Factory Service Training For Bomag Tandem Vibratory Roller And Asphalt Manager. The Bomag Service Training Manual Describes The Disassembly, Dismantling, Assembly, Installation And Repair Of Components And Assemblies. Manual Addresses The Professionally Qualified Personnel Or The After Sales Service Of Bomag, And Should Be Of Help And Assistance In Correct And Efficient Repair And Maintenance Work.

Format: PDF

Language: English

Pages: 676

Number: 00891927 (april 2001)

Bookmarks: Yes

Searchable: Yes

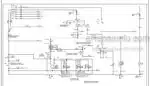

Wiring Diagram: Yes

Hydraulic Diagram: Yes

Model

Bomag Tandem Vibratory Roller And Asphalt Manager

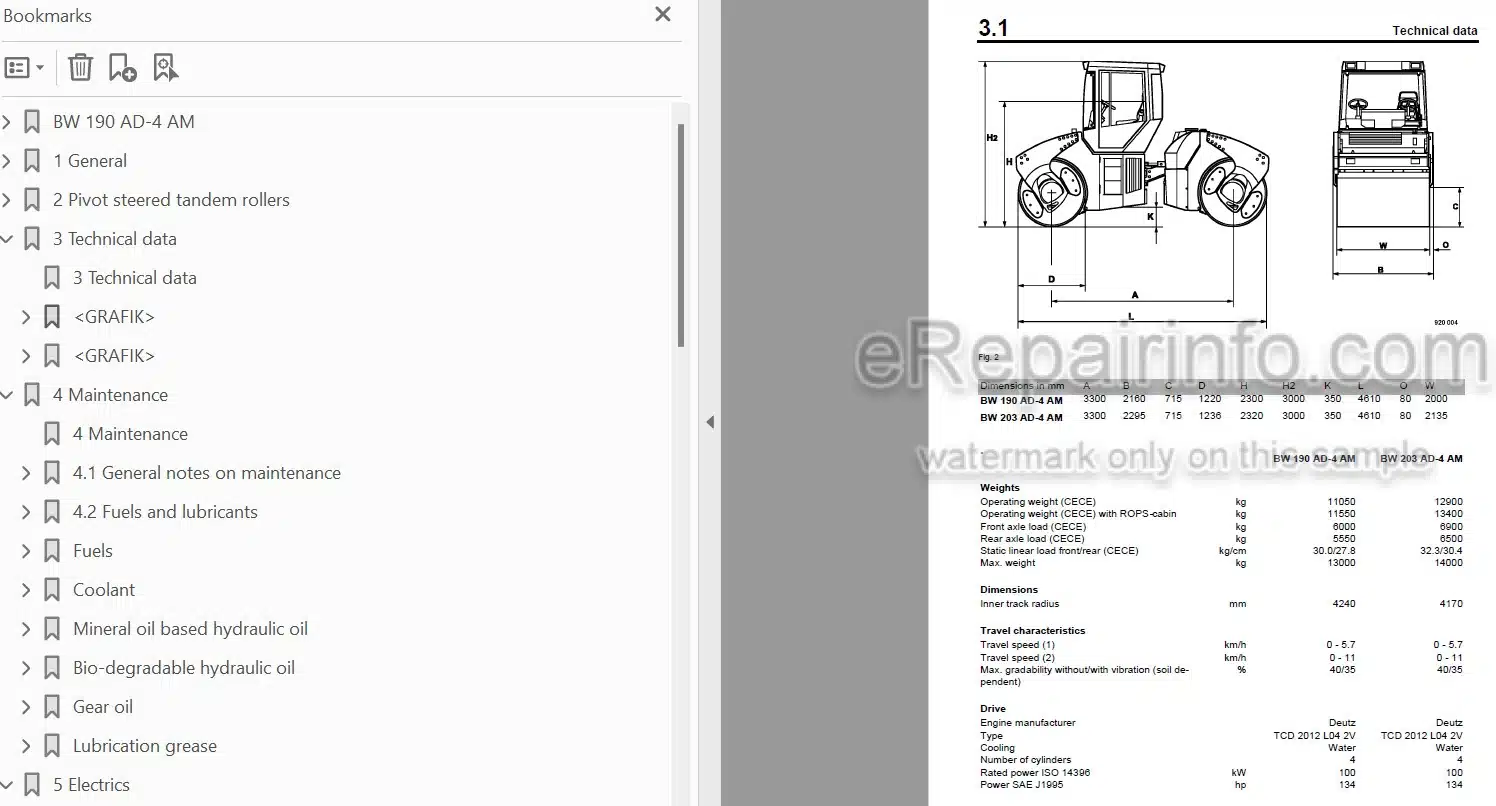

BW190AD-4AM

BW203AD-4AM

S/N 101 920 29 1001 > 101 920 29 1024

S/N 101 920 28 1001 > 101 920 28 1015

Contents

-GENERAL

Introduction

Safety Regulations

General Repair Instructions

Tightening Torques

-PIVOT STEERED TANDEM ROLLERS

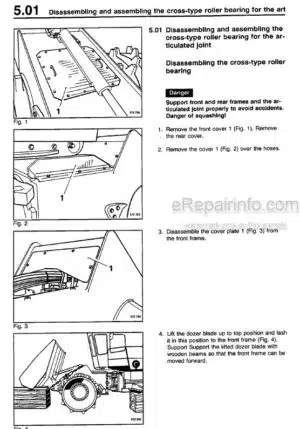

Heavy Vibratory Rollers, Articulated

-TECHNICAL DATA

Technical Data

-MAINTENANCE

General Notes On Maintenance

Fuels And Lubricants

Table Of Fuels And Lubricants

Running-In Instructions

Maintenance Table

-ELECTRICS

Understanding Circuit Diagrams

Designation Of Components In The Wiring Diagram

Terminal Designations In Wiring Diagram

Circuit Symbols In The Circuit Diagram

Inductive Proximity Switch, B63

Angle Sensor On Travel Control Lever, B39

Pressure Sensor In Water Tank (R14)

Level Sensor In Diesel Tank (R03)

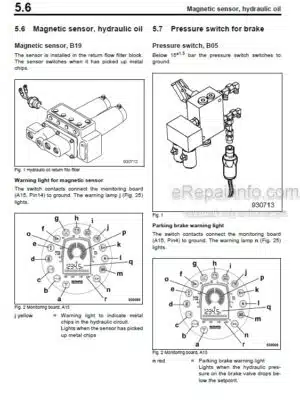

Hydraulic Oil Filter Differential Pressure Switch, B21

Float Switch In Water Tank, B33

Batteries

Battery Service, Check The Main Battery Switch

Main Battery Switch

Starting With Jump Wires

Potentiometer On Slewing Motor, B97

Acceleration Transducer

Speed Sensor, B15

Asphalt Temperature

Drivers Stand With Cabin

Fuses

MESX, B83

Electronic Control Units

Checking The Voltage Supply For The Control Unit

Diagnostics Concept

-ELECTRONIC MODULES

Electrics BAM

Electrics Module A03

Electrics Module A68

Electrics Module A71

Electric Module A72, Old Design

Electric Module A72

-ENGINE ELECTRICS

Emr3 System Components

Pin Assignment Of Engine Control Ed016 / Emr3

Rotary Speed Sensor For Camshaft

Rotary Speed Sensor For Crankshaft

Rail Pressure Sensor

Fuel Pressure Sensor

Fuel Control Unit

Injector

Oil Pressure Sensor

Sensor For Charge Air Temperature And Charge Air Pressure

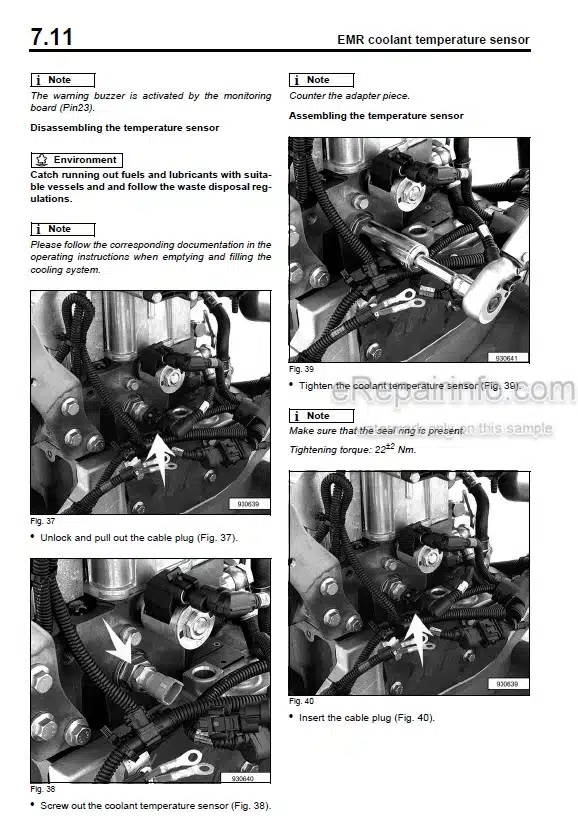

EMR Coolant Temperature Sensor

Glow Plugs

Sensor, Water In Fuel

Rotary Switch For Engine Speed

Air Filter Vacuum Switch

Float Switch In Coolant Container

Charge Control Light, Operating Hour Meter

System Faults Indicated By Flashing Code

Flashing Code

Diagnose With Serdia

EMR3 List Of Fault Codes

Diagnose With Can-Bus

Diagnostics Interface

Generator

Electric Starter

-ASPHALT MANAGER

Asphalt Manager

-HYDRAULICS

Hydraulic Circuit

Travel Pump, A4VG56 HW

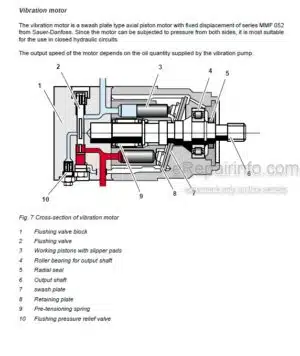

Vibration Pump, A10VG45 EZ

Overview Of Travel/Vibration Pump Connections

Travel Circuit

Vibration Circuit, Without Bam

Steering Circuit

Working Hydraulics

Fan Drive And Manifold Block With Thermostat

Check The Hydraulic Oil Level

Changing The Hydraulic Oil Filter

Changing Hydraulic Oil And Breather Filter

-TESTS AND ADJUSTMENTS

Special Tools, Tests And Adjustments

Checking The Rotation Speeds

Pressure Tests In The Travel Circuit

Checking / Adjusting The Neutral Positions Of The Travel Pump

Checking The Setting Of The High Pressure Relief Valves In The Travel Circuit

Pressure Tests In The Vibration Circuit

Check The Setting Of The High Pressure Relief Valves In The Vibration Circuit

Checking / Adjusting The Vibrator Shaft Speeds

Check The Leakage Rate Of The Vibration Motor

Pressure Test In Steering Circuit

-TROUBLE SHOOTING

Trouble Shooting

Trouble Shooting Chart – Travel System

Trouble Shooting Chart – No Vibration

Trouble Shooting Chart Steering System

Troubleshooting Axial Piston Pumps

Engine Problems

-FLUSHING AND BLEEDING

Special Tools For Flushing

Flushing – General

Flushing Schematic For Front Drum Drive

Flushing The Front Drum Drive

Flushing Schematic For Rear Drum Drive System

Flushing The Rear Drum Drive

Flushing Schematic For Vibration Drive On Ad-Machines

Flushing The Vibration Circuit

Bleeding The Travel Circuit

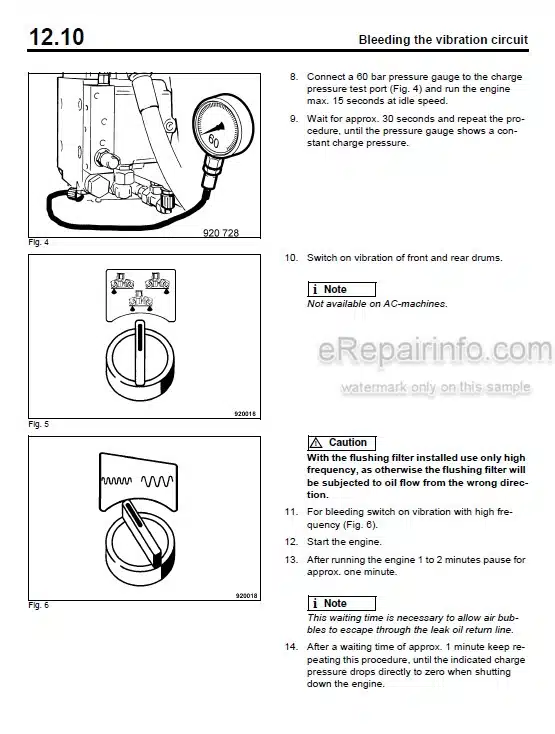

Bleeding The Vibration Circuit

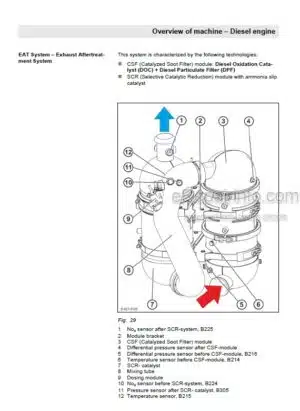

-ENGINE

Diesel Engine

Engine Description TCD 2012

Lubrication Oil Circuit TCD 2012/2013

Coolant Circuit TCD 2012 / 2013

Fuel System TCD 2012/2013

Deutz Common Rail (DCR) Injection System For TCD 2012 / 2013

Exhaust Gas Recirculation TCD 2012 / 2013

Adjusting The Valve Clearance

Adjusting The Control Piston Play

General Trouble Shooting Chart TCD 2012 / 2013

Check The Engine Oil Level

Change The Engine Oil

Change The Engine Oil Filter Cartridge

Change The Fuel Filter Cartridge

Checking, Cleaning The Water Separator

Change The Fuel Pre-Filter Cartridge

Check The Coolant Level

Checking The Anti-Freeze Concentration

Change The Coolant

Checking The V-Belt, Tighten, If Necessary Replace The V-Belt

Check, Clean, Change The Combustion Air Filter

Replacing The Crank Case Ventilation Valve

Check The Engine Mounts

Electronic Injector Test EMR

Special Tools, Deutz Engine (TCD 2012 2V)

-AIR CONDITIONING SYSTEM

Physical Basics

Refrigerant R134A

Compressor Oil / Refrigeration Oil

Working Principle Of The Air Conditioning System

Monitoring Devices

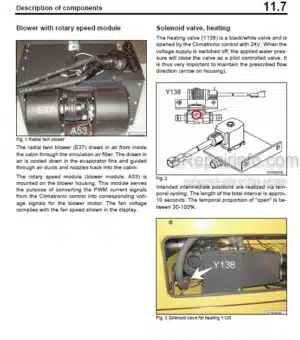

Description Of Components

Measuring The Compressor Oil Level

Checking The Magnetic Clutch

Inspection And Maintenance Work

Checking, Tensioning, Replacing The Refrigerant Compressor V-Belt

Service The Air Conditioning

Drying And Evacuation

Emptying In Case Of Repair

Leak Test

Filling Instructions

Trouble Shooting In Refrigerant Circuit, Basic Principles

Trouble Shooting, Refrigerant Circuit Diagram

Trouble Shooting Procedure

Steam Table For R134A

-DRUM

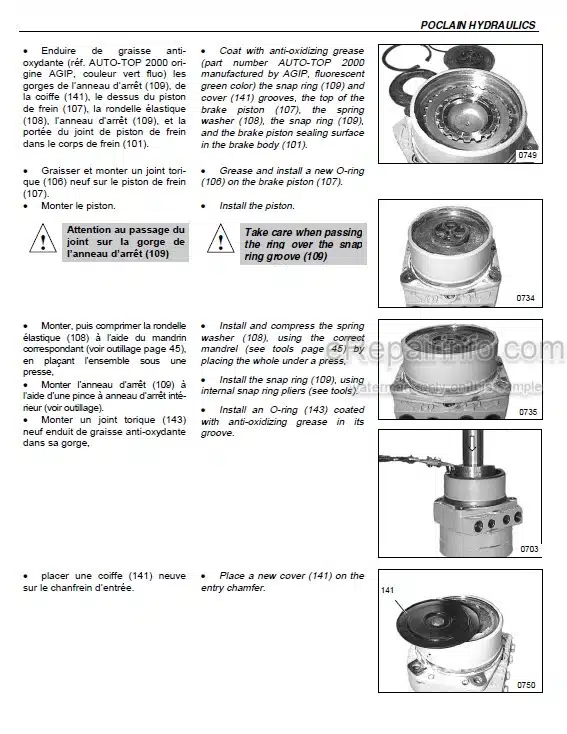

Repair Overview AD-Drum

Repair Overview AM-Drum

-CIRCUIT DIAGRAMS

Hydraulic Diagram

Wiring Diagram

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet