Factory Operators Manual For Case Long Track Excavator. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: English

Pages: 140

Number: 880172

Model

Case Long Track Excavator

1088

Contents

IDENTIFICATION NUMBERS

-SAFETY/DECALS/HAND SIGNALS

Decals

Hand Signals

Safety

-SPECIFICATIONS

Air Filtration System

Approximate Overall Measurements For Transport

Approximate Overall Measurements

Buckets

Cab

Cabin Weight

Cooling System

Counterweight

Diesel Engine

Engine Lubrication System

Fuel System

Ground Bearing Pressure

Hydraulic Circuit

Operating Data

Operation

Safety Features

Travel

Turntable

Undercarriage

Weights

-INSTRUMENTS/CONTROLS

Air Cleaner Restriction Warning Lamp

Air Distributor

Ashtray

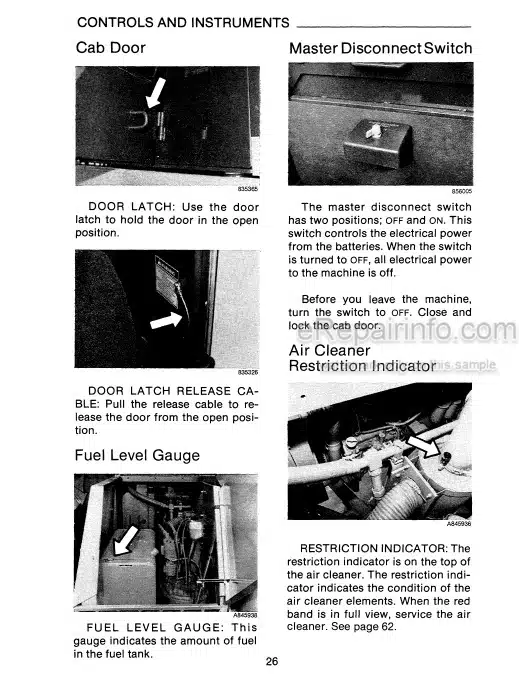

Battery Disconnect Master Switch

Battery Warning Lamp

Cab Lamp

Cigarette Lighter

Coat Hook

Control Cutout Armrest

Control Levers

Control Panel

Emergency Pump

Engine Oil Pressure Warning Lamp

Engine Stop Control

Engine Temperature Gauge

Ether Button

Fire Extinguisher

Fuel Gauge

Hand Throttle

Heating Control

Heating System

Horn Button

Hourmeter

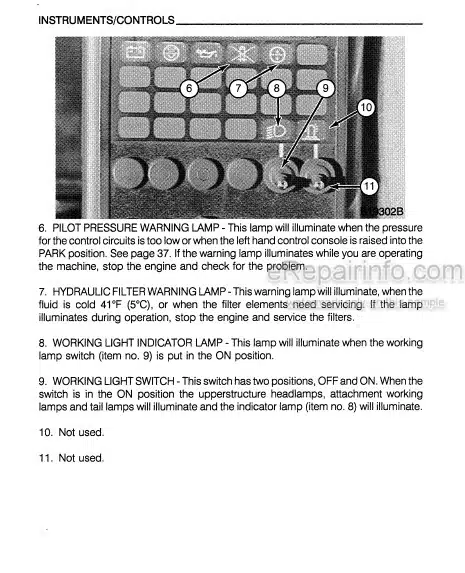

Hydraulic Filter Warning Lamp

Location For Cab Radio

Operating Controls

Operators Seat

Pedals

Pilot Pressure Warning Lamp

Power Line Connection

Recirculation Inlet

Starter Key Switch

Tool Compartment

Turntable Locking Lever

Ventilation Blower Switch

Warning Lamp Check Switch

Windshield Defrosting Air Distributor

Windshield Washer Reservoir

Windshield Washer Switch

Windshield Wiper Control

Working Light Indicator Lamp

Working Light Switch

-OPERATING INSTRUCTIONS

Before Using The Machine

Cab Door

Cold Temperature Operation

Connecting A Booster Batteries

Control Pattern C

Control Pattern D

Engine Operation

Engine Starting Using Ether Starting Fluid

Footboard And Access Handles

Fuel Tank Filler Pump

Fuel Tank

Hand And Foot Controls

Locking The Upperstructure

Machine Operation

Normal Starting Procedure

Parking The Machine

Power-Line Sockets

Preparing Machine For Transport

Roof Hatch

Run-In Period

Stopping The Engine

Towing

Turntable Leveler Operation

Windshield

-JOB SITE OPERATION

Backhoe Buckets

Operating Tips

Replacing A Backhoe Bucket

Replacing A Sidecutter On A Backhoe Bucket

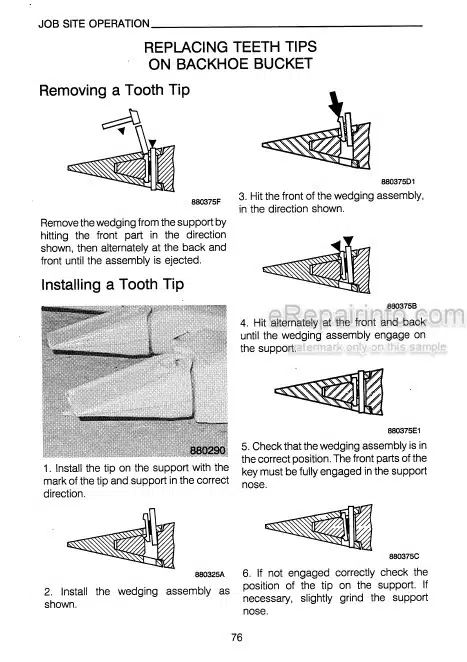

Replacing Teeth Tips On Backhoe Bucket

-TRACKS

Adjusting Tension

Checking Tension

Cleaning

Track Shoes

-LUBRICATION/MAINTENANCE CHART

Hourmeter

Lubrication Maintenance Chart

-LUBRICATION/FILTERS/FLUIDS

Access Panels

Air Filter Installation

Air Filter Removal

Air Filter System

Air Filter

Bleeding And Repriming Fuel Circuit

Bleeding The Cooling System

Cleaning Primary Air Filter

Coolant Draining

Coolant Filling

Coolant Level

Coolant Solutions

Cooling System

Dust Ejector

Engine Covers

Engine Lubrication Oil Viscosity

Engine Lubrication

Engine Oil Change

Engine Oil Level

Engine Oil Type

Fuel Circuit,

Fuel Filter Replacement

Fuel System

Grease Fittings

Grease Fittings “Turntable Leveler”

Hydraulic Oil Change

Hydraulic Oil Level

Hydraulic System

Levels

Oil Change Swing Reduction Gear

Oil Change Travel Reduction Gear

Oil Level Swing Reduction Gear

Oil Level Travel Reduction Gear

Primary Air Filter Inspection

Replacing Engine Oil Filter

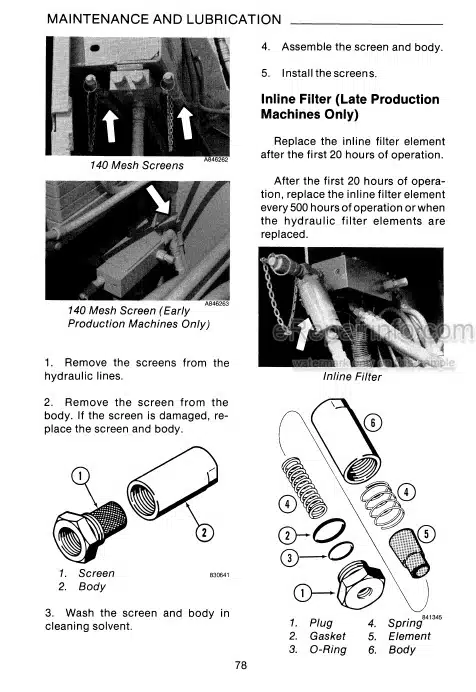

Replacing Filter On Anti Surge Valve

Reservoir Filters Replacement

Tank Breather Plug

Travel And Swing Reduction Gear

Water And Sediment Removal

-MAINTENANCE/ADJUSTMENTS

Checking Engine Fan Drive Belt

Coolant Radiator

Fire-Extinguisher

Hydraulic Cylinder Leakage Check

Hydraulic Reservoir Shutoff Valve

Releasing Pressure In The Hydraulic Circuit

Starting Fluid Container

Turntable Leveler Cylinders

-ELECTRICAL SYSTEM

Adjusting Upper Structure Headlamp’s

Alternator

Batteries

Battery Shutoff

Electrical Specifications

Electrolyte Level Check

Fuses

Lamps

Replacing A Battery

Replacing A Bulb

Starter

Temperature Sender Unit

STORAGE

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet