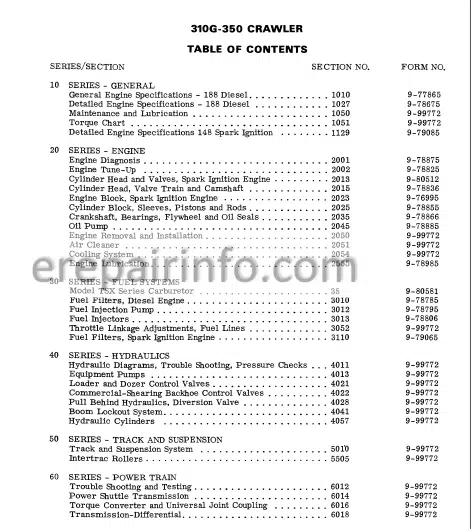

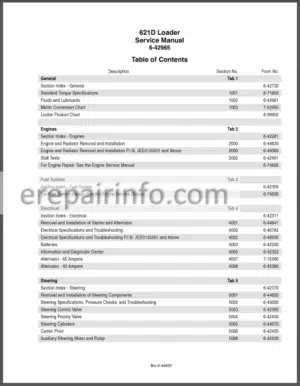

Factory Service Repair Manual For Case 310G 350 Crawler. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Bookmarks: Yes

Number: 974

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Case 310G, 350

Contents

- -GENERAL

General Engine Specifications – 188 Diesel

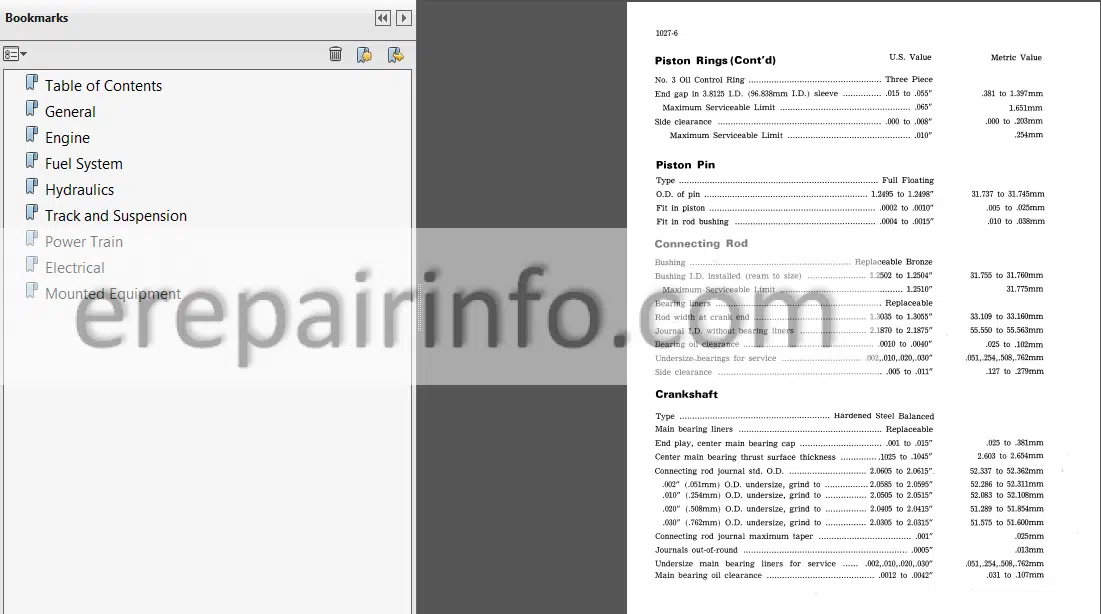

–Detailed Engine Specifications – 188 Diesel

Run-In Instructions

Detailed Engine Specifications

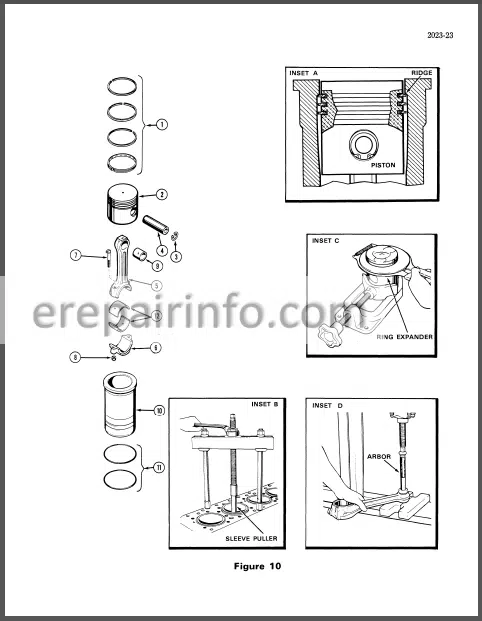

Cylinder Sleeves

Piston

Piston Rings

Piston Pin

Connecting Rod

Crankshaft

Camshaft

Valve Push Rod Lifters

Gear Train

Pil Pump

Cylinder Head

Intake Valve

Exhaust Valve

Intake Valve Guides

Exhaust Valve Guides

Valve Spring

Rocker Arm Assembly

Special Torques

General Torque Specification Table

Maintenance and Lubrication

Torque Chart

Detailed Engine Specifications 148 Spark Ignition - -ENGINE

Engine Diagnosis

Engine Tune-Up

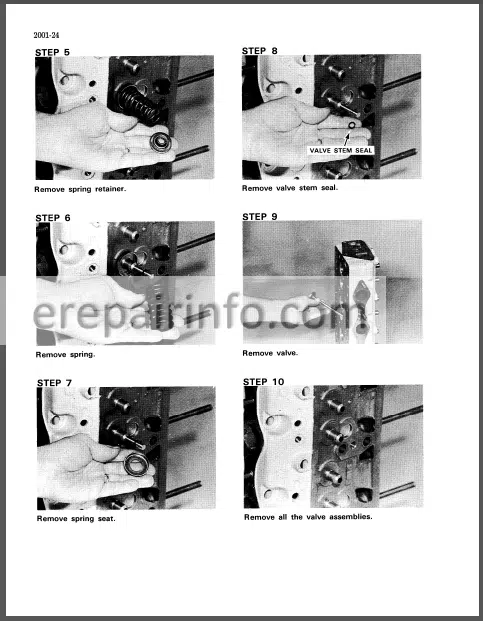

–Cylinder Head and Valves, Spark Ignition Engine

Specifications

Special Torques

Checking Compression Pressure

Cylinder Head and Components (148 and 159), (188 and 201)

Rocker Arm Assembly,(148 and 159),(188 and 201)

Cylinder Head Assembly,(148 and 159),(188 and 201)

Inspection of Valves, Guides, Head and Springs

Refacing Intake and Exhaust Valves

Grinding Intake and Exhaust Valve Seats

Locating Top Dead Center and Tappet Adjustments

–Cylinder Head, Valve Train and Camshaft

SPECIAL TOOLS

SPECIFICATIONS FOR TOOLS WHICH MUST BE MADE

CYLINDER HEAD

Cylinder Head Assembly

Cylinder Head Inspection

Cylinder Head Installation

Cylinder Head Removal

Cylinder Head Torquing – Cold or Initial Torque

Cylinder Head Torquing – Hot

Diagnosis of Various Valve Bluing Patterns

Expansion Plug Replacement

Locating Top Dead Center

Manifolds, Water Pump and Fuel Injectors Installation

Refacing Valves and Valve Seats

Rocker Arm Assembly

Valve Bluing

Valve Guide Replacement

Valve Inspection

Valve Seat Inspection

Valve Seat Replacement

Valve Tappet Adjustment – Cold Setting

Valve Tappet Adjustment – Hot Setting with Engine Stopped

CAMSHAFT

Backlash – Camshaft to Crankshaft

Backlash – Camshaft to Idler Gear

Backlash – Idler Gear to Injection Pump

Bushing Replacement – Front

Bushing Replacement – Intermediate

Bushing Replacement – Rear

Camshaft – Assembly

Camshaft – Installation

Camshaft – Removal

Idler Gear – Inspection

Idler Gear – Installation

Valve Lifters – Inspection

Valve Lifters – Replacement

–Engine Block, Spark Ignition Engine

Camshaft, Bushings and Lifters

Crankshaft, Bearings, Liners and Oil Pump

Cylinder Sleeves – Deglazing

Cylinder Sleeves – Honing

Cylinder Sleeves – Inspection

Engine Lubrication

Flywheel, Oil Pan, Seal Retainer and Oil Filter

Locating Top Dead Center

Oil Pump

Pistons and Cylinder Sleeves – Inspection

Pistons, Rings, Sleeves and Connecting Rods – Assembly

Pistons, Rings, Sleeves and Connecting Rods – Disassembly, Inspection

Special Torques

Specifications

Timing Gear Cover, Gear and Water Pump

Thermostat and Fan Belt

–Cylinder Block, Sleeves, Pistons and Rods

SPECIAL TOOLS

CYLINDER BLOCK, SLEEVES, PISTONS AND RODS

Checking Connecting Rod Journals

Checking Ring Gap

Checking Sleeve Protrusion

Connecting Rod Bearing Replacement

Connecting Rod Bushing Replacement

Connecting Rod Inspection

Cylinder Sleeve Inspection

Piston Inspection

Piston Installation

Piston Removal

Sleeve Deglazing

Sleeve Installation

Sleeve Removal

–Crankshaft, Bearings, Flywheel and Oil Seals

Special Tools

Front Oil Seal Replacement

Rear Oil Seal Replacement

Crankshaft and Main Bearings

Removal

Main Bearing Cap Replacement

Crankshaft Inspection and Installation

Flywheel

–Oil Pump

SPECIAL TOOLS

OIL PUMP

Oil Pump Removal

Oil Pump Inspection

Oil Pump Installation

–Engine Removal and Installation

Removing Engine and Clutch Assembly

Installing Engine and Clutch Assembly

View of Engine Controls on Diesel Engine Models

View of Engine Controls on Gasoline Engine Models

Installing Hoses and Tubes on Crawler

–Air Cleaner

Air Cleaner

Description

Exploded Views

Dry Type Air Cleaner, Gasoline Engine

Dry Type Air Cleaner, Diesel Engine

Dry Type Air Cleaner

Operation

Service Instructions

Cleaning Filter Assembly

Oil Bath Air Cleaner

Description

General Service

Exploded View of Oil Bath Type Air Cleaner

Removal

Servicing Oil Cups

Servicing Body Assembly

Air Restriction Indicator

Operation

Trouble Shooting

Safety Filter

Air Cleaner Cap

Air Pre-Cleaner

General Description

Servicing

–Cooling System

Specifications

Trouble Shooting Chart

Checking a Cooling System that Overheats

Description

Circulation

Thermostat

Radiator and Radiator Cap

Fan

Water Pump

Anti-Freeze

Draining and Filling the Cooling System

Cleaning the Cooling System

Cleaning Period

Cleaning Procedure

Reverse Flushing

Cleaning Exterior of Radiator

Radiator

Removing Radiator

Repair and Installation

Anti-Sandblast Screen

Installation

Checking and Replacing the Thermostat

Thermostat Replacement (Gasoline Engine)

Thermostat Replacement (Diesel Engine)

Testing the Thermostat

Fans

Description

Replacement

Fan Belts

Adjustment

Replacement

Water Pump

Engine Lubrication - -FUEL SYSTEMS

Model TSX Series Carburetor

Fuel Filters, Diesel Engine

–Fuel Injection Pump

SPECIAL TOOLS

SPECIFICATIONS

SPECIAL TORQUES

GENERAL INFORMATION

FUEL PUMP REMOVAL

Pump Drive Shaft Removal

Pump Drive Shaft Installation

FUEL PUMP INSTALLATION

Checking Pump Gear Backlash

Replacing Pump Inlet Filter

ENGINE SPEED

Checking Engine Speed

ENGINE SPEED ADJUSTMENTS

No Load Governed Speed

Low Idle Speed Adjustment

–Fuel Injectors

General Information

Injector Adjustments

Injector Test Stand

Installing Injectors

Isolating Faulty Injectors

Nozzle Identification

Operating Principles

Removing Injectors

Servicing Injectors

Special Tools

Special Torques

Specifications

Testing Injectors

–Throttle Linkage Adjustments, Fuel Lines

Adjusting Governor and Throttle Linkage on Diesel Engine Crawlers

Low Idle Adjustment

High Idle Adjustment

Foot Pedal Stop Adjustment

Hand Throttle Adjustment

Friction Disc Adjustment

Adjustment Idle Speed and Throttle Linkage on Gasoline Engine Crawlers

Adjusting Governor Linkage

Foot Pedal Stop Adjustment

Hand Throttle Adjustment

Friction Disc Adjustment

Fuel Lines

Fuel Filters, Spark Ignition Engine - -HYDRAULICS

–Hydraulic Diagrams, Trouble Shooting, Pressure Checks

Specifications

Pump and Reservoir

Hydraulic Systems Diagrams

Loader Hydraulic System with Drott 4-In-l Bucket

Mechanical Angling Dozer

Power Angling Dozer

Power Tilt Dozer

Power Angle-Tilt Dozer (Case)

Power Angle-Tilt Dozer (Ormco)

Model 26 and 33 Backhoe Hydraulic System

Loader-Backhoe Supply and Return Circuits

Dozer-Backhoe Pump Supply and Return Circuits

Ripper Hydraulic System with Diversion Valve

3-Point Hitch Hydraulic System with Diversion Valve

Pull Behind Hydraulics with Diversion Valve

Flushing the Hydraulic System

Trouble Shooting

Identifying Causes of Pump Failure

Problem: Poor Operation of a Single Circuit Only

Problem: Poor Operation of All Circuits

Trouble Shooting Chart

Problem: Poor Loader or Dozer Performance

Problem: Poor Backhoe Performance

Problem: Failure of Pump, Valves, or Cylinders

Testing the Hydraulic System With a Flowmeter

Flowmeter Check Sheet

Testing Secondary Relief Valves With a Hand Pump

Pressure Specifications

Backhoe Control Valves

Loader Relief Valves

Dozer Relief Valves

Testing Relief Valves With a Pressure Gauge

Loader Main Relief Valve

Dozer Main Relief Valve

Adjusting Relief Valves

–Equipment Pumps

Exploded Views

Cessna Hydraulic Pump (350 After S/N 3046500 and

310G After S/N 3025561)

Hydreco Hydraulic Pump (350 Before S/N 3046501)

Commercial Shearing Hydraulic Pump (310G Before S/N 3025562)

Webster Hydraulic Pump (310G Before S/N 3025562)

Specifications

Operation

Cessna

Removal

Disassembly

Inspection

Assembly

Pump Coupling

Testing and Installing Pump

Hydreco

Removal

Disassembly

Inspection

Assembly

Pump Coupling

Testing and Installing Pump

Commercial Shearing

Removal

Disassembly by Subassembly

Assembly by Subassembly

Pump Coupling

Testing and Installing Pump

Webster

Removal

Disassembly

Inspection

Assembly

Pump Coupling

Testing and Installing Pump

–Loader and Dozer Control Valves

Trouble Shooting Chart

Specifications

VDP-22

VDP-12

Exploded Views of VDP-22 Control Valves

Exploded Views of VDP-12 Control Valves

Servicing

Removal

Main Relief Valve

Dual-Stage Main Relief Valve

VDP-22 Secondary Relief Valves

VDP-22 Check Valves

VDP-12 Secondary Relief Valves

VDP-12 Check Valves

Spools

Disassembly

Inspection

Assembly

Installation

Special Tools

Spool Gland Tool

Spring Compressor

Snap Ring Installing Tool

Operating Principles

Valve Circuits

Valve Spools

Valve Ports

Oil Flow Spools in Neutral

Actuating a Spool

Main Relief Valve

Dual Stage Main Relief Valve

Power Beyond

Float Detent Position

Secondary Relief Valves

Check Valves

–Commercial-Shearing Backhoe Control Valves

Specifications

Servicing

Exploded View

Removing Control Valve

Special Wrench

Regeneration Check Valve

Regeneration Spool

Valve Sections and Spools

Load Check Valves

Secondary Relief Valves

Crossover Relief Valves

Assembling Valve Sections

Operating Principles

General Descriptions

Regeneration

Actuating More Than One Cylinder

Main Relief Valve

Check Valve

High Pressure Secondary Relief Valves

Boom Down Secondary Relief Valves

Swing Circuit Relief Valves

Swinging the Boom

Stopping the Boom

–Pull Behind Hydraulics, Diversion Valve

Pull Behind Hydraulics

Exploded Views

Pull Behind Coupling Female

Pull Behind Coupling Male

Diversion Valve

–Boom Lockout System

Operation

Operation of Lockout Valve

D49932 Lockout Valve

D46850 Relief Valve

–Hydraulic Cylinders

Torque Specifications

Piston Rod Bolts and Nuts

Packing Glands

Hydraulic Fittings

Spanner Wrench Kit

Removing Cylinders

Procedure

Swing Cylinders

Dipper Extension Cylinders

Group I – Case Manufactured Cylinders without Cushion Device

Glands

Removal

Disassembly

Inspection

Assembly

Installation

Group – Backhoe Boom and Swing Cylinders with Cushion Device

Glands

Removal

Disassembly

Inspection

Assembly

Group III – Grapple Cylinder D39720

Removal

Disassembly

Inspection

Assembly

Installation

Group IV – Clam Bucket Cylinders

Removal

Disassembly

Inspection

Assembly

Installation

Installing Cylinders

Group V – Ormco Power-Angle-Tilt Dozer Cylinders

Removal

Disassembly

Inspection

Assembly - -TRACK AND SUSPENSION

–Track and Suspension System

Assembly of Track Plates and Links

Track Service and Maintenance

Specifications

Track Service Kits

Track Wear Gauge

Turning Pins and Bushings

Replacing Track Links

Sprockets

Rotating Track Rollers

Rebuilding Idlers and Rollers

Track Removal and Installation

Track Adjustments

Track Tension

Carrier Roller Alignment

Rear Track Roller Alignment

Idler Adjustments

Removal/lnstallation of Track Frame and Side Plate(Applies to Models 350 and 310G After S/N 3039619)

Removal/lnstallation of Track Frame and Side Plate (Applies to Model 310G Before S/N 3039620)

Removal/lnstallation of Track Frame and Suspension (Applies to 36” Gauge Models)

Face Seal Assembly

Idler

Replacing Idler Bracket Wear Plates

Track Rollers

Track Rollers – Standard and Heavy Duty

Track Rollers – Face Seal Type

Carrier Rollers

Sprockets

Track Adjusters

Recoil Spring Assembly

Rock Guards (Track Guides) (Models 350 and 310G After S/N 3039619)

Rock Guards (Track Guides (Model 310G Before S/N 3039620 and Models with 36″ Gauge)

–Intertrac Rollers

Specifications

Identification

Loctite

Special Tools

Removal/lnstallation of Rollers

Face Seal Assembly

Track Rollers

Disassembly

Inspection

Assembly - -POWER TRAIN

Trouble Shooting and Testing

–Power Shuttle Transmission

Specifications

Lubrication

Torque Converter Oil Drain Access Hole

Checking Oil Level

Drain and Refill

Description

Operation

Oil Flow – Power Shuttle in Neutral

Oil Flow – Power Shuttle in Forward

Oil Flow – Power Shuttle in Reverse

Servicing the Power Shuttle

Removal

Disassembly

Inspection

Assembly

Installation

Torque Converter and Universal Joint Coupling

–Transmission-Differential

Description and Operation

Removing Transmission-Differential

Differential and Brakes Disassembly

Removal From Housing

Disassembly of Differential

Transmission Disassembly

Removal of Shafts and Gears

Assembly

Assembly of Differential

Assembly of Transmission

Ring Gear Backlash

Assembling Brakes

Installing Cover Plate

Brake Adjustment

Shift Lever

Disassembly

Assembly

Brake Pedal and Steering Levers

Installing Transmission-Differential

–Clutch

Description

Specifications

Removal of Clutch, Clutch Shaft, and Flywheel

Disassembly of Clutch

Inspection

Servicing the Flywheel

Clutch Housing

Assembly of Clutch

Balancing the Clutch

Adjusting the Release Levers

Installation of Clutch, Clutch Shaft, and Clutch Pedal

Clutch Pedal (Free Play) Adjustments

Drive Shaft

–Final Drives

Final Drives

Disassembly

Assembly

Assembly of Final Drives Face Seals

Assembly

Servicing

Axle Shaft Replacement

Removal

Installation

–Power Takeoff

Power Takeoft (Late Production)

Removal

Disassembly

Assembly

Installation

Power Takeoff (Early Production)

Disassembling PTO – Belt Pulley Housing

Assembling PTO – Belt Pulley Housing - -ELECTRICAL

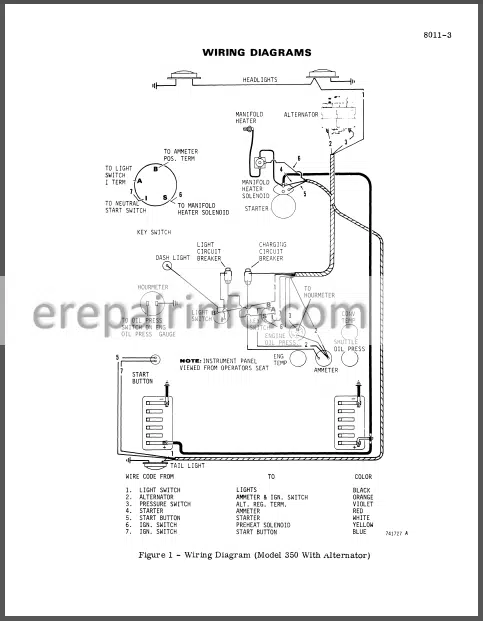

–Wiring Diagrams

Wiring Diagrams

350 With Alternator

350 With Generator

Late Production 310G (Diesel)

Late Production 310G (Gas)

Early Production 310G (Diesel)

Early Production 310G (Gas)

Exploded Views

350 With Alternator

350 With Generator and 310G Diesel

310G Gas

–Trouble Shooting

Specifications

Trouble Shooting Chart

Spark Ignition Problems (Gasoline Engine Only)

Trouble Shooting The alternator Charging Circuit

Trouble Shooting The Generator Charging Circuit

Trouble Shooting The Starting Circuit

Manifold Heater Circuit Check

Fuel Shutoff Solenoid

–Ignition System

Specifications

Troubleshooting The Ignition System

Distributor

Removal And Installation

Breaker Points And Condenser

Breaker Point Gap Adjustment

Breaker Point Alignment

Breaker Point Spring Tension

Ignition Timing – Static

Distributor Cap

Rotor

Distributor Spark Advance – Mechanical

Checking And Adjusting The Mechanical Advance

High Tension Spark Plug And Coil Wire

Servicing The Distributor

Exploded View Of Distributor

Ignition Coil

Spark Plugs

–Batteries

Specifications

Care and Maintenance

Nonspill Battery Caps

Battery Tests

Specific Gravity Check

Capacity (Load) Test

Individual Battery Cell Test

Soft Top Battery or Exposed Cell Connectors

Hard Top Battery

Battery Charging

Activating Dry Charged Batteries

Battery Charging Guide

Battery Check Sheet

–Starter and Starter Solenoid

SPECIFICATIONS

NO-LOAD TEST

SERVICING THE STARTER

Disassembly (Delco-Remy)

Disassembly (Prestolite)

Inspection

Armature Tests

Field Coil Tests

Assembly (Delco-Remy)

Assembly (Prestolite)

Pinion Clearance (Delco-Remy)

Pinion Position (Prestolite)

STARTER SOLENOID (DELCO-REMY)

Solenoid Tests

Exploded View of Solenoid

STARTER SOLENOID (PRESTOLITE)

Solenoid Test

–Alternator

Specifications

Alternator Charging Circuit

Charging System Tests

Test No 1 – Alternator Output

Test No 2 – Voltage Regulator Setting

Test No 3 – Oil Pressure Switch Test

Alternator Belt Adjustment

–Generator and Voltage Regulator

Specifications

Ambient Temperature

Generator and Voltage Regulator Tests

General Instructions

Cleaning Contact Points

Test Equipment

Generator Output Test

Voltage Regulator Tests

Servicing the Generator

Delco-Remy Generators

Prestolite Generator

Generator Belt Adjustment - -MOUNTED EQUIPMENT

–Loader

Exploded Views

Loader

Lift Cylinder Hydraulics

Tilt and Hydra-Level Cylinders Hydraulics

Ulrich Multi-Purpose Bucket

Drott 4-In-l Bucket

4-In-l Bucket

Logging Fork and Grapple Attachment

Logging Fork Pallet Fork & Grapple Attachment

4-In-l Bucket Cylinder Hydraulics

Drott Bucket Hydraulics with Diversion Valve

Single Lever Control

Dual Lever Control

Anti-Rollback

Description

Operation

Adjustment

Replacing Control Levers

Adjustment

Removing the Loader

Removal as a Complete Unit

Removing Loader Arms and Bucket

Servicing the Loader Frame and Bucket

Correcting Bucket Stops

Bucket Cutting Edge

Replacing Bucket Teeth

Replacing Leveling Gauge

Replacing 4-In-l Bucket Teeth

Replacing Clam Cutting Edges

Removing Front Cutting Edge

Removing Wear Plate

Installing Cutting Edge and Wear Plate

Replacing Cutting Edge on Blade Assembly

Removal

Installation

Replacing Grab Hook

Decal Replacement

–Dozers

Exploded Views

Mechanical Angling Dozer

Mechanical Angling Dozer Hydraulics

Power Angling Dozer

Pow’er Angling Dozer Hydraulics

Power Tilt Dozer

Power Tilt Dozer Hydraulics

Power Angle-Tilt Dozer S/N 3047966 and After

Power Angle-Tilt Dozer Hydraulics S/N 3047966 & After Power Angle-Tilt Dozer Before S/N 3047966

Power Angle-Tilt Dozer Hydraulics Before S/N 3047966 Power Angle-Tilt Dozer (Ormco)

Power Angle-Tilt Dozer Hydraulics (Ormco)

Replacing Control Levers

Removing the Moldboard

Mechanical Angling Dozer

Power Angling Dozer

Power Tilt Dozer

Power Angle Tilt Dozer

Removing ”C” Frame

Mechanical Angling Dozer

Pow’er Angling Dozer

Power Tilt Dozer

Power Angle-Tilt Dozer

Removing Leveling Beam & Trunnion Outer Race on Power Tilt Dozer

Removing Leveling Beam on Power Angle Tilt Dozers

Replacing Cutting Edge

Use of End Cap Shims..

Removing Inner Race of Lift Cylinder Trunnion

Installation of Moldboard Counterweight Bosses & Brackets

–Winch

Description

Power Train

Adapter

Master Control Unit

Serial Number Location

Lubrication

Draining the Winch

Filling the Winch

Fairleads

Specifications

Trouble Shooting Chart

Instructions for Installing Model 9 Winch and Master

Control Unit on 310G and 350 Crawler

Installing Adapter on Winch

Installing Master Control Unit on Dozer & Drawbar Models

Installing Master Control Unit on Loader Models

Bleeding Hydraulic System

Installing the Cable

Installing Fairlead Assembly (Early Production)

Installing Fairlead Assembly (Late Production)

Servicing

General Instructions

Brake Bands and Brake Cylinder

Clutch and Clutch Cylinder

Cable Drum and Brake Drum

Ring Gear and Pinion

Ring Gear and Pinion Adjustments

Master Control Unit

Adapter

Disassembly

Assembly

Ripper

Three-Point Hitch

Roll-Over Protection Structure

–Model 26 and 26C Backhoe

Exploded Views

Crawler to Backhoe Mounting Parts

Mounting Frame and Stabilizers

Control Tower and Standard Controls

Control Tower and Twin Lever Controls

Swing Tower, Boom, Dipper and Bucket

Extendable Dipper and Boom

Seat and Light

Dipper Light (Standard Dipper)

Dipper Light (Extendable Dipper)

Crawler to Backhoe Hydraulics

Swing and Stabilizer Hydraulics

Boom, Dipper and Bucket Hydraulics

Extendable Dipper Hydraulics

Boom Lockout

Removing the Backhoe from the Crawler

Installing the Backhoe on the Crawler

Disassembling the Backhoe

Bucket Removal

Dipper Removal

Boom Removal

Swing Tower, Boom, Dipper and Bucket Removal

Assembling the Backhoe

Swing Tower to Boom Installation

Swing Tower to Main Frame Installation

Dipper Installation

Bucket Installation

Dipper Extension

Inner Dipper Removal

Inner Dipper Installation

Extension Cylinder Removal

Extension Cylinder Installation

Replacing Wear Strips

Replacing Guide Blocks

Controls

Assembly Instructions

Standard Control Tower

Twin Lever Control Tower

Twin Lever Control Linkage

Servicing the Bushings

Lower Pivot Bushing

Self-Aligning Type

One Piece Type

–Model 32 Backhoe

Exploded Views

Mounting Parts and Main Frame

Bucket, Dipper, Boom and Swing Tower

Extendable Boom

Dipper Light

Control Tower and Seat

Crawler to Backhoe Hydraulics

Swing and Stabilizer Hydraulics

Boom, Dipper and Bucket Hydraulics

Removing the Backhoe from the Crawler

Installing the Backhoe on the Crawler

Disassembling the Backhoe

Bucket Removal

Dipper Removal

Boom Removal

Swing Tower, Boom, Dipper and Bucket Removal

Assembling the Backhoe

Swing Tower to Boom Installation

Swing Tower to Main Frame Installation

Dipper Installation

Bucket Installation

Extendable Boom

Disassembling the Boom

Assembling the Boom

Checking Slide Plate Clearance

Servicing the Bushings

Replacing the Bucket Cutting Edges and Teeth

Torque Specifications

–Model 33 Backhoe

EXPLODED VIEWS

Crawler to Backhoe Mounting Parts

Mounting Frame and Stabilizers

Swing Tower, Boom, Dipper and Bucket

Extendable Dipper and Boom

Dipper Light

Control Tower with Standard Controls

Control Tower with Twin Lever Controls

Backhoe Seat

Crawler to Backhoe Hydraulics

Swing and Stabilizer Hydraulics

Boom Dipper and Bucket Hydraulics

RE MOVING/ATTACHING THE BACKHOE

Uncoupling Backhoe from Crawler

Coupling Backhoe to Crawler

DISASSEMBLING THE BACKHOE

Bucket Removal

Dipper Removal

Boom Removal

Swing Tower, Boom, Dipper and Bucket Removal

ASSEMBLING THE BACKHOE

Swing Tower to Boom Installation

Swing Tower to Main Frame Installation

Boom Installation

Dipper Arm Installation

Bucket Installation

CONTROLS

Assembly Instructions

Standard Control Tower

Twin Lever Control Tower

Twin Lever Control

EXTENDABLE DIPPER MECHANICAL STOPS

SERVICING THE BUSHINGS

REPLACING THE BUCKET CUTTING EDGES AND TEETH

TORQUE SPECIFICATIONS

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet