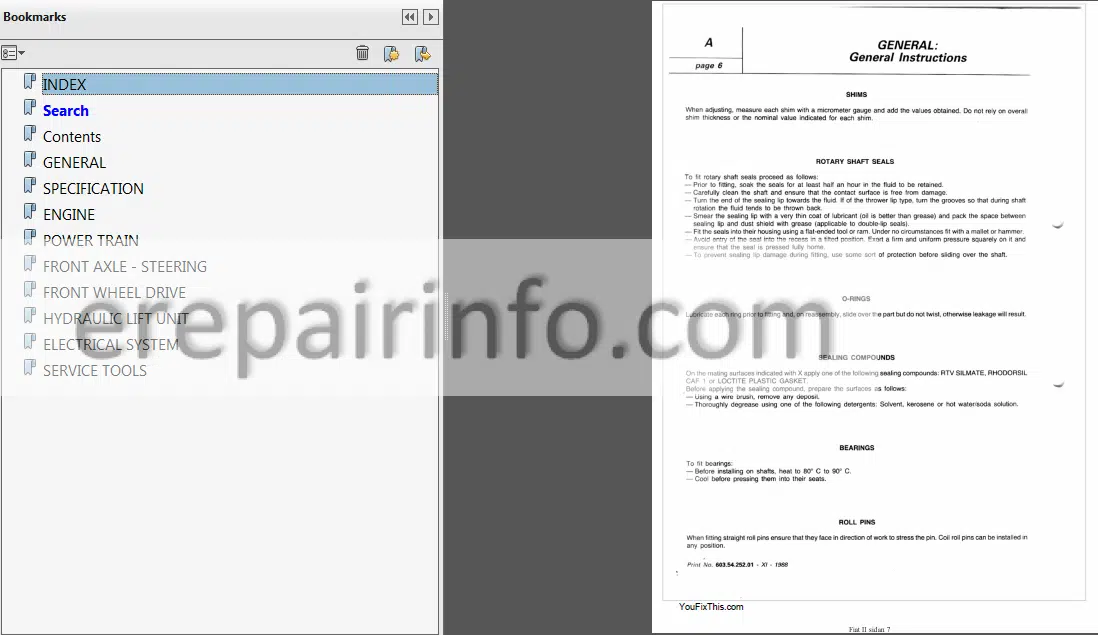

Factory Service Repair Manual For Fiat 115-90 130-90 140-90 160-90 180-90 and Turbo series Tractors. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 507

Bookmarks: Yes

Searchable: Yes

Number: 603.54.252.01

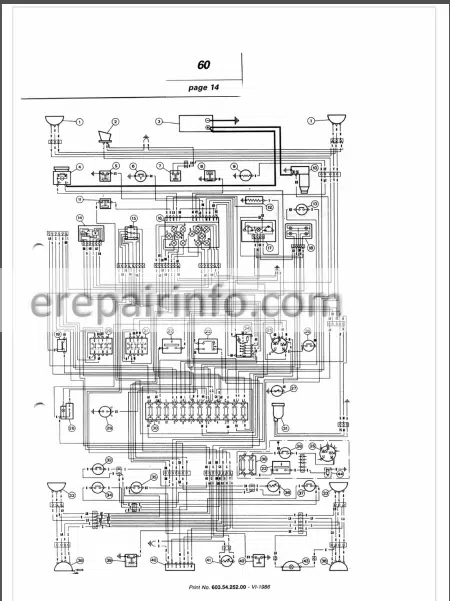

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Fiat Tractor

115-90

130-90 Turbo

140-90 Turbo

160-90 Turbo

180-90 Turbo

Contents

- – GENERAL

General instructions

Safety precautions

— SPECIFICATIONS

Identification data

Weights

Engine

Power Train – Brakes – Steering

Front axle – Front wheel drive – Rear wheels – Power take-off – Lift

Towing attachments – Ballasting – Body • Electrical system – Lighting – Instrument and accessories – Tire sizes

Mod 115-90H

Mam dimensions

Power train schematics

Capacities

Ricofield version tractors

Mods 160-90 Turbo and 180-90 Turbo Late mod engine - – ENGINE: SPECIFICATIONS AND DATA

Engine Block – Cylinder Head

Crank Gear

Valve gear

Lubncationsystem

Cooling System

Fuel system

Torque Data

Fasteners

Engine Sections - – ENGINE: DESCRIPTION – PERFORMANCE DATA -REMOVAL – INSTALLATION

Description

Engine Performance Data

Turbocharged Engine Performance Test

Compression Test

Removal – Installation - – ENGINE: ENGINE BLOCK – CYLINDER HEAD

Cylinderimers

Cylinder Head

Ol Pan-160-90 Turbo And 180-90 Turbo - – ENGINE: VALVE GEAR

Camshaft – Valves, Guides And Springs

Tappets, Pushrods And Rockers

Valve Gear Train - – ENGINE: CRANKGEAR

Crankshaft

Main and big end bearings and caps Pistons and nngs

Connecting rods

Flywheel - – ENGINE: FUEL SYSTEM

Air cleaner

Fuel filters

Turbocharger components – 130-90 Turbo, 140-90 Turbo 160-90 Turbo and 180-90 Turbo

Turbocharger Description and operation ¦

General

Removal and replacement

Garrett Turbocharger Service

Holset Turbocharger Service

Turbocharger Trouble Shooting

Pump Removal And Replacement - – ENGINE: LUBRICATION SYSTEM

Lubrication System Diagram 115-90

Lubrication System Diagram 130-90 And 140-90 Turbo

Lubrication System Diagram 160-90 Turbo

Lubrication System Diagram 180-90 Turbo

Oil Pump – Oil Filter

Heat Exchanger – Low Oil Pressure Indicating System - – ENGINE: COOLING SYSTEM

Cooling System Diagram

Description Water Pump

Radiator

Belt Tension Adjustment – Water Temperature Gauge Thermostat

Water Pump – Late Mods 115-90 130-90 Turbo And 140-90 Turbo - – POWER TRAIN: SPECIFICATIONS AND DATA

Clutch

Transmission And Splitter

Power Shift Transmission

Creeper

Reverser

Rear Bevel Drive And Differential

Brakes

Final drive

Power takeoff

Torque data

Longitudinal And Cross Sections Through Powertrain

Power Train Cross Section

Late Model Master Clutches

Front PTO

Late Model PTO Clutch - – POWER TRAIN: REMOVAL AND INSTALLATION

Platform Removal And Installation

Platform Removal And Installation Together

With Fiat Cab - – POWER TRAIN: MASTER CLUTCH

Removal And Installation

Valeo 12-/12* Clutch Service

Valeo 12″/12* Clutch Adjustment

Luk 12-/12* Clutch Service

Luk 12″/12“ Dutch Adjustment

Clutch Linkage Adjustment

Section Through Valeo 14′ Clutch

Section Through Luk 14″ Clutch

Luk 12* * 12- Clutch Service

Luk 12” ¦ 12* Clutch Adjustment

Master Clutch Hydraulic Control

Valeo 12-/12* Clutch Service

Valeo 12712* Clutch Late Models

Omg 12-/12* Clutch Service

Omg 12-/12* Clutch Service

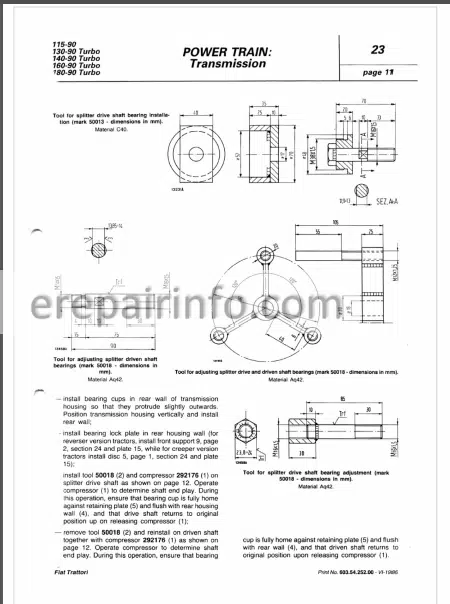

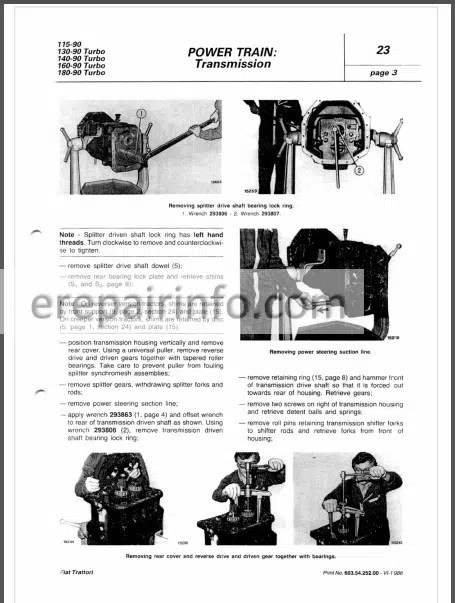

-POWER TRAIN: TRANSMISSION AND SPLITTER

Removal and installation

Disassembly

Inspection – Assembly

Longitudinal and cross sections through transmission and splitter

Transmission lubrication circuit 15 VI -1986 - – POWER TRAIN: POWERSHIFT TRANSMISSION

Removal and installation

Disassembly

Clutch B service

Longitudinal and cross sections through POWER SHIFT transmission

Clutch C (or D) service

Control valve service

Accumulator service

Sections through control valve and accumulators

Assembly

Installation – Hydraulic test

Hydraulic tests

Drive shaft bearing replacement

Transmission and steering pump

Hydraulic system schematics

Transmission and control valve modifications - – POWER TRAIN: CREEPER

Creeper Description – service

Mechanical reverser: Description Service

Creeper and reverser linkage adjustment

Mechanical reverser - – POWER TRAIN: BEVEL DRIVE AND DIFFERENTIAL

Removal

Removal and installation – Bevel drive and differential (mechanical differential lock version)

Removal and installation – Bevel drive and differential (hydraulic differential lock version)

Bevel pinion shaft removal and installation

Longitudinal and cross sections through bevel drive and differential

Bevel drive adjustment

Differential pinion and side gear backlash adjustment

Mechanical differential lock assembly and adjustment

Mechanical differential lock pedal adjustment

Hydraulic differential lock pedal adjustment

Hydraulic differential lock – Removal and installation

Hydraulic differential lock – Circuit pressure test

Hydraulic pump

Hydraulic differential lock schematics - – POWER TRAIN: BRAKES

Hydraulic system operation

Brake unit assembly and disassembly

Master cylinder assembly and disassembly

Brake pedal adjustment

Brake pedal installation – Brake system

Master cylinder bench test

Parking brake

Parking brake lever adjustment - – POWER TRAIN: FINAL DRIVES

Removal

Assembly

Side final drive units with twin wheels

Double-flange side final drives - – POWER TRAIN: POWER TAKE-OFF

Removal and installation

Disassembly and assembly

Longitudinal section through PTO

PTO hydraulic clutch removal and installation

PTO hydraulic clutch pressure relief valve setting check

Hydraulic pump – service

PTO hydraulic operation schematics

Front power take-off

Late PTO hydraulic clutch

Front PTO; Removal and installation

Hydraulic system schematics - – FRONT AXLE – STEERING: SPECIFICATIONS AND DATA

Front axle

Power steering

Torque data - – FRONT AXLE – STEERING: FRONT AXLE

Removal and installation – Steering knuckle service

Axle check - – FRONT AXLE – STEERING: POWER STEERING

Power steering service

Hydraulic cylinder service

Power steering checks

Power cylinder pressure relief/safety valve setting

Hydraulic system operation schematics and sections

Trouble-shooting chart

Hydraulic pump service

Output test - – FRONT WHEEL DRIVE: SPECIFICATIONS AND DATA

Live front axle – Early Models

Live front axle – Late Models (50° – steer)

Axle drive – Mechanical

Axle drive – Electrohydraulic

Torque data - – FRONT WHEEL DRIVE; LIVE FRONT AXLE

Early models; Removal – Final drive; wheel hub and steering knuckle service

Early models: Bevel drive adjustment and service

Early models: Differential hydraulic lock clutch service

NO-SPIN differential

Late models: Differential hydraulic lock clutch service

Late models: Removal – Final drive, wheel hub and steering knuckle service (50° – steer)

Late models: Bevel drive adjustment and service - – FRONT WHEEL DRIVE: DRIVE SHAFTS – AXLE DRIVE

Drive shaft disassembly and assembly

Mechanical axle drive removal, disassembly adjustment, assembly and installation

Early model axle sections

Late model axle sections (50° – steer)

Electro-hydraulic axle drive removal, disassembly adjustment, assembly and Installation - – HYDRAULIC LIFT UNIT: SPECIFICATIONS AND DATA

Lift

Lift pump

implement attachment

Auxiliary cylinder

Remote control valves

Torque data

Trailer brake control valve trouble chart

Lift troubleshooting chart

Electronically controlled kit - – HYDRAULIC LIFT UNIT: LIFT

Description

Removal Disassembly

Inspection

Assembly

Lift adjustments

Lift control linkage adjustments

Control valve assembly with LIFT-O-MATIC

Valve-checks

Hydraulic system schematics

Operation

Electronically controlled lift

Removal – Disassembly

Inspections Assembly

Operation schematics

Front lift

Operation schematics

Description – Operation stages

Disassembly-Assembly – Adjustment - – HYDRAULIC LIFT UNIT: LIFT PUMP

Service

Output test - – HYDRAULIC LIFT UNIT: IMPLEMENT ATTACHMENT

Three point linkage – Right-hand lifting rod

Draft control device

Three point linkage with hydraulic adjustment - – HYDRAULIC LIFT UNIT: REMOTE CONTROL VALVES

Description and operation

Hydraulic system diagrams

Disassembly

Relief valve adjustment

Spool return test

Remote control valve leakage test

Trailer brake remote control valve

Description

Hydraulic system diagram - – ELECTRICAL SYSTEM – SPECIFICATIONS AND DATA

Charging system – Battery – Lighting – Signals – Accessories

MARELLI starter

BOSCH starter

Fuses – Switches

Control and instruments

Control operation

Wiring diagram

Data monitor panel operation check - -SERVICE TOOLS

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet