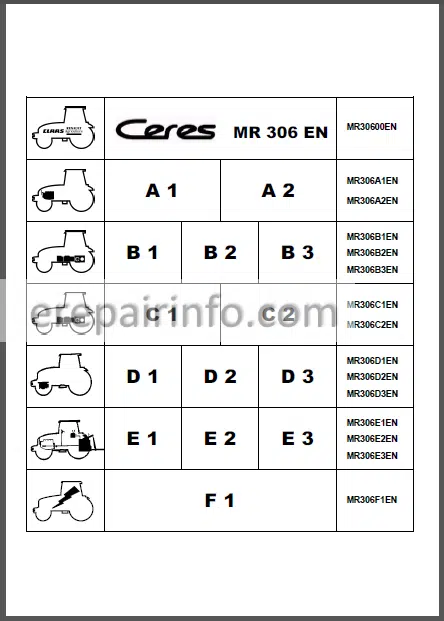

Factory Service Repair Manual For Claas Renault Ceres 316 326 336 346 Tractors. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Claas Renault Ceres 316, 326, 336, 346

Contents

-ENGINE Ceres 326 – 336 – 346

–GENERAL SPECIFICATIONS

Engine Specifications

Fuel System Data

Service Data And Tolerances

Tightening Torque

Longitudinal Section

Cross Section

Lubrication System

Cooling System

Fault Diagnosis Chart

–ENGINE REMOVAL & INSTALLATION

Engine Removal

Engine Installation

–ENGINE DISASSEMBLING & ASSEMBLING

Engine Disassembling

Engine Assembling

–CHECKS, DIMENSIONS & REPAIRS

Cylinder Block and Cylinder Liner

Crankshaft, Main Bearing and Flywheel

Connecting Rods

Pistons

Camshaft, Tappets and Valves

Cylinder Head

Valve Guides

Valve Seat In Cylinder Head

Injector Sleeves

Rotating Counterweight Dynamic Balancer

Lubrication System

Cooling System

Coolant Pump and Alternator Drive Belt

Engine Compression Test

–SUB ASSEMBLY REMOVAL / INSTALLATION & SETTING

Crankshaft Front Oil Seal

Coolant Pump

System Thermostat Cooling

Bosch Injection Pump

Fuel Injectors

Valve Clearance Adjustment

Water Pump

–TOOLS

Special Tools

-ENGINE Ceres 316

–GENERAL SPECIFICATIONS

Engine Specifications

Service Data

Longitudinal Section

Cross- Section

Lubrication Chart

Fault Diagnosis Chart

Key to Fault Diagnosis Chart

–ENGINE REMOVAL & INSTALLATION Refer to Al Chapter for Engine removal Procedure

—DISASSEMBLING – ASSEMBLING

Engine Assembly

Engine Trimming

–TOOLS

Tools

Special Tools

General Tools

-CLUTCH

–SPECIFICATIONS

Clutch Specifications

Cross Section

Tightening Torque and Adjustments

–DRIVE & POWER TAKE-OFF MECHANICAL CLUTCHES

Clutch Removal

Clutch Disassembly

Clutch Inspection

Friction Disc Inspection

Clutch Re-assembly

Inspection and Reconditioning Of The Engine Flywheel Thrust Surfaces

Inspection Of The Engine Flywheel Spigot Bearing

Engine Flywheel Removal & Installation

Clutch Installation

Clutch Lever Adjustment

–THRUST BEARINGS AND GUIDE

Removal / Installation Of The Trust Bearing and Guide

–DRIVE & POWER TAKE-OFF CLUTCH CONTROL

Drive Clutch Control

Power Take-off Clutch Control

-GEARBOX

–PRIMARY SHAFT

Introduction

Preliminary Operations

Removal / Installation Of The Primary Shaft

–SECONARY SHAFT

Introduction

Preliminary Operations

Removal I Installation Of The Secondary Shaft

Removal / Installation Of The Drive Intermediate Shaft

Adjustment Of The Pinion Protrusion

Final Operations

Types Of Interventions On Secondary Shaft

–FRONT INTERMEDIATE SHAFT

Introduction

Preamble

Preliminary Operations

Removal I Installation Of Shaft

Adjustment

Final Operations

–REAR INTERMEDIATE SHAFT

Introduction

Preamble

Preliminary Operations

Removal/Installation Of Shaft

Pre-loading The Bearings

Final Operations

–SPECIFICATIONS

Gearbox Specifications

Mechanical Gearboxes Kinematics

Adjustments and Tightening Torque

Casing Tightening Torque

Cover Tightening Torque

–GEARBOX CONTROLS

Gearboxes with Mechanical Reverser

Gearboxes with Mechanical Gear Shuttier and Reverser

Gearboxes with Creeper Range + Mechanical Gear Shuttier and Reverser

Control Locking

Adjustment of the Mechanical Controls

–POWER TAKE-OFF CLUTCH SHAFT

Removal / Installation Of The Power Take-off Shaft

–INPUT HOUSING

Drive Shaft

Input Housing With Mechanical Reveser

Input Housing With Mechanical Reveser + Shuttier

Input Housing With Mechanical Reveser + Shuttier + Creeper Range

Removal I Installation

Adjustment of the Reverser / Splitter Drive Clearance

Adjustment of the Bearing Preload

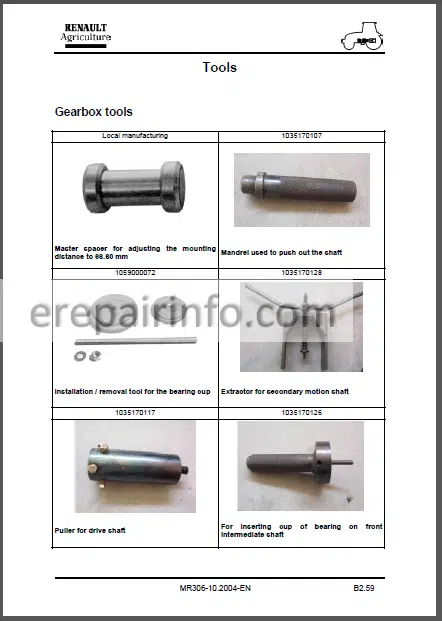

–TOOLS

Gearbox Tools

-LOW PRESSURE HYDRAULIC SYSTEM

–PRESENTATION

Tightening Torque For The Hydraulic Components And Fittings

Principle Diagram

Pressure Restrictor

Flow Divider/ Regulator

Hydraulic Unit

–HYDRAULIC CHECKS

Hydraulic Controls

“Checking Values Reading” Sheet

–TOOLS

Hydraulic Tools

-REAR AXLE

–PRESENTATION

Specifications

Kinematics

Attachment points

Adjustment And Tightening Torque

Power Take-Off

–POWER TAKE-OFF

General

Removal / Installation

–DIFFERENTIAL SHAFTS

Section View

Removal / Installation

–DIFFERENTIAL CROWN WHEEL AND PINION

Removal / Installation Of The Crown Wheel And Pinion

Adjustment Of The Pre-load Of The Bearing

Checking The Clearance Of The Crown Wheel Teeth

Changing The Crown Wheel

Changing The Rear Axle Casing

–AXLE TUBES AND SHAFTS

Removal / Installation Of The Axle Tubes And Shafts

Adjustment Of The Shaft End Float

Final Operations

–DIFFERENTIAL LOCK / RELEASE CONTROLS

Description

Removal / Installation Of The Differential Lock Mechanism

Adjustment Of The Differential Lock Inside Mechanism

–TOOLS

Rear Axle Tools

-BRAKE

–SERVICE BRAKES – HANDBRAKE

Specifications

Brake Removal / Installation

Brake Control Adjustment

–TOOLS

Brake Tools

-FRONT AXLE (4WD)

–PRESENTATION

General Specifications

Kinematics

–REMOVAL / INSTALLATION

Wheel Alignment adjustment

Preliminary Operations

Reducers And Wheel Hubs

2011 And 2014 Front Axle Tightening Torque And Tools

Planet Gear Reducer

Differential

Wheel Pivots – Universal Joint Shafts

Differential – Bevel Gear

Adjustment For The Bevel Gear Preload

Adjustment For The Apex Distance

Backlash Adjustment

Preload Of Differential Bearings

Final Operations

–TOOLS

Front Axle 4WD Tools

-4 WHEEL DRIVE DROP BOX

–4WD DROP BOX

Safety Devices

Tightening Torque Adjustments

Removal I Installation

4WD Housing Removal

Belville Spring Assembly Shimming

Piston Stroke Shimming

4WD Housing Installation

Bearing Clearance Adjustment

Operating Check

Final Operations

4WD Drop Box Clutch Control

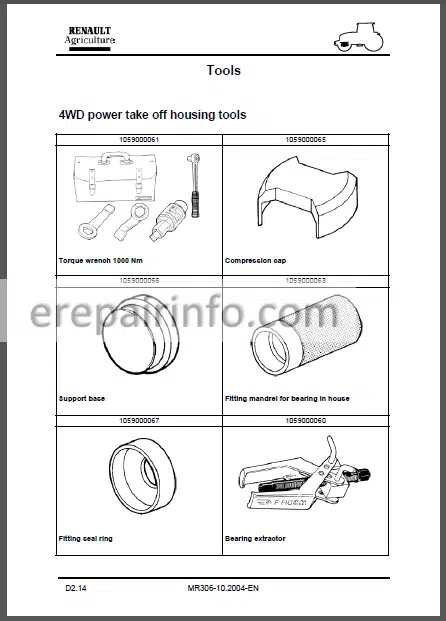

–TOOLS

4WD Power Take Off Housing Tools

-FRONT AXLE (2WD)

–PRESENTATION

General Specifications

–REMOVAL / INSTALLATION

Disassembly Of Tie Rod

Servicing Of Wheel End Assembly

Axle Tread Adjustment

Disassembly / Assembly Of Tie Rod Cylinder

–SPECIFICATIONS

Torque Values And Other Specifications

Service Frequency

Trouble Shooting

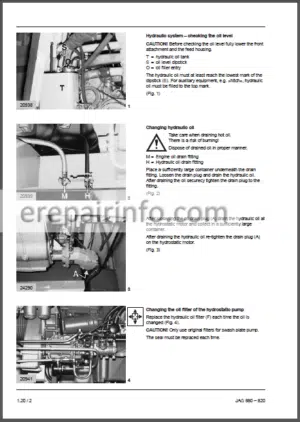

-HYDRAULICS

–PRESENTATION

General Specifications

Hydraulic Controls

Hydraulic circuit

Schematic Diagram

Hydraulic Components And Unions Tightening Torque

–REMOVAL / INSTALLATION OF THE ELEMENTS

Brake Valve

Flow Divider

Auxiliary Valves

Auxiliary Distributors – Overall View

Changing The Suction Strainer

Changing The Filtering Cartridge

Changing The Breather

Bleeding The Air

Changing The Pump

–MEASUREMENT POINTS AND CHECKS

Checking Values Reading Sheet

–TOOLS

Hydraulic Tools

-LIFT HITCH

–PRESENTATION

General Specifications

Hydraulic Unions Tightening Torque

Hydraulic Controls

Main Distributor

Schematic Diagrams Of The Distributor

–REMOVAL / INSTALLATION

Disassembly Of Tie Rod

Lift Casing

Lift Arm And Piston

Internal Controls

Control Levers

Hydraulic Distributor

Position Control Lever Adjustment

Draft Control Lever Adjustment

Draft Sensor Lever Adjustment

Checking Forces On The Flexion Bar

Lower Link Bearing Clearance

Draft And Position Control Adjustment

–DIAGNOSTIC

Sheet №1: No Descent – Hitch Loaded

Sheet №2: No Rise Or Slow Rise

Sheet №3: Lack Of Stability (Jerking)

–TOOLS

Lift Tools

-STEERING

–PRESENTATION

Specifications

General

Schematic Diagrams

–REMOVAL/INSTALLATION

Steering Unit

–CHECKS AND ADJUSTMENTS

Steering Unit

Shock Valves

Steering Cylinder

Pump Flow Check

–DIAGNOSTIC

Wheel Hard To Steer

Abnormal Vibration In The Wheel – Oscillation In The Steering Inaccurate Steering – Path Correction

–TOOLS

Steering Tools

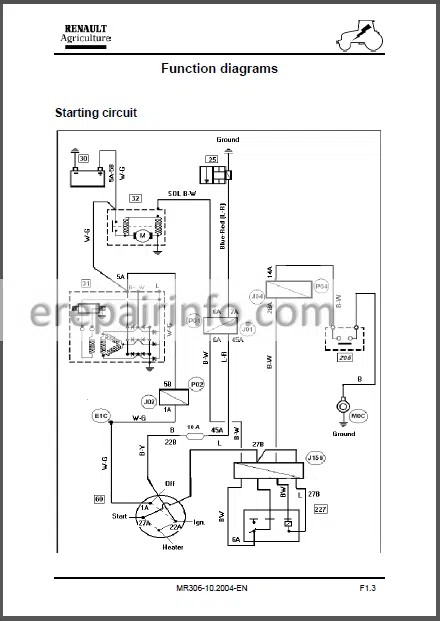

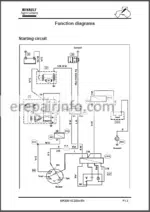

-ELECTRICS

Fuse Box

Starting Circuit

Charging Circuit

Dipped Beam – Main Beam – Hom

Revolving Light

Front And Rear Work Light

Brake Lights – Front Axle Engaging / Control

Side Lights – Number Plate Lighting – Instrument Panel Lighting Indicators And Hazard Warning Lights

Instrument Panel – Fuel Gauge – Oil Pressure Gauge – Engine Temperature – Air Filter Clogging

Hand Brake

Engine Speed – Tachometer Input

Power Supply Socket – 20A

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet