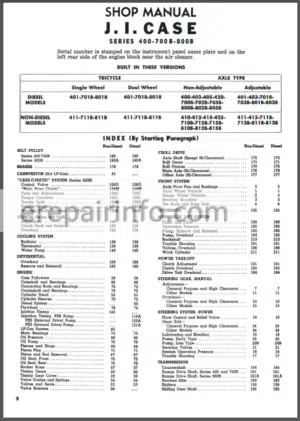

Factory Operators Manual For Case Excavator. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: English

Pages: 238

Number: 6-34450NA (june 2002)

Bookmarks: Yes

Model

Case Excavator

CX460

Contents

-TO THE OWNER

CX460 Excavator

Right, Left, Front And Rear Of The Machine

-IDENTIFICATION NUMBERS

Type, Serial Number And Year Of Manufacture

Machine Components

-SAFETY/DECALS/HAND SIGNALS

Safety Rules

Utility Safety

Personal Safety

Safety Area

Operator Precautions

Decals

Hand Signals

-INSTRUMENTS/ CONTROLS

Cab Door

Steps And Access Handles

Function Cancellation Lever And Safety Bar

Operator’S Compartment Controls

Location Of Controls And Associated Components

Right-Hand Control Arm

Left-Hand Control Arm

Systems Display And Control Panel

Anti-Theft Device

Arm And Upperstructure Swing Control

Left-Hand Control Lever

Boom And Bucket Control

Right-Hand Control Lever

Optional Control Pattern

Arm And Upperstructure Swing Left-Hand Control Lever

Optional Control Pattern

Boom And Bucket Right-Hand Control Lever

Travel Control Levers And Pedals

Automatic Temperature Control System

Operator’s Seat

Windshield

Lower Front Window

Rear Window And Emergency Exit

Fuel Tank

Rear View Mirrors

Side Doors

Engine Hood

Lower Panels

Windshield Washer Reservoir

Towing Holes

Cylinder Mounted Load Holding

Control Devices (Optional)

Tool Supply Valves (Optional)

-OPERATING INSTRUCTIONS

Before Operating The Machine

Machine Operation

Break-In Period

Anti-Vandal Guard

Starting The Engine

Bringing The Machine Up To Operating Temperature

Engine Operation

Operating The Machine In Cold Weather

Operating The Machine In Hot Weather

Stopping The Engine

Machine Travel

Lifting Loads With The Machine

Operating The Machine In Water

Operating The Machine On Sloping Ground

Operating The Bucket

Parking The Machine

Setting The Tracks In Transport Position

Setting The Tracks In Working Position

Self-Detaching Counterweight (Optional)

Removal

Installation

Auxiliary Hydraulic (Optional)

Transporting The Machine

-LUBRICATION

Fluids And Lubricants

Systemguard Lubrication Analysis Program

Hourmeter

Daily Inspection

Intervals

Engine Oil

Oil Viscosity/Oil Range

Fluid And Lubricant Capacities And Specifications

Hydraulic Fluid Chart

Grease Points

Attachment

Greasing The Turntable Teeth

Greasing The Swing Reduction Gear

Fluid Levels

Engine

Cooling System

Fuel System

Releasing Pressure In The Hydraulic System

Hydraulic System

Reservoir Breather Replacement

Bleeding Air From The Hydraulic Components

Air Filter

Service Specifications

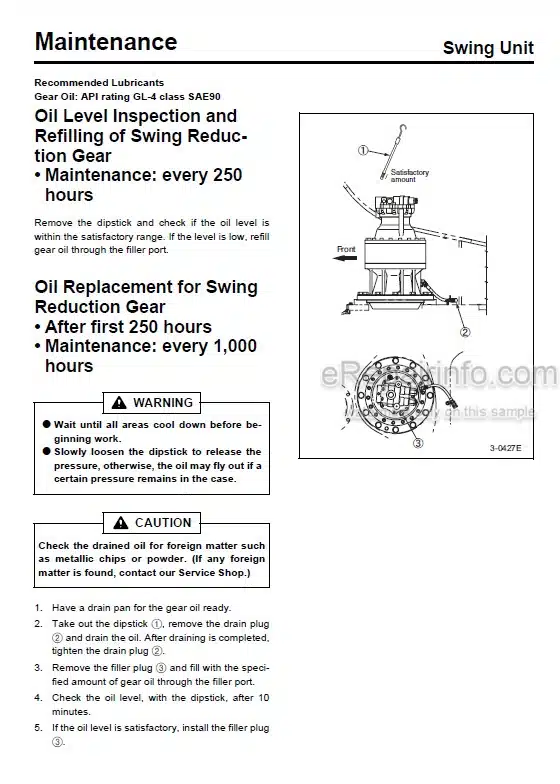

Swing Reduction Gear

Travel Reduction Gears

-ADJUSTMENT/ MAINTENANCE

Tracks

Track Shoe Bolt Torque

Track Rollers And Idler Wheels

Radiator And Oil Cooler

Fan And Alternator Drive Belt

Fuel Tank Filter

Inspecting And Cleaning The Machine

Checking For Cylinder Leakage

Plastic And Resin Parts

Replacing A Bucket

Welding On The Machine

Fire Extinguisher (Optional)

Air Conditioning

Hardware Torque Inspection

Torque Specifications Per Component

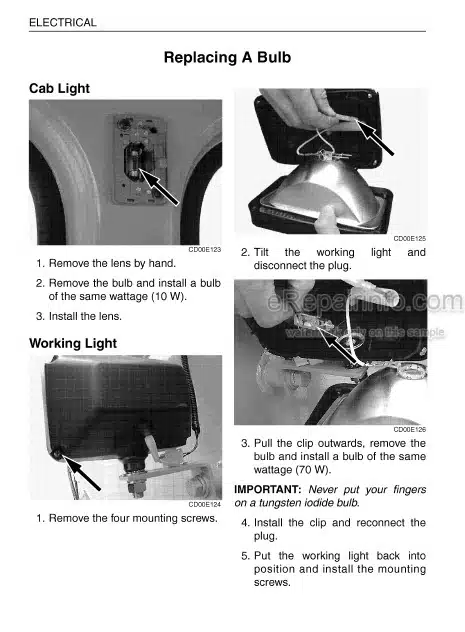

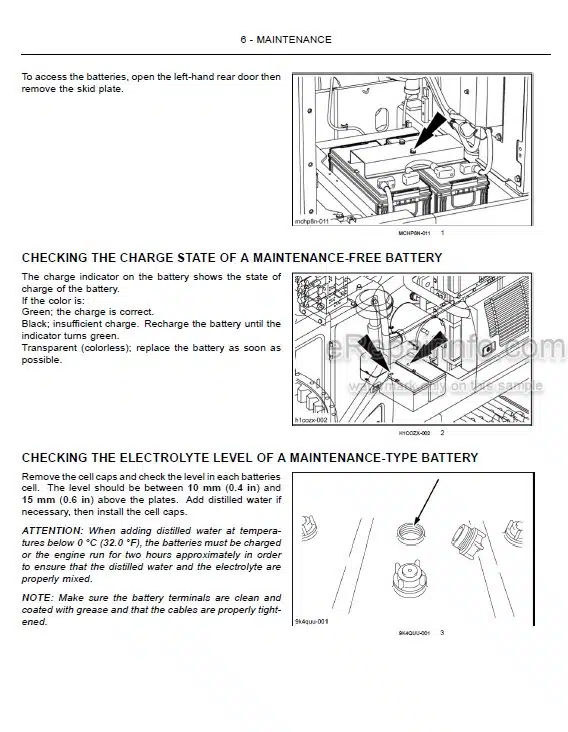

-ELECTRICAL

Batteries

Connecting Booster Batteries

Replacing A Bulb

MACHINE STORAGE

-SPECIFICATIONS

Engine

Hydraulic System

Weights

Buckets

Dimensions

Working Range With Retractable Frames

Working Range With Fixed Side Frames

Lifting Capacities

INDEX

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet