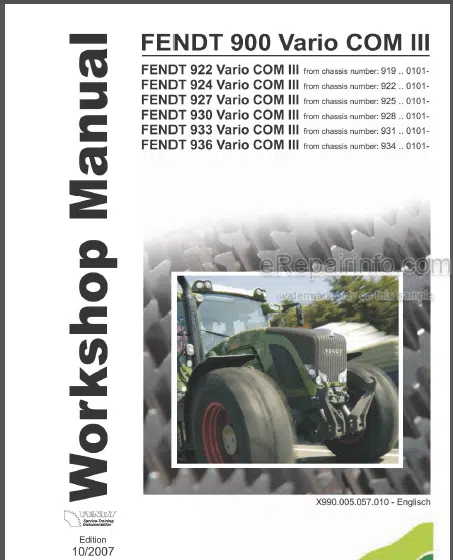

Factory Workshop Manual For Fendt 922 924 927 930 933 936 Vario Com III Tractors. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 859

Hydraulic Diagrams: Yes

Model

Fendt 922, 924, 927, 930, 933, 936 Vario Com III

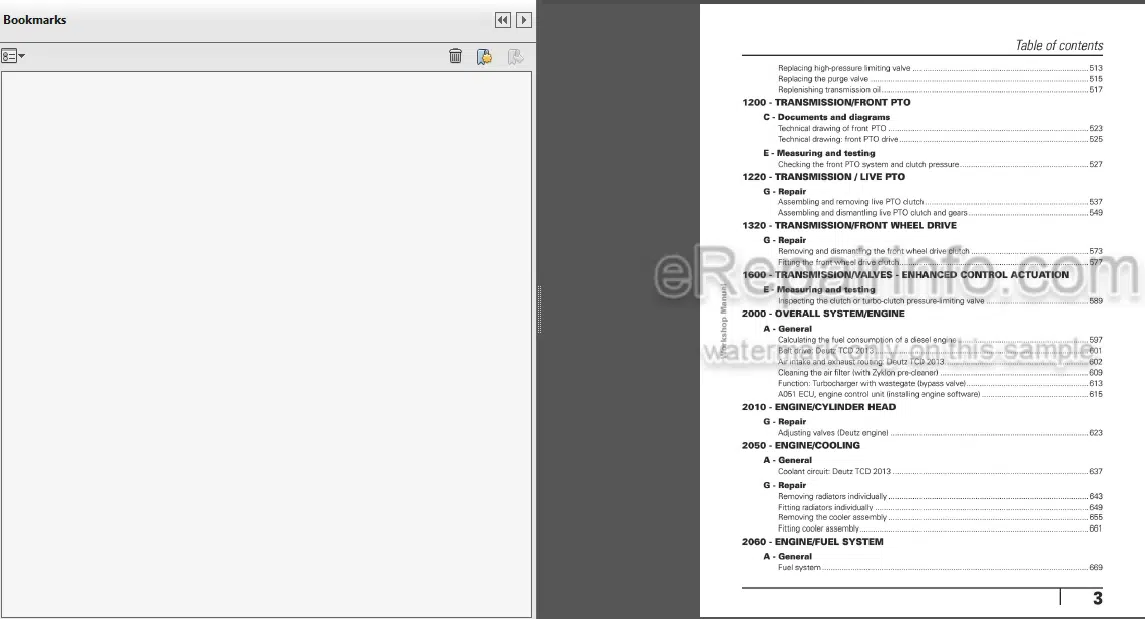

Contents

1.Workshop Manual-Tractor Steering Axle

2.Workshop Manual

3.Workshop Manual-Motor

1.Workshop Manual-Tractor Steering Axle

-Introduction

-Maintenance And Lubricant

Definition Of Viewpoints

Data Plate

Maintenance Points

Maintenance Intervals

Adjustment And Checks

Screw-Locking, Sealing And Lubricating Materials

-Notes On Safety Precautions

Conversion tables

Tightening Torques

-Planetary Reduction

Disassembling

Assembling

-Assembly Instructions For Pre-Assembled Eo-Stand Pipe And Adjustable Fittings

–Suspension

Disassembling

Assembling

Replacing The Lower Wishbone And Joint Case Bushings

-Steering Cylinder

Removal

Adjusting And Installation

Disassembly

Assembly

-Installing And Adjusting Suspension Sensor And Convergence

Removal

Adjusting And Installation

2.Workshop Manual

-Verall System

–Tractor

–General

Component Overview

Documentation Layout

Notes On Documentation

Safety Briefing And Measures

Tightening Torques For Bolts In Nm Ikpm)

History Of The Fendt 900 Vario (Com Iii) Farm Tractor

–Faults

Fault Code Table Fendt 900 Vano – Com Iii

Faults On The Common Rail Diesel Engine (Without Fault Code)

Auto-Guide – Error Code Table

Checking The Satellite Reception By The Auto-Guide System

Setting The Frequency And Channel Of The Radio Module (Tractor And Base Station)

Error Search Plan, Compressed Air System (Trailer Brake)

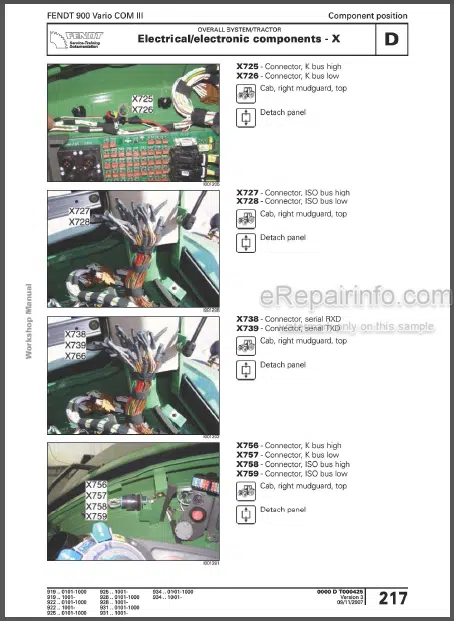

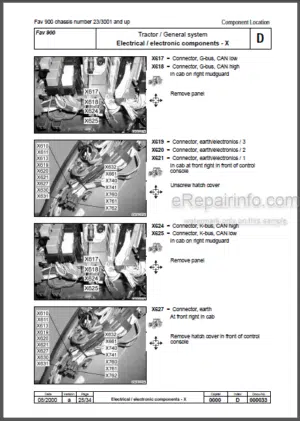

—Component Position

Electrical/Electronic Components – A

Electncal/Electronic Components – B

Electrical/Electronic Components – E

Electrical/Electronic Components – G

Electncal/Electronic Components – H

Electrical/Electronic Components -K

Electrical/Electronic Components – M

Electncal/Electronic Components – S

Electncal/Electronic Components – U

Electncal/Electronic Components – X

Electrical/Electronic Components – Y

Hydraulic Components

–Setting -And Calibrating

General Information On Calibration

Calibration Code 80018002 (Epc Rear)

Calibration Code 90019002 (Front Epc)

Calibration Code 1001 (Crossgate Lever)

Calibration Code (1003 1006) (Linear Module)

Calibration Code 7666 (Front Axle Suspension)

Calibration Code 2401 (Steering Angle Sensor) (Calibration Only Possible For Tractors With Auto-Guide)

Calibration Code 2403 (Auto-Guide Control Valve) (Calibration Only Possible For Tractors With Auto-Guide)

Calibration Code 6034 (Rear Pto Clutch)

Calibration Code /034 (Front Pi U Clutch)

Calibration Code 4001 (Drive Clutch Pedal)

Calibration Code 4002 (Hand Throttle)

Calibration Code 4003 (Travel Range Selector)

Calibration Code 4005 (Foot Throttle/Throttle Pedal)

Calibration Code 4007 (Transmission Ratio Characteristic)

Calibration Code 4009 (Turbo-Clutch Function):

Calibration Code 4010 (Throttle Pedal Resolution)

Calibrating The Heater Valve (No Code)

Calibrating The Speed Display (A007 Instrument Panel And A011 Radar Sensor)

Auto-Guide System: Calibration Of Roll Bias (Dmu) (Only With Omnistar Hp Or Basic Station)

–Overall System/Transmission

— General

Transmission Control System Functional Sequence

Transmission Function Diagram

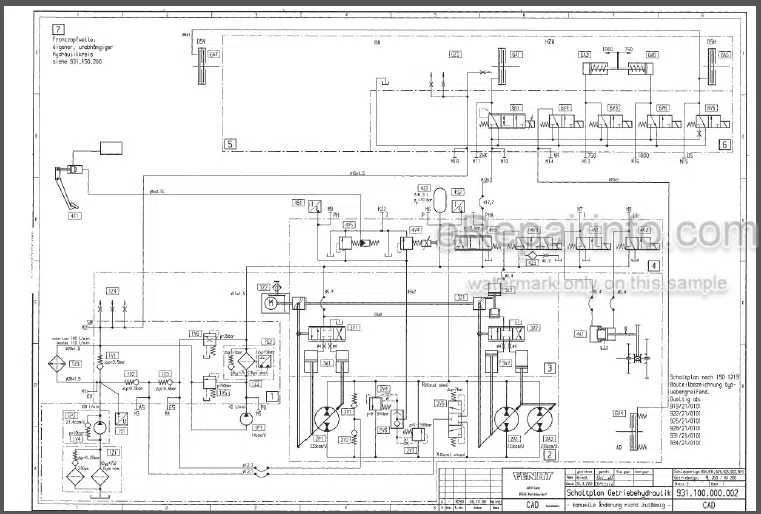

—Documents An Diagrams

93110000-002 – Transmission Hydraulic System DiagramI

—Measuring And Testing

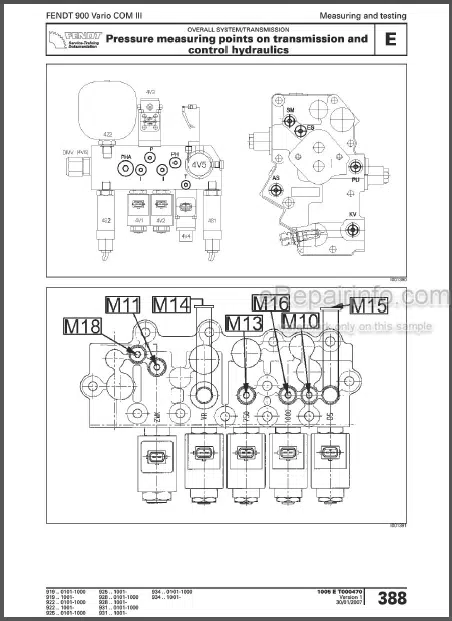

Pressure Measunng Points On Transmission And Control Hydraulics

Measuring Transmission Pressure

Transmission Pressure Measurement (Fax Template)

Enhanced Control Hydraulics Valve Block (Rear Axle)

Valve Block, Inlet/Lubrication

— Transmission/Axle Drive

—Repair

Dismantling And Reassembling Axle Drive

Dismantling Differential Gear

Assembling The Differential Gear

Dismantling The Pinion Shaft

Adjusting And Fitting The Pinion Shaft

Pinion Shaft – Ring Gear Backlash Adjustment

–Transmission/Housing

—Repair

Separating Tractor – Engine And Clutch Housing

Assembling Tractor – Engine And Clutch Housing

–Transmission-Brake System

—Documents And Diagrams

Technical Drawing Of The Rear Wheel Brake

Technical Drawing Of The Wheel Brake Cylinder

—Setting -And Calibrating

Adjusting Rear Wheel Brake

–Transmission/Drive Train

—General

2V3/2V4 High-Pressure Limiting Valve

2V5 Purge Valve (Function)

–Repair

Dismantling The Continuous Drive Train

Fitting The Continuous Drive Train

Replacing High-Pressure Limiting Valve

Replacing The Purge Valve

Replenishing Transmission Oil

–Transmission/Front Pto

—Documents And Diagrams

Technical Drawing Of Front Pto

Technical Drawing: Front Pto Drive

–Measuring And Testing

Checking The Front Pto System And Clutch Pressure

–Transmission I Live Pto

—Repair

Assembling And Removing Live Pto Clutch

Assembling And Dismantling Live Pto Clutch And Gears

–Transmission/Front Wheel Drive

—Repair

Removing And Dismantling The Front Wheel Drive Clutch

Fitting The Front Wheel Drive Clutch

–Transmiss Ion/Valves – Enhanced Control Actuation

—Measuring And Testing

Inspecting The Clutch Or Turbo-Clutch Pressure-Limiting Valve

-Overall System/Engine

–General

Calculating The Fuel Consumption Of A Diesel Engine

Belt Drive: Deutz Tcd 2013

Air Intake And Exhaust Routing: Deutz Tcd 2013

Cleaning The Air Filter (With Zyklon Pre Cleaner)

Function: Turbocharger With Wastegate (Bypass Valve)

A051 Ecu, Engine Control Unit (Installing Engine Software)

-Engine/Cylinder Head

–Repair

Adjusting Valves (Deutz Engine)

-Engine/Cooling

–General

Coolant Circuit: Deutz Tcd 2013

–Repair

Removing Radiators Individually

Fitting Radiators Individually

Removing The Cooler Assembly

Fitting Cooler Assembly

-Engine/Fuel System

–General

Fuel System

–Repair

Bleeding Air From The Fuel System

Measuring Fuel Return Pressure

-Engine/Crankcase

–Repair

Crankcase Air Bleed: Deutz Tcd 2013

-Engine/Lubrication

–General

Diagram: Engine Lubrication

-Overall System/Front Axle

–General

Functional Description: Front Axle Suspension

–Repair

Removing Front Axle

Fitting Front Axle

-Overall System/Steering

–General

Steering Hydraulics

–Repair

Removing The Steering Servo Unit

Installing The Steering Servo Unit

-Overall System/Air Conditioning System

–General

Diagram: Automatic Air Conditioning System

–Repair

Air Conditioning Unit Service Hatch

Removing The Air Conditioning Unit (Hvao

Installing The Air Conditioning Unit (Hvac)

Removing The Air Box (B071, M015, M016)

Installing The Air Box

-Overall System/Cab

–Repair

Removing The Cab

Attaching The Cab

Removing The Cab Roof

-Power Lift/Epc Electro-Hydraulic Control

–Documents And Diagrams

Epc Valves

–Repair

Removing The Rear Ehr Valve

Installing The Rear Ehr Valve

Removing The Central Ehr Valve

Installing The Central Ehr Valve

Dismantling The Rear Pressure-Limiting Valve Dw Y062

Assembling The Rear Pressure-Limiting Valve Dw Y062

-Power Lift/Hydraulic Lift

–Documents And Diagrams

Technical Drawing Of The Hydr Lower Link Support

–Repair

Removing The Understeer Stabiliser Solenoid Valve Y082/Y083

Fitting The Understeer Stabiliser Solenoid Valve Y082/Y083

-Overall System/Compressed Air System

–Documents And Diagrams

Diagram Of Compressed Air System (1-Circuit And 2-Circuit Brake Systems)

Wiring Diagram: Fendt 900 Com Iii Compressed Air System (4-Circuit)

–Measuring And Testing

Compressed Air System (Area: Front Wheel Brake, Rear Wheel Brake, Hand Brake)

Compressed Air System (Area: Trailer Brake)

-OVERALL SYSTEM/ELECTRICAL SYSTEM

–Measuring and testing

A007 instrument panel

A009 actuator unit

A011 radar sensor (optional)

A013 PCB, microfuse

A036 (A037) instrument panel

A038 ECU central electrical system(area: function; +supply; K bus)

A038 ECU central electrical system(area: driving light, position light, direction indicator)

A038 ECU, central electrical system(area: horn, rotating beacon, wide vehicle marker light)

A038 ECU central electrical system(area: work light)

A038 ECU central electrical system(area: intenor lighting)

A038 ECU central electrical system(area: wipers, rear window heater,mirror heater)

A038 ECU, central electrical system(area: automatic air conditioning system)

A038 ECU, central electrical system(area: sockets)

A038 ECU, central electrical system(area: starter, tank pump)

A038 ECU, central electrical system(area: reverse operation (RUFA)

A039 multifunction armrest (MFA) and driver seat

A050 ECU, basic control unit (area: +power supply)

A050 ECU, basic control unit (area: CAN bus connection)

A050 – ECU, basic control unit (area: Hydraulics protection and supply (working and steering hydraulics))

A050 – C CU basic control unit (area- rear power lift CPC snd rear power lift additional functions)

A050 ECU basic control unit (area: electr auxiliary control valves Bosch SB23 EHS 2)

A050 ECU, basic control unit (area: standard front power lift)

A050 ECU, basic control unit (area: enhanced control front power lift)

A050 ECU basic control unit (area: front axle suspension – 1-circuit brake system)

A050 Ecu, Basic Control Unit (Area: Front Axle Suspension, 2-Arcuit Brake System)

A050 Ecu, Basic Control Unit (Area: Rear Pto “Hzw”)

A050 Ecu, Basic Control Unit (Area: Front Pto)

A050 Ecu, Basic Control Unit (Area: 4Wd And Diff Lock (Front And Rear))

A050 Ecu, Basic Control Unit (Area: Vario Transmission Control)

A050 Ecu, Basic Control Unit (Area: Brake)

A050 Ecu, Basic Control Unit (Area: Autoguide ‘auto Steering Assist System*)

A051 Ecu, Edc Engine Control Unit (Pin Assignment)

A051 Ecu, Edc Engine Control Unit, “Engine Controller*

A053 Air Conditioning System (Hvac), Area: Fan (Continuous)

A053 Air Conditioning System (Hvac), Area: Evaporator Sensor

A053 Air Conditioning System (Hvac), Area: Heater Valve ‘stepper”

A05S Autoguide Topdock (Receiver Unit)

A059 Autoguide Terminal

B002 Sensor, Front Pto Stub Shaft Speed

Bow Vacuum Switch (Engine-Air Filter)

B008 Sensor, High Pressure 1 (Transmission)

B009 Sensor, Discharge Temperature

BOЮ Sensor, Engine Speed (To Transmission Control)

B013 Sensor, Hydraulic Oil Temperature

B014 Sensor, Hydrostatic Collecting Shaft

B015 – Sensor, Bevel Pinion

B016 Sensor, Travel Range Detection

B017 Dutch Pedal Sensor

B019/B060 Compressed Air Supply Sensor

B020 Rear Pto Stub Shaft Speed Sensor

B021 Rear Pto Clutch Speed Sensor

B030 Rear Power Lift Position Sensor

B031/B032 Right/Left Draught Sensing Pin

B034 Fuel Level Sensor (Immersed Tube Sensor)

B039 High Pressure 2 (Push/Pull Detection)

B040 Front Power Lift Position Sensor (For Front Power Lift Enhanced Control Only)

B055 Foot Throttleahrottle Pedal Sensor

B019/B060 Compressed Air Supply Sensor

B063 Filter Contamination Pressure Switch (Hydraulic Circuit)

B066 Sensor, Wheel Position Left

B067 Sensor, Steering Angle

B068 Sensor, Wheel Position Right

B071 Output Temperature Sensor (Automatic Air Conditioning System)

B073 Solar Sensor (Automatic Air Conditioning System)

B074 Interior Temperature Sensor

D076 Exterior Temperature Sensor (Automatic Air Conditioning System)

B077 Electr Viscous Fan (Magnetic Clutch Speed Sensor)

B081 Steering Wheel Sensor

B083 Immobiliser Control Unit

B084 Hydraulic Oil Level Sensor

B085 Edc (Camshaft) Sensor

B086 Rail Pressure Sensor (High Pressure)

B087 Fuel Low Pressure Sensor (Fuel Pressure After The Fuel Filter)

B088 Edc (Crankshaft) Sensor

B089 Coolant Temperature Sensor

B090 Engine Oil Pressure Sensor

B091 Water In Fuel Sensor

B092 Boost Pressure/Charge Air Temperatjre Sensor

E – Work Lights (Xenon)

E063 Heater Element (Air Dryer)

G001 Battery / K068 Battery Disconnect Relay

G002 / G004 Alternator Right/Left

M001 Starter

M002 Front Wipar Motor

M003 / M005 Front/Rear Wiper Pump

M004 Rear Wiper Motor

MOЮ Fuel Pump ‘circulation Pump’

M017 Primary Fan ‘intake Air*

R002 Heater Flange

S005/S006 Right/Left Brake Switch

S017 Transmission Oil Contamination Switch

S019/S020 Left/Right Rear Pto (External) Switch

S021/S022 Front Power Lift Raise/Lower Switch (External)

5025 Pressure Monitor Control Pump (Pr? Switch

5026 Auxiliary Pump Flow Monitor (Ph)

S027/S028/S029/S030 Rear Power Lift Switch (External)

S034 Coolant Level Switch

S047 Engine Brake Switch

S067/S0&8 Switch (External), Raise/Lower Valve Actuation

S075 Emergency Steering Pump (Pnl) Flow Monitor

S079 Steering Column/Quick Reverse Switch (Area: Quick Reverse)

5079 Steering Column/Quick Reverse Switch (Area: Steering Column)

5080 Hand Brake Switch

S086/S087 Right/Left Brake Wear Switch

X007 Implement Socket “Black*

X008 Counter Input (Onboard Computer) “Blue*

X015 External Control, Rear Epc (External Position Sensor)

X015 External Control (Range: 3Rd And 4Th Hydraulic Circuit) (Professional Version Only)

X017 Front Socket (With Front Power Lift Only)

X018 Trailer Socket

X028 Iso Bus Implement Socket (In Cab)

X400 Iso Bus Pcb (Implement Socket)

X1040 Ads Socket (Antilock System On Trailer)

Y002/Y003 Solenoid Valve, Travel Range L/Ll

Y004 Turbo Clutch/Transmission Neutral Solenoid Valve

Y005 Speed Governor Solenoid Valve

Y008 Rear Pto Clutch Solenoid Valve

Y009 4Wd Solenoid Valve

Y010 Differential Lock Solenoid Valve (Front And Rear}

Y011 Front Pto Clutch Solenoid Valve

Y012 Charging Solenoid Valve

Y021/Y022 Raise/Lower Solenoid Valve (Standard Front Power Lift)

Y021 ‘sa-Da Switchover* Solenoid Valve (Front Power Lift Enhanced Control)

Y022 Field Pressure Control Solenoid Valve (Front Power Lift Enhanced Control)

Y024 Magnetic Clutch (Air Conditioning Compressor)

Y026/Y027 Solenoid Valve, Rear Pto Stage 540 (540E)/ 1000

Y032 Control Pressure Solenoid Valve

Y053 Active Hold Function Solenoid Valve,

Y055 ‘Sa-Da Switchover’ Solenoid Valve, Rear Ehr

Y060/Y061 Rear/Front Hydraulic Oil Pre-Heater Solenoid Valve

Y062 Field Pressure Control Solenoid Valve (Rear Power Lift)

Y063 Wobble Stabiliser Solenoid Valve

Y064 Load Pressure/Lower Solenoid Valve

Y065 Raise Suspension Solenoid Valve

Y067 Lock Suspension Solenoid Valve

Y070 Ehr Cut-Off Valve (Front Power Lift Enhanced Control)

Y071/Y072/Y0747Y075/Y076/Y078/Y079/Y080 Auxiliary Control Valve

Y077 Ehr Cut-Off Valve (Rear Power Lift)

Y082/Y083 Lower Link Stabiliser L/Ll Soleno D Valve

Y084 Control Pressure Increase Solenoid Valve

Y085 Solenoid Valve For *Autoguide* Automatic Track Guide Switch-Off

Y086 Steering Disconnect Solenoid Valve

Y087 Autoguide Control Valve

Y091 Dispensing Unit (Fuel)

Y094 Exhaust Gas Recirculation Actuator Motor

Y095 Y098, Y100 Y101 Injector 1 6

-Electrical System/Starter Lockout

–Setting -And Calibrating

Teaching In The Vehicle Key

Teaching In B083 Immobiliser Control Unit And/Or A051 Ecu, Engine Control Unit

-Hydraulic Pump Installation/Ls Pump

–Repair

Removing The Ls Pump

Installing The Ls Pump

-Hydraulic Pump Installation/Steering Pump

–Repair

Removing The Wheel-Driven Emergency Steering Pump

Installing The Wheel-Driven Emergency Steenng Pump

-Overall System/Hydraulic Equipment

–General

Pressure Regulation – Pr (Ls Pump)

Hydraulic Comparison: Fendt900 Com Iii To Fendt900 Com Ii

Technical Specification: Working And Steering Hydraulics

Overview Of Pressure Measuring Points

External Pressure Rise (Power Beyond)

–Documents And Diagrams

Hydraulic Circuit Diagram With Legend

–Measuring And Testing

Test Report, Fax Template

-Hydraulic Equipment/Hydraulic Connections

–Repair

Removing Rear Hydraulic Quick-Release Coupler

Installing Rear Hydraulic Quick-Release Coupler

-Hydraulic Equipment/Central Control Block <Zsb)

–General

Central Control Block

-Hydraulic Equipment/Valve Fitting

–General

Control Valves Sb 23 Ls-Ehs 2/Emergency Mode

Control Pressure

Oil Pre-Heater

–Documents And Diagrams

Control Valves Sb 23 Ls-Ehs 2

–Repair

Removing Rear Control Valve

Installing Rear Control Valve

Removing Central Control Valve

Installing Central Control Valve

Dismantling Rear Entry Plate

Reassembling Rear Entry Plate

Dismantling Rear End Plate

Reassembling Rear End Plate

-Service/Special Tools

–General

Special Tools

Special Tools For Common Rail

-Service/Serdia – Deutz Engine Diagnostics Program

–General

Engine Diagnostics Using The Deutz Diagnostics Program (Serdia)

3.Workshop Manual-Motor

Foreword

General

-User Notes

General

Specifications

Safety Regulations And Rules For The Prevention Of Accidents

Disposal Regulations

Operating Manual And Workshop Manual

Job Cards

Explanation Of Symbols

-Technical Data

Testing And Setting Data

Tightening Specifications

-Job Card Overview

Sorted Alphabetically

Sorted Numerically

Job Card References

-Job Cards

Commercial Tools

Special Tools

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet