Factory Service Manual For Bomag Single Drum Roller. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: ENG

Pages: 1392

Number: 00840190 (december 2016)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Bomag Single Drum Roller

BW211D-40

BW211PD-40

BW212D-40

BW212PD-40

BW213D-40

BW213PD-40

S/N 101 583 48 1095>

S/N 861 583 55 1001>

S/N 861 583 56 1001>

S/N 101 582 42 1940>

S/N 101 582 43 2399>

S/N 101 582 44 1209>

S/N 101 582 47 1053>

S/N 101 582 48 1239>

S/N 101 582 49 1019>

Contents

-GENERAL

Introduction

Concerning Your Safety

Notes On Repair

Fuels And Lubricants

List Of Fuels And Lubricants

-OVERVIEW OF MACHINE

Diesel Engine

Travel / Vibration Pump

Drum

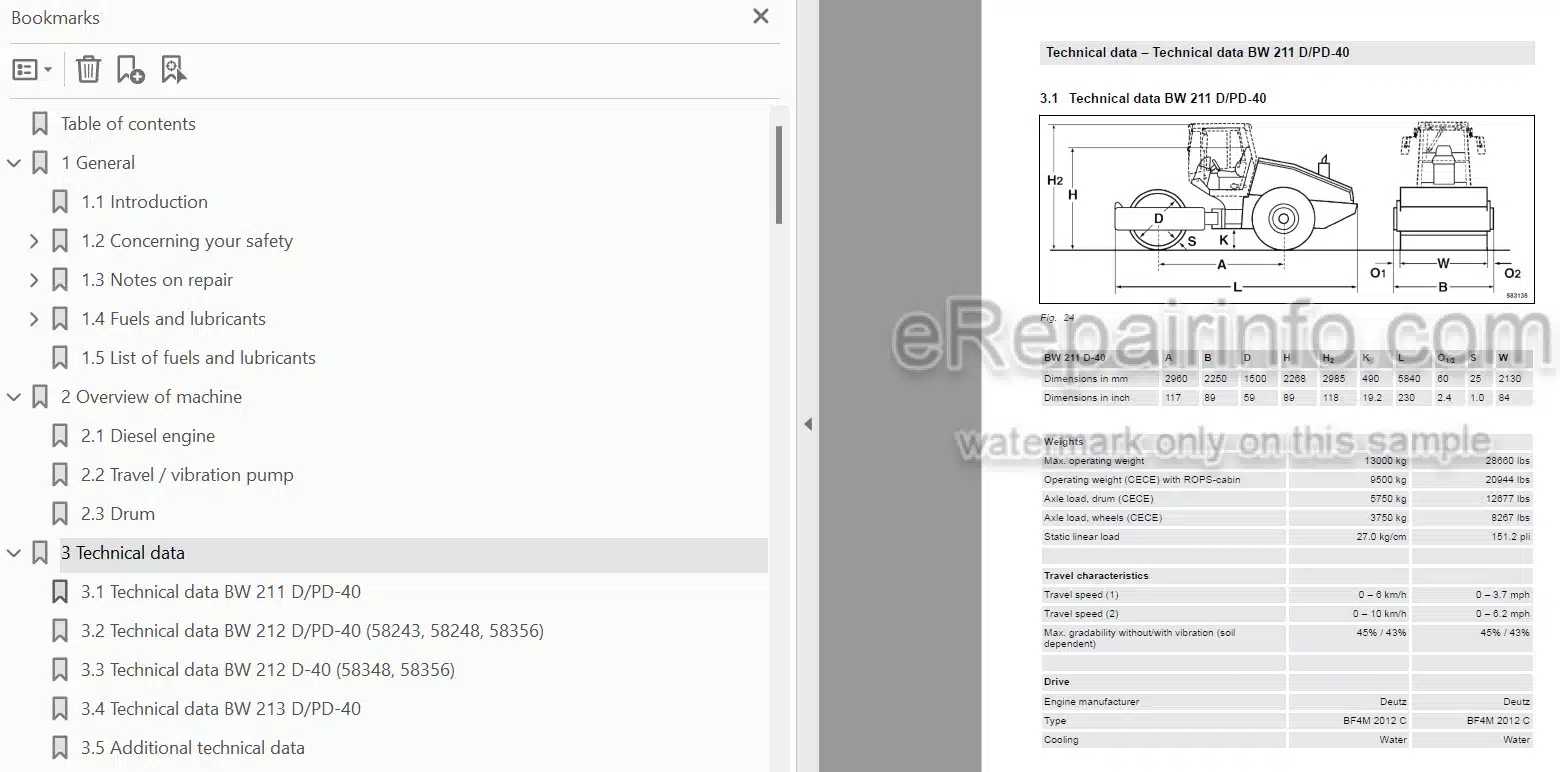

-TECHNICAL DATA

Technical Data BW 211 D/PD-40

Technical Data BW 212 D/PD-40 (58243, 58248, 58356)

Technical Data BW 212 D-40 (58348, 58356)

Technical Data BW 213 D/PD-40

Additional Technical Data

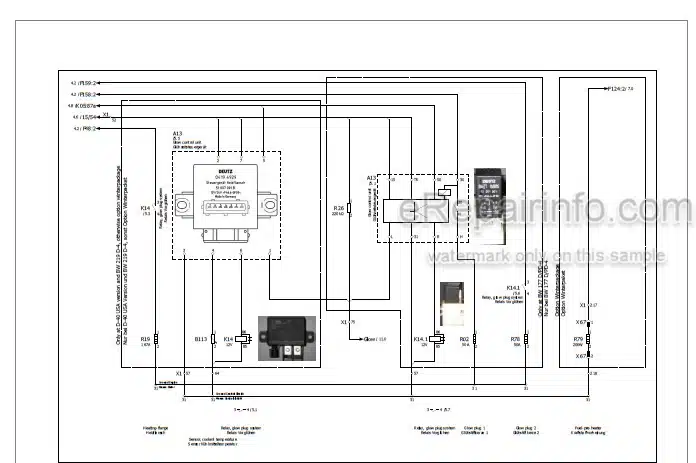

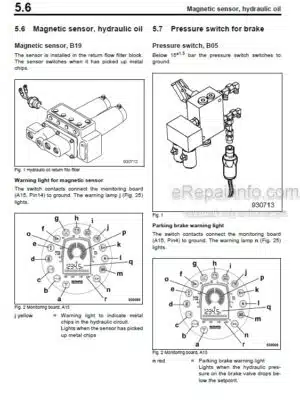

-ELECTRIC SYSTEMS

Table Of Fuels And Lubricants

Central Electrics

Fuse Assignment

Operator’s Stand

Wiring

Starting The Engine With Jump Leads

Proximity Switches On Travel Lever, B13 And B14

Differential Pressure Switch For Hydraulic Oil Filter, B21

Level Sensor In Diesel Tank, R03

Float Switch, Coolant Tank, B55

Air Filter Vacuum Switch, B03

Sensor For Water In Fuel, B124

Fuel Pre-Heating, R79

Oil Pressure Switch, B06

Coolant Temperature Switch, B30

Boost Fuel Solenoid Valve, Y01

Solenoid Actuator To Shut Down The Engine, Y13

Engine Solenoid Actuator, Y120

Charge Control Light, Engine Tachometer

Heating Flange On Engine, R19

Messx, A83

Acceleration Transducer, B62

Control Unit For Air Conditioning, A108

Module For Seat Contact Monitoring, A68

Vibration Module, K04

Speedometer Module, A05

Telemecanique Switch

Deutsch Plug, Series DT And DTM

Magnetic Coil Plug

Inspection And Maintenance Work

-DIESEL ENGINE

Diesel Engine, General

Service Side

Starter Side

Lubrication Oil Circuit

Coolant Circuit

Replacing The Thermostat

Fuel Supply

Injection System

Injection Pump Replacement During Service

Injection Valve Replacement During Service

Checking / Repairing Injection Valves

Checking The Compression

Inspection And Maintenance Work

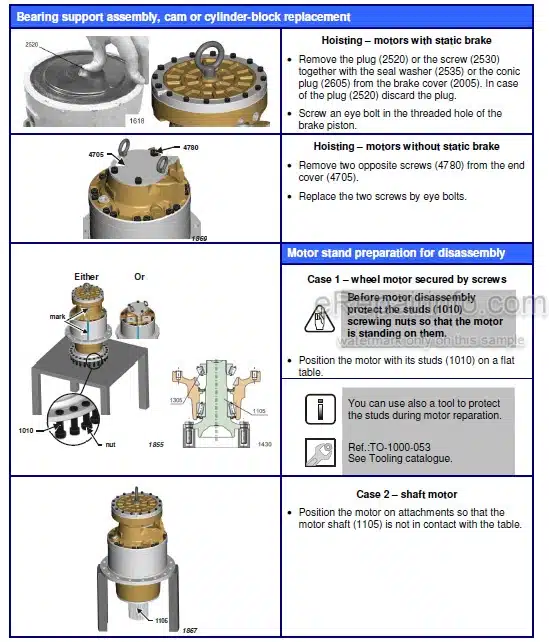

-HYDRAULIC SYSTEM

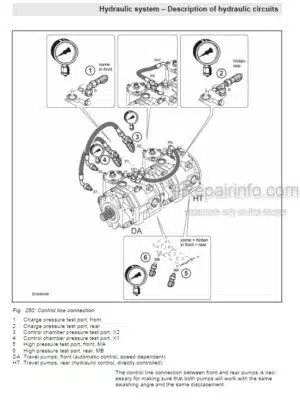

Overview Of Travel/Vibration Pump Connections

Open And Closed Hydraulic Circuit

Hydraulic Units

Charge Circuit

Travel Circuit

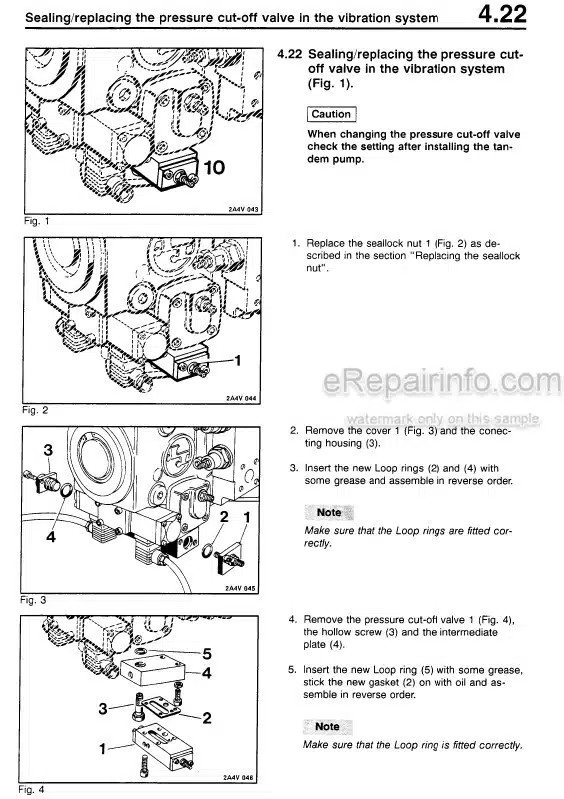

Vibration Circuit

Steering Circuit

Tests And Adjustments

Flushing And Bleeding

Inspection And Maintenance Work

-AIR CONDITIONING

Overview

Physical Principles

Refrigerant R134A

Compressor Oil / Refrigeration Oil

Working Principle Of The Air Conditioning System

Monitoring Devices

Description Of Components

Compressor

Emptying In Case Of Repair

Drying And Evacuation

Filling Instructions

Steam Table For R134A

Inspection And Maintenance Work

-CABIN ASSEMBLY BEFORE INITIAL COMMISSIONING

Preparations

Cabin Assembly

Final Function Tests And Checks

-REPLACING THE CAB WINDOW PANES

Assembly Of Window Panes

Auxiliary Materials

Removing And Installing The Window Pane

-OSCILLATING ARTICULATED JOINT

Overview Oscillating Articulated Joint

Removing And Installing The Oscillating Articulated Joint

Dismantling The Oscillating Articulated Joint

Assembling The Oscillating Articulated Joint

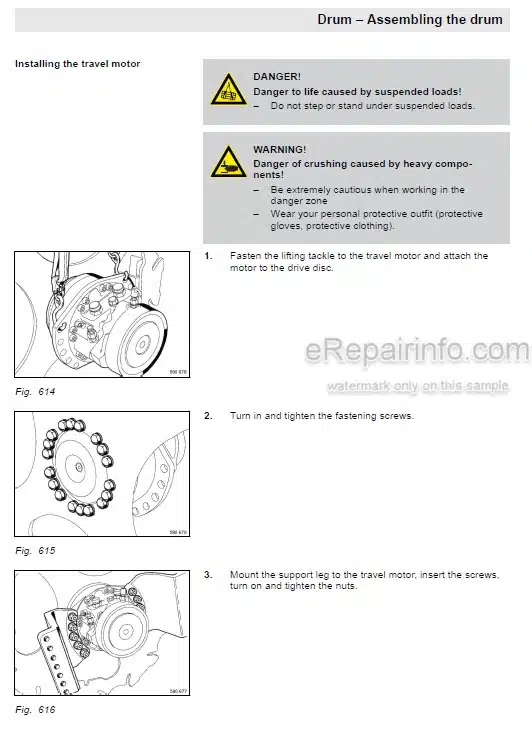

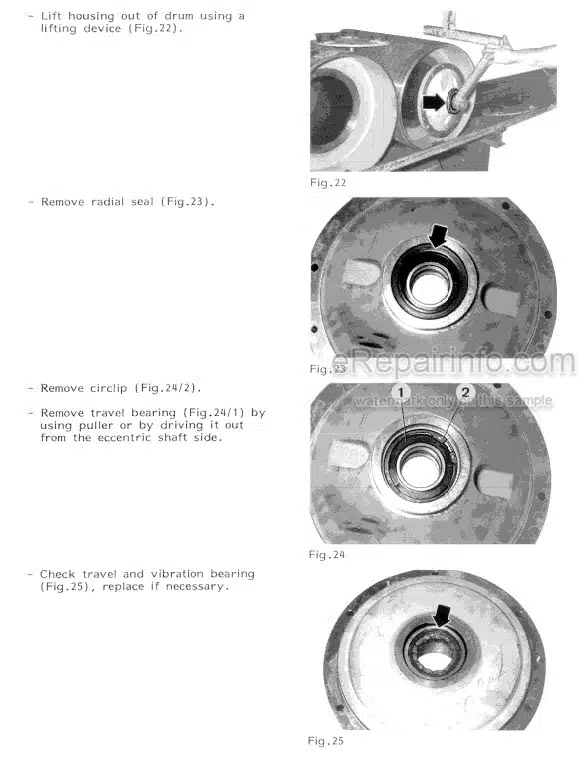

-DRUM

Assembly Of Padfoot Shell

Overview Drum

Removing And Installing The Drum

Dismantling The Drum

Dismantling And Assembling The Change-Over Weight

Assembling The Drum

Changing The Rubber Buffers, Adjusting The Pretension

Inspection And Maintenance Work

-DRIVE AXLE

Drive Axle

Checks Prior To Start Up

Every 250 Operating Hours

Every 1000 Operating Hours

As Required

-TROUBLESHOOTING

Preliminary Remarks

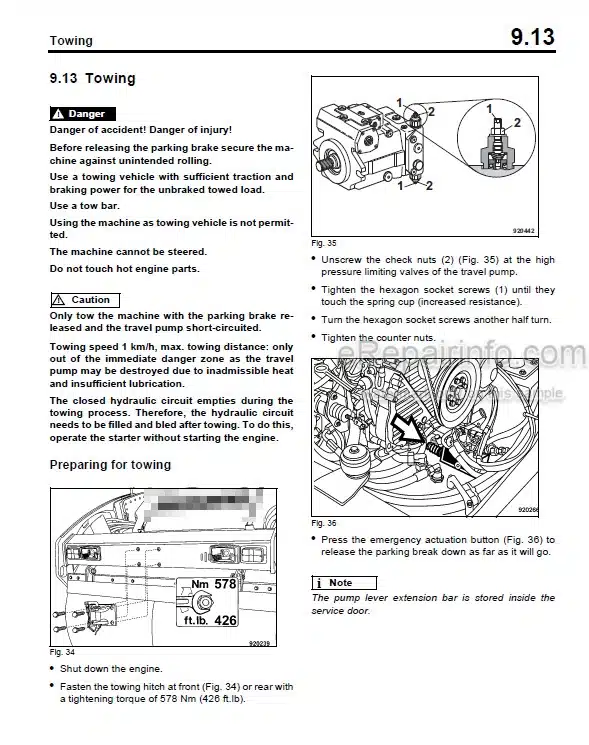

Emergency Procedures

Troubleshooting, Electrical Systems

Troubleshooting, Diesel Engine

Trouble Shooting, Hydraulics

Trouble Shooting, Air Conditioning System

-DISPOSAL

Final Shut-Down Of Machine

-SPECIAL TOOLS

Special Tools, Electrics

Special Tools, Hydraulic System

Special Tools For Oscillating Articulated Joint

Special Tools, Drum

INDEX

-APPENDIX

Supplier Documentation

Circuit Diagrams

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet