Factory Shop Manual For Cummins Engine. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 585

Number: 3666075-00 (november 1944)

Bookmarks: Yes

Model

Cummins Engine

M11 Series

Contents

-INTRODUCTION

About The Manual

Definition Of Terms

General Cleaning Instructions

General Repair Instructions

General Safety Instructions

How to Use The Manual

Illustrations

Symbols

-ENGINE IDENTIFICATION

Engine Diagrams

Engine Identification

Engine Specifications

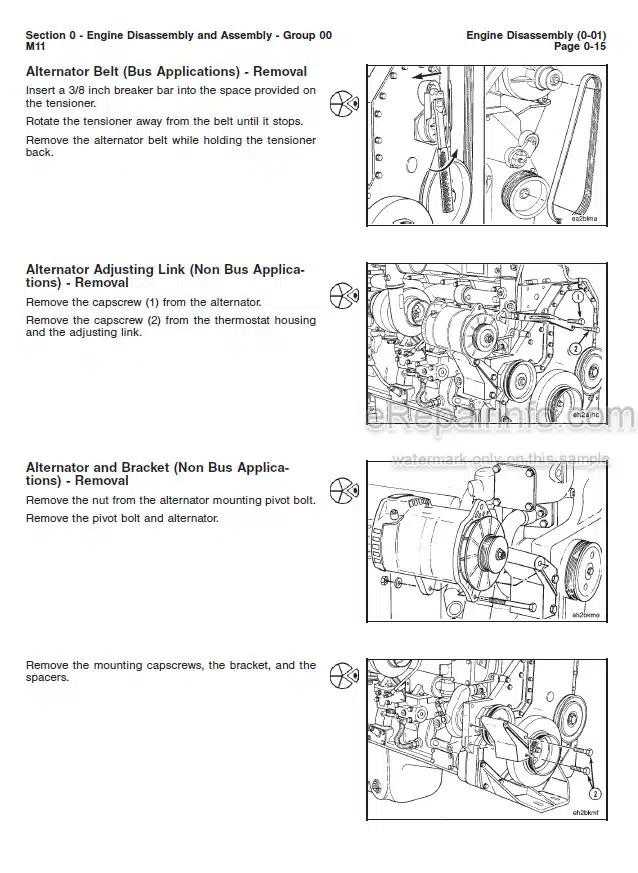

-ENGINE DISASSEMBLY AND ASSEMBLY

Engine Assembly

Engine Disassembly

Engine Disassembly And Assembly – General Information

Service Tools – Disassembly And Assembly

-CYLINDER BLOCK

Camshaft – Cleaning And Inspection For Reuse

Camshaft – Magnetic Crack Inspection

Camshaft Bushing – Replacement

Camshaft Gear – Replacement

Camshaft Or Idler Gear – Magnetic Crack Inspection

Connecting Rod – Bend And Twist Inspection

Connecting Rod – Cleaning And Inspection For Reuse

Connecting Rod – Magnetic Crack Inspection

Connecting Rod Bearings – Cleaning And Inspection For Reuse

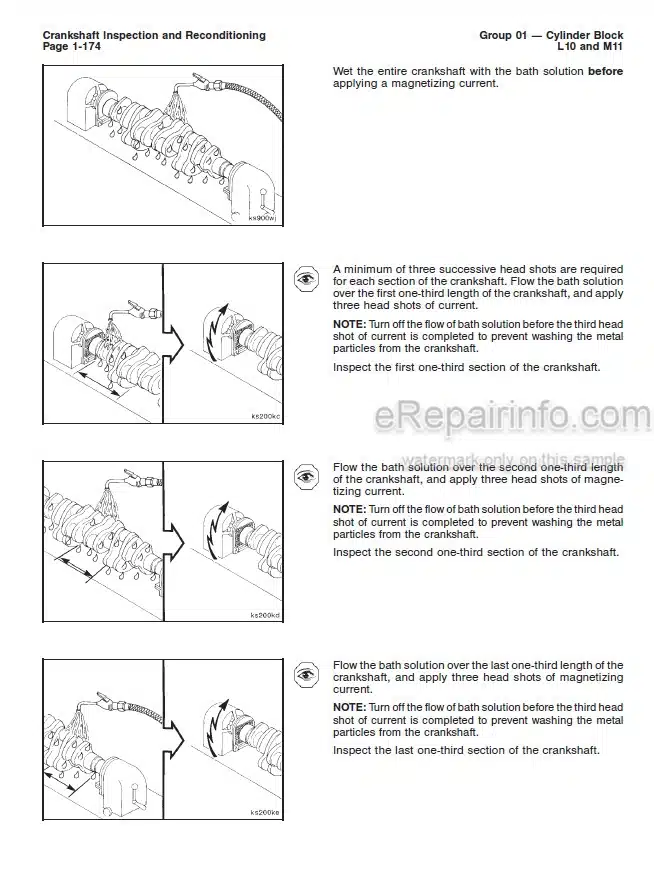

Crankshaft – Cleaning And Inspections For Reuse

Crankshaft Gear – Replacement

Crankshaft Magnetic Crack Inspection

Crankshaft Pulley – Cleaning And Inspection For Reuse

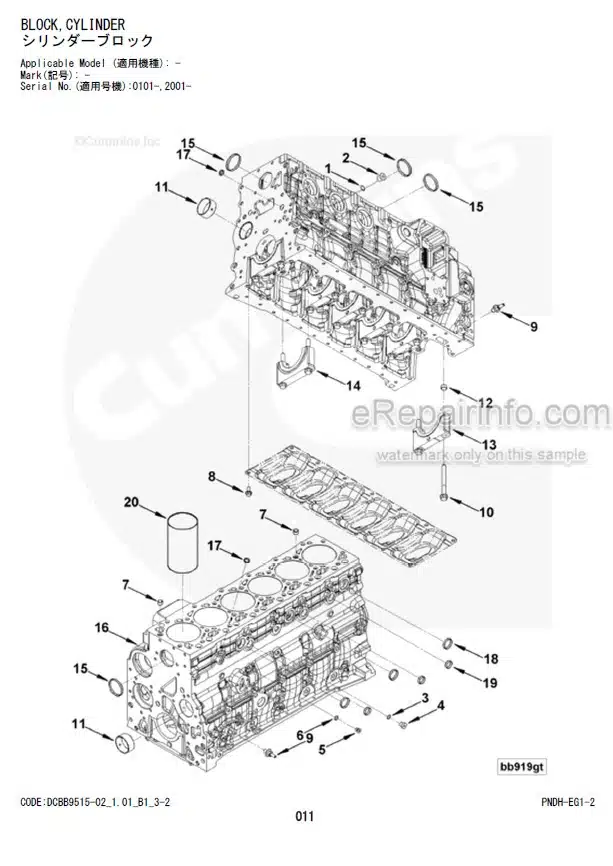

Cylinder Block – Exploded View

Cylinder Block – General Information

Cylinder Block – Inspection For Reuse

Cylinder Block

Cylinder Liner – Cleaning And Inspection For Reuse

Dipstick Tube Bracket – Cleaning And Inspection For Reuse

Gear Cover – Cleaning And Inspection For Reuse

Gear Housing – Cleaning And Inspection For Reuse

Hand Hole Cover – Cleaning And Inspection For Reuse

Idler Gear Assembly – Cleaning And Inspection For Reuse

Main Bearings – Cleaning And Inspection For Reuse

Piston – Cleaning And Inspection For Reuse

Service Tools – Cylinder Block

Vibration Damper (Viscous) – Cleaning And Inspection For Reuse

-CYLINDER HEAD

Cylinder Head – Cleaning And Inspection For Reuse

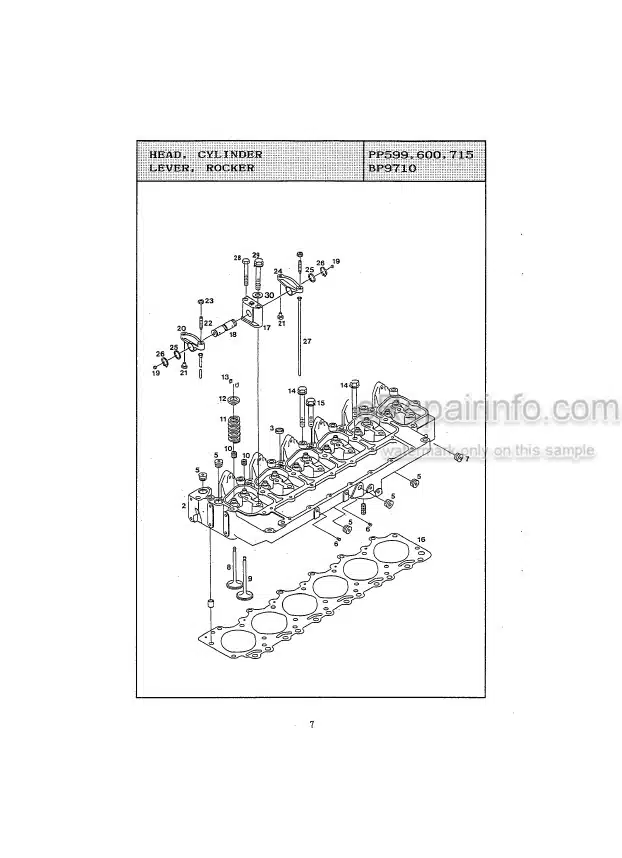

Cylinder Head – Exploded View

Cylinder Head – General Information

Cylinder Head – Pressure Test For Reuse

Cylinder Head-Rebuild

Cylinder Head – Vacuum Test Valve Seating

Cylinder Head – Valve Grinding

Cylinder Head Injector Sleeve – Replacement

Cylinder Head Oversize Valve Seat Insert – Installation

Cylinder Head Valve Guide – Replacement

Cylinder Head Valve Seat Insert – Replacement

Cylinder Head Valves – Magnetic Crack Inspection

Service Tools – Cylinder Head

Valve Crosshead – Cleaning And Inspection For Reuse

Valve Crosshead – Magnetic Crack Inspection

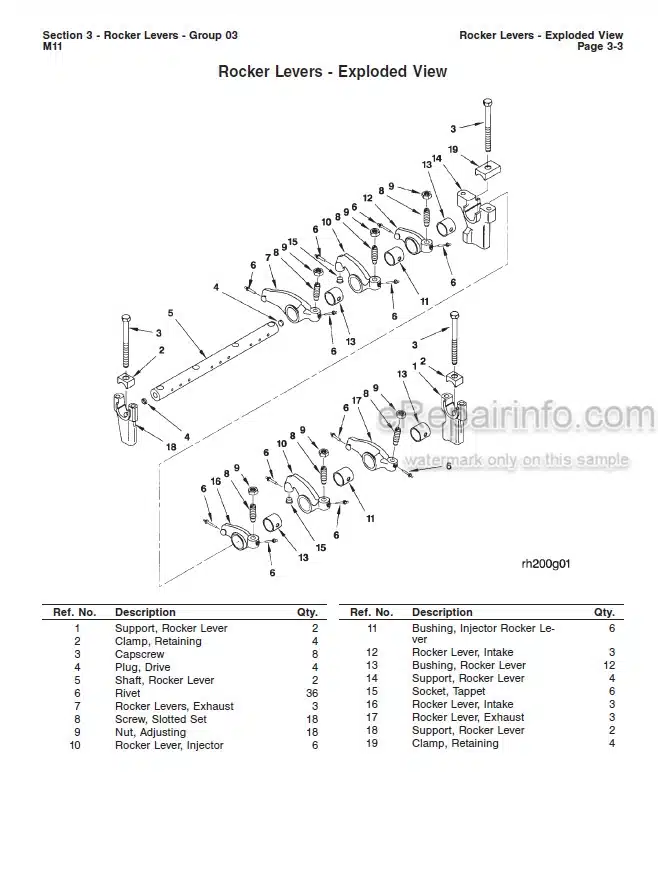

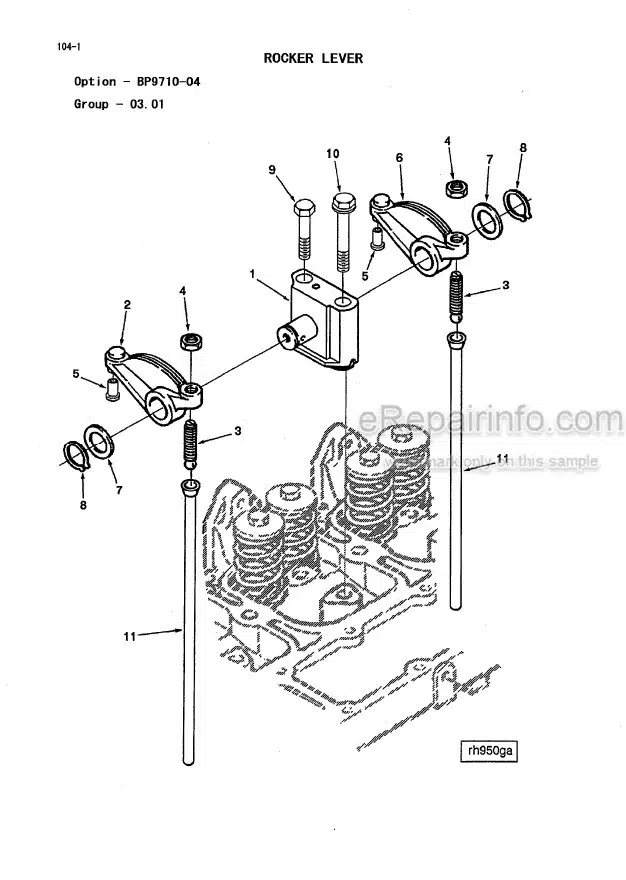

-ROCKER LEVERS

Crankcase Breather (Internal) – Cleaning And Inspection

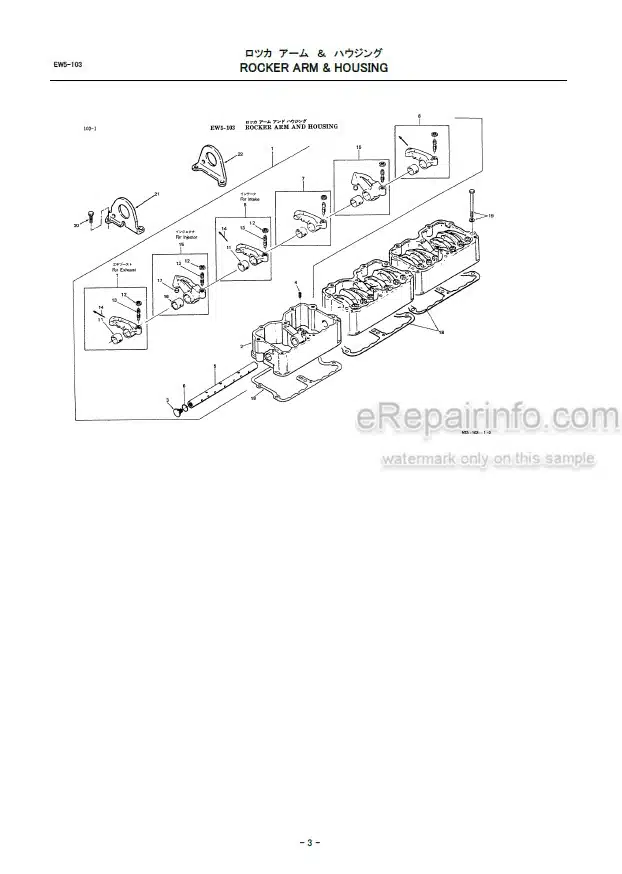

Rocker Housing And Cover (Automotive) – Exploded View

Rocker Lever – Magnetic Crack Inspection

Rocker Lever Assembly – Cleaning And Inspection For Reuse

Rocker Lever Assembly – Rebuild

Rocker Lever Bushing – Replacement

Rocker Lever Cover – Cleaning And Inspection For Reuse

Rocker Lever Housing – Cleaning And Inspection For Reuse

Rocker Levers – Exploded View

Rocker Levers – General Information

Service Tools – Rocker Levers

-CAM FOLLOWERS

Cam Follower Assembly – Cleaning And Inspection For Reuse

Cam Follower Assembly – Exploded View

Cam Follower Assembly – General Information

Cam Follower Assembly – Rebuild

Cam Follower Lever – Magnetic Crack Inspection (Roller Removed)

Cam Follower Lever – Roller Replacement

Cam Follower Lever Socket – Replacement (Roller Removed)

Push Rods And Tubes – Cleaning And Inspection For Reuse

Service Tools – Cam Follower Assembly

-FUEL SYSTEM

Fuel Pump – Cleaning And Inspection For Reuse

Fuel Pump – General Information

Fuel Pump – Rebuild

-INJECTORS AND FUEL LINES

Fuel Tubes, Fittings And Mounting Parts – Cleaning And Inspection For Reuse

Injector – Celect – Exploded View

Injectors – Calibration

Injectors – Cleaning And Inspection For Reuse

Injectors – General Information

Injectors – Rebuild

-LUBRICATING OIL SYSTEM

Lubricating Oil Cooler – Cleaning And Inspection For Reuse

Lubricating Oil Dipstick – Calibration

Lubricating Oil Dipstick And Dipstick Tube – Cleaning And Inspection For Reuse

Lubricating Oil Filter Head – Cleaning And Inspection For Reuse

Lubricating Oil Filter Head – Rebuild

Lubricating Oil Pan – Cleaning And Inspection For Reuse

Lubricating Oil Pan Transfer Tube – Cleaning And Inspection For Reuse

Lubricating Oil Pump – Cleaning And Inspection For Reuse

Lubricating Oil Pump – Rebuild

Lubricating Oil System – Exploded View

Lubricating Oil System – General Information

Service Tools – Lubricating Oil System

-COOLING SYSTEM

Fan Hub – Cleaning And Inspection For Reuse

Fan Hub – Exploded View

Fan Hub And Fan Idler Pulley – General Information

Fan Hub (Belt Driven) – Rebuild

Fan Idler Pulley – Cleaning And Inspection For Reuse

Fan Idler Pulley – Rebuild

Fan Idler Pulley And Bracket – Exploded View

Heater Housing, Thermostat Support And Water Header Cover – Cleaning And Inspection

Service Tools – Cooling System

Thermostat – Operating Temperature Inspection

Thermostat Housing Assembly – Rebuild

Water Filter Head Assembly – Cleaning And Inspection For Reuse

Water Filter Head Assembly – Rebuild

Water Pump – Cleaning And Inspection For Reuse

Water Pump – Rebuild

Water Pump Assembly – Exploded View

Water Pump Assembly – General Information

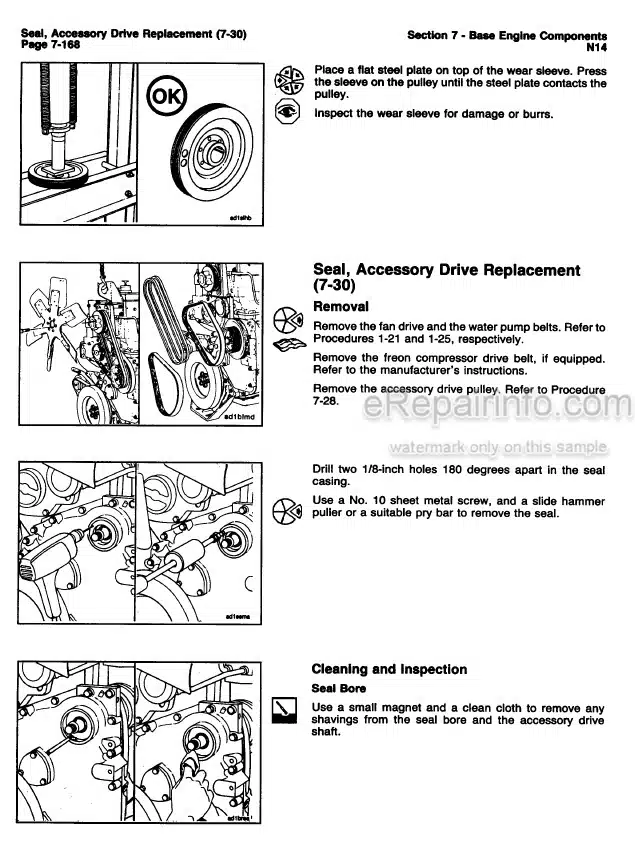

-DRIVE UNITS

Accessory Drive Pulley – Cleaning And Inspection For Reuse

Drive Units – General Information

Fuel Pump And Compressor Drive – Cleaning Inspection For Reuse

Fuel Pump And Compressor Drive – Exploded View

Fuel Pump And Compressor Drive – Rebuild

Hydraulic Pump Drive – Cleaning And Inspection For Reuse

Hydraulic Pump Drive – Exploded View

Hydraulic Pump Drive – Rebuild

Service Tools – Drive Units

-AIR INTAKE SYSTEM

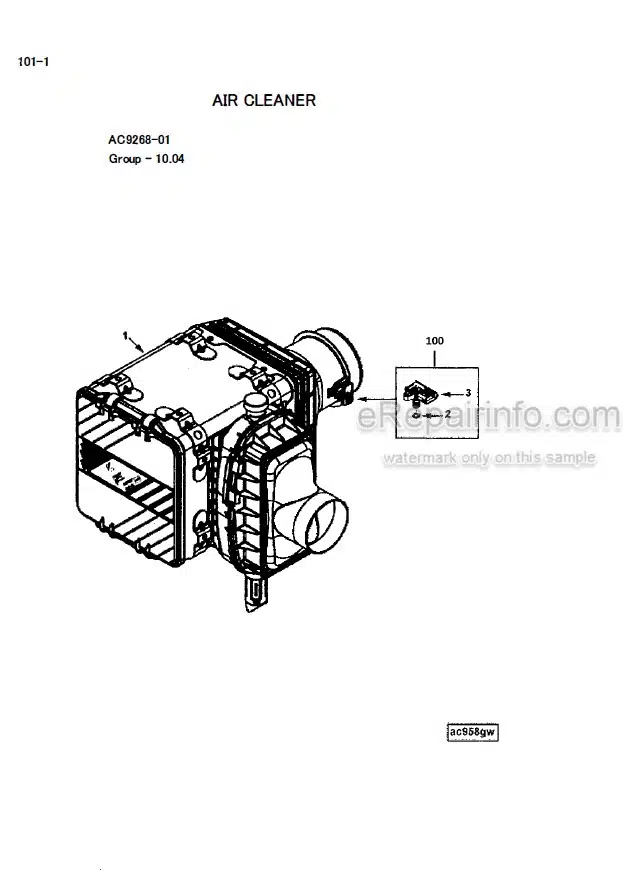

Air Intake System – General Information

Cac Air Intake System Exploded View

Intake Manifold – Cleaning And Inspection For Reuse

Service Tools – Air Intake System

Turbocharger – Cleaning And Inspection For Reuse

-EXHAUST SYSTEM

Exhaust Manifold – Cleaning Inspection For Reuse

Exhaust System – Exploded View

Exhaust System – General Information

-AIR EQUIPMENT

Air Compressor – Cleaning And Inspection For Reuse

Air Equipment – General Information

Compressed Air Systems Flow Diagrams

-ELECTRICAL EQUIPMENT

Alternator Adjusting Link – Cleaning And Inspection For Reuse

Alternator Bracket – Cleaning And Inspection For Reuse

Alternator Bracket (Bus Applications) – Cleaning And Inspection For Reuse

Automatic Belt Tensioner Bracket (Bus Applications) – Cleaning And Inspection For Reuse

Automatic Belt Tensioner (Bus Applications) – Cleaning And Inspection For Reuse

Electrical Equipment – General Information

Starting Motor – Cleaning And Inspection For Reuse

Wiring Diagrams

-ENGINE TESTING

Chassis Dynamometer

Dynamometer Worksheet

Engine Dynamometer – Install Engine

Engine Painting

Engine Run-In Procedure -Chassis Dynamometer

Engine Run-In Procedure – Engine Dynamometer

Engine Run-In Procedure – Without Dynamometer

Engine Storage – Long Term

Engine Storage – Short Term

Engine Testing – General Information

Engine Testing – Specifications

Service Tools – Engine Testing

-INSTRUMENTS AND CONTROLS

Instruments And Controls – General Information

-MOUNTING ADAPTATIONS

Flywheel – Cleaning And Inspection For Reuse

Flywheel Housing – Cleaning And Inspection For Reuse

Flywheel Ring Gear – Replacement

Front Engine Support – Cleaning And Inspections

Mounting Adaptations – Exploded View

Mounting Adaptations – General Information

Rear Engine Power Takeoff – Exploded View

Rear Engine Power Takeoff (Repto) Rebuilding

Service Tools – Mounting Adaptations

-SPECIFICATIONS

Capscrew Markings And Torque Values

Component Specifications And Torque Values

Drive Belt Tension

Injections Timing Codes

Newton-Meter to Foot-Pound Conversation Chart

Pipe Plug Torque Values

Specifications – General Information

Tap-Drill Chart – U.S. Customary & Metric

Weight And Measures – Conversion Factors

-VEHICLE BRAKING

Vehicle Braking – General Information

-SERVICE LITERATURE

Additional Service Literature

Service Literature Ordering Location

COMPONENT MANUFACTURERS: NAMES AND ADDRESSES

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet