Factory Repair Manual For Caterpillar 313B CR Excavator. Illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 2838

Bookmarks: Yes

Searchable: Yes

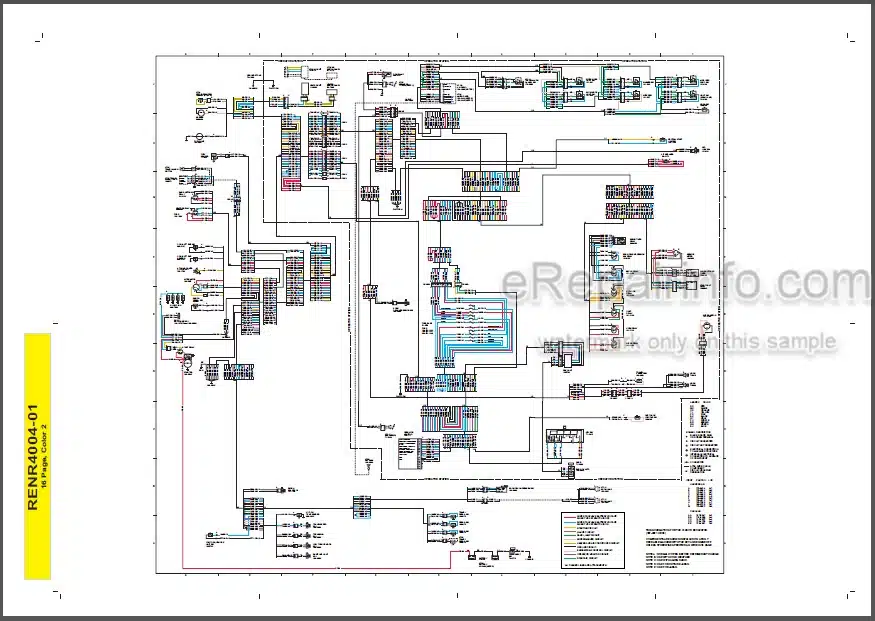

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Caterpillar 313B CR

BAS00001-UP

Contents

-AIR INLET AND EXHAUST SYSTEM

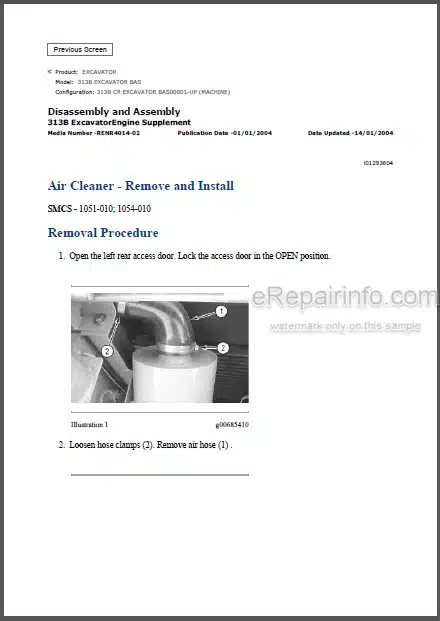

Air Cleaner – Remove and Install

Exhaust Manifold – Remove and Install

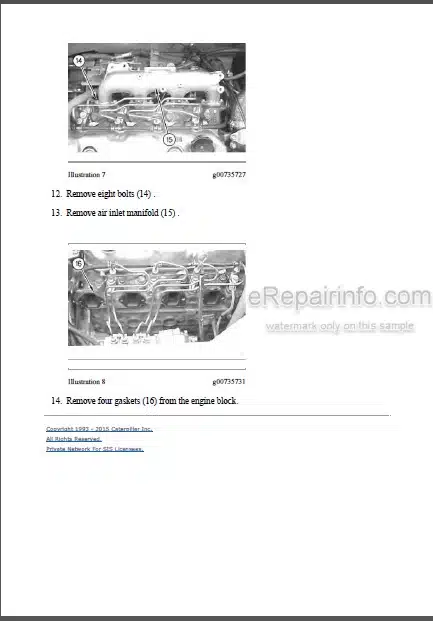

Air Inlet Manifold – Remove

Air Inlet Manifold – Install

Turbocharger – Remove

Turbocharger – Install

-BASIC ENGINE

Engine Performance Test – Engine Speed

Engine and Main Hydraulic Pump – Remove

Engine and Main Hydraulic Pump – Install

Cylinder Head – Remove

Cylinder Head – Install

Valve Mechanism Cover – Remove and Install

Rocker Shaft and Push Rod – Remove

Rocker Shaft and Push Rod – Install

-COOLING SYSTEM

Water Temperature Regulator – Remove and Install

Radiator and Hydraulic Oil Cooler – Remove

Radiator and Hydraulic Oil Cooler – Install

-ELECTRICAL AND STARTING SYSTEM

Systems Operation

Testing and Adjusting

Specifications / Disassembly and Assembly

-FRAME AND BODY

Counterweight – Remove and Install

Swing Drive – Remove

Swing Drive – Assemble

Swing Drive – Install

Upper Frame

Undercarriage Frame – Remove

Undercarriage Frame – Install

Swing Gear and Bearing

Swing Gear and Bearing – Remove and Install

Travel Motor Guard

-FUEL SYSTEM

Systems Operation

Testing and Adjusting

Specifications / Disassembly and Assembly

-HYDRAULIC SYSTEM

Systems Operation

Testing and Adjusting

Specifications / Disassembly and Assembly

-IMPLEMENTS

CP Boom – Auxiliary

Boom – 4650 mm (15 feet 3 inch)

Boom – Remove

Boom Bearings and Seals – Remove

Boom Bearings and Seals – Install

Boom – Install

Bucket Linkage

Specifications / Disassembly and Assembly

Bucket Linkage – Remove

Bucket Linkage Bearings and Seals – Remove

Bucket Linkage Bearings and Seals – Install

Bucket Linkage – Install

Stick – Auxiliary 2500 mm (8 feet 2 inch)

Stick – 2500 mm (8 feet 2 inch)

Stick – 3000 mm (9 feet 10 inch)

Stick – Auxiliary 3000 mm (9 feet 10 inch)

Stick – Remove

Stick Bearings and Seals – Remove

Stick Bearings and Seals – Install

Stick – Install

-LUBRICATION SYSTEM

Engine Oil Level Gauge (Dipstick) – Remove and Install

-MACHINE ARRANGEMENT

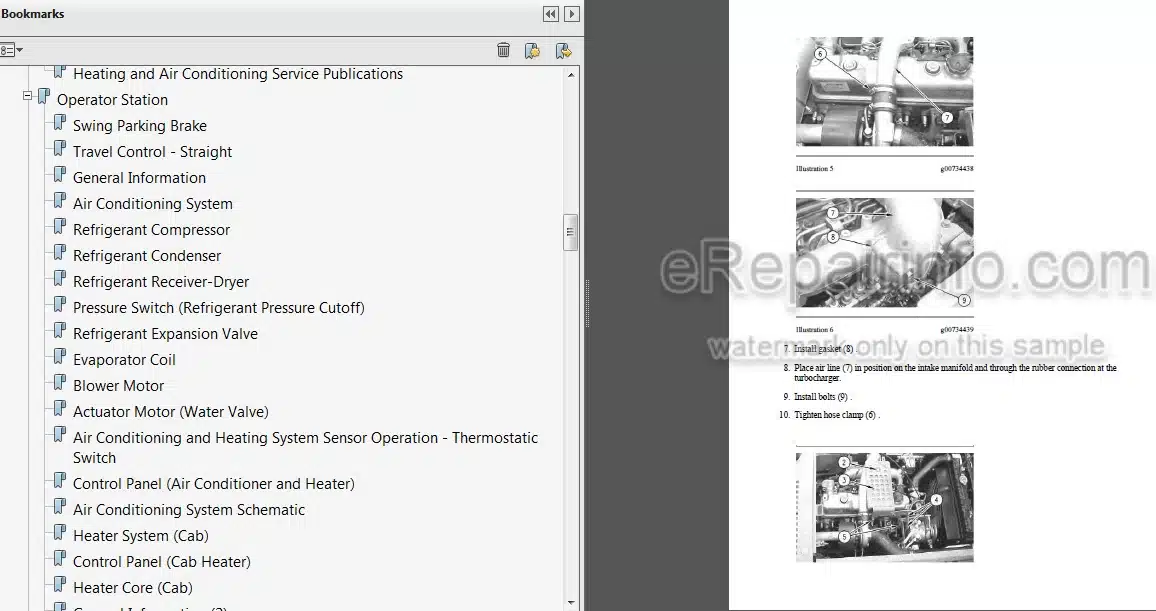

Heating and Air Conditioning Service Publications

-OPERATOR STATION

Swing Parking Brake

Travel Control – Straight

General Information

Air Conditioning System

Refrigerant Compressor

Refrigerant Condenser

Refrigerant Receiver-Dryer

Pressure Switch (Refrigerant Pressure Cutoff)

Refrigerant Expansion Valve

Evaporator Coil

Blower Motor

Actuator Motor (Water Valve)

Air Conditioning and Heating System Sensor Operation – Thermostatic Switch

Control Panel (Air Conditioner and Heater)

Air Conditioning System Schematic

Heater System (Cab)

Control Panel (Cab Heater)

Heater Core (Cab)

Identifying the Refrigerant

Identifying the Air Conditioning System

Identifying the Heating System

Refrigerant Expansion Valve System

Refrigerant Orifice Tube System

Refrigerant Compressor

Refrigerant Receiver-Dryer

Refrigerant Expansion Valve

In-line Refrigerant Dryer

Refrigerant Orifice Tube Assembly

Evaporator Coil

Refrigerant Accumulator

Refrigerant Compressor Protection System

Temperature Control

Cab Pressurization and Filtration System

Condensate Drainage System

Service Intervals

Glossary of Terms

Wiper Motor Does Not Rotate – Troubleshoot

Wiper Motor Does Not Stop – Troubleshoot

Window Washer Does Not Activate – Troubleshoot

Horn Does Not Sound – Troubleshoot

Radio Does Not Activate – Troubleshoot

Radio Does Not Sound – Troubleshoot

Heater Does Not Activate – Troubleshoot

Circuit for Low Idle Switch – Troubleshoot

Machine Preparation for Troubleshooting

General Troubleshooting Information

Visual Inspection

Air Conditioning System Troubleshooting – Faulty Cooling

Air Conditioning System Troubleshooting – Gauge Pressure

Air Conditioning System Schematic

Heating System Troubleshooting – Faulty Heating

Heating System Schematic

Refrigerant Recovery

Manifold Gauge Set (Refrigerant) – Install

Refrigerant System – Evacuate

Refrigerant System – Flush

Refrigerant Leakage – Test

Refrigerant System – Charge

Manifold Gauge Set (Refrigerant) – Remove

Pressure Switch (Refrigerant Pressure Cutoff) – Test

Control Panel – Test

Speed Control – Test

Belt – Test

Machine Preparation for Testing and Adjusting

Air Conditioning Performance – Test

Refrigerant Leakage – Test

Manifold Gauge Set (Refrigerant) – Install

Refrigerant Recovery

Refrigerant System – Flush

Refrigerant Oil – Test

Refrigerant Compressor – Test

Refrigerant System – Evacuate

Refrigerant System – Charge

Manifold Gauge Set (Refrigerant) – Remove

Compressor Protection System – Test

Electronic Heat Control – Test

Heater Performance – Test

Required Tools

Machine Preparation for Troubleshooting

General Troubleshooting Information

Visual Inspection (Troubleshooting)

Air Conditioning System Troubleshooting

Heating System Troubleshooting

Troubleshooting Heating and Air Conditioning Control System

Troubleshooting Condensate Drainage System

Refrigerant Compressor

Pressure Switch (Refrigerant Pressure Cutoff)

Refrigerant Relief Valve

Air Conditioner Lines

System Capacities for Refrigerant (Excavators) – 304 CR, 305 CR, 313B CR, 321BCR

Refrigerant Receiver-Dryer – Remove and Install

Refrigerant Compressor – Remove and Install

Machine Preparation for Disassembly and Assembly

Air Conditioner Lines – Remove and Install

Refrigerant Accumulator – Remove and Install

Refrigerant Expansion Valve – Remove and Install

Refrigerant Receiver-Dryer – Remove and Install

In-Line Refrigerant Dryer – Remove and Install

Refrigerant Orifice Tube Assembly – Remove and Install Cab – Remove

Cab – Install

Pilot Valve (Travel) – Remove

Pilot Valve (Travel) – Disassemble

Pilot Valve (Travel) – Assemble

Pilot Valve (Travel) – Install

Lines (Heater)

Seat – Remove and Install

-POWER TRAIN

Final Drives and Travel Motors

Duo-Cone Conventional Seals – Install (2)

Final Drive and Travel Motor – Remove

Final Drive and Travel Motor – Disassemble

Final Drive and Travel Motor – Assemble

Final Drive and Travel Motor – Install

Final Drives and Travel Motors (2)

Final Drive Sprocket – Remove and Install

Track Roller – Remove

Track Roller – Disassemble

Track Roller – Assemble

Track Roller – Install

Track – Separate

Track – Connect

Final Drive

Duo-Cone Conventional Seals – Install

-SERVICE EQUIPMENT AND SUPPLIES

Cab Pressurization and Filtration System

Required Tools

Manifold Gauge Set (Refrigerant) – Install

Manifold Gauge Set (Refrigerant) – Remove

Heating and Air Conditioning Service Publications

Required Tools (3)

Hydraulic Tank and Filter

Fuel Filter (Primary) and Fuel Filter Base – Remove and Install

Air Cleaner – Remove and Install

-TORQUE SPECIFICATIONS

English (SAE) Fasteners

Ground Engaging Tool (G.E.T.) Fasteners

Installation of Fittings

Straight Thread O-Ring Fittings

Plugs

O-Ring Face Seal Fittings

Bulkhead Nuts

Flare Fittings

Air Conditioning Fittings

Air Brake Fittings

Tapered Pipe Thread Fittings

Miscellaneous Fittings

Hose Clamps

General Information

Metric (ISO) Fasteners

-UNDERCARRIAGE

Front Idler

Recoil Spring

Front Idler and Recoil Spring – Remove

Front Idler – Disassemble

Front Idler – Assemble

Front Idler and Recoil Spring – Install

Track Carrier Roller

Track Roller (Single Flange)

Track Roller Mounting

Track Carrier Roller – Remove

Track Carrier Roller – Disassemble

Track Carrier Roller – Assemble

Track Carrier Roller – Install

Track Roller – Remove

Track Roller – Disassemble

Track Roller – Assemble

Track Roller – Install

Front Idler and Recoil Spring – Remove

Front Idler and Recoil Spring – Install

Recoil Spring

Recoil Spring – Disassemble

Recoil Spring – Assemble

Track Adjuster – Disassemble

Track Adjuster – Assemble

Track Adjuster – Remove

Track Adjuster – Install

-WORK TOOLS

Blade Lift Cylinder

Blade Mounting

Bucket – 1075 Mm (42 Inch)

Bucket – 925 Mm (36 Inch)

Bucket – 625 Mm (24 Inch)

Bucket – 775 Mm (30 Inch)

Bucket – 1225 Mm (48 Inch)

Bucket – Remove

Bucket – Install

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet