Factory Service Manual For Flexi Coil S65, S65XL, S65XLT, S55 Field Sprayer. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 279

Number: SQ-093.01

Bookmarks: Yes

Model

Flexi Coil Field Sprayer

S65

S65XL

S65XLT

S55

Contents

-SAFETY IN SERVICE

Use Safe Service Procedures

Air And Air Hoses

Hydraulics And Hydraulic leaks

Shields

Electrical

Tires

-GENERAL INFORMATION

Torque Charts

Post Assembly Adjustment

Nozzle Delivery Rate Charts

Pump Load Characteristics (Charts)

Nozzle Check Flow Rate And Pattern Uniformity

Calibration

Setting The Spray Rate

The Effect Of Solution Density On Nozzle Flow

Setting Spray Nozzles

Calculating Application Rate- All Nozzle Spacing

-MECHANICAL SERVICE

Trouble Shooting

Axles Wheels Tires Hubs

Universal Cross/Wing Boom Angle

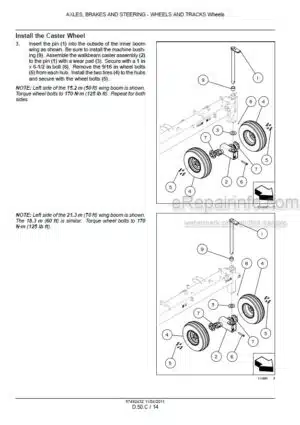

Castor Wheel

Locking Castor Wheel Fold Assist

Locking Castor Wheel Adjustments

Boom Impact Releases Or Break-Away System

Hydraulics

Latches And Draw Tubes

Primary Wing Booms

Secondary Wing Boom

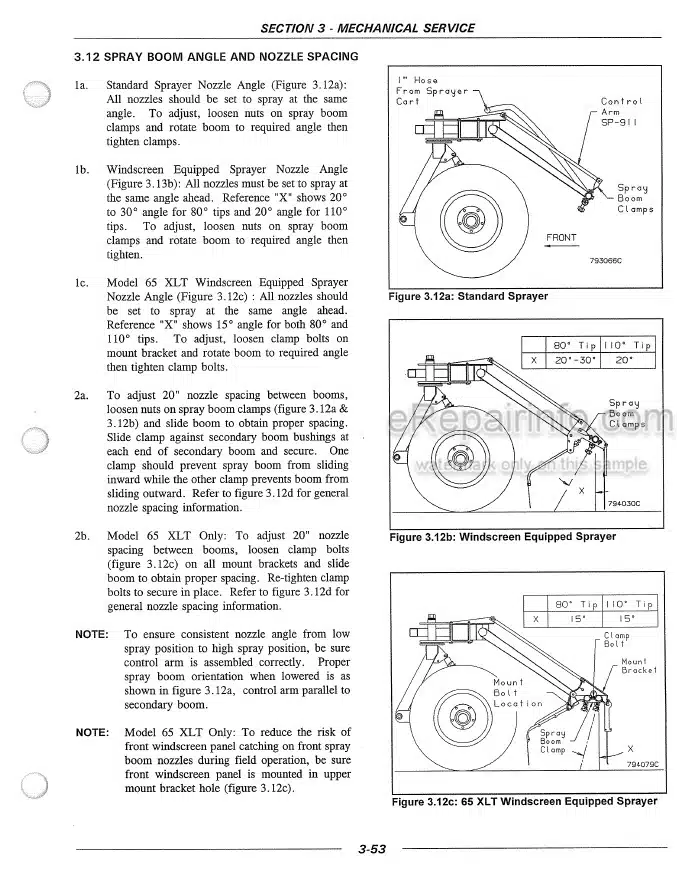

Spray Boom Angle And Nozzle Spacing

-PLUMBING & RELATED COMPONENT SERVICE

Trouble Shooting

Explanation Of Operation

Normal Operating Valve Position

Chemical Fill Tank

Water Transfer Operation – Optional On 55 Model

Nozzle Cleaning

Spray Booms

Tank /Plumbing Cleaning Procedure

Draining The Sprayer

Sprayer 744A Control System

Solenoid Maintenance And Repair (145H – Models 65,65 XL,65 XLT)

Solenoid Maintenance And Repair (144A – Model 55)

-HYDRAULIC PUMP SERVICE

Trouble Shooting

Tractor Operations

Pressure Adjustments for Hydraulic Pump Systems

Hypro Hydraulic Pump Repair

Centrifugal Pump Repair

-PTO PUMP SERVICE

Trouble Shooting

Explanation Of Operation

Pressure Adjustment for PTO/Hydraulic Pumps

Pump Repair

Gearbox Repair

Drive Belt Adjustment and Repair

PTO Shaft Repair and Maintenance

ON 7 – SPECIFICATIONS

Model 55 Sprayer

Model 65 Sprayer – 50 TO 70 Foot

Model 65 Sprayer – 80 TO 130 Foot

Model 65 XL Sprayer

Model 65 XLT Sprayer

-WINDSCREEN SERVICE

Trouble Shooting

Introduction

Windscreen Features

Spraying Conditions

Secondary Boom Spring Assist

Double Shock Assembly

Molded Frame Windscreen Assembly

Steel Frame Windscreen Assembly

– ENDMARKER SERVICE

Assembly Safety

Trouble Shooting

Introduction

Positioning the Markers

Field Operation

Transporting

Marker Disc Adjustment

Trailing End Marker

Marker Cylinder – Mount Bracket Assembly

Marker Arm Assembly

Cable Guide Assembly

Cable Adjustments

Disc Alignment

-ELECTRONICS

SP655 Trouble Shooting

SP 655 General Information

Monitor Display And Keys

Programming the Monitor

Initial Setup – Measurement Units

Calibrating for Distance and Ground Speed

In-Field Distance Calibration

Calibrating the Flow Sensor

Setting Boom Section Widths

Speed / Area / Rate / Volume

Zeroing Areas or Volumes

Automatic Measurement Reset

Boom Control

Alarms

Automatic Rate Control

Automatic and Manual Modes

Alarm Setup

Band Spraying

Summary and Conversions

-OPTIONS

Axle Extensions

Chemical Container Rinse Wand

Dry Boom Option

End Nozzles

Hydraulic Cylinder Valve Option

Transfer Valve (S65 XLT)

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Anonymous (verified owner) –

Very happy the transaction was smooth and fast just as they said