Describes The Disassembly, Dismantling, Assembly, Installation And Repair Of Components And Assemblies. Manual Addresses The Professionally Qualified Personnel Or The After Sales Service Of Bomag, And Should Be Of Help And Assistance In Correct And Efficient Repair And Maintenance Work.

Format: PDF

Language: English

Pages: 330

Number: 00891942 (march 2012)

Bookmarks: Yes

Searchable: Yes

Wiring Diagram: Yes

Hydraulic Diagram: Yes

Model

Bomag Cold Milling Machine

BM1000-30-2

BM1200-30-2

BM1300-30-2

BM1000-30-2PB

BM1200-30-2PB

BM1300-30-2PB

S/N 821 836 34 1001 ….

S/N 821 836 35 1001 ….

S/N 821 836 30 1001 ….

S/N 821 836 36 1001 ….

S/N 821 836 37 1001 ….

S/N 821 836 32 1001 ….

Contents

-GENERAL

Introduction

Safety Regulations

General Repair Instructions

Tightening Torques

-TECHNICAL DATA

Technical Data

-MAINTENANCE

Fuels And Lubricants

Running-In Instructions

-ELECTRICS

Designation Of Components In The Wiring Diagram

Terminal Designations In Wiring Diagram

Control Elements

Main Fuse

Fuses

Component Overview

Control Elements

View Of Operator’s Stand

View Rear Right Hand Control Panel (B4)

View Rear Left Hand Control Panel (B3)

View Front Right Hand Control Console (B7)

View Front Left Hand Control Console (B5)

View Control Panel For Auxiliary Control / Limp Home Control (B10)

Multi-Function Display (MFD)

Levelling Control Console, General

Levelling Control Console, Description

Viewing Switching States Of Switches And Valves

Work Parameters For Engine Load And Height Control

Rope Sensors For Height Control, C22 And C24

Operating Conditions For Height Regulation

Rope Sensor, Front Steering, 264R1

Cable Sensor, Rear Steering, C16

Operating Conditions For Rear Steering

Height Limitation, Rear

Operating Conditions For Rear Posts

Limit Switch On Scraper, C48 And C49

Functional Conditions For Scraper

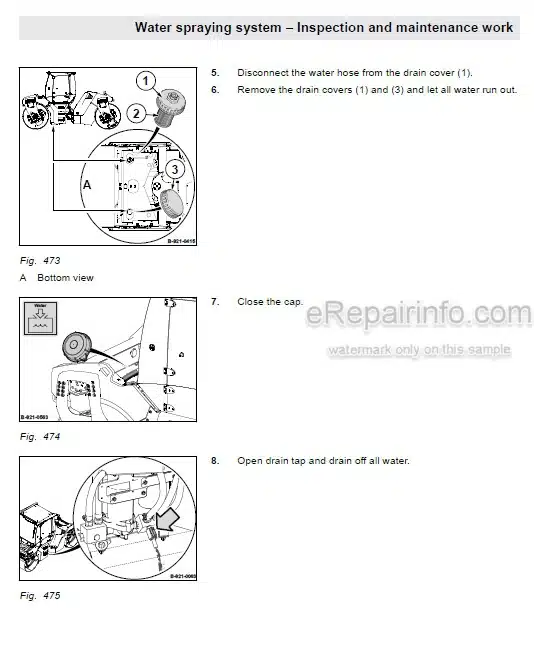

Water Sprinkling System

Operating Condition For Sprinkling System

Differential Pressure Switch For Hydraulic Oil

Speed Sensor, C53

Operating Conditions For Travel Drive

Functional Conditions For Hold-Down

Functional Conditions Right Side Plate

Functional Conditions For Milling Drum Drive

Functional Conditions For Conveyor Belts

Engine Speed Sensor, C8

Terminal Box

Pin Assignment For Control

-ENGINE

General Information On Diesel Engine

Engine Attachment Parts

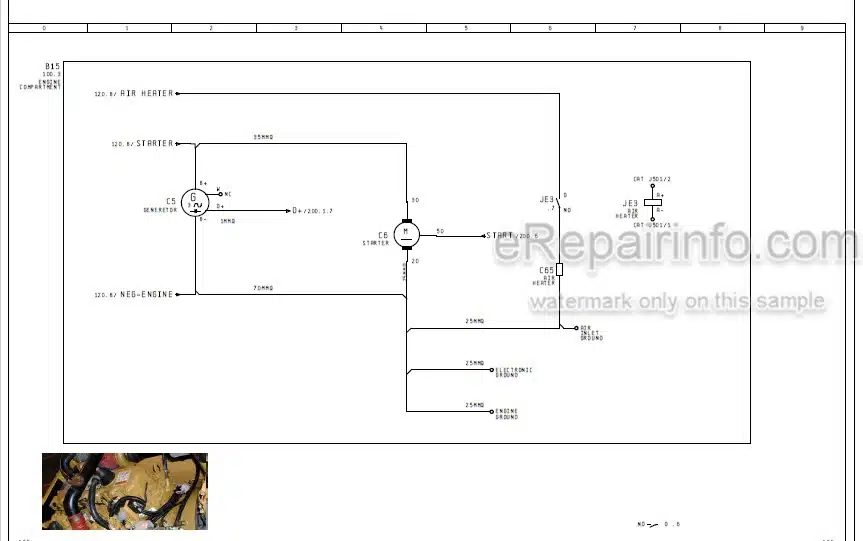

Engine Electrics

Checking The Cylinder Head Ground Cable

Engine Diagnostics Lamps, H8 And H9

General Notes On Flashing Codes

Table Of Flashing Codes

Check The Engine Oil Level

Change Engine Oil And Oil Filter Cartridge

Check, Clean The Water Separator

Change The Fuel Pre-Filter Cartridge

Replace The Fuel Filter Cartridge

Checking The Combustion Air Filter

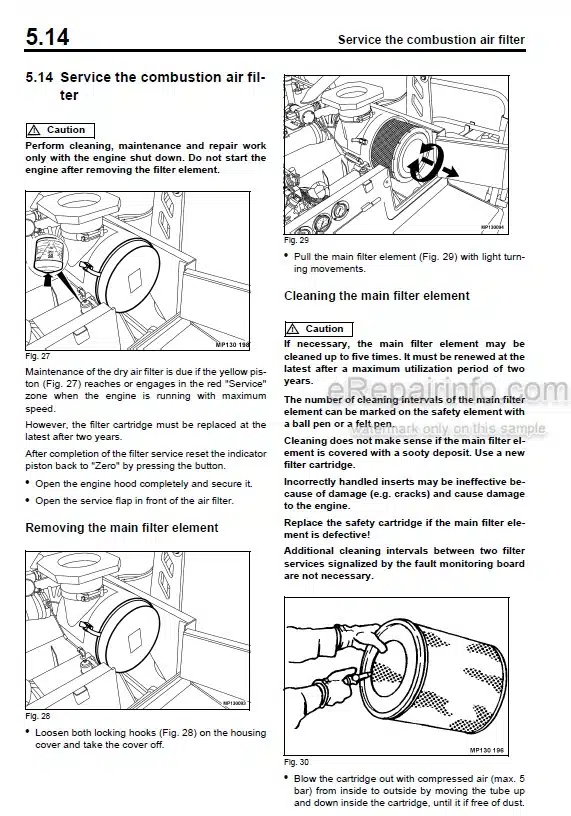

Service The Combustion Air Filter

Check The Coolant Level

Checking The Condition Of The Coolant Hoses

Change The Coolant

Clean The Cooling Fins On Engine And Hydraulic Oil Cooler

Checking, Tensioning The V-Belt For The Generator System

Cleaning The Crankcase Ventilation

Check The Engine Mounts

Checking The Valve Clearance

Engine Problems

-MILLING DRIVE, DESCRIPTION

Milling Drive

-MILLING UNIT, DESCRIPTION

Description Of Milling Unit

-TRAVEL DRIVE, DESCRIPTION

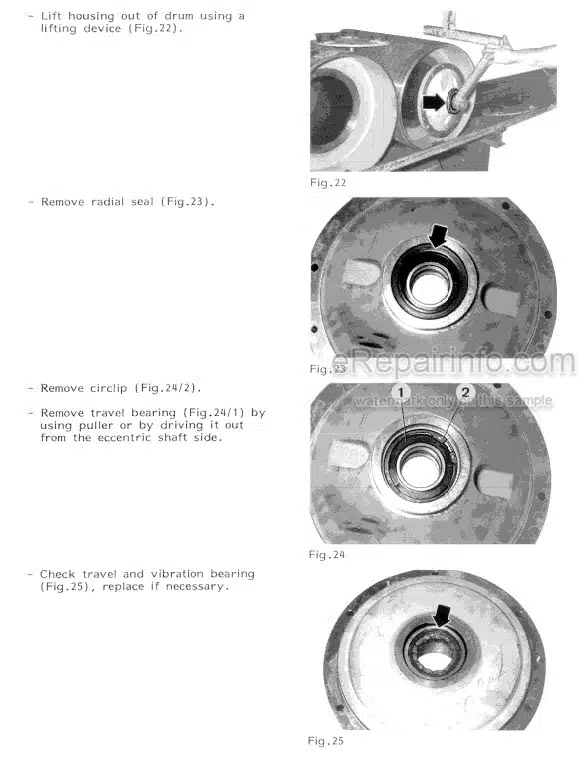

Travel System

-CONVEYOR BELT, DESCRIPTION

Conveyor Belts

Folding / Unfolding The Loading Conveyor Belt

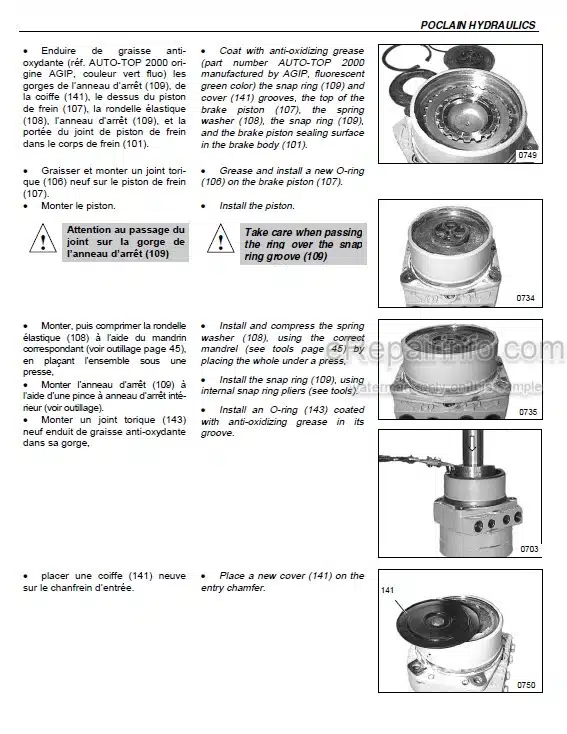

-HYDRAULICS

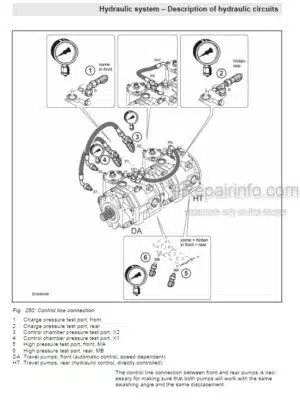

Hydraulic Circuit

Component Overview – Hydraulics

Description Of Travel Pump

View Of The Machine

Description Of Working Pump

View Of The Machine

Description Of Conveyor Belt Pump

View Of The Machine

Troubleshooting Axial Piston Pumps

Description Of Fan Pump

View Of The Machine

Description Of Travel Motor Bosch Rexroth

View Of The Machine

Check The Hydraulic Oil Level

Clean The Cooling Fins On Engine And Hydraulic Oil Cooler

Changing Hydraulic Oil And Breather Filter

Changing The Hydraulic Oil Filter

-HYDRAULICS – TRAVEL CIRCUIT

Description Of Driving

Description Of Crawler System

Description Of Steering

-HYDRAULICS – MILLING OPERATION

Description Of Clutch

View Of The Machine

Milling Box Hydraulics

View Of The Machine

-TESTS AND ADJUSTMENTS

Special Tools, Tests And Adjustments

Checking/Adjusting The Travel Pump

-CIRCUIT DIAGRAMS

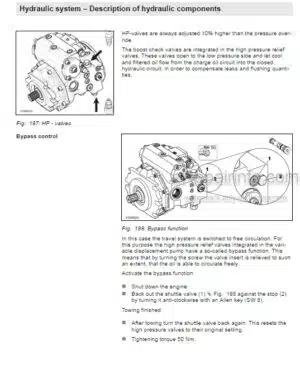

Hydraulic Diagram

Electric Circuit Diagrams

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet