Factory Operating Maintenance Instructions For Bomag Single Drum Roller. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: ENG

Pages: 166

Number: 00804461 (may 2007)

Bookmarks: Yes

Searchable: Yes

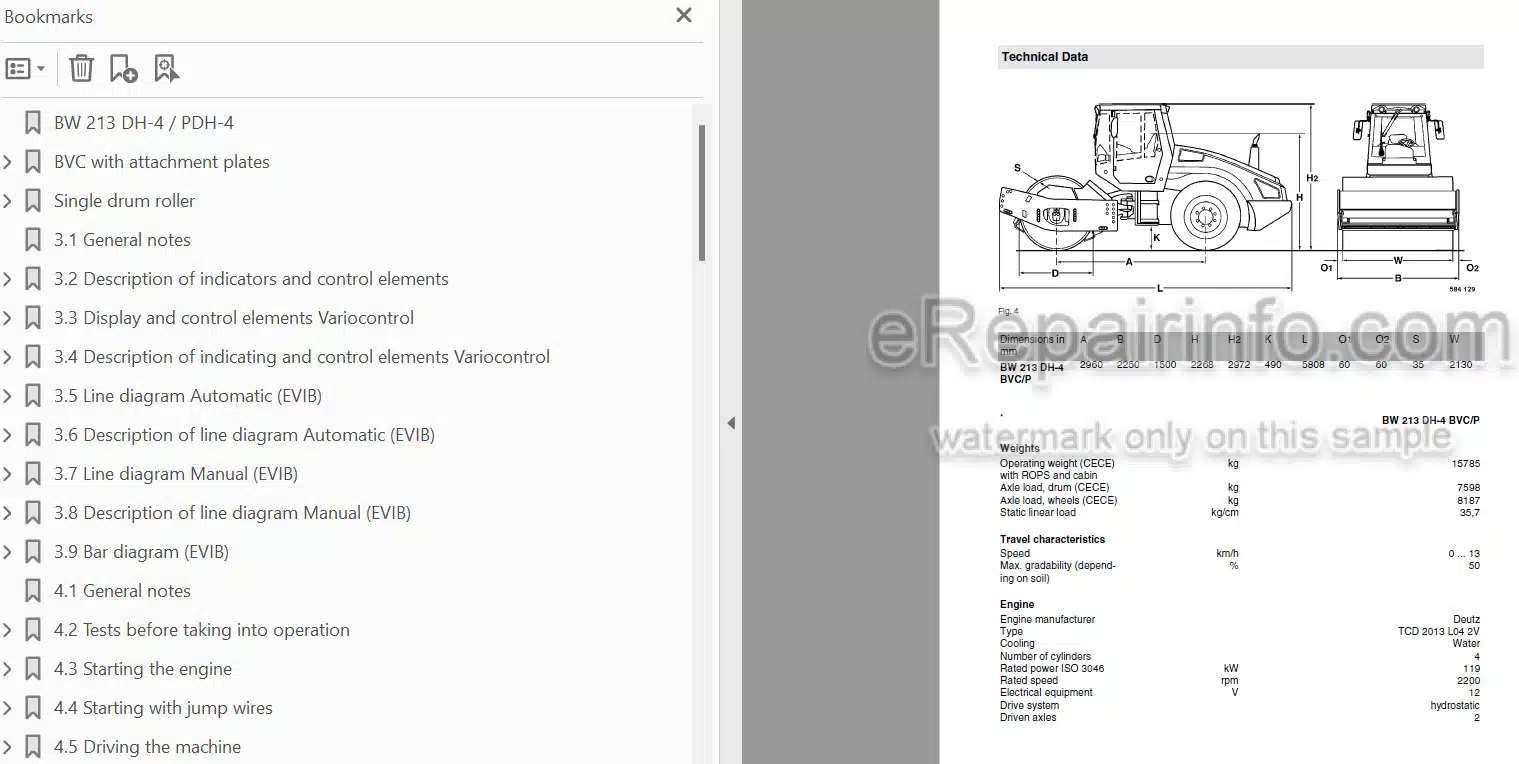

Model

Bomag Single Drum Roller BVC With Attachment Plates

BW213DH-4

BW213PDH-4

S/N 101 583 06 ….

Contents

TECHNICAL DATA

SAFETY REGULATIONS

-INDICATORS AND CONTROLS

General Notes

Description Of Indicators And Control Elements

Display And Control Elements Variocontrol

Description Of Indicating And Control Elements Variocontrol

Line Diagram Automatic (EVIB)

Description Of Line Diagram Automatic (EVIB)

Line Diagram Manual (EVIB)

Description Of Line Diagram Manual (EVIB)

Bar Diagram (EVIB)

-OPERATION

General Notes

Tests Before Taking Into Operation

Starting The Engine

Starting With Jump Wires

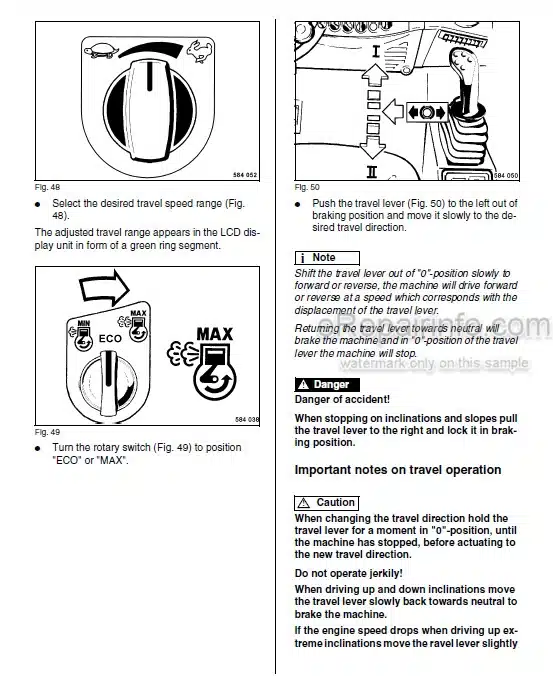

Driving The Machine

Switching The Vibration On And Off

Operating The Parking Brake, Stopping The Machine

Shutting The Engine Down

Changing The LCD-Display

Emergency Exit

Adjusting The Seat

Operating The Hood

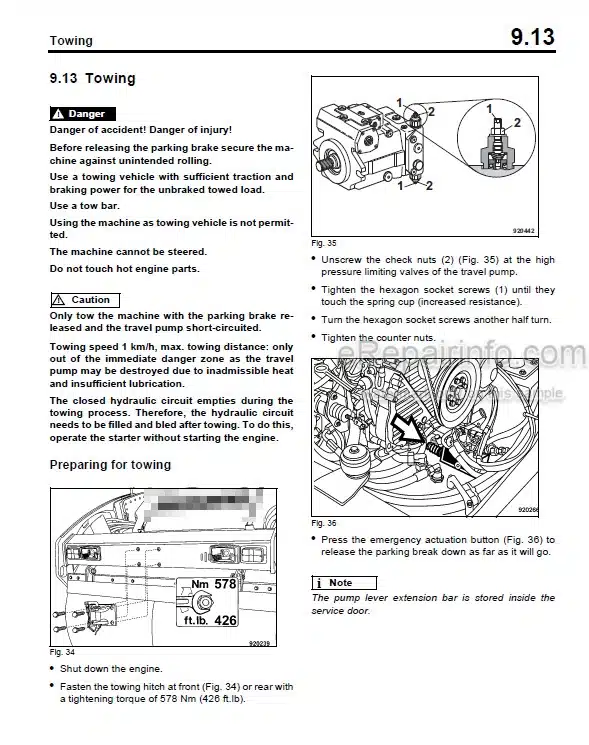

Towing In Case Of An Engine Failure

Transport

Tests Before Starting To Operate

Mounting The Attachment Plates

Taking The Attachment Plates Into Service

Detaching The Attachment Plates

Variocontrol, Selecting The Operating Mode

Measuring Pass With Variocontrol

Finishing Compaction Of A Track

Printing Measuring Data After Completing Compaction

Teaching Distance Pulses

Amplitude Limitation (BVC Only)

Changing The Paper Roll In The Measuring Value Printer

Changing The Printer Ribbon In The Measuring Value Printer

-MAINTENANCE

General Notes On Maintenance

Fuels And Lubricants

Table Of Fuels And Lubricants

Running-In Instructions

Maintenance Chart

Check The Engine Oil Level

Check, Clean The Water Separator

Check The Fuel Level

Check The Hydraulic Oil Level

Check The Coolant Level

Checking The Dust Separator On The Oil Bath Air Filter

Checking The Tire Pressure

Clean The Cooling Fins On Engine And Hydraulic Oil Cooler

Check The Oil Level In The Drive Axle

Checking The Oil Level In Left/Right Wheel Hubs

Check The Oil Level In The Axle Reduction Gear

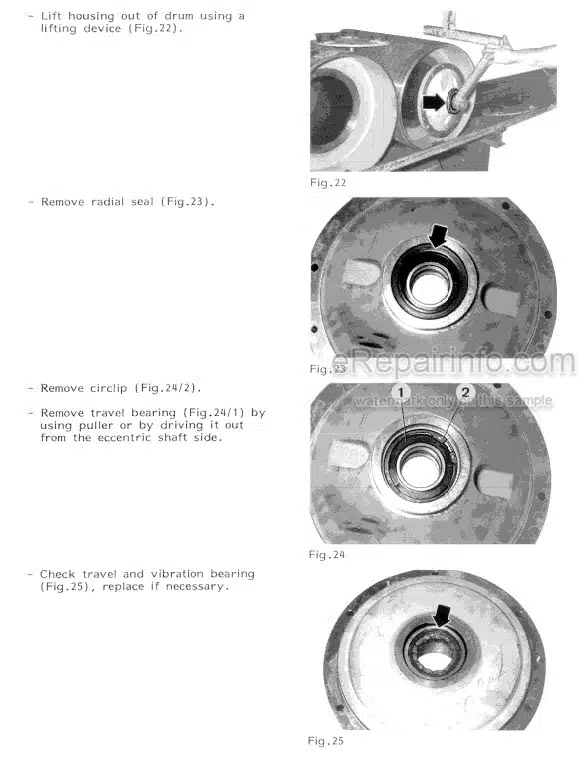

Check The Oil Level In The Drum Reduction Gear

Checking The Vario Exciter Oil Level

Changing Engine Oil And Oil Filter Cartridges

Change The Fuel Filter Cartridge

Draining The Sludge From The Fuel Tank

Service The Battery

Change The Fuel Pre-Filter Cartridge

Checking, Replacing The Refrigerant Compressor V-Belt

Service The Air Conditioning

Adjusting The Valve Clearance

Adjusting The Control Piston Play

Checking / Replacing The Ribbed V-Belt

Check The Engine Mounts

Change The Oil In The Drive Axle

Changing The Oil In The Wheel Hubs

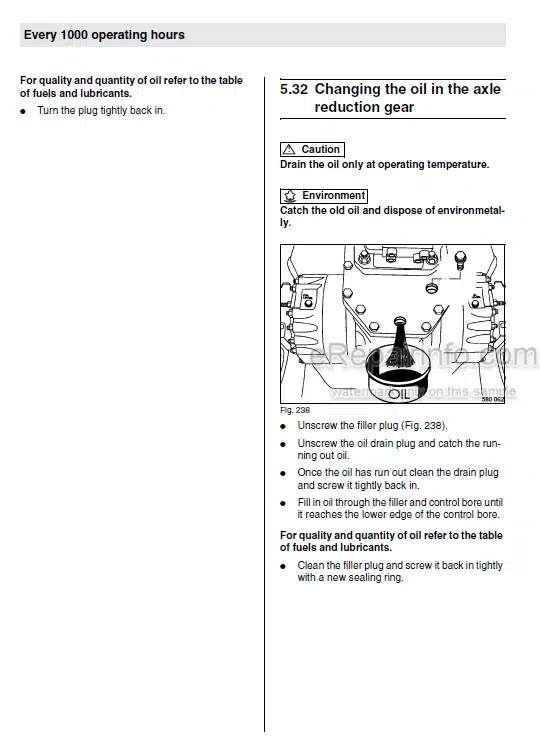

Changing The Oil In The Axle Reduction Gear

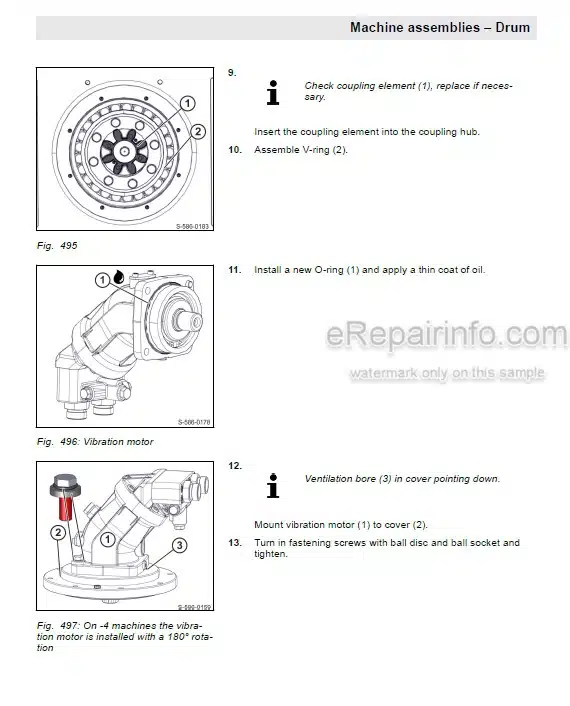

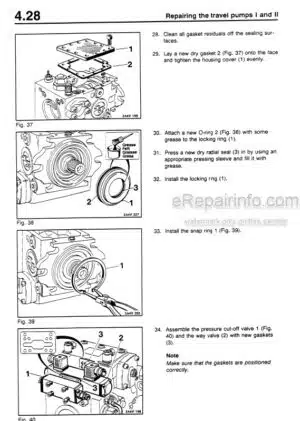

Change The Oil In The Drum Reduction Gear

Vario Exciter Oil Change

Change The Oil In The Exciter Shaft Housing Of The Attachment Plates

Tightening The Fastening Of The Axle To The Frame

Tightening The Wheel Nuts

Check The Rops

Cleaning The Oil Bath Air Filter

Changing Hydraulic Oil And Breather Filter

Changing The Hydraulic Oil Filter

Changing The Steering Oil Filter

Changing The Attachment Plate Oil Filter

Change The Coolant

Replacing The Crank Case Ventilation Valve

Electronic Injector Test EMR

Service The Combustion Air Filter

Adjust The Scrapers

Adjust The Parking Brake

Change The Tires

Change The Fresh Air Filter In The Cabin

Tightening Torques

Engine Conservation

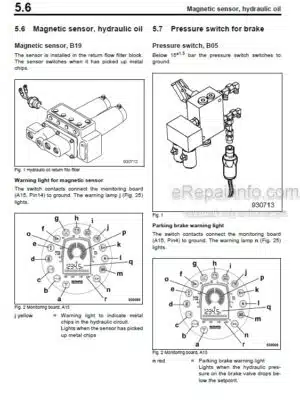

-TROUBLESHOOTING

General Notes

Reading Out Faults BVC/BTM05

Engine

-CAB ASSEMBLY BEFORE INITIAL START-UP

Preparations

Cabin Assembly

Final Function Tests And Checks

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet