Caterpillar 236B, 246B, 252B, 262B Repair Manual Skid Steer Loader

Overview

The Factory Repair Manual for Caterpillar 236B, 246B, 252B, and 262B Skid Steer Loaders is an indispensable resource for technicians and owners. This comprehensive manual provides detailed illustrations, step-by-step instructions, and diagrams essential for the maintenance, service, and repair of these robust machines, ensuring they operate at peak performance.

Key Features

- Format: PDF

- Language: English

- Pages: 4453

- Bookmarks: Yes

- Searchable: Yes

- Wiring Diagrams: Yes

- Hydraulic Diagrams: Yes

Models Covered

This manual specifically covers the following Caterpillar skid steer loader models:

- Caterpillar 236B: HEN00001-06749

- Caterpillar 246B: PAT00001-UP

- Caterpillar 252B: SCP00001-04599

- Caterpillar 262B: PDT00001-UP

Comprehensive Contents

The manual is organized into clear sections for easy navigation, providing detailed information on a wide range of topics:

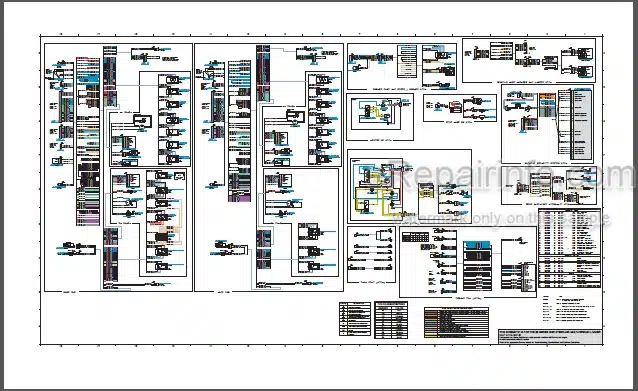

Schematics

- Fluid Power Graphic Symbols

- Electrical Power Graphic Symbols

- RENR8755

- RENR4869-03

- KENR8654-02

- RENR6419-05

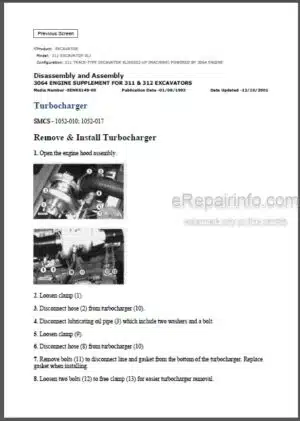

Air Inlet and Exhaust System

- Systems Operation

- Testing and Adjusting

- Specifications / Disassembly and Assembly

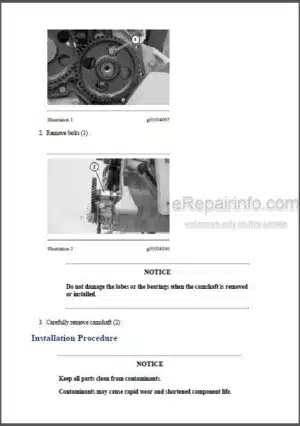

Basic Engine

- Systems Operation

- Testing and Adjusting

- Specifications / Disassembly and Assembly

Cooling System

- Systems Operation

- Testing and Adjusting

- Specifications / Disassembly and Assembly

Electrical and Starting System

- Systems Operation

- Testing and Adjusting

- Troubleshooting

- Specifications / Disassembly and Assembly

Engine Arrangement

- Systems Operation

- Testing and Adjusting

- Specifications / Disassembly and Assembly

Frame and Body

- Machine Frame and Mounting

- Engine Enclosure

- Machine Frame and Mounting

- Engine Enclosure – Remove and Install

- Lift Arm Cylinder and Mounting

- Lift Arm Cylinder and Mounting

Fuel System

- Systems Operation

- Testing and Adjusting

- Specifications / Disassembly and Assembly

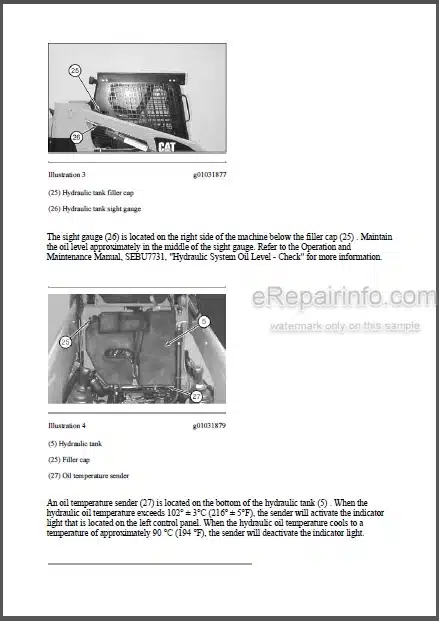

Hydraulic System

- Systems Operation

- Testing and Adjusting

- Troubleshooting

- Specifications / Disassembly and Assembly

Implements

- Lift Arms – Remove – Extended Reach Machines

- Lift Arms – Remove – Radial Arc Machines

- Lift Arms – Install – Extended Reach Machines

- Lift Arms – Install – Radial Arc Machines

Lubrication System

- Systems Operation

- Testing and Adjusting

- Specifications / Disassembly and Assembly

Machine Arrangement

- Service Intervals

- Heating and Air Conditioning Service Publications

Operator Station

- Systems Operation

- Testing and Adjusting

- Troubleshooting

- Specifications / Disassembly and Assembly

Power Train

- Systems Operation

- Testing and Adjusting

- Troubleshooting

- Specifications / Disassembly and Assembly

Service Equipment and Supplies

- Systems Operation

- Testing and Adjusting

- Troubleshooting

- Specifications / Disassembly and Assembly

Torque Specifications

- General Information

- Metric (ISO) Fasteners

- English (SAE) Fasteners

- Ground Engaging Tool (G.E.T.) Fasteners

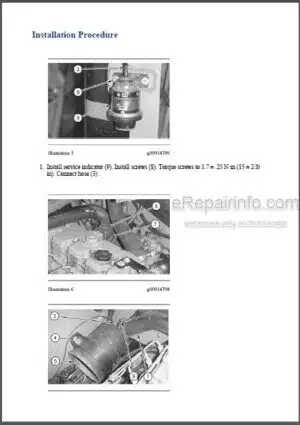

- Installation of Fittings

- Straight Thread O-Ring Fittings

- Plugs

- O-Ring Face Seal Fittings

- Bulkhead Nuts

- Flare Fittings

- Air Conditioning Fittings

- Air Brake Fittings

- Tapered Pipe Thread Fittings

- Miscellaneous Fittings

- Hose Clamps

Work Tools

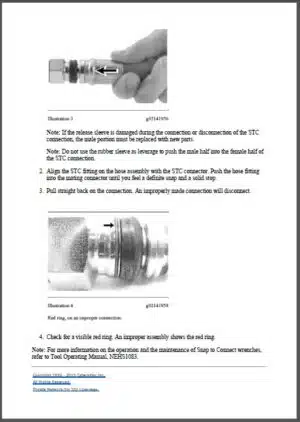

- Coupler Cylinder

- Quick Coupler

Detailed Illustrations and Diagrams

The manual includes high-quality illustrations and diagrams to simplify complex procedures:

- Wiring Diagrams to assist with diagnosing and repairing electrical issues.

- Hydraulic Diagrams to help troubleshoot and repair hydraulic systems.

User-Friendly Features

The PDF format ensures easy accessibility and navigation. The manual is fully searchable, allowing users to quickly find the information they need. Bookmarks provide convenient navigation to various sections of the manual.

Ideal for Technicians and Owners

Whether you are a professional technician or a skid steer loader owner, this manual is an invaluable tool. It provides clear, concise instructions and detailed diagrams to guide you through every aspect of loader repair and maintenance.

How to Use This Manual

- Step-by-Step Instructions: Follow the detailed, step-by-step instructions for disassembly, inspection, and reassembly of components.

- Routine Maintenance: Regular maintenance guides ensure your skid steer loader operates at peak performance.

- Inspection and Repair: Use the inspection and repair sections to diagnose and fix issues effectively.

- Electrical and Hydraulic Systems: Refer to the wiring and hydraulic diagrams for clear visual guidance.

Get Your Copy

Ensure the longevity and optimal performance of your Caterpillar skid steer loaders by utilizing this comprehensive repair manual. With 4453 pages of detailed information, this manual is your ultimate guide to maintaining and repairing your equipment.

Invest in the Caterpillar 236B, 246B, 252B, 262B Repair Manual Skid Steer Loader today and keep your loaders in top working condition.

Anonymous (verified owner) –

Great seller