Factory Operating Maintenance Instructions For Bomag Combination Roller. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: ENG

Pages: 234

Number: 00820131 (october 2017)

Bookmarks: Yes

Searchable: Yes

Model

Bomag Combination Roller

BW120AC-5

S/N 101 880 35 1046>

Contents

-INTRODUCTION

Foreword

Machine Type Plate And Engine Type Plate

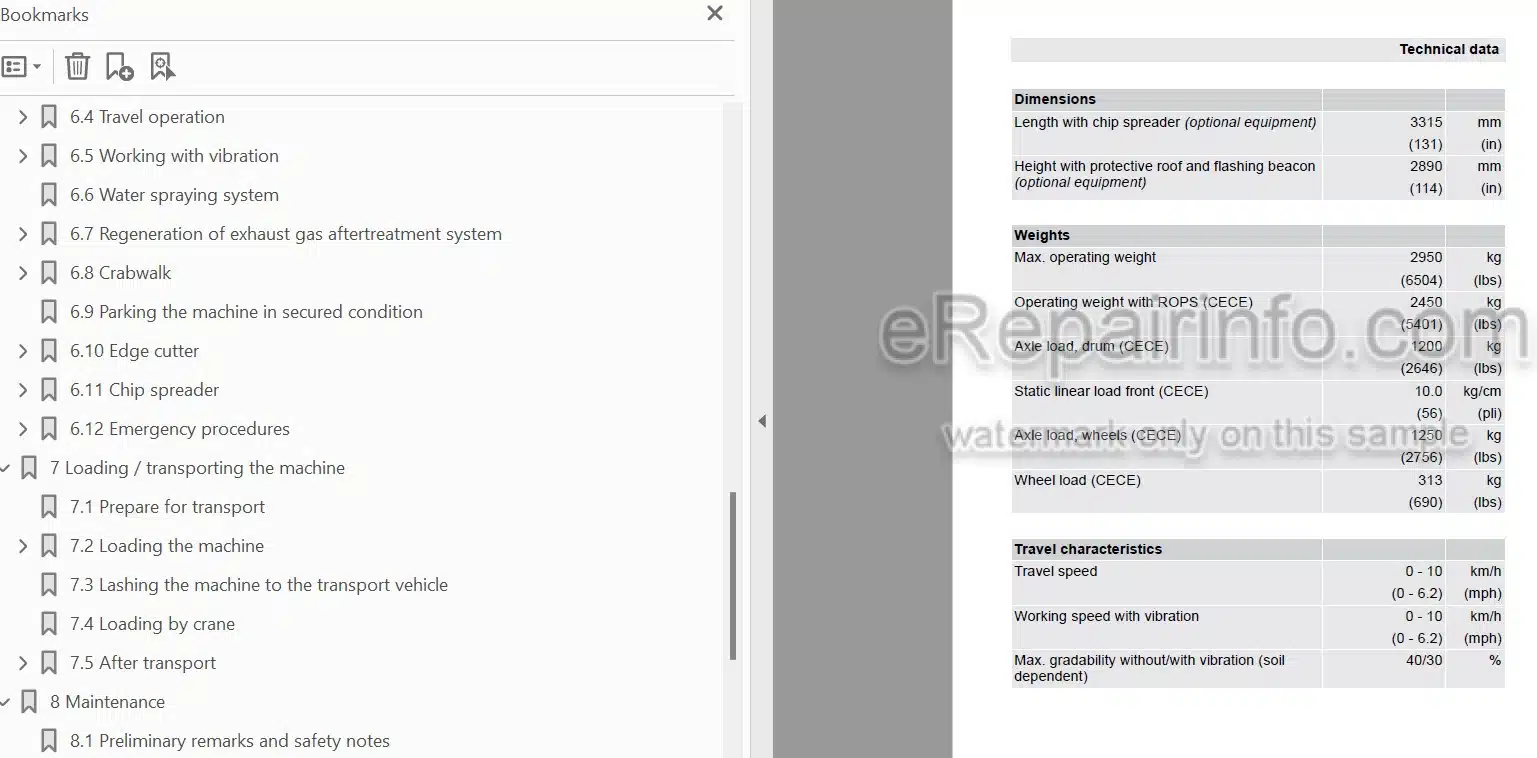

-TECHNICAL DATA

Noise And Vibration Data

-CONCERNING YOUR SAFETY

Basic Prerequisites

Definition Of Responsible Persons

Fundamentals For Safe Operation

Handling Fuels And Lubricants

Loading / Transporting The Machine

Start-Up Procedure

Driving The Machine; Working Operation

Refuelling

Regeneration Of Exhaust Gas Aftertreatment System

Emergency Procedures

Maintenance Work

Repair

Signage

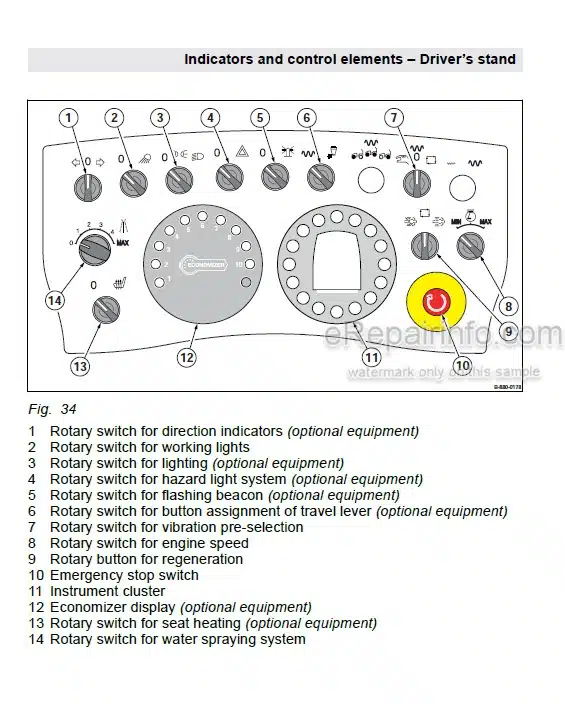

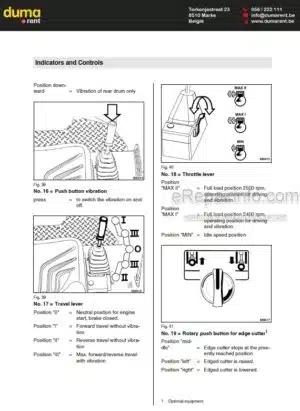

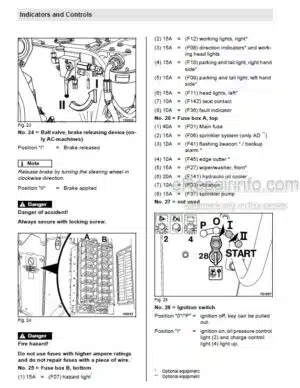

-INDICATORS AND CONTROL ELEMENTS

Driver’s Stand

Outside Of Machine

Engine Compartment

-CHECKS PRIOR TO START UP

Notes On Safety

Visual Inspections And Function Tests

Checking The Engine Oil Level

Checking The Fuel Level, Topping Up Fuel

Checking The Hydraulic Oil Level

Checking The Hydraulic Oil Filter

Checking The Coolant Level

Checking The Air Filter

Checking The Water Level, Topping Up

Checking The Emulsion Level, Topping Up

Checking, Adjusting The Scrapers

Checking Wheels And Tyres

-OPERATION

Setting-Up The Work Place

Electronic Immobilizer

Starting The Engine

Travel Operation

Working With Vibration

Water Spraying System

Regeneration Of Exhaust Gas Aftertreatment System

Crabwalk

Parking The Machine In Secured Condition

Edge Cutter

Chip Spreader

Emergency Procedures

-LOADING / TRANSPORTING THE MACHINE

Prepare For Transport

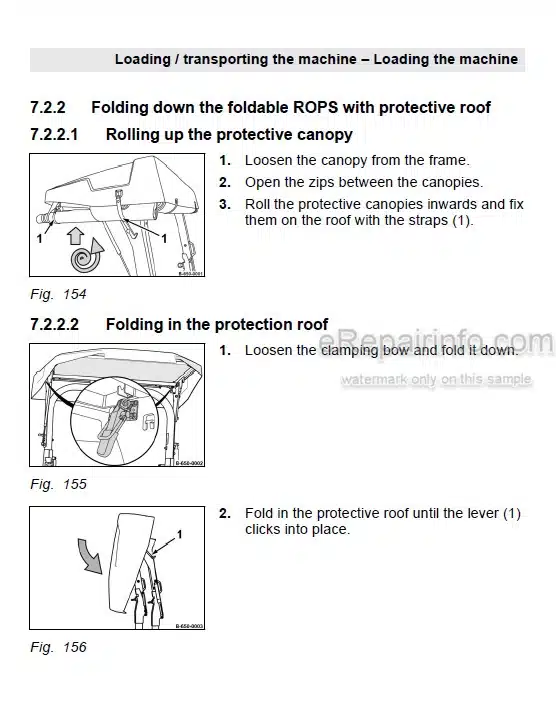

Loading The Machine

Lashing The Machine To The Transport Vehicle

Loading By Crane

After Transport

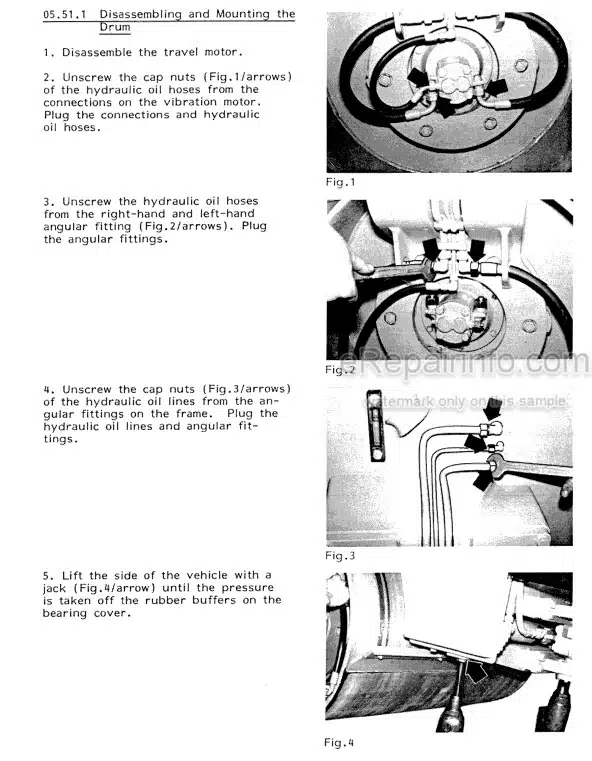

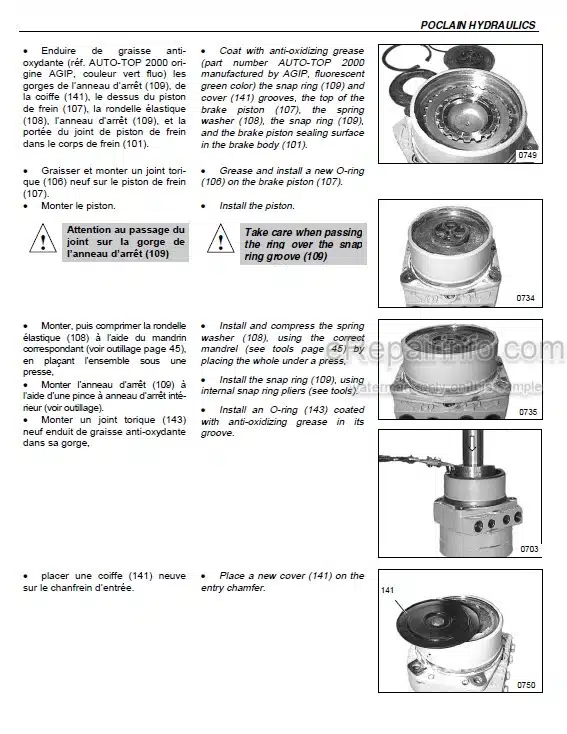

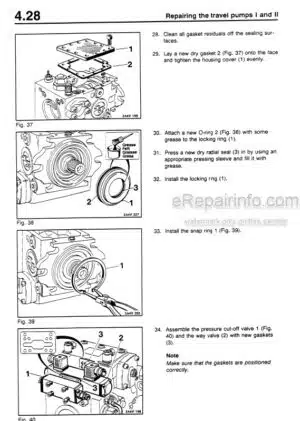

-MAINTENANCE

Preliminary Remarks And Safety Notes

Fuels And Lubricants

List Of Fuels And Lubricants

Running-In Instructions

Maintenance Table

Every 50 Operating Hours

Every 250 Operating Hours

Every 500 Operating Hours

Every 1000 Operating Hours

Every 2000 Operating Hours

Every 3000 Operating Hours

As Required

-TROUBLESHOOTING

Preliminary Remarks

Starting The Engine With Jump Leads

Fuse Assignment

Fault Code Display

Engine Faults

Trouble Shooting Economizer

-DISPOSAL

Final Shut-Down Of Machine

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet