Factory Service Training For Bomag Single Drum Roller. The Bomag Service Training Manual Describes The Disassembly, Dismantling, Assembly, Installation And Repair Of Components And Assemblies. Manual Addresses The Professionally Qualified Personnel Or The After Sales Service Of Bomag, And Should Be Of Help And Assistance In Correct And Efficient Repair And Maintenance Work.

Format: PDF

Language: English

Pages: 468

Number: 00891968 (january 2013)

Bookmarks: Yes

Searchable: Yes

Wiring Diagram: Yes

Hydraulic Diagram: Yes

Model

Bomag Single Drum Roller

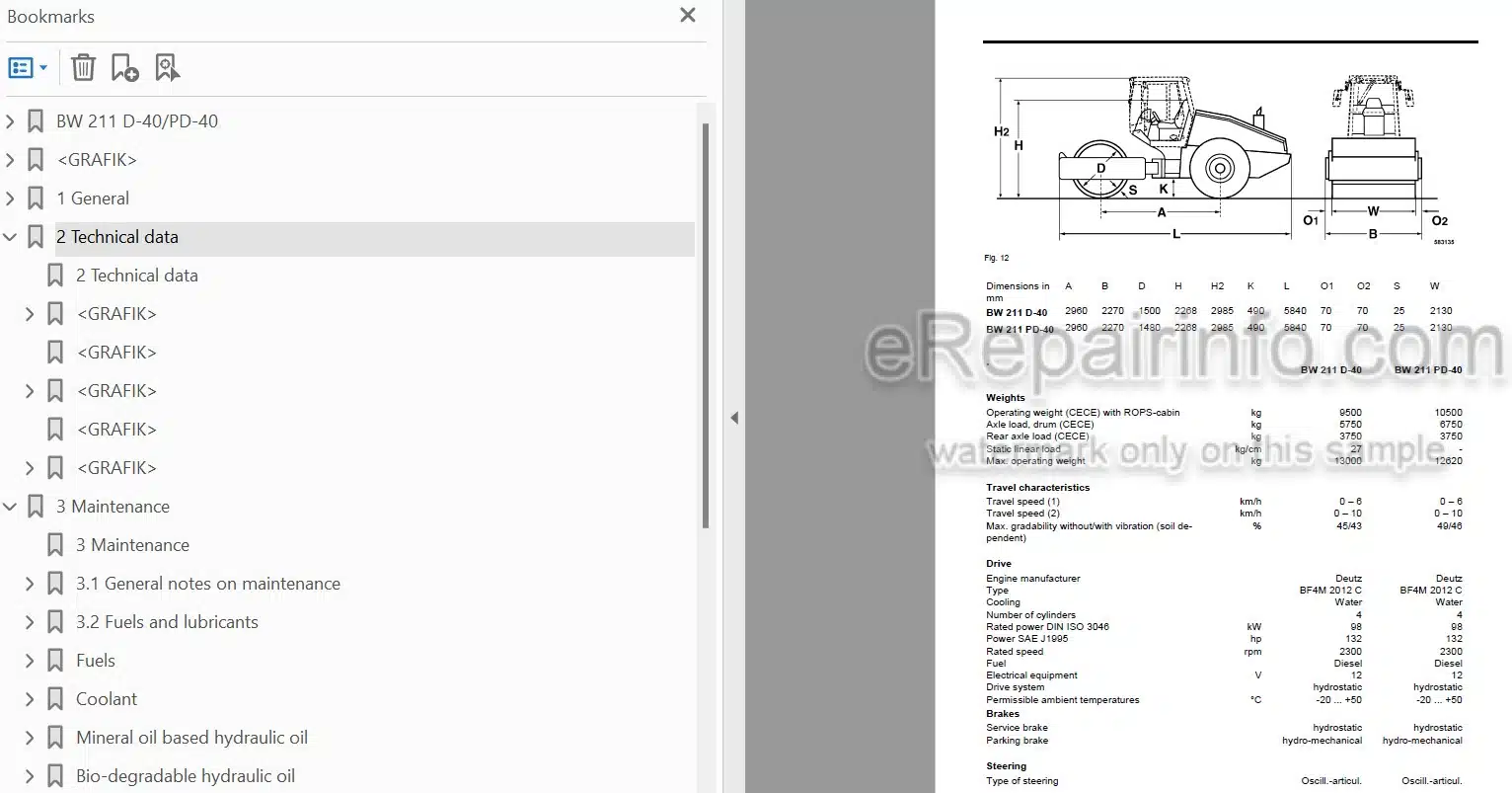

BW211D-40

BW212D-40

BW213D-40

BW211PD-40

BW212PD-40

BW213PD-40

S/N 101 582 42 1940>

S/N 101 582 47 1053>

S/N 861 583 55 ….

S/N 981 582 14 ….

S/N 101 582 43 2399>

S/N 101 583 49 ….

S/N 101 582 48 1239>

S/N 901 583 38 ….

S/N 101 583 50 ….

S/N 101 582 44 1209

S/N 101 582 49 1019>

Contents

-GENERAL

Introduction

Safety Regulations

General Repair Instructions

Tightening Torques

TECHNICAL DATA

-MAINTENANCE

General Notes On Maintenance

Fuels And Lubricants

Table Of Fuels And Lubricants

Running-In Instructions

Maintenance Table

-ELECTRICS

Acceleration Transducer

Proximity Switches

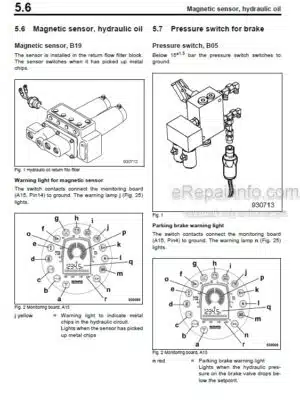

Differential Pressure Switch For Hydraulic Oil Filter, B21

Battery Service

Main Battery Fuse

Starting With Jump Wires

Replacing The Voltage Regulator

Overview Of Electric Components

Driver’s Stand

Cabin

Fuses

Checking The Voltage Supply For The Control Unit

Diagnostics Concept

-ELECTRONIC MODULES

BEM, Bomag EVIB-Meter

Electrics Module A68

Electric Module K04

Electric Module A108

-SPEEDOMETER MODULE

Speedometer Module

-HYDRAULICS

Hydraulic Circuit

Connection Overview

Travel Pump 075

Vibration Pump 42R 041

Axial Piston Swash Plate Principle / Pump

Troubleshooting Axial Piston Pumps

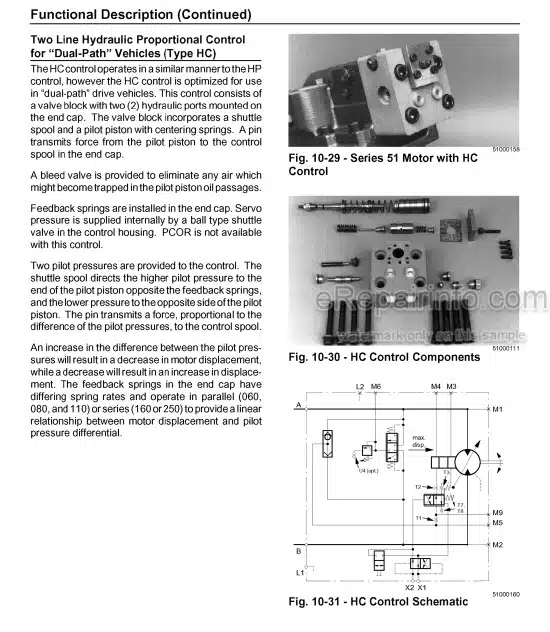

Travel Motor 51 C/D 110

Trouble Shooting, Variable Displacement Axial Piston Motor

Drum Drive Motor MSE 02

Vibration Motor A10Fm 45

Axial Piston Swash Plate Principle / Motor

External Gear Pumps

Travel Circuit

Stopping The Machine, Operating The Parking Brake

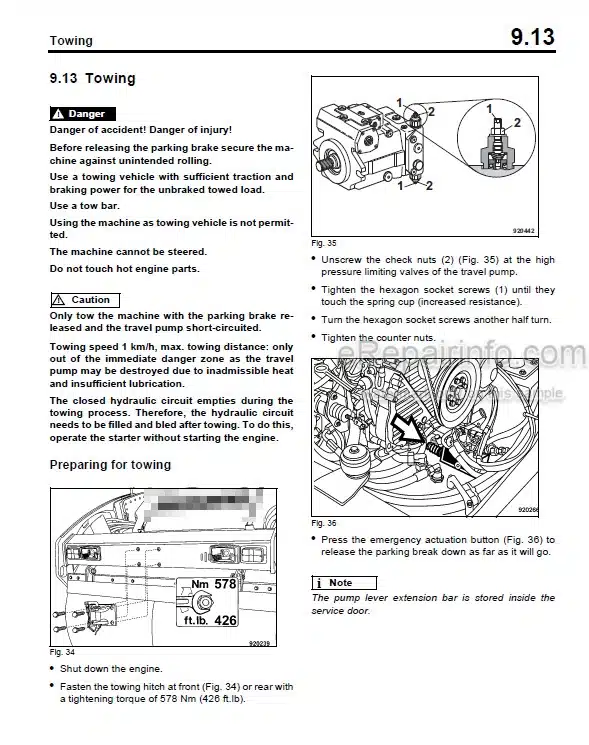

Towing In Case Of An Engine Failure

Adjust The Parking Brake

Vibration Circuit

Steering Circuit

Check The Hydraulic Oil Level

Changing Hydraulic Oil And Breather Filter

Changing The Hydraulic Oil Filter

-TESTS AND ADJUSTMENTS

Special Tools, Tests And Adjustments

Checking The Rotation Speeds

Checking / Adjusting The Neutral Positions Of The Travel Pump

Pressure Tests In The Travel Circuit

Checking / Adjusting The Vibrator Shaft Speeds

Pressure Measurements In The Vibration Circuit

Check The Leakage Rate Of The Vibration Motor

Pressure Test In Steering Circuit

-FLUSHING AND BLEEDING

Special Tools For Flushing

Flushing – General

Flushing Schematic Travel Circuit (Distribution Travel Pump)

Flushing The Travel Circuit (Travel Pump Distribution)

Flushing Schematic Travel Circuit (Distribution Axle Motor)

Flushing The Travel Circuit (Axle Motor Distribution)

Flushing Schematic For Vibration Drive

Flushing The Vibration Circuit

Bleeding The Travel Circuit

Bleeding The Vibration Circuit

-ENGINE

Diesel Engine, General

Service Side

Starter Side

Lubrication Oil Circuit

Oil Pressure Switch And Low Oil Pressure Circuitry

Check The Engine Oil Level

Changing Engine Oil And Oil Filter

Coolant Circuit

Coolant Temperature Switch

Disassembling And Assembling The Coolant Temperature Switch

Replacing The Thermostat

Checking The Thermostat In Disassembled State

Check The Coolant Level

Changing The Coolant

Checking The Anti-Freeze Concentration

Clean The Cooling Fins On Engine And Hydraulic Oil Cooler

Three-Phase Generator

Fuel Supply

Injection System

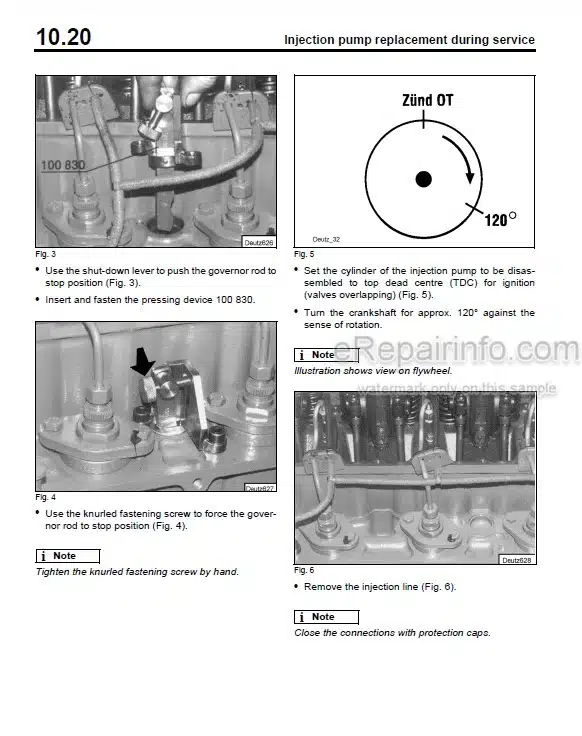

Injection Pump Replacement During Service

Injection Valve Replacement During Service

Checking / Repairing Injection Valves

Fuel Filter

Check, Clean The Water Separator

Change The Fuel Pre-Filter Cartridge

Checking The Compression

Check, Adjust The Valve Clearance

Boost Fuel Solenoid Valve

Engine Shut-Down Solenoid

Air Filter

Air Filter Maintenance

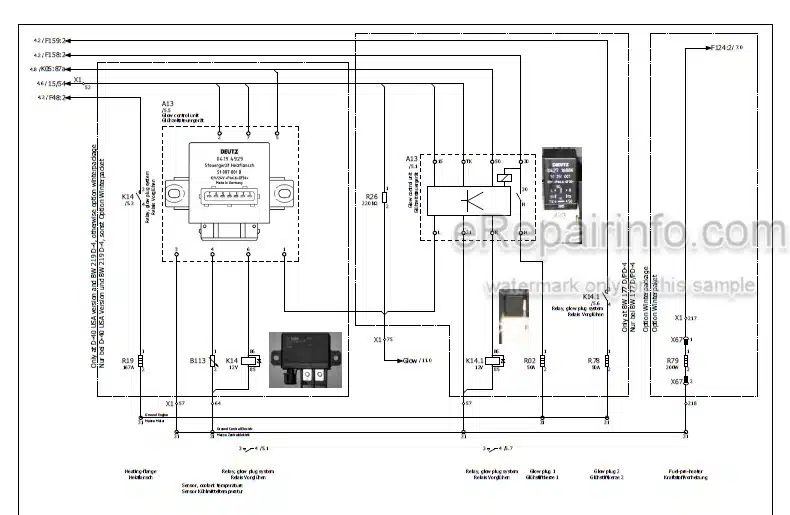

Heating Flange On Engine

Checking The Heating Flange Control

Electric Throttle Control

Engine Monitoring

Engine

Special Tools, Deutz Engine (BFM 2012)

-AIR CONDITIONING SYSTEM

Physical Basics

Refrigerant Rl34A

Compressor Oil / Refrigeration Oil

Working Principle Of The Air Conditioning System

Monitoring Devices

Description Of Components

Measuring The Compressor Oil Level

Checking The Magnetic Clutch

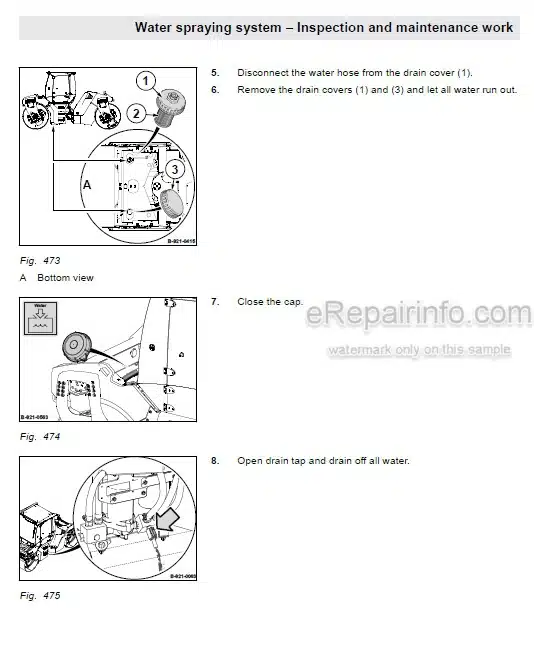

Inspection And Maintenance Work

Checking, Replacing The Refrigerant Compressor V-Belt

Air Conditioning Service (Old Design)

Service The Air Conditioning

Drying And Evacuation

Emptying In Case Of Repair

Leak Test

Filling Instructions

Trouble Shooting In Refrigerant Circuit, Basic Principles

Trouble Shooting, Refrigerant Circuit Diagram

Trouble Shooting Procedure

Steam Table For Rl34A

-DRUM

Repair Overview For Drum

-CIRCUIT DIAGRAMS

Hydraulic Diagram

Wiring Diagram

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet