Factory Service Manual For Bomag Single Drum Roller. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: ENG

Pages: 1484

Number: 00891677 (august 2012)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Bomag Single Drum Roller

BW 213 DH-4 BVC

BW 213 DH-4 BVC With Attachment Plate Variocontrol / Variocontrol+

S/N 101 583 16 1176 >

S/N 101 584 12 ….

S/N 101 583 06 1083 >

S/N 101 582 12 1024 >

S/N 101 582 13 1006 >

Contents

-GENERAL

Introduction

Safety Regulations

General Repair Instructions

Tightening Torques

-BOMAG SINGLE DRUM ROLLERS

Bomag Single Drum Rollers

-TECHNICAL DATA

Technical Data

-MAINTENANCE

General Notes On Maintenance

Fuels And Lubricants

Table Of Fuels And Lubricants

Running-In Instructions

Maintenance Table

-E-PLAN WIRING DIAGRAMS

Understanding Wiring Diagrams

Circuit Symbols In The Circuit Diagram

Identification Of Switch Blocks In The Wiring Diagram

Designation Of Components In The Wiring Diagram

Terminal Designations In Wiring Diagram

-ELECTRICS

Battery Ground And Analog Ground

Current And Voltage

Pulse Width Modulation (Pwm)

Resistance

Series / Parallel Connection

Ohm’s Law

Electrical Energy

Formula Diagram

Metrology

Diodes, Relays, Fuses

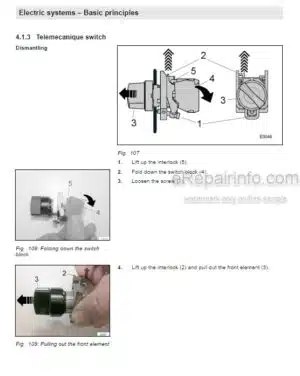

Telemecanique Switch

Plug Connectors

Magnetic Coil Plug

Deutsch Plug, Series DT And DTM

Inductive Proximity Switches

Plugs And Terminals In Spring Clamping Technology

Batteries

Battery Service

Starting With Jump Wires

Main Battery Switch

Overview Of Electric Components

Cabin

Fuses

Main Battery Fuse

Electronic Control Units

Checking The Voltage Supply For The Control Unit

Diagnostics Concept

-ELECTRONIC MODULES

Electrics SX

Electrics MESX

Electric Module A108

-ENGINE ELECTRICS

Emr3 System Components

Pin Assignment Of Engine Control EDC16 / EMR3

Rotary Speed Sensor For Camshaft

Crankshaft Speed Sensor

Rail Pressure Sensor

Fuel Pressure Sensor

Fuel Control Unit

Injector

Oil Pressure Sensor

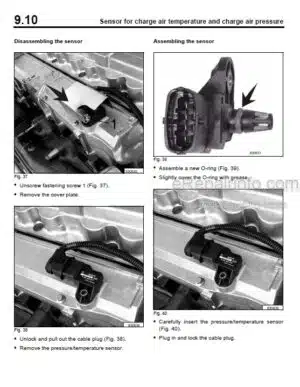

Sensor For Charge Air Temperature And Charge Air Pressure

EMR Coolant Temperature Sensor

Glow Plugs

Sensor, Water In Fuel

Fuel Pre-Heating

Rotary Switch For Engine Speed

Data Collector

Fault Display

Diagnose With Serdia

Diagnose With Can-Bus

Diagnostics Interface

Emr3 List Of Fault Codes

Generator

Electric Starter

-BOMAG, VARIOCONTROL

Variocontrol

Control Circuit And MESX

Acceleration Transducer

Potentiometer On The Slewing Motor, B62

Display And Control Elements Variocontrol

Description Of Indicating And Control Elements Variocontrol

BVC/BTM05 Settings Before Start-Up

Variocontrol, Selecting The Operating Mode

Measuring Pass With Variocontrol

Teaching Distance Pulses

Amplitude Limitation (BVC Only)

-HYDRAULICS

Hydraulic Circuit

Travel And Vibration Pump, H1

Troubleshooting Axial Piston Pumps

Travel Motor 51 C/D 110

Vibration Motor A2Fm56

Trouble Shooting, Variable Displacement Axial Piston Motor

External Gear Pumps

Slewing Motor

Travel Circuit

Stopping The Machine, Operating The Parking Brake

Towing In Case Of An Engine Failure

Adjust The Parking Brake

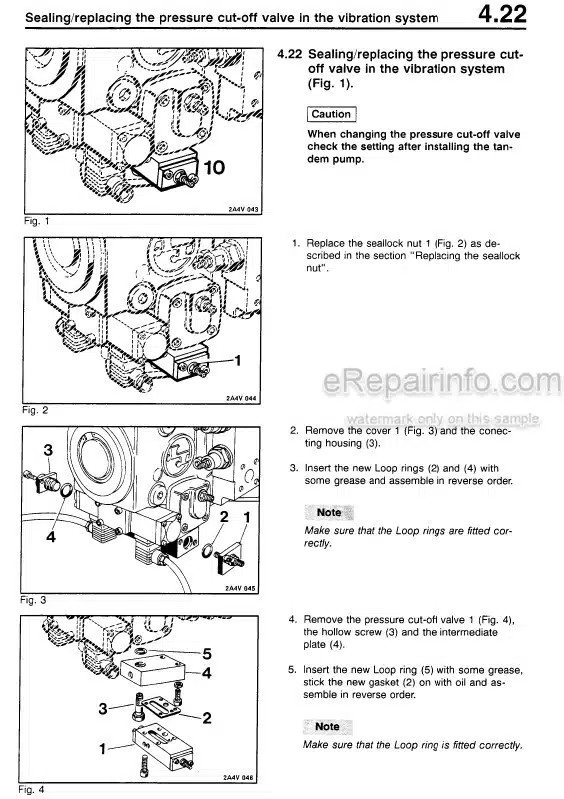

Vibration Circuit

Check The Hydraulic Oil Level

Changing Hydraulic Oil And Breather Filter

Replace Hydraulic Oil Filter

-ELECTRIC STEERING

Steering Circuit

Electric Steering Wheel

-HYDRAULIC STEERING (OPTIONAL)

Steering Circuit

-TESTS AND ADJUSTMENTS

Special Tools, Tests And Adjustments

Activate Service Mode

Driving Against The Closed Brake

Turn The Steering Against An End Stop.

Check The Leakage Rate Of The Vibration Motor

Pressure Test In Steering Circuit

-FLUSHING AND BLEEDING

Special Tools For Flushing

Flushing – General

Flushing Schematic Travel Circuit (Distribution Travel Pump)

Flushing The Travel Circuit (Travel Pump Distribution)

Flushing Schematic Travel Circuit (Distribution Axle Motor)

Flushing The Travel Circuit (Axle Motor Distribution)

Flushing Schematic For Vibration Drive

Flushing The Vibration Circuit

Bleeding The Travel Circuit

Bleeding The Vibration Circuit

-582 502 15 DUST PROTECTION / 582 502 16 GASKET

Assembling The Dust Protection

-ENGINE

Diesel Engine

Engine Description TCD 2013, 4 And 6 Cylinder

Lubrication Oil Circuit TCD 2012 / 2013

Coolant Circuit TCD 2012/2013

Fuel System TCD 2012/2013

Deutz Common Rail (DCR) Injection System For TCD 2012 / 2013

Exhaust Gas Recirculation TCD 2012 / 2013

Wastegate – Charge Pressure Controller On TCD-Engines

Engine Problems

Check The Engine Oil Level

Changing Engine Oil And Oil Filter Cartridges

Change The Fuel Pre-Filter Cartridge

Replace The Fuel Filter Cartridge

Check, Clean The Water Separator

Check The Coolant Level

Change The Coolant

Combustion Air Filter Service

Check The Dust Separator

Cleaning The Oil Bath Air Filter

Adjusting The Valve Clearance

Adjusting The Control Piston Play

Checking / Replacing The Ribbed V-Belt

Check The Engine Mounts

Replacing The Crank Case Ventilation Valve

Engine Conservation

Special Tools, Deutz Engine (TCD 2013 2V)

-AIR CONDITIONING SYSTEM

Physical Basics

Refrigerant R134A

Compressor Oil / Refrigeration Oil

Working Principle Of The Air Conditioning System

Monitoring Devices

Description Of Components

Measuring The Compressor Oil Level

Checking The Magnetic Clutch

Inspection And Maintenance Work

Checking, Replacing The Refrigerant Compressor V-Belt

Service The Air Conditioning

Drying And Evacuation

Emptying In Case Of Repair

Leak Test

Filling Instructions

Trouble Shooting In Refrigerant Circuit, Basic Principles

Trouble Shooting, Refrigerant Circuit Diagram

Trouble Shooting Procedure

Steam Table For Rl34A

-CABIN ASSEMBLY

Preparations

Cabin Assembly

Final Function Tests And Checks

-REPLACING THE CAB WINDOW PANES

Assembly Of Window Panes

Special Tools, Cabin Windows

Auxiliary Materials

Removing And Installing The Window Pane

-DRUM

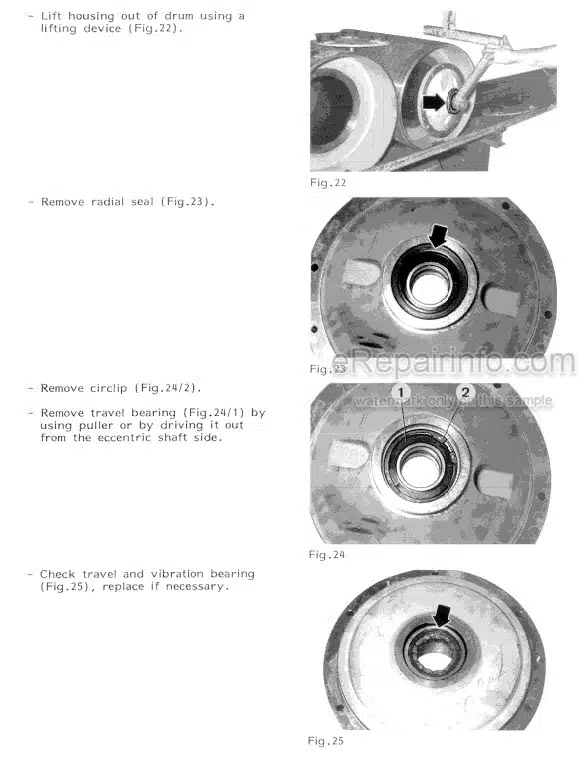

Repair Overview For Drum

Removing And Installing The Drum

Dismantling The Drum

Assembling The Vibrator Unit

Installing The Exciter Unit

Changing The Rubber Buffers And Adjusting The Pretension

Special Tools, Drum BW 213/226 DH-4 BVC And Variocontrol

-ARTICULATED JOINT, ELECTRIC STEERING

Special Tools

Repair Overview Oscillating Articulated Joint

Removing And Installing The Oscillating Articulated Joint

Dismantling The Oscillating Articulated Joint

Assembling The Oscillating Articulated Joint

-ARTICULATED JOINT, HYDRAULIC STEERING

Special Tools

Repair Overview Oscillating Articulated Joint

Removing And Installing The Oscillating Articulated Joint

Dismantling The Oscillating Articulated Joint

Assembling The Oscillating Articulated Joint

-SUPPLIERS DOCUMENTATION

Travel And Vibration Pump

Vibration Motor

Axle Drive Motor

Drum Reduction Gear

Steering Valve

Axle

-CIRCUIT DIAGRAMS

Hydraulic Diagram

Wiring Diagram

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet