Factory Workshop Manual For Fendt Favorit Farmer Vario Series Tractors. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Factory Operating Manual For Fendt Favorit Farmer Vario Series Tractors. Manual for owners and operators. It contains important information and instructions for maintenance description of the functions and capabilities of the system. Description of possible faults/problems and their solution.

Format: PDF

Language: English

Pages:

Bookmarks: Yes

Searchable: Yes

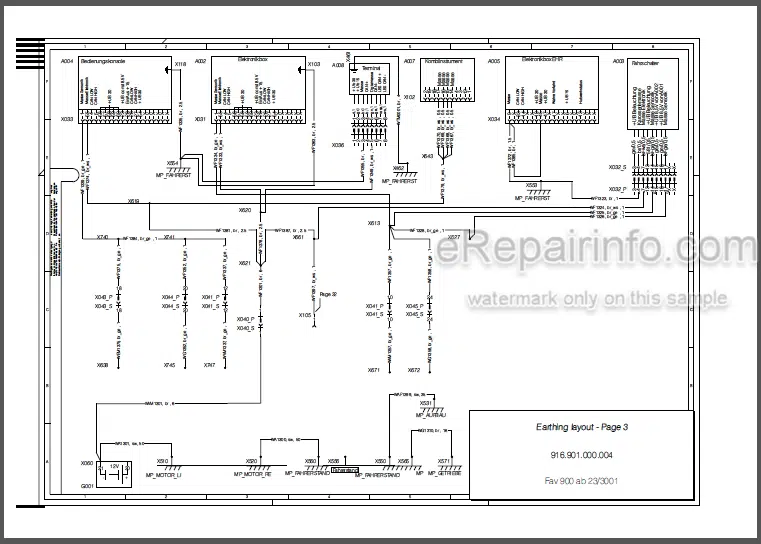

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Fendt Favorit 711, 712, 714, 716, 916, 920, 924, 926

Contents

1.Operating Manuals

2.Standard Times

3.Wiring Diagrams

4.Service-Trainings

5.Technical Data

6.Workshop Manuals

Workshop Manual-Favorit 916-920-924-925-Tractor Steering Axle

INTRODUCTION

MAINTENANCE AND LUBRICANT

Definition of viewpoints

Data plate

Maintenance points

Maintenance intervals

Conversion tables

Tightening torques

Screw-locking, sealing and lubricating materials

NOTES ON SAFETY PRECAUTIONS

STEERING CYLINDER

Disassembly

Installation

PLANETARY REDUCTION

Disassembly

Assembly

STEERING CASE

Removal

Assembly

2.Workshop Manual-Motor Deutz

Specification Data

Schematic For Valve Clearance Adjustment

Tightening Order For Cylinder Head Bolts

Tightening Order For Rocker Casing Bolts

Determining Commencement Of Delivery

Determining Shim Thickness For Commencement Of Delivery. Bosch Injection Pump

Determining Shim Thickness For Commencement Of Delivery With Bfm 2013 Bosch Injection Pump Replacement In Case Of Service. Basic Dimension L0 = 117.5 Mm

Determining Corrected Installation Dimension And Ep Code For Bosch Injection Pump.

Key To Symbols

Checking And Adjusting

Valve Clearance

Injector

Compression Pressure

Repair Of Components

Crankcase

Front Cover / Lube Oil Pump

Crankshaft

Starter Ring Gear / Flywheel

Connecting Rod

Piston

Cylinder Head

Timing Case

Camshaft

Rocker Casing

Oil Cooler Housing

Injector

Control Rod

Air Compressor

Fan Mounting

Idler Pulley

Mass Balancing Shaft

Hydraulic Pump Drive

Hydraulic Pump With Fastening Flange

Disassembly And Reassembly Of Complete Engine

Removing And Installing Components

Poly-V-Belt

Idler Pulley

Guide Pulley

Fuel Pump

Alternator

Coolant Pump

Fan Drive

Injector

Starter

Thermostat

Exhaust Turbocharger

Flame-Type Heater Plug System

Engine Shutdown Solenoid

Governor

Crankcase Breather

Fuel Filter

Oil Pressure Sensor

Charge Air Temperature Sensor

Coolant Temperature Sensor

Shaft Seals

Injection Pump

Tools

Order All Your Special Tools

Commercial Tools

Special Tools

3.Workshop Manual-Favorit 711, 712, 714, 716

-Tractor

General System

-Transmission

Transmission Control Unit

Differential

Axle Drive

Handbrake

Housing

Brake System

Vario Transmission Unit

Emergency Control

Clutch Actuation System

Cardan Brake

Ml Range Control

Front Pto

Live Pto

Front-Wheel Drive

Hydrodamp

Hydraulic Pump

Transmission Lubrication System

Pump Drive

Ml Variable-Displacement System

Enhanced Actuation System Valves

Enhanced Actuation System Pipes

-Engine

Cylinder Head

Speed Adjustment

Cooling System

Fuel System

Exhaust Brake

Cold-Start System

Intercooler

Crankcase

Engine Preheater

Lubrication

Injection Pump

Injectors

Governor

-Front Axle

Front Axle Support

Axle Housing

Suspension

Suspension Valve Fitting

Suspension Pipe

Track Rod

Steering Cylinder

Frame

Cardan Shaft

Diff Lock Actuation System

-Steering

Steering Wheel

Hydr Steering Assembly

-Vehicle Body

Body

Driver’s Seat

Hitch

Hitch Trailer Coupling

Cab Mount, Suspension

-Air Conditioning

Compressor Drive

Coolant Lines

Evaporator

Condenser

Electric Cables

-Cab

Heater

Ventilation

Windscreen Wiper

Cable Loom

-Power Lift

Electrohydraulic Control Epc

Electrohydraulic Remote Control

Power Lift

-Three-Point Hitch

Lift Arms

Support

-Air Compressor

Compressor

Brake Fittings

Lines

Electrical Actuation System

Air Tank

-Front Loader

Mounting Frame

Hydr Implement Actuation System

3Rd Hydr Circuit

Multi-Coupling

Pipes

Lift Cylinder

-Electrics

Generator

Starter Inhibitor

Fuses

Battery System

Starter Motor System

-Front Power Lift

Power Lift

Electrohydraulic Remote Control

Cylinder

Pipes

Enhanced-Control Power Lift

Frame

-Hydr Pump Assembly

Ls Pump

Transmission Pump

Steering Pump

-Hydraulic Pipes

Basic Circuit

Power Lift

With Oil Cooler

Hydr Trailer Brake

Steering

Reversing System

-Hydr Equipment

Hydr Connections

Central Control Block (Zsb)

Valve Fitting

External Hydraulic Supply

Valve Supplement

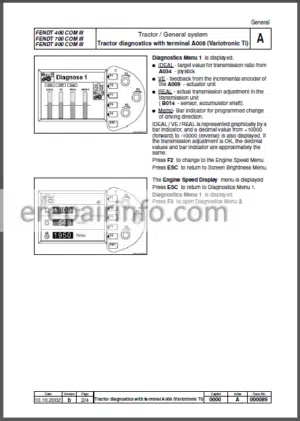

-Electronics

Instrument Panel

Vario Terminal

Lbs – Agricultural Bus System

Transducer

Radar Sensor

E-Box

Transmission Actuator Unit

Joystick

Control Unit

Engine Edc

Ecu, Power Lift

-Service

Special Tools

Fendias

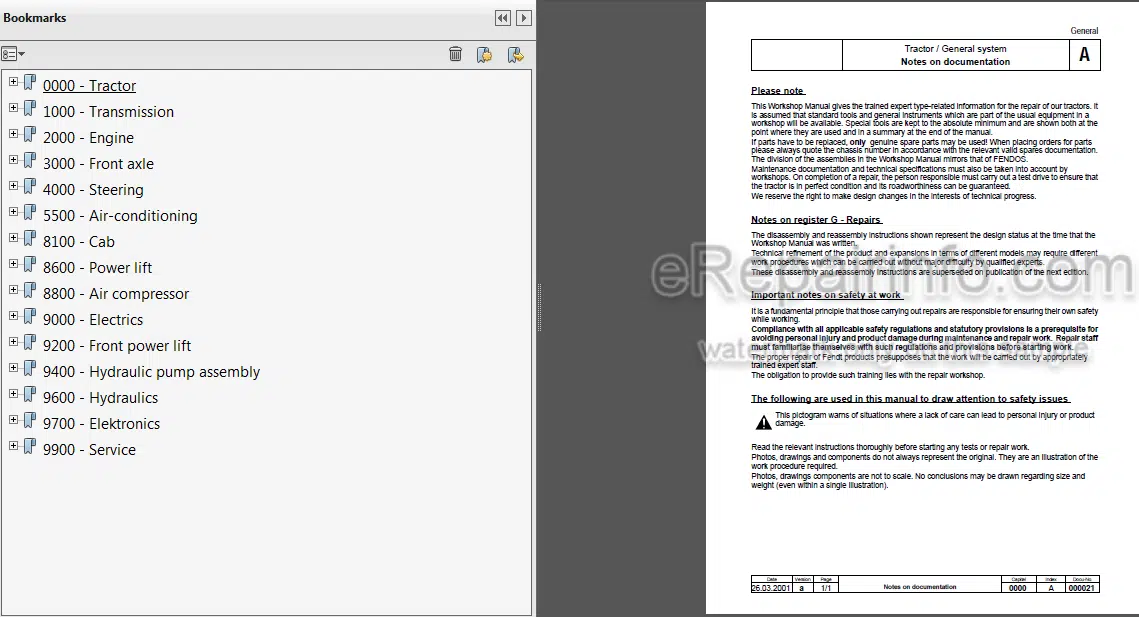

4.Workshop Manual-Favorit 916, 920, 924, 926

-Tractor

General system

-Transmission

Transmission control unit

Differential

Axle drive

Handbrake

Housing

Brake system

Vario transmission unit

Emergency control

Clutch actuation system

Cardan brake

ML range control

Front PTO

Live PTO

Front-wheel drive

Hydrodamp

Hydraulic pump

Transmission lubrication system

Pump drive

ML variable-displacement system

Enhanced actuation system valves

Enhanced actuation system pipes

-Engine

Cylinder head

Speed adjustment

Cooling system

Fuel system

Exhaust brake

Cold-start system

Intercooler

Crankcase

Engine preheater

Lubrication

Injection pump

Injectors

Governor

-Front Axle

Front Axle Support

Axle Housing

Suspension

Suspension Valve Fitting

Suspension Pipe

Track Rod

Steering Cylinder

Frame

Cardan Shaft

Diff Lock Actuation System

-Steering

Steering Wheel

Hydr Steering Assembly

-Vehicle Body

Body

Driver’s Seat

Hitch

Hitch Trailer Coupling

Cab Mount, Suspension

-Air Conditioning

Compressor Drive

Coolant Lines

Evaporator

Condenser

Electric Cables

-Cab

Heater

Ventilation

Windscreen Wiper

Cable Loom

-Power Lift

Electrohydraulic Control Epc

Electrohydraulic Remote Control

Power Lift

-Three-Point Hitch

Lift Arms

Support

-Air Compressor

Compressor

Brake Fittings

Lines

Electrical Actuation System

Air Tank

-Front Loader

Mounting Frame

Hydr Implement Actuation System

Rd Hydr Circuit

Multi-Coupling

Pipes

Lift Cylinder

-Electrics

Generator

Starter Inhibitor

Fuses

Battery System

Starter Motor System

-Front Power Lift

Power Lift

Electrohydraulic Remote Control

Cylinder

Pipes

Enhanced-Control Power Lift

Frame

-Hydr Pump Assembly

Ls Pump

Transmission Pump

Steering Pump

-Hydraulic Pipes

Basic Circuit

Power Lift

With Oil Cooler

Hydr Trailer Brake

Steering

Reversing System

-Hydr Equipment

Hydr Connections

Central Control Block (Zsb)

Valve Fitting

External Hydraulic Supply

Valve Supplement

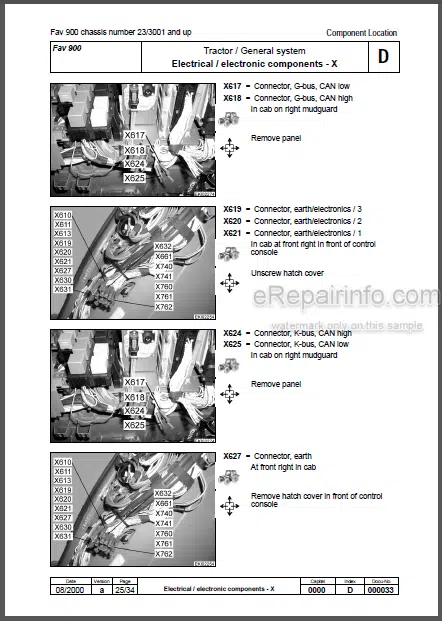

-Electronics

Instrument Panel

Vario Terminal

Lbs – Agricultural Bus System

Transducer

Radar Sensor

E-Box

Transmission Actuator Unit

Joystick

Control Unit

Engine Edc

Ecu, Power Lift

-Service

Special Tools

Fendias

5.Workshop Manual(Transmissions-Favorit 500 Series)

Transmission

Disconnect Favorit 509 C – 515 C Tractor

Removing And Fitting Turboclutch

Disconnecting Tractor At Clutch Housing/Manual Transmission Joint In Favorit 509 C To 515 C

Removing And Fitting Transmission In Xylon 520 To 524

Repairing Powershift Transmission

Page_Leftright:M-Chapter Ne1 Power Flow Of Powershift Gears

Repairing P.T.O. Clutch

P.T.O. Gear Train With 750/1400 And 540/1000 P.T.O. Gear

Check Drive Clutch Cooling System

Check/Adjust Drive Clutch Operation

Bleed Drive Clutch Operation System (Favorit 509 C To 515 C)

Check Operating Pres-Sure Of Drive Clutch

Repair Drive Clutch

Disconnecting Tractor At Manual Transmission/ Rear-Axle Housing Joint In Favorit 509 C To 515 C

Repairing Manual Transmission

Gearshift (Manual Trans-Mission)

Front-Wheel Drive

Differential

Front-Wheel Drive

Differential

Brake System

Axle Drive

Front P.T.O.

6.Workshop Manual-Motor MAN D 0836 LE

Specifications

Service Data

Tightening Torque Values

Turbocharger, Troubleshooting

View Of Engine D 0836 Le 501

Checking Compression

Checking Valve Timing

Setting Valve Clearance

Reassembling And Refitting Intake Pipe

Removing And Refitting Turbocharger

Removing And Refitting Manifold

Removing And Refitting Cylinder Head

Dismantling And Reassembling The Rocker Arm Assembly

Removing And Refitting Valves

Removing And Refitting Valve Guides

Replacing Valve Seat Insert

Re-Machining The Valve Seat

Reseating Valves

Replacing Engine Coolant

Removing And Refitting The Thermostatic Valve

Removing And Refitting Water Pump

Removing And Refitting Coolant Pipe

Layout Of Fuel System

Fuel Pre Filter / Cartridge

Purging Air From Fuel Supply System

Removing And Refitting Heater Plug

Power – Belts

Removing And Refitting The Starter Engine

Removing And Refitting Generator

Removing And Refitting Air Compressor

Replacing Crankshaft Front Seal

Removing And Refitting Flywheel

Removing And Refitting Crankshaft Seal (Flywheel)

Removing And Refitting Flywheel

Removing And Refitting The Timing Case

Removing And Refitting Camshaft

Removing And Refitting Intermediate Flange

Removing And Refitting The Con-Rod Bearing Shells

Removing And Refitting The Crankshaft

Removing And Refitting Con-Rod

Removing And Refitting The Piston Rings

Replacing Cylinder Liners

Layout Of Engine Lubrication

Replacing Oil Filter

Removing And Refitting Oil Cooler

Removing And Refitting Oil Pan

Removing And Refitting Oil Pump

Removing And Refitting Splash Nozzle

Checking Start Of Delivery Vp44

Fuel Injection Pump Vp 44 – Mounting – Dismounting

Checking Injection Nozzles

Replacing Injection Valve With Needle Motion Sensor

Special Tools

7.Workshop Manual-Tractor Steering Axle(Version AS 2025,2035,2045,2055,2060,2075)

-INDEX

Preface

General Working Instructions

Important Information Concerning The Work Safety

Lubrication And Maintenance Instructions

Examples Of Gear-Tooth Contact Patterns For The Gleason Gear Tooth System

Lettering Of The Type Plate And Information For Spare Parts Ordering

Conversion Table For Dimensional Units

Denomination Of Standard Dimensions

Torque Limits For Screws

-SPECIAL TOOLS

List Of Tools – Disassembly

List Of Tools – Assembly

Tools – Illustrations

-DISASSEMBLY

STEERING SYSTEM

OUTPUT

Planet carrier

Internal Gear / Multi-Disc Brake

Version “With” Multi-Disc Brake

Version “Without” Multi-Disc Brake

Hub

Joint Housing – Steering Sensor System

Swivel Bearing

Bearing Bolt – Version “A” (Standard – Without Steering Sensor)

Bearing Bolt – Version “B” (“With” Angle Sensor)

Bearing Bolt – Version “C” (“With” Dual Sensors)

DIFFERENTIAL

Version “DZ 250”

Version “DZ 400/500”

Version “DHL with DZ 250” (hydr. 100% lock)

Version “DHL with DZ 400/500 (hydr. 100% lock)

Version “DHL with DZ 750 (hydr. 100% lock)

INPUT FLANGE / PINION

Version “A”

Version “B”

Version “C”

SELF-ALIGNING BEARING

Version “A” (Top-Mounted Self-Aligning Bearing)

Version “B” (Twin Bearing Support)

Version “C” (Unilateral Axle Mounting)

Assembly

Input Pinion

Determining The Adjusting Spacer For The Contact Pattern Of The Bevel Gear Set

Setting The Rolling Moment Of The Input Pinion Bearing

Differential

Dz 250 (Multi-Disc Self-Locking Diff.) Or D 250 (Standard Diff.)

Dhl (Diff. Hydr. Power Shiftable

Dz 400/500 Or D 400/500

Dhl With Dz 400/500 Or D 400/500

Dhl With Dz 750 Or D750

Setting The Backlash Of The Bevel Gear Set And The Rolling Moment Of The Differential Bearing

Check Dhl (100% Lock) For Tightness

Check Backlash And Contact Pattern Of The Bevel Gear Set

Mounting Input Flange And Shaft Sealing Ring

Version “A”

Version “B”

Version “C”

OUTPUT

Pre-Assembly Of Axle Casing

Mounting The Foot Plate Of The Angle Sensor

Joint Housing

Swivel Bearing

Hub

Internal Gear / Multi-Disc Brake

Standard Version “Without” Multi-Disc Brake

Version “With” Multi-Disc Brake

Setting The Piston Stroke

Checking The Hydraulic Brake System For Tightness

Planet Carrier

Version “A” (Planet Gear Bearing With Cylindrical Roller Bearing)

Version “B” (Planet Gear Bearing With Angular Roller Bearing)

Steering Angle Sensor System

Version “With” Angle Sensor

Version “With” Dual Sensors

Checking The On/Off – Function Of The Inductive Sensors

Steering System

Steering Cylinder

Version “A”

Version “B”

Setting And Checking The Steering System

Basic Setting Of The Track

Setting The Steering Angle

Checking The Steering System For Tightness

Self-Aligning Bearing

Version “A”

Version “B”

Version “C”

Version “D”

Breather

Version “A” (Plug-Type Version)

Version “B” (Screw-Type Version)

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet